engine SKODA FABIA 2014 3.G / NJ Repair Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: FABIA, Model: SKODA FABIA 2014 3.G / NJPages: 216, PDF Size: 30.7 MB

Page 159 of 216

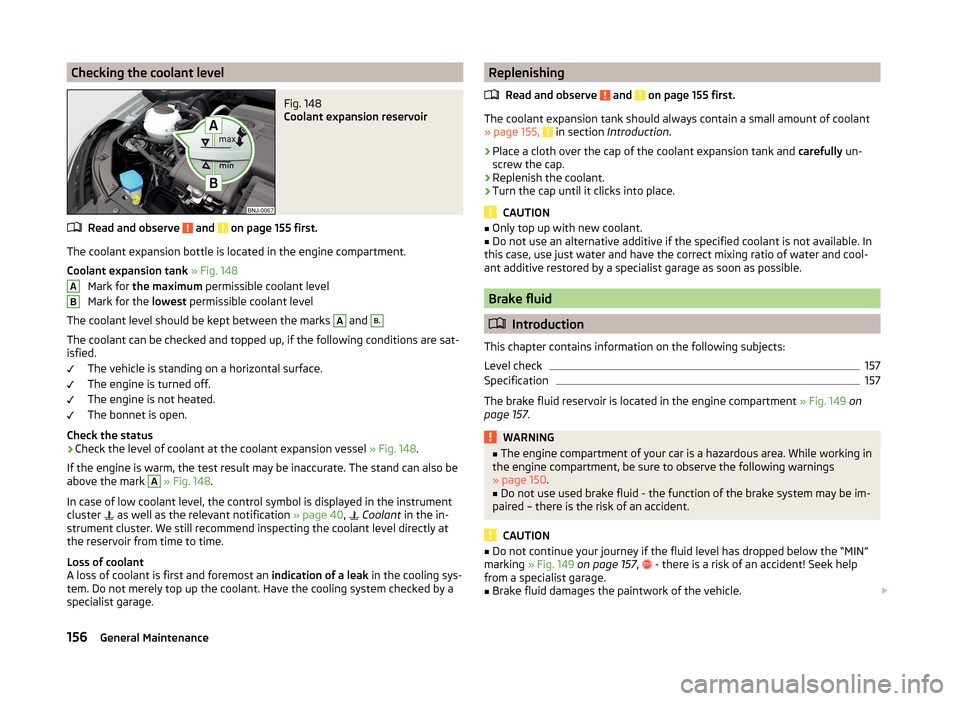

Checking the coolant levelFig. 148

Coolant expansion reservoir

Read and observe and on page 155 first.

The coolant expansion bottle is located in the engine compartment.

Coolant expansion tank » Fig. 148

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

The coolant level should be kept between the marks

A

and

B.

The coolant can be checked and topped up, if the following conditions are sat-

isfied.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The engine is not heated.

The bonnet is open.

Check the status

›

Check the level of coolant at the coolant expansion vessel » Fig. 148.

If the engine is warm, the test result may be inaccurate. The stand can also be

above the mark

A

» Fig. 148 .

In case of low coolant level, the control symbol is displayed in the instrument

cluster as well as the relevant notification

» page 40,

Coolant

in the in-

strument cluster. We still recommend inspecting the coolant level directly at

the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the cooling sys-

tem. Do not merely top up the coolant. Have the cooling system checked by a

specialist garage.

ABReplenishing

Read and observe

and on page 155 first.

The coolant expansion tank should always contain a small amount of coolant» page 155, in section Introduction .

›

Place a cloth over the cap of the coolant expansion tank and carefully un-

screw the cap.

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

CAUTION

■ Only top up with new coolant.■Do not use an alternative additive if the specified coolant is not available. In

this case, use just water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Level check

157

Specification

157

The brake fluid reservoir is located in the engine compartment » Fig. 149 on

page 157 .

WARNING■

The engine compartment of your car is a hazardous area. While working in

the engine compartment, be sure to observe the following warnings

» page 150 .■

Do not use used brake fluid - the function of the brake system may be im-

paired – there is the risk of an accident.

CAUTION

■ Do not continue your journey if the fluid level has dropped below the “MIN”

marking » Fig. 149 on page 157 , - there is a risk of an accident! Seek help

from a specialist garage.■

Brake fluid damages the paintwork of the vehicle.

