lock SKODA RAPID 2013 1.G Repair Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID, Model: SKODA RAPID 2013 1.GPages: 226, PDF Size: 15.16 MB

Page 183 of 226

Full wheel trimFirst read and observe the introductory information and safety warn-

ings

on page 175.

Extracting

›

Hook the clamp found in the vehicle tool kit into the reinforced edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off the

wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks cor- rectly in place.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim. Avoid

heavy impacts when the trim has not yet been inserted into the wheel rim. This

could cause damage to the guide and centring elements of the trim.■

When using the anti-theft wheel bolt, ensure that it is in the hole in the valve

area » page 186 , Securing wheels against theft .

■

If wheel trims are retrofitted it must be ensured that an adequate flow of air is

assured to cool the brake system.

Wheel bolts

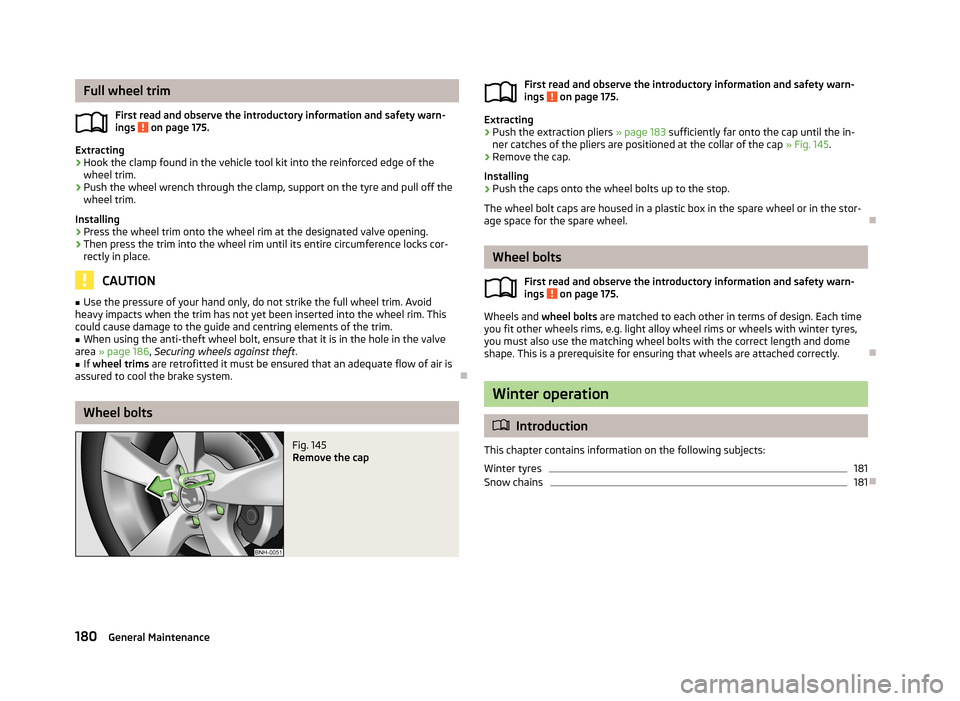

Fig. 145

Remove the capFirst read and observe the introductory information and safety warn-

ings on page 175.

Extracting

›

Push the extraction pliers » page 183 sufficiently far onto the cap until the in-

ner catches of the pliers are positioned at the collar of the cap » Fig. 145.

›

Remove the cap.

Installing

›

Push the caps onto the wheel bolts up to the stop.

The wheel bolt caps are housed in a plastic box in the spare wheel or in the stor-

age space for the spare wheel.

Wheel bolts

First read and observe the introductory information and safety warn-ings

on page 175.

Wheels and wheel bolts are matched to each other in terms of design. Each time

you fit other wheels rims, e.g. light alloy wheel rims or wheels with winter tyres,

you must also use the matching wheel bolts with the correct length and dome

shape. This is a prerequisite for ensuring that wheels are attached correctly.

Winter operation

Introduction

This chapter contains information on the following subjects:

Winter tyres

181

Snow chains

181

180General Maintenance

Page 184 of 226

Winter tyresFirst read and observe the introductory information given on page 180.

Fitting winter tyres will significantly improve the handling of your vehicle whendriving in wintry road conditions. Summer tyres have less grip on ice, snow and attemperatures below 7 °C. This is especially true of vehicles fitted with wide tyres

or high-speed tyres .

