jack points SKODA FABIA 2014 2.G / 5J Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: FABIA, Model: SKODA FABIA 2014 2.G / 5JPages: 197, PDF Size: 13.56 MB

Page 13 of 197

WARNING (Continued)■The lock tongue should only be inserted into the lock which is the correct

one for your seat. Wrong use of the safety belt will reduce its capacity to

protect and the risk of injury increases.■

The slot of the belt tongue must not be blocked otherwise the belt

tongue will not lock in place properly.

■

Many layers of clothing and loose clothing (e. g. a winter coat over a jack-

et) do not allow you to be correctly seated and impairs proper operation of

the seat belts.

■

It is prohibited to use clamps or other objects to adjust seat belts (e. g. for

shortening the belts for smaller persons).

■

The seat belts for the rear seats can only fulfil their function reliably

when the seat backrests are correctly locked into position » page 66.

WARNINGInformation on the care and maintenance of the safety belts■The belt webbing must always be kept clean. Soiled belts may impair

proper operation of the inertia reel » page 134, Seat belts .■

The seat belts must not be removed or changed in any way. Do not at-

tempt to repair the seat belts yourself.

■

Check the condition of all the seat belts on a regular basis. If any damage

to the seat belts, seat belt connections, inertia reel or the lock is detected,

the seat belt concerned must be replaced by a specialist garage.

■

Damaged seat belts which have been subjected to stress in an accident

and were therefore stretched, must be replaced - this is best done by a

specialist garage. The anchorage points of the belts must also be inspec-

ted. The anchorage points for the belts should also be checked.

Note

The national legal requirements must be observed when using seat belts.The physical principle of a frontal collisionFig. 4

Driver without a fastened seat belt/rear seat passenger without a

fastened seat belt

Read and observe

on page 10 first.

As soon as the vehicle is moving, so-called kinetic energy (the energy of mo-

tion) is produced both in terms of the car as well as in terms of the occupants.

The magnitude of this kinetic energy depends essentially on the speed at

which the vehicle is travelling and on the weight of the vehicle including the

occupants. The greater the speed and weight increase, the greater the

amount of energy which has to be absorbed in the event of an accident.

The speed of the vehicle is the most important factor. Doubling the speed of

the vehicle from 25 km/h up to 50 km/hour increases the kinetic energy four

times.

The notion that it is possible to support your body with your hands in a minor

accident is incorrect. Even in a collision at only a low speed, the forces acting

on the body are such that it is no longer possible to support your body.

Even if you only drive at a speed of 30 km/h to 50 km/h, the forces that your body is exposed to in the event of an accident can exceed a ton (1000 kg).

For example, a person's weight of 80 kg “increases” at 50 km/h to 4.8 tons (4800 kg).

In the event of a frontal collision, occupants of the car not wearing a seat belt

are thrown forward and strike parts of the interior of the car, such as the

steering wheel, dash panel, windscreen in ways which cannot be control-

led » Fig. 4 -

. In certain circumstances you could even be thrown out of the

vehicle, which could cause life threatening or even fatal injuries.