156General Maintenance

Page 160 of 216

Note■The brake fluid is changed as part of a prescribed inspection service.■We recommend using oils from the ŠKODA Original Accessories range.

Level check

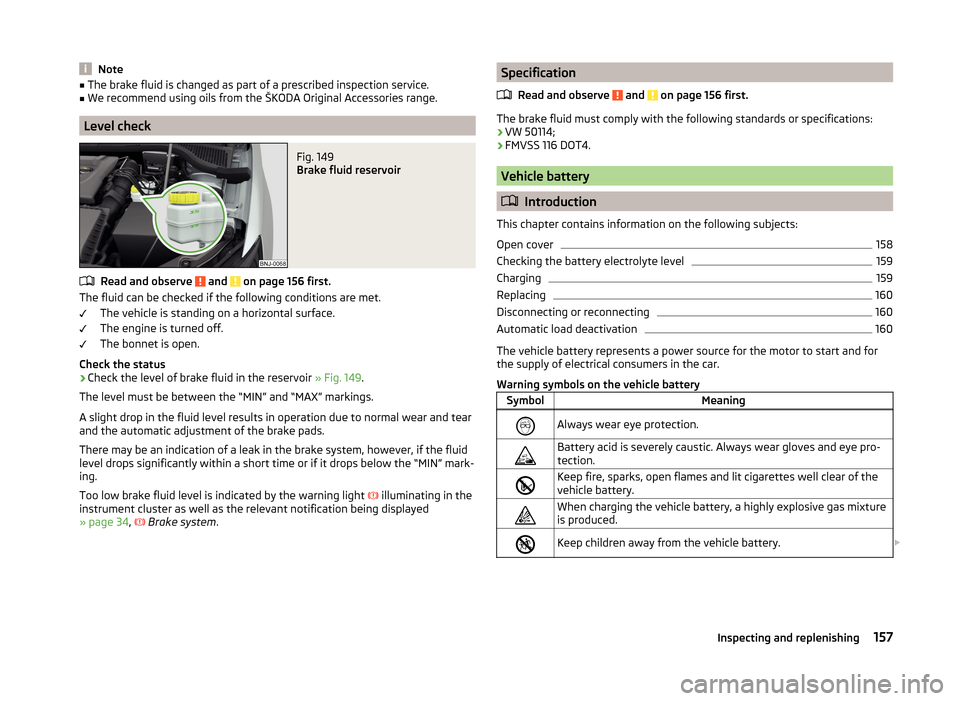

Fig. 149

Brake fluid reservoir

Read and observe and on page 156 first.

The fluid can be checked if the following conditions are met.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Check the status

›

Check the level of brake fluid in the reservoir » Fig. 149.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results in operation due to normal wear and tear

and the automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid level drops significantly within a short time or if it drops below the “MIN” mark-

ing.

Too low brake fluid level is indicated by the warning light

illuminating in the

instrument cluster as well as the relevant notification being displayed

» page 34 ,

Brake system .

Specification

Read and observe

and on page 156 first.

The brake fluid must comply with the following standards or specifications:› VW 50114;

› FMVSS 116 DOT4.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Open cover

158

Checking the battery electrolyte level

159

Charging

159

Replacing

160

Disconnecting or reconnecting

160

Automatic load deactivation

160

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection.Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery.When charging the vehicle battery, a highly explosive gas mixture

is produced.Keep children away from the vehicle battery. 157Inspecting and replenishing

Page 161 of 216

WARNINGThere is a risk of injuries, poisoning, chemical burns, explosions or fire

when carrying out any work on the battery and on the electrical system. It

is essential to comply with the generally applicable rules of safety as well

as the warning instructions outlined below.■

Keep the vehicle battery away from people who are not completely inde-

pendent, especially children.

■

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings. Protect your eyes by wearing safety glasses or a

face shield – there is a risk of being blinded.

■

Always wear protective gloves, eye and skin protection when handling

the vehicle battery.

■

The battery acid is strongly corrosive and must, therefore, be handled

with the greatest of care.

■

Corrosive fumes in the air irritate the air passages and lead to conjunctivi-

tis and inflammation of the air passages in the lungs.

■

Battery acid corrodes dental enamel and creates deep wounds on contact

with the skin which take a long time to heal.