In order to achieve the best possible handling properties, winter tyres must be fit-

ted on all four wheels, the minimum tread depth must be 4 mm and tyres must be

no older than 4 years.

Winter tyres of a lower speed category can be used provided that the permissible

maximum speed of these tyres is not exceeded even if the possible maximum

speed of the vehicle is higher.

The speed limit for winter tyres can be set in the MAXI DOT display in the menu

item Winter tyres » page 28 .

For the sake of the environment

Fit the summer tyres on again in good time as they provide better handling prop-

erties, a shorter braking distance, less tyre noise, and reduced tyre wear on roadswhich are free of snow and ice as well as at temperatures above 7 °C. The fuel

consumption is also lower.

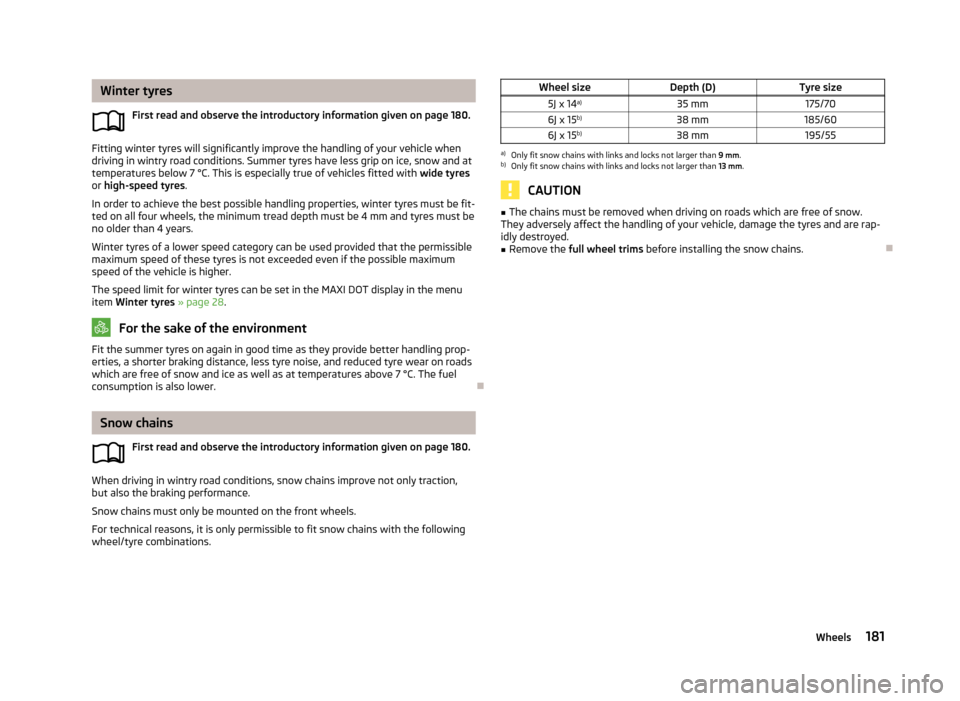

Snow chains

First read and observe the introductory information given on page 180.

When driving in wintry road conditions, snow chains improve not only traction,but also the braking performance.

Snow chains must only be mounted on the front wheels.

For technical reasons, it is only permissible to fit snow chains with the following wheel/tyre combinations.

Wheel sizeDepth (D)Tyre size5J x 14 a)35 mm175/706J x 15 b)38 mm185/606J x 15b)38 mm195/55a)

Only fit snow chains with links and locks not larger than

9 mm.

b)

Only fit snow chains with links and locks not larger than 13 mm.

CAUTION

■

The chains must be removed when driving on roads which are free of snow.

They adversely affect the handling of your vehicle, damage the tyres and are rap-

idly destroyed.■

Remove the full wheel trims before installing the snow chains.

181Wheels

Page 187 of 226

WARNING■The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances use it to lift heavier vehicles or other loads – risk of

injury!■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

184

Changing a wheel

185

Follow-up work

185

Loosening/tightening wheel bolts

185

Raising the vehicle

186

Securing wheels against theft

186WARNING■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on as

flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory-fitted ones » page 177,

New tyres .

WARNINGObserve the following instructions for lifting the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack.

■

Never start the engine when the vehicle is raised – risk of injury.

CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.■

If the wheel bolts are fastened too tightly, this can cause damage to the anti-

theft wheel bolt or the adapter.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

First read and observe the introductory information and safety warn-ings

on page 184.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Have all of the occupants get out of the vehicle. While changing a tyre, the oc-

cupants of the vehicle should not stand on the road (they should instead remain

behind a crash barrier).

184Do-it-yourself

Page 191 of 226

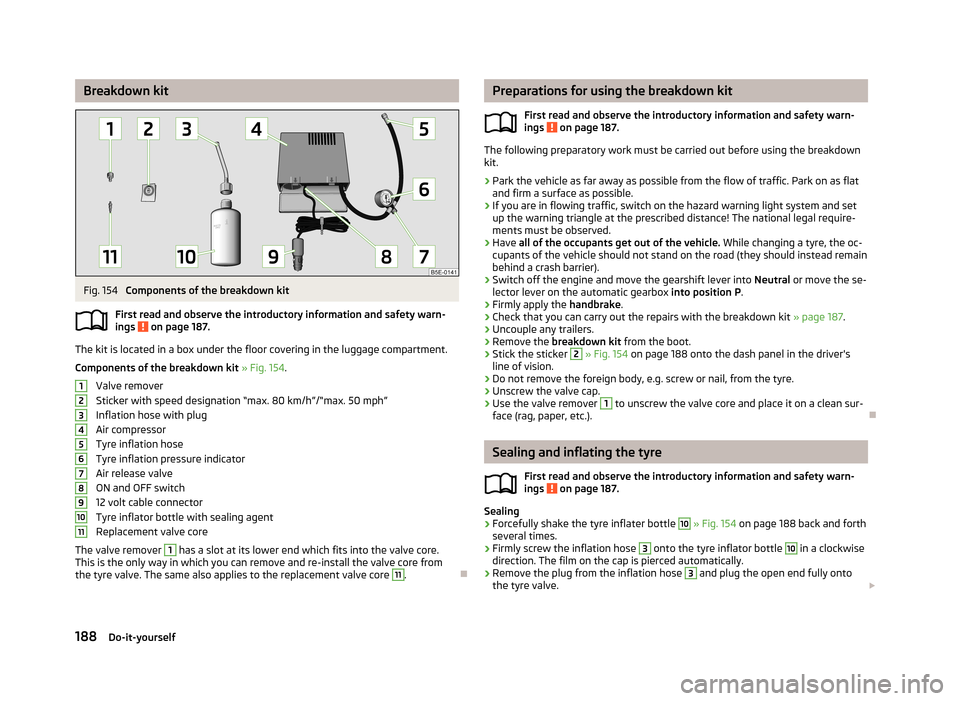

Breakdown kitFig. 154

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 187.

The kit is located in a box under the floor covering in the luggage compartment.

Components of the breakdown kit » Fig. 154 .

Valve remover

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover

1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core

11

.

1234567891011Preparations for using the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 187.

The following preparatory work must be carried out before using the breakdown kit.

›

Park the vehicle as far away as possible from the flow of traffic. Park on as flat and firm a surface as possible.

›

If you are in flowing traffic, switch on the hazard warning light system and setup the warning triangle at the prescribed distance! The national legal require-

ments must be observed.

›

Have all of the occupants get out of the vehicle. While changing a tyre, the oc-

cupants of the vehicle should not stand on the road (they should instead remain

behind a crash barrier).

›

Switch off the engine and move the gearshift lever into Neutral or move the se-

lector lever on the automatic gearbox into position P.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 187.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

2

» Fig. 154 on page 188 onto the dash panel in the driver's

line of vision.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.).

Sealing and inflating the tyre

First read and observe the introductory information and safety warn-

ings

on page 187.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 154 on page 188 back and forth

several times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clockwise

direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

188Do-it-yourself

Page 193 of 226

WARNING (Continued)■The non-insulated parts of the terminal clamps must never touch each other

– there is a risk of short circuit.■

The jump-start cable connected to the positive terminal of the battery must

not come into contact with electrically conducting parts of the vehicle – there

is a risk of short circuit.

■

Do not clamp the jump-start cable to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

■

Route the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

■

Do not bend over the battery – there is a risk of caustic burns.

■

The vent screws of the battery cells must be tightened firmly.

■

Keep any sources of ignition (naked flame, lit cigarettes, etc.) away from the

battery – there is a risk of explosion.

■

Never jump-start vehicle batteries with insufficient acid levels – risk of ex-

plosion and chemical burns.