11Seat belts

Page 78 of 197

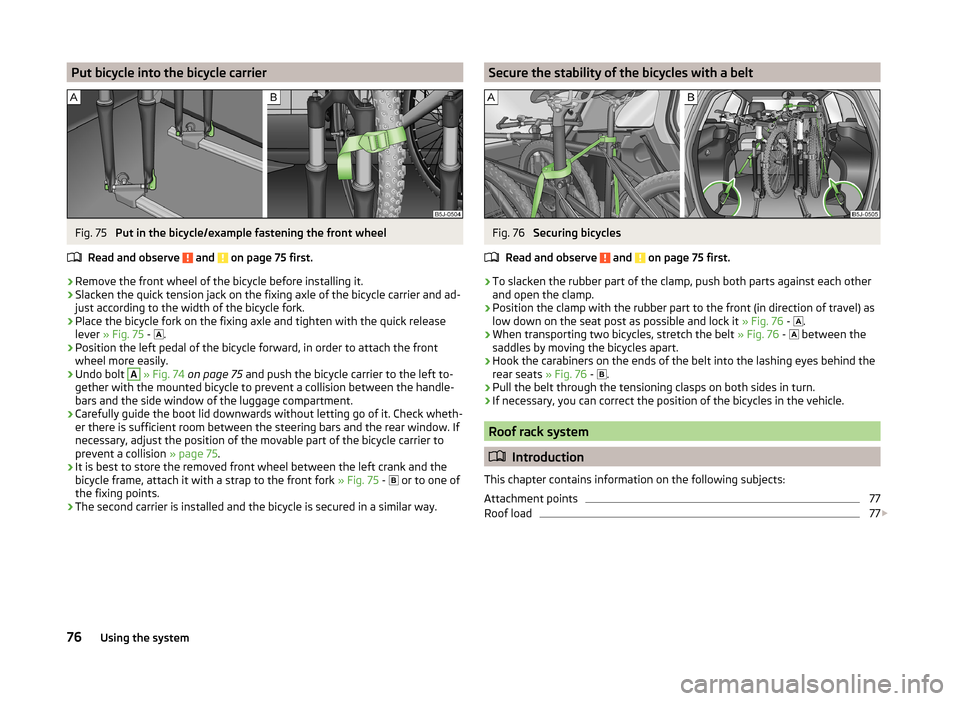

Put bicycle into the bicycle carrierFig. 75

Put in the bicycle/example fastening the front wheel

Read and observe

and on page 75 first.

›

Remove the front wheel of the bicycle before installing it.

›

Slacken the quick tension jack on the fixing axle of the bicycle carrier and ad-

just according to the width of the bicycle fork.

›

Place the bicycle fork on the fixing axle and tighten with the quick release

lever » Fig. 75 -

.

›

Position the left pedal of the bicycle forward, in order to attach the front

wheel more easily.

›

Undo bolt

A

» Fig. 74 on page 75 and push the bicycle carrier to the left to-

gether with the mounted bicycle to prevent a collision between the handle-

bars and the side window of the luggage compartment.

›

Carefully guide the boot lid downwards without letting go of it. Check wheth-

er there is sufficient room between the steering bars and the rear window. If

necessary, adjust the position of the movable part of the bicycle carrier to

prevent a collision » page 75.

›

It is best to store the removed front wheel between the left crank and the

bicycle frame, attach it with a strap to the front fork » Fig. 75 -

or to one of

the fixing points.

›

The second carrier is installed and the bicycle is secured in a similar way.

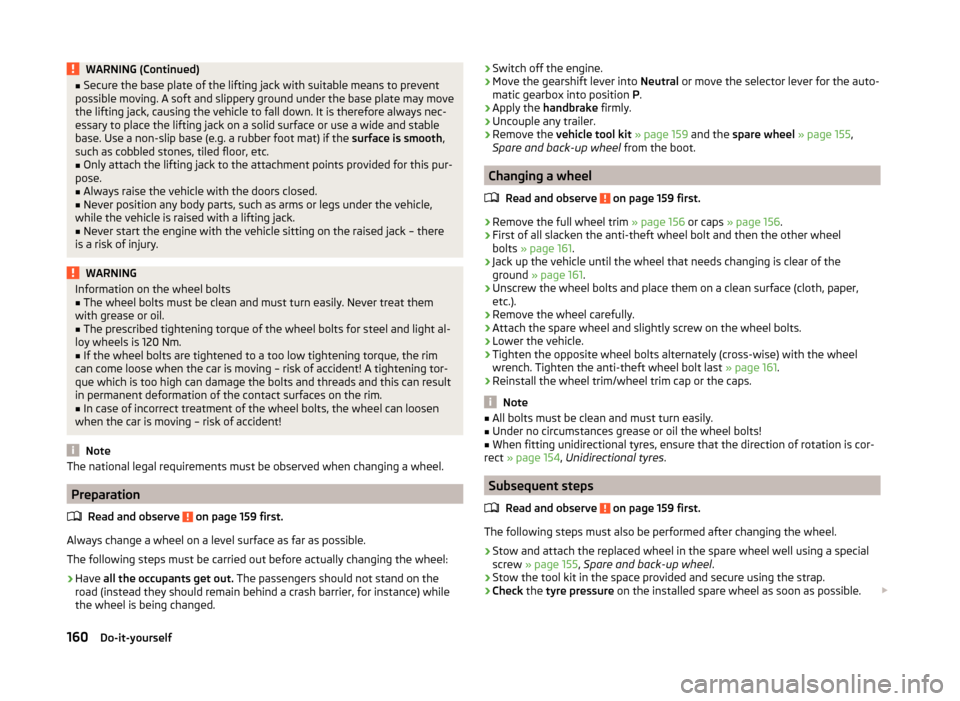

Secure the stability of the bicycles with a beltFig. 76

Securing bicycles

Read and observe

and on page 75 first.

›

To slacken the rubber part of the clamp, push both parts against each other

and open the clamp.