■

If any battery electrolyte comes into contact with your eyes, rinse the

eyes immediately with clear water for several minutes - consult a doctor

immediately.

■

Splashes of acid on your skin or clothes should be neutralised as soon as

possible using soap suds and then rinsed with plenty of water.

■

Seek immediate medical assistance if you swallow battery acid.

WARNING■ The use of open flames and light should be avoided.■Smoking and radio triggering activities should be avoided.■

Never use a damaged vehicle battery – there is a risk of explosion.

■

Never charge a frozen or thawed vehicle battery – there is a risk of explo-

sion and caustic burns.

■

Replace a frozen vehicle battery.

■

Never jump-start vehicle batteries with an electrolyte level that is too low

– risk of explosion and caustic burns.

CAUTION

■ Improper handling of the vehicle battery may cause damage.■Ensure that battery acid does not come into contact with the bodywork –

there is a risk of damage to the paintwork.■ If the vehicle has not been driven for more than 3 to 4 weeks, the battery will

discharge. Prevent the battery from discharging by disconnecting the battery's

negative terminal

or continuously charging the battery with a very low

charging current.■

Do not place the battery in direct daylight in order to protect the vehicle bat-

tery housing from the effects of ultra-violet light.

■

If the vehicle is frequently used for making short trips, the vehicle battery

will not have time to charge up sufficiently and may discharge.

For the sake of the environment

A vehicle battery that has been removed is a special type of hazardous waste.

These must be disposed of in accordance with national legal regulations.

Note

■ We recommend having all work on the vehicle battery carried out by a spe-

cialist garage.■

You should replace batteries older than 5 years.

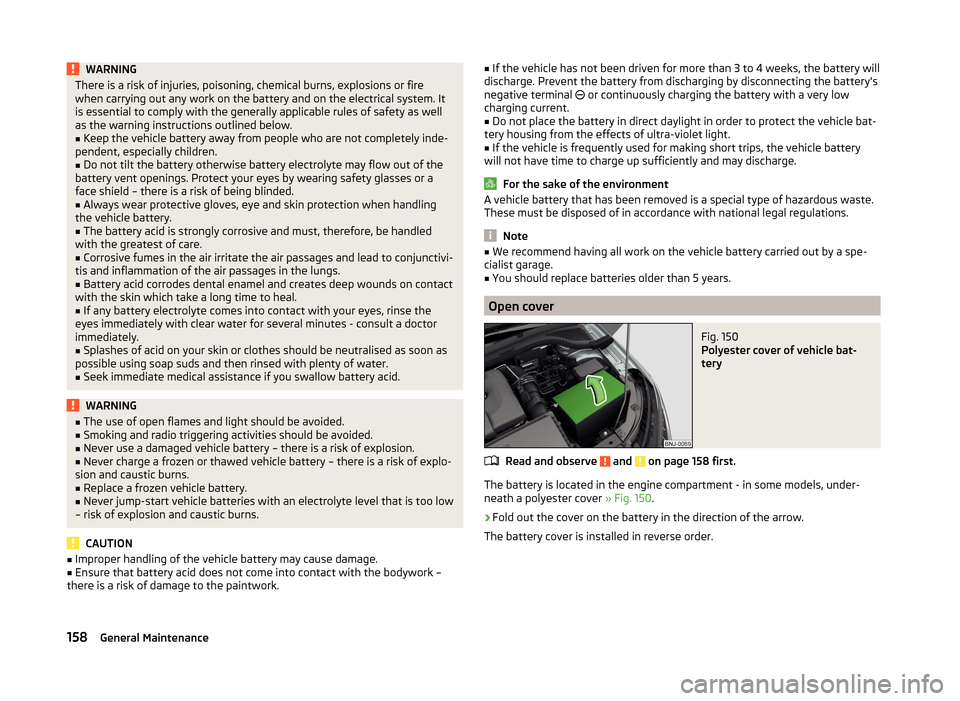

Open cover

Fig. 150

Polyester cover of vehicle bat-

tery

Read and observe and on page 158 first.

The battery is located in the engine compartment - in some models, under-

neath a polyester cover » Fig. 150.

›

Fold out the cover on the battery in the direction of the arrow.

The battery cover is installed in reverse order.