CAUTION

■ There must not be any contact between the two vehicles otherwise current

may flow as soon as the negative terminals are connected.■

The discharged battery must be properly connected to the system of the vehi-

cle.

■

We recommend you buy jump-start cables from a car battery specialist.

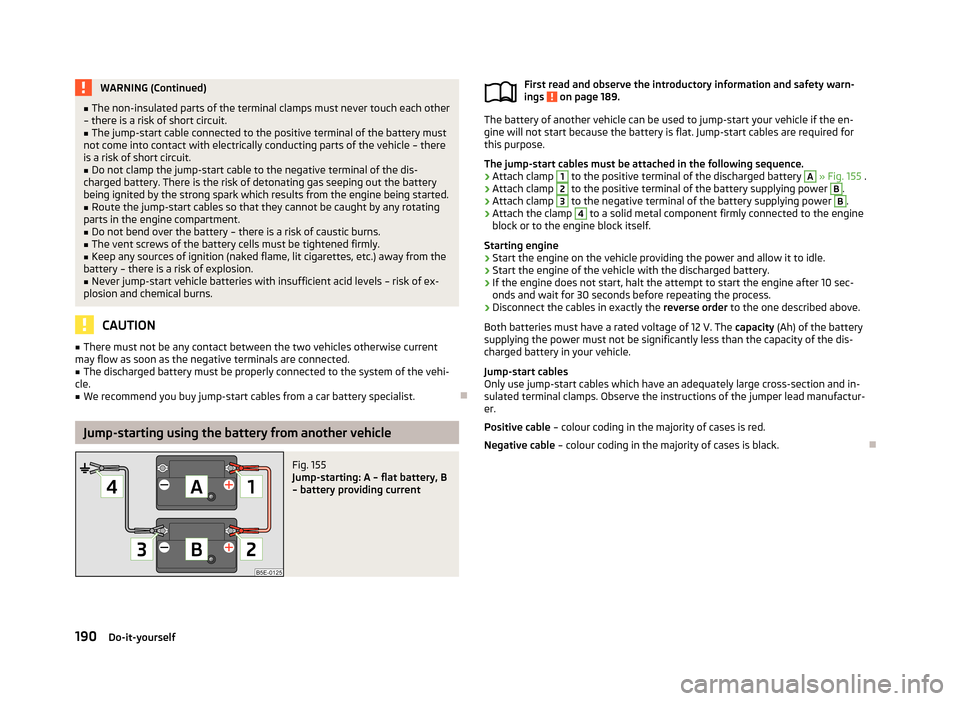

Jump-starting using the battery from another vehicle

Fig. 155

Jump-starting: A – flat battery, B

– battery providing current

First read and observe the introductory information and safety warn-

ings on page 189.

The battery of another vehicle can be used to jump-start your vehicle if the en-

gine will not start because the battery is flat. Jump-start cables are required for

this purpose.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery

A

» Fig. 155 .

›

Attach clamp

2

to the positive terminal of the battery supplying power

B

.

›

Attach clamp

3

to the negative terminal of the battery supplying power

B

.

›

Attach the clamp

4

to a solid metal component firmly connected to the engine

block or to the engine block itself.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine of the vehicle with the discharged battery.

›

If the engine does not start, halt the attempt to start the engine after 10 sec- onds and wait for 30 seconds before repeating the process.

›

Disconnect the cables in exactly the reverse order to the one described above.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the battery

supplying the power must not be significantly less than the capacity of the dis-

charged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and in-

sulated terminal clamps. Observe the instructions of the jumper lead manufactur-

er.

Positive cable – colour coding in the majority of cases is red.

Negative cable – colour coding in the majority of cases is black.