›

Position the clamp with the rubber part to the front (in direction of travel) as

low down on the seat post as possible and lock it » Fig. 76 -

.

›

When transporting two bicycles, stretch the belt

» Fig. 76 -

between the

saddles by moving the bicycles apart.

›

Hook the carabiners on the ends of the belt into the lashing eyes behind the

rear seats » Fig. 76 -

.

›

Pull the belt through the tensioning clasps on both sides in turn.

›

If necessary, you can correct the position of the bicycles in the vehicle.

Roof rack system

Introduction

This chapter contains information on the following subjects:

Attachment points

77

Roof load

77

76Using the system

Page 162 of 197

WARNING (Continued)■Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

Never start the engine with the vehicle sitting on the raised jack – there

is a risk of injury.

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving – risk of accident! A tightening tor-

que which is too high can damage the bolts and threads and this can result

in permanent deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving – risk of accident!

Note

The national legal requirements must be observed when changing a wheel.

Preparation

Read and observe

on page 159 first.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

› Switch off the engine.›Move the gearshift lever into

Neutral or move the selector lever for the auto-

matic gearbox into position P.›

Apply the handbrake firmly.

›

Uncouple any trailer.

›

Remove the vehicle tool kit » page 159 and the spare wheel » page 155 ,

Spare and back-up wheel from the boot.

Changing a wheel

Read and observe

on page 159 first.

›

Remove the full wheel trim » page 156 or caps » page 156 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 161 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 161 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last » page 161.

›

Reinstall the wheel trim/wheel trim cap or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 154 , Unidirectional tyres .

Subsequent steps

Read and observe

on page 159 first.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 155 , Spare and back-up wheel .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

160Do-it-yourself

Page 163 of 197

›Have the

tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.›

Change the damaged wheel or consult a specialist garage about repair possi-

bilities.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn

when changing the wheel, the bolts must be replaced before checking the

tightening torque.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

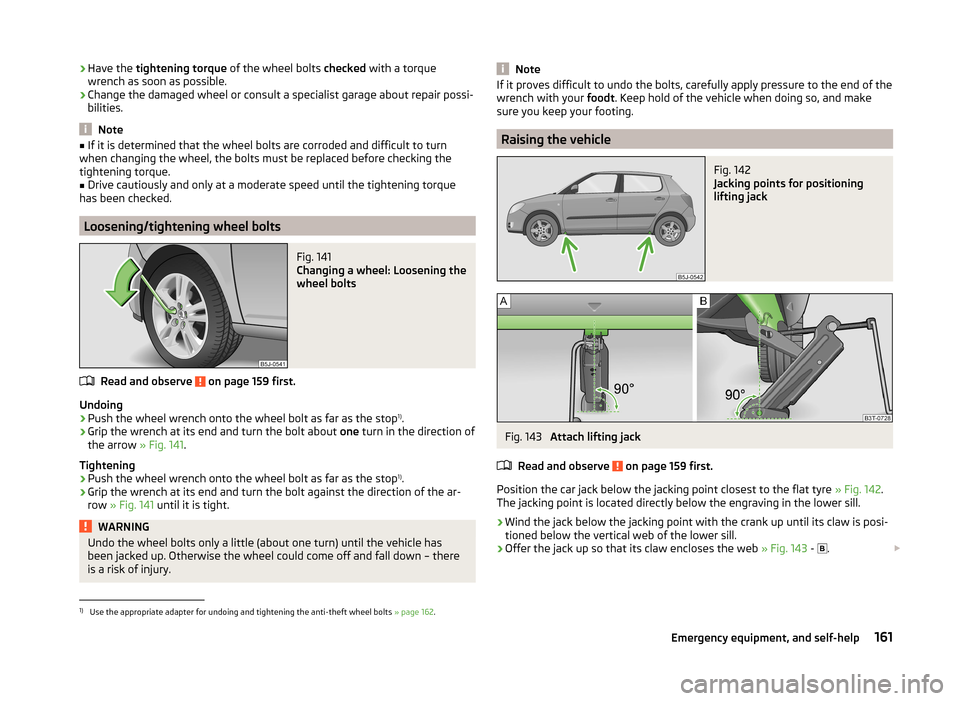

Loosening/tightening wheel bolts

Fig. 141

Changing a wheel: Loosening the

wheel bolts

Read and observe on page 159 first.

Undoing

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt about one turn in the direction of

the arrow » Fig. 141.

Tightening

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt against the direction of the ar-

row » Fig. 141 until it is tight.