158General Maintenance

Page 162 of 216

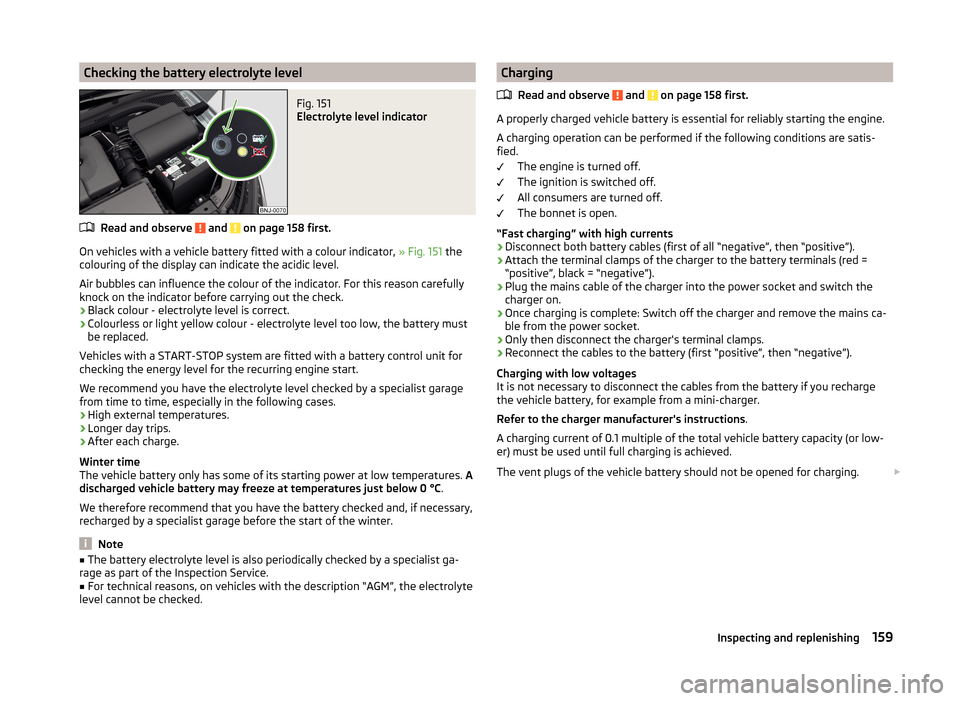

Checking the battery electrolyte levelFig. 151

Electrolyte level indicator

Read and observe and on page 158 first.

On vehicles with a vehicle battery fitted with a colour indicator, » Fig. 151 the

colouring of the display can indicate the acidic level.

Air bubbles can influence the colour of the indicator. For this reason carefully knock on the indicator before carrying out the check.

› Black colour - electrolyte level is correct.

› Colourless or light yellow colour - electrolyte level too low, the battery must

be replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

We recommend you have the electrolyte level checked by a specialist garage from time to time, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has some of its starting power at low temperatures. A

discharged vehicle battery may freeze at temperatures just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

Note

■ The battery electrolyte level is also periodically checked by a specialist ga-

rage as part of the Inspection Service.■

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Charging

Read and observe

and on page 158 first.

A properly charged vehicle battery is essential for reliably starting the engine.

A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch the

charger on.

›

Once charging is complete: Switch off the charger and remove the mains ca-

ble from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the charger manufacturer's instructions .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

159Inspecting and replenishing

Page 163 of 216

WARNING■When you charge a battery, hydrogen is released, and a highly explosive

gas mixture is also produced. An explosion can be caused through sparkling

over during unclamping or loosening of the cable plug while the ignition is

on.■

Creating a bridge between the poles on the battery (e.g. with metal ob-

jects - cables) creates a short circuit - risk of damage to the battery, explo-

sion and burning of the battery, jets of acid spurting out.

■

Avoid creating sparks when working with cables and electrical devices.

Strong sparking represents a risk of injury.

■

Before carrying out any work on the electrical system, switch off the en-

gine, the ignition and all electrical consumers and disconnect the negative

terminal

.

■

“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

■

We therefore recommend that vehicle batteries be “rapidly charged” by a

specialist garage.

CAUTION

On vehicles with the START/STOP system or additional heating (auxiliary heat-

ing), the pole terminal of the charger must not be connected directly to the

negative terminal of the vehicle battery, but only to the engine earth

» page 176 .

Replacing

Read and observe

and on page 158 first.