190Do-it-yourself

Page 194 of 226

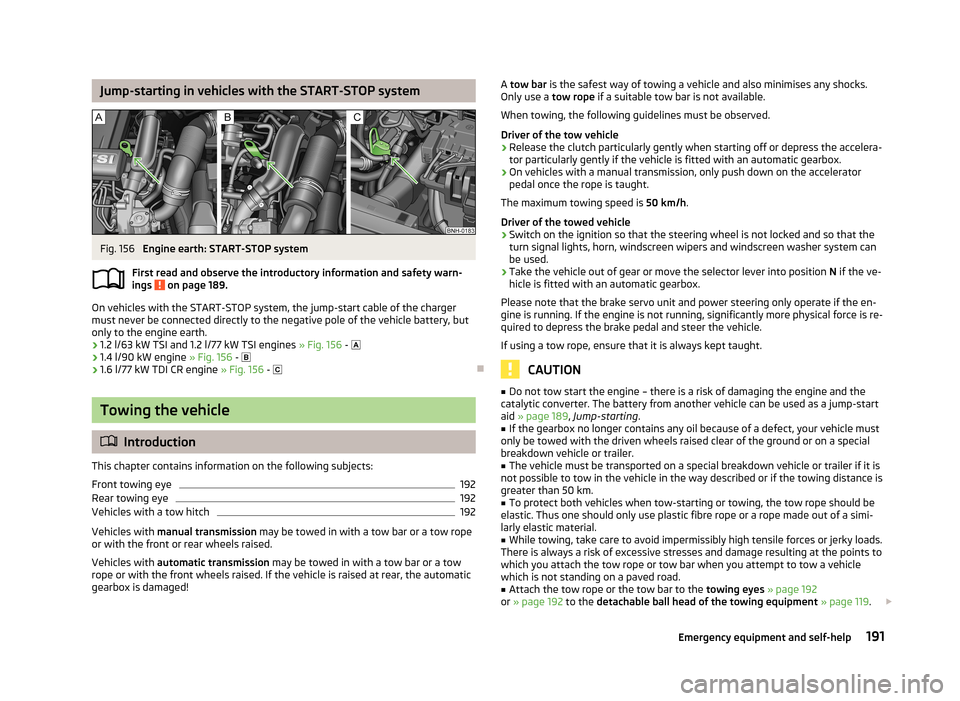

Jump-starting in vehicles with the START-STOP systemFig. 156

Engine earth: START-STOP system

First read and observe the introductory information and safety warn- ings

on page 189.

On vehicles with the START-STOP system, the jump-start cable of the charger must never be connected directly to the negative pole of the vehicle battery, but

only to the engine earth.

› 1.2 l/63 kW TSI and 1.2 l/77 kW TSI engines

» Fig. 156 -

› 1.4 l/90 kW engine

» Fig. 156 -

› 1.6 l/77 kW TDI CR engine

» Fig. 156 -

Towing the vehicle

Introduction

This chapter contains information on the following subjects:

Front towing eye

192

Rear towing eye

192

Vehicles with a tow hitch

192

Vehicles with manual transmission may be towed in with a tow bar or a tow rope

or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the automatic

gearbox is damaged!

A tow bar is the safest way of towing a vehicle and also minimises any shocks.

Only use a tow rope if a suitable tow bar is not available.

When towing, the following guidelines must be observed.

Driver of the tow vehicle›

Release the clutch particularly gently when starting off or depress the accelera-

tor particularly gently if the vehicle is fitted with an automatic gearbox.

›

On vehicles with a manual transmission, only push down on the accelerator pedal once the rope is taught.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

›

Switch on the ignition so that the steering wheel is not locked and so that the turn signal lights, horn, windscreen wipers and windscreen washer system can

be used.

›

Take the vehicle out of gear or move the selector lever into position N if the ve-

hicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the en-

gine is running. If the engine is not running, significantly more physical force is re- quired to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

CAUTION

■ Do not tow start the engine – there is a risk of damaging the engine and the

catalytic converter. The battery from another vehicle can be used as a jump-start

aid » page 189 , Jump-starting .■

If the gearbox no longer contains any oil because of a defect, your vehicle must

only be towed with the driven wheels raised clear of the ground or on a special

breakdown vehicle or trailer.

■

The vehicle must be transported on a special breakdown vehicle or trailer if it is

not possible to tow in the vehicle in the way described or if the towing distance is

greater than 50 km.

■

To protect both vehicles when tow-starting or towing, the tow rope should be

elastic. Thus one should only use plastic fibre rope or a rope made out of a simi-

larly elastic material.

■

While towing, take care to avoid impermissibly high tensile forces or jerky loads.

There is always a risk of excessive stresses and damage resulting at the points to

which you attach the tow rope or tow bar when you attempt to tow a vehicle

which is not standing on a paved road.

■

Attach the tow rope or the tow bar to the towing eyes » page 192

or » page 192 to the detachable ball head of the towing equipment » page 119 .

191Emergency equipment and self-help

Page 196 of 226

CAUTIONThe detachable ball rod and/or the vehicle can be damaged if an unsuitable towbar is used.