WARNINGUndo the wheel bolts only a little (about one turn) until the vehicle has

been jacked up. Otherwise the wheel could come off and fall down – there

is a risk of injury.NoteIf it proves difficult to undo the bolts, carefully apply pressure to the end of the

wrench with your foodt. Keep hold of the vehicle when doing so, and make

sure you keep your footing.

Raising the vehicle

Fig. 142

Jacking points for positioning

lifting jack

Fig. 143

Attach lifting jack

Read and observe

on page 159 first.

Position the car jack below the jacking point closest to the flat tyre » Fig. 142.

The jacking point is located directly below the engraving in the lower sill.

›

Wind the jack below the jacking point with the crank up until its claw is posi-

tioned below the vertical web of the lower sill.

›

Offer the jack up so that its claw encloses the web » Fig. 143 -

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 162.

161Emergency equipment, and self-help

Page 164 of 197

›Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the point where

the claw encloses the web » Fig. 143 -

.›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ Only raise the vehicle at the jacking points.■Choose a flat and firm surface for jacking the vehicle.

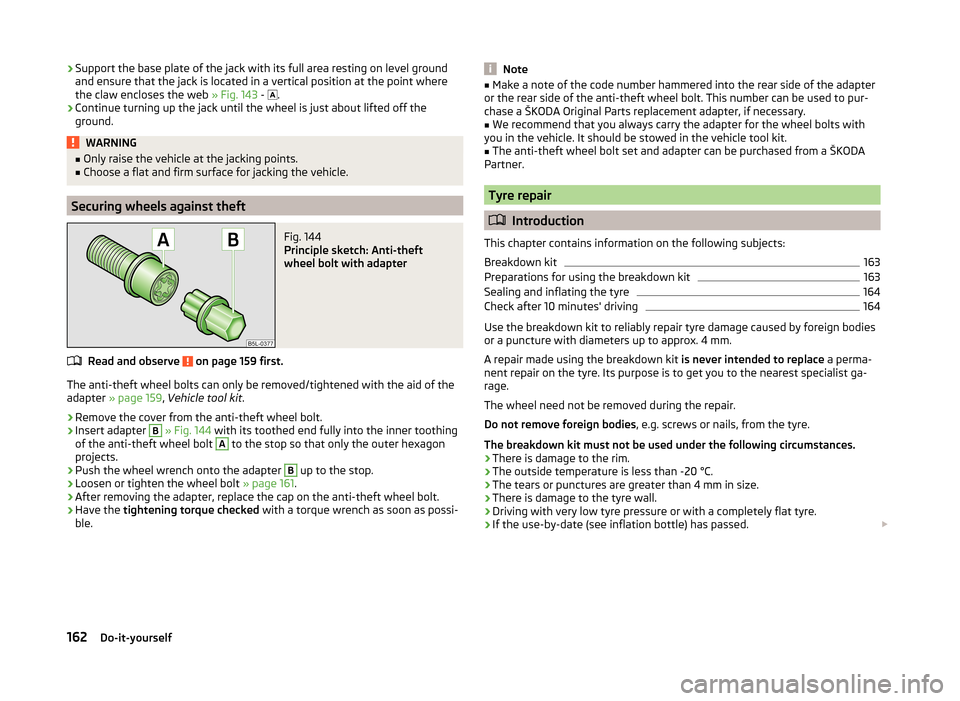

Securing wheels against theft

Fig. 144

Principle sketch: Anti-theft

wheel bolt with adapter

Read and observe on page 159 first.

The anti-theft wheel bolts can only be removed/tightened with the aid of the

adapter » page 159 , Vehicle tool kit .

›

Remove the cover from the anti-theft wheel bolt.

›

Insert adapter

B

» Fig. 144 with its toothed end fully into the inner toothing

of the anti-theft wheel bolt

A

to the stop so that only the outer hexagon

projects.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 161.

›

After removing the adapter, replace the cap on the anti-theft wheel bolt.

›

Have the tightening torque checked with a torque wrench as soon as possi-

ble.

Note■ Make a note of the code number hammered into the rear side of the adapter

or the rear side of the anti-theft wheel bolt. This number can be used to pur-

chase a ŠKODA Original Parts replacement adapter, if necessary.■

We recommend that you always carry the adapter for the wheel bolts with

you in the vehicle. It should be stowed in the vehicle tool kit.

■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

Tyre repair

Introduction

This chapter contains information on the following subjects:

Breakdown kit

163

Preparations for using the breakdown kit

163

Sealing and inflating the tyre

164

Check after 10 minutes' driving

164

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

The wheel need not be removed during the repair.

Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

162Do-it-yourself

Page 190 of 197

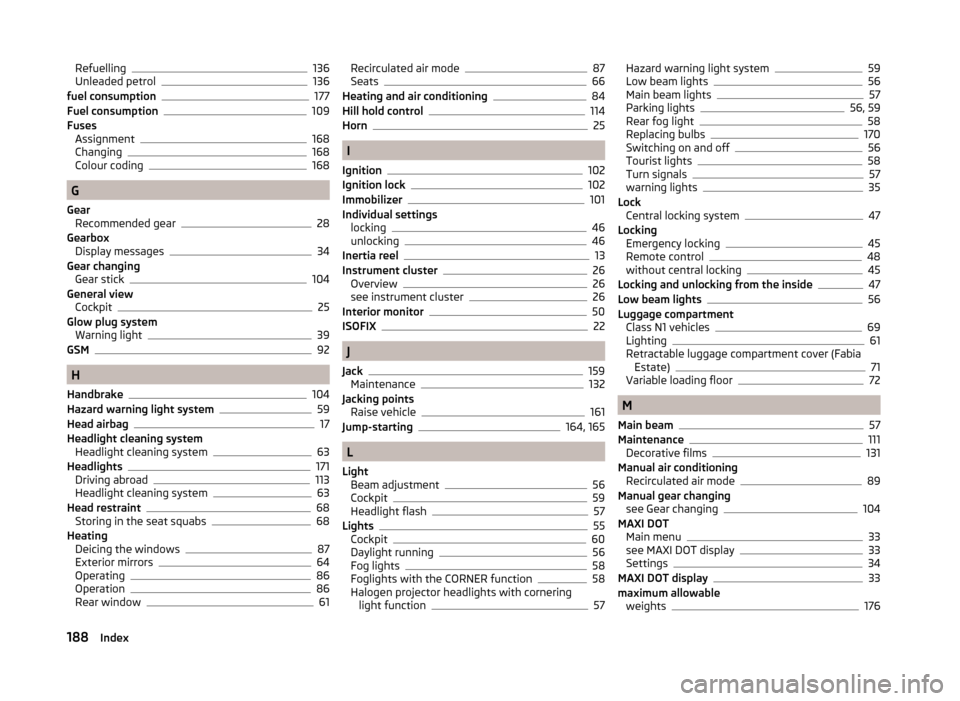

Refuelling136

Unleaded petrol136

fuel consumption177

Fuel consumption109

Fuses Assignment

168

Changing168

Colour coding168

G

Gear Recommended gear

28

Gearbox Display messages

34

Gear changing Gear stick

104

General view Cockpit

25

Glow plug system Warning light

39

GSM92

H

Handbrake

104

Hazard warning light system59

Head airbag17

Headlight cleaning system Headlight cleaning system

63

Headlights171

Driving abroad113

Headlight cleaning system63

Head restraint68

Storing in the seat squabs68

Heating Deicing the windows

87

Exterior mirrors64

Operating86

Operation86

Rear window61

Recirculated air mode87

Seats66

Heating and air conditioning84

Hill hold control114

Horn25

I

Ignition

102

Ignition lock102

Immobilizer101

Individual settings locking

46

unlocking46

Inertia reel13

Instrument cluster26

Overview26

see instrument cluster26

Interior monitor50

ISOFIX22

J

Jack

159

Maintenance132

Jacking points Raise vehicle

161

Jump-starting164, 165

L

Light Beam adjustment

56

Cockpit59

Headlight flash57

Lights55

Cockpit60

Daylight running56

Fog lights58

Foglights with the CORNER function58

Halogen projector headlights with cornering light function

57

Hazard warning light system59

Low beam lights56

Main beam lights57

Parking lights56, 59

Rear fog light58

Replacing bulbs170

Switching on and off56

Tourist lights58

Turn signals57

warning lights35

Lock Central locking system

47

Locking Emergency locking

45

Remote control48

without central locking45

Locking and unlocking from the inside47

Low beam lights56

Luggage compartment Class N1 vehicles

69

Lighting61

Retractable luggage compartment cover (Fabia Estate)

71

Variable loading floor72

M

Main beam

57

Maintenance111

Decorative films131

Manual air conditioning Recirculated air mode

89

Manual gear changing see Gear changing

104

MAXI DOT Main menu

33

see MAXI DOT display33

Settings34

MAXI DOT display33

maximum allowable weights

176

188Index