The new vehicle battery must have the same capacity, voltage, current and the

same size as the original battery. Suitable vehicle battery types can be pur-

chased from a specialist garage.

We recommend that the battery is replaced by a specialist garage, where the

new vehicle battery will be installed properly and the original battery will be

disposed of in accordance with national regulations.

Disconnecting or reconnecting

Read and observe

and on page 158 first.

Disconnecting

›

Switch off the ignition.

›First, disconnect the negative terminal

first, then the positive terminal

of the battery.

Connecting›

First, connect the positive

first, then the negative

battery terminal.

After disconnecting and re-connecting the vehicle battery, the following func-

tions or devices are partially or completely inoperative.

Function / deviceOperating measureElectric window levers» page 58RadioEnter code » operating instruc-

tions for the Infotainment dis-

play radioTime settings» page 33

CAUTION

■ Disconnect the vehicle battery only with the ignition turned off - there is a

risk of damaging the electrical system of the vehicle.■

Under no circumstances must the battery cables be connected incorrectly –

risk of a cable fire.

Note

■ After disconnecting and re-connecting the vehicle battery, we recommend

having the vehicle checked by a specialist to ensure that the full functionality

of all electrical systems is guaranteed.■

The data of the multi-function display will be reset.

Automatic load deactivation

Read and observe

and on page 158 first.

The vehicle voltage control unit automatically prevents the battery from dis-

charging when the battery is subjected to heavy loads. This may be noticed

from the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where appropriate large convenience consumers, e.g. seat heaters, rear win-

dow heaters, have their power limited or shut off completely if necessary.

160General Maintenance

Page 164 of 216

CAUTION■Despite such intervention by the vehicle electric system management, the

vehicle battery may be drained. For example, when the ignition is switched on

a long time with the engine turned off or the side or parking lights are turned

on during longer parking.■

Consumers which are supplied via a 12 V socket can cause the vehicle battery

to discharge when the ignition is switched off.

Note

Driving comfort is not disrupted by any shutting off of consumers. Often the

driver is not aware of it having taken place.Wheels

Tyres and rims

Introduction

This chapter contains information on the following subjects:

Notes on using wheels

161

Tyre pressure

162

Tyre wear

162

Tyre wear indicator and wheels exchange

163

Tyre damage

163

Unidirectional tyres

164

Only use those tyres or wheel rims which have been approved by ŠKODA for

your model of vehicle.

WARNINGNational legal requirements must be observed for the use of tyres.WARNINGFor safety reasons, do no replace tyres individually.

For the sake of the environment

Old and unserviceable tyres are a polluting hazardous waste. These must be disposed of in accordance with national legislation.

Note

■ We recommend that any work on the wheels or tyres is carried out by a spe-

cialist garage.■

We recommend that you use wheel rims, tyres, full wheel trims and snow

chains from ŠKODA Original Accessories.

Notes on using wheels

Read and observe

on page 161 first.

During the first 500 km, new tyres do not offer optimum grip and appropriate

care should therefore be taken when driving.

Always fit the tyres with the deeper tread depth to the front wheels.

161Wheels

Page 167 of 216

Unidirectional tyresRead and observe

on page 161 first.

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The direction of rotation indicated must be complied with to obtain the best

benefits from the characteristics of these tyres.

These characteristics are principally the following.

› Increased driving stability.

› Reduced risk of aquaplaning.

› Reduced tyre noise and reduced tyre wear.

Manufacturer-approved tyre variants

Introduction

This chapter contains information on the following subjects:

Explanation of the tire labelling

164

Manufacturer-approved tyre variants

165

Authorised tyre variants are to be selected according to the engine size of your

vehicle » page 165 , Manufacturer-approved tyre variants .

Only fit radial tyres of the same type, size (rolling circumference) and the same

tread pattern on one axle on all four wheels.

When mounting new tyres the tyres have to be replaced axle by axle.

The information listed in the table corresponds to the information available at the time of going to press.

The approved tyre / rim combinations for your car are given on the sales and

technical vehicle documentation.

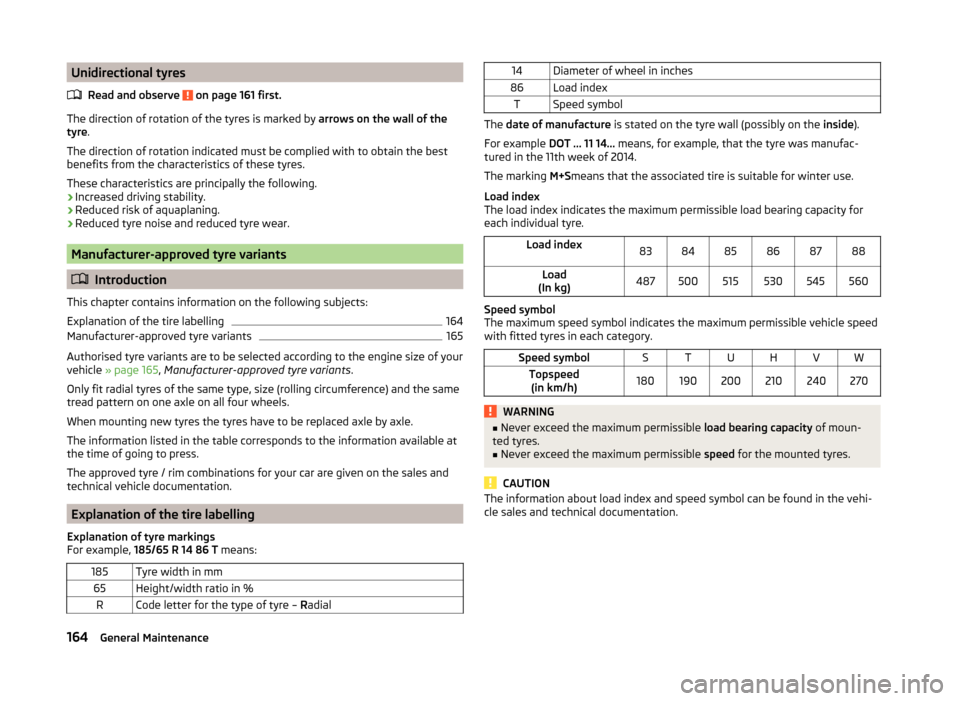

Explanation of the tire labelling

Explanation of tyre markings

For example, 185/65 R 14 86 T means:

185Tyre width in mm65Height/width ratio in %RCode letter for the type of tyre – Radial14Diameter of wheel in inches86Load indexTSpeed symbol

The date of manufacture is stated on the tyre wall (possibly on the inside).

For example DOT ... 11 14... means, for example, that the tyre was manufac-

tured in the 11th week of 2014.

The marking M+Smeans that the associated tire is suitable for winter use.

Load index

The load index indicates the maximum permissible load bearing capacity for

each individual tyre.

Load index838485868788Load

(In kg)487500515530545560

Speed symbol

The maximum speed symbol indicates the maximum permissible vehicle speed

with fitted tyres in each category.

Speed symbolSTUHVWTopspeed (in km/h)180190200210240270WARNING■ Never exceed the maximum permissible load bearing capacity of moun-

ted tyres.■

Never exceed the maximum permissible speed for the mounted tyres.

CAUTION

The information about load index and speed symbol can be found in the vehi-

cle sales and technical documentation.164General Maintenance

Page 173 of 216

Please note the following if you intend to use the temporary spare wheel.› The warning label must not be covered after installing the wheel.

› Be specially attentive when driving.

› The temporary spare wheel is inflated to the maximum inflation pressure for

the vehicle » page 162.

› Only use the temporary spare wheel to reach the nearest specialist garage

since it is not intended for permanent use.WARNING■ Never drive with more than one spare wheel mounted!■Only use the spare wheel while absolutely necessary.■

Avoid accelerating at full throttle, sharp braking and fast cornering.

■

The snow chains cannot be used on the spare wheel.

■

Observe the instructions on the warning sign of the temporary spare

wheel.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preparation

170

Full wheel trim

170

Wheel bolts

171

Changing a wheel

171

Subsequent steps

171

Loosening/tightening wheel bolts

172

Raising the vehicle

172

Anti-theft wheel bolts

173

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard lights.

The warning triangle must be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Find a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

If the vehicle has been retrofitted with tyres which are different from those it

was fitted with at the works, follow these guidelines » page 164, Explanation

of the tire labelling .

The national legal requirements must be observed when changing a wheel.

Preparation

Before changing the wheel, the following work should be carried out.

›

Switch off the engine.

›

Engage the first gear or place the selector lever of the automatic transmis-

sion in the P-position.

›

Apply the handbrake firmly.

›

Uncouple any trailer.

›

Remove the vehicle tool kit » page 168 and the spare wheel » page 169 from

the boot.

Full wheel trim

Before removing the wheel bolts the wheel trim should be removed.

Pulling off

›

Hook the clamp found in the vehicle tool kit » page 168 into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Fitting

›

Press the wheel trim onto the wheel rim at the designated valve opening

» .

›

Then press the trim into the wheel rim until its entire circumference latches

correctly into position.

CAUTION

Notes from the factory or from the ŠKODA Original accessory delivered trim..■When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.■

On the back of the wheel cover, the position for the anti-theft wheel bolt is

marked by means of a symbol. If the wheel cover is set outside the position

marked for the anti-theft wheel bolt, there is a risk of damaging the wheel

cover.

170Do-it-yourself

Page 176 of 216

WARNING■Choose a flat and firm surface for jacking the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

Make sure that the jack is attached correctly to the web on the lower sil, oth-

erwise there is a risk of damage to the vehicle.

Anti-theft wheel bolts

Fig. 164

Principle sketch: Anti-theft

wheel bolt with adapter

The anti-theft wheel bolts protect wheels from being stolen. These can only

be removed/tightened with the aid of the adapter

B

» Fig. 164 .

›

Remove the full wheel trim or the caps of the wheel bolts.

›

The adapter

B

» Fig. 164 with the toothed side all the way into the inner

teeth in the head of the anti-theft wheel bolts

A

stuck.

›

Push the wheel wrench onto the adapter

B

up to the stop.

› Loosen or tighten the wheel bolt

» page 172.›Remove the adapter.›

Replace the wheel trim or the caps.

For a possible wheel change the adapter for the anti-theft wheel bolts

should always be kept in the vehicle. The adapter is kept in the vehicle tool

kit.

Note

■ Note the embarked code number on both the adapter and at the end of each

anti-theft wheel bolt. This number can be used to purchase a ŠKODA Original

Parts replacement adapter, if necessary.■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

■

The position of the anti-theft wheel bolt is marked on the back of the wheel

cover with every ŠKODA supplied original equipment hub cap or directly at the

factors. When using an anti-theft wheel bolt, make sure that this has been fit-

ted according to the position marked on the back of the wheel cover position.

Breakdown kit

Introduction

This chapter contains information on the following subjects:

Components of the puncture repair kit

174

General information

174

Preparations for using the breakdown kit

175

Sealing and inflating the tyre

175

Notes for driving with tyre repaired

175

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

The wheel need not be removed during the repair.

Do not remove foreign bodies , e.g. screws or nails, from the tyre.

173Emergency equipment, and self-help

Page 178 of 216

Preparations for using the breakdown kitRead and observe

on page 174 first.

The following preparatory work must be carried out before using the break-

down kit.

›

Switch off the engine.

›

Engage the first gear or place the selector lever of the automatic transmis-

sion in the P-position.

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit » page 174,

General information .

›

Uncouple trailer, if attached.

›

Remove the breakdown kit from the boot.

›

Stick the corresponding sticker

1

» Fig. 165 on page 174 on the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 174 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 165 on page 174 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and push the open end fully on-

to the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the air compressor tyre inflation hose

7

» Fig. 165 on page 174 firmly

onto the tyre valve.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 Volt socket » page 79.

›

Switch on the air compressor with the ON and OFF switch

9

.

›Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

If you still cannot reach the required tyre inflation pressure, this means the

tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre pressure of 2.0 – 2.5 bar is reached, the journey may be continued

at a maximum speed of 80 km/h (50 mph).

WARNING■ If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the

tyre.

Do not drive the vehicle! Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot while the tyre is

being inflated – there is a risk of injury.

CAUTION

Switch off the air compressor after running 8 minutes at the most – risk of

overheating. Allow the air compressor to cool a few minutes before switching

it on again.

Notes for driving with tyre repaired

Read and observe

on page 174 first.

The filling pressure of the repaired tyre is a 10-minute test drive.

If the tyre pressure is 1.3 bar or less

›

Do not drive the vehicle! You cannot properly seal with tyre with the

breakdown kit.

If the tyre pressure is 1.3 bar or more

›

Correct the tyre pressure back to the correct value.

175Emergency equipment, and self-help