Note

The detachable ball rod must always be in the vehicle so that it can be used for

towing, if necessary.

Remote control

Introduction

This chapter contains information on the following subjects:

Replacing the battery in the remote control key

193

Synchronising the remote control

194

CAUTION

■ The replacement battery must have the same specification as the original bat-

tery.■

When replacing the battery, pay attention to the correct polarity.

For the sake of the environment

Dispose of the used battery in accordance with national legal provisions.

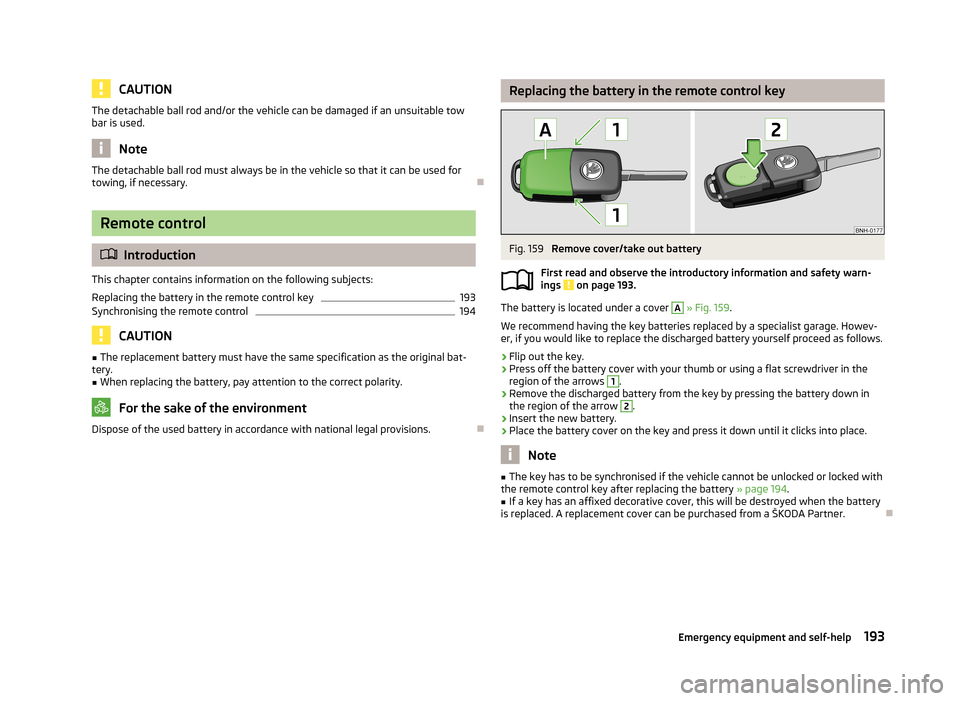

Replacing the battery in the remote control keyFig. 159

Remove cover/take out battery

First read and observe the introductory information and safety warn-

ings

on page 193.

The battery is located under a cover

A

» Fig. 159 .

We recommend having the key batteries replaced by a specialist garage. Howev- er, if you would like to replace the discharged battery yourself proceed as follows.

›

Flip out the key.

›

Press off the battery cover with your thumb or using a flat screwdriver in the region of the arrows

1

.

›

Remove the discharged battery from the key by pressing the battery down inthe region of the arrow

2

.

›

Insert the new battery.

›

Place the battery cover on the key and press it down until it clicks into place.

Note

■ The key has to be synchronised if the vehicle cannot be unlocked or locked with

the remote control key after replacing the battery » page 194.■

If a key has an affixed decorative cover, this will be destroyed when the battery

is replaced. A replacement cover can be purchased from a ŠKODA Partner.

193Emergency equipment and self-help

Page 197 of 226

Synchronising the remote controlFirst read and observe the introductory information and safety warn-

ings

on page 193.

If the vehicle does not unlock when pressing the remote control, the key may not

be synchronised. This can occur when the buttons on the remote control key are actuated a number of times outside of the operative range of the equipment or

the battery in the remote control key was replaced.

Synchronise the key as follows.

›

Press any button on the remote control key.

›

Pressing of the button means that the door will unlock with the key within 1 mi-

nute.

Emergency unlocking/locking

Introduction

This chapter contains information on the following subjects:

Locking a door

194

Unlocking the tailgate

194

Selector lever-emergency unlocking

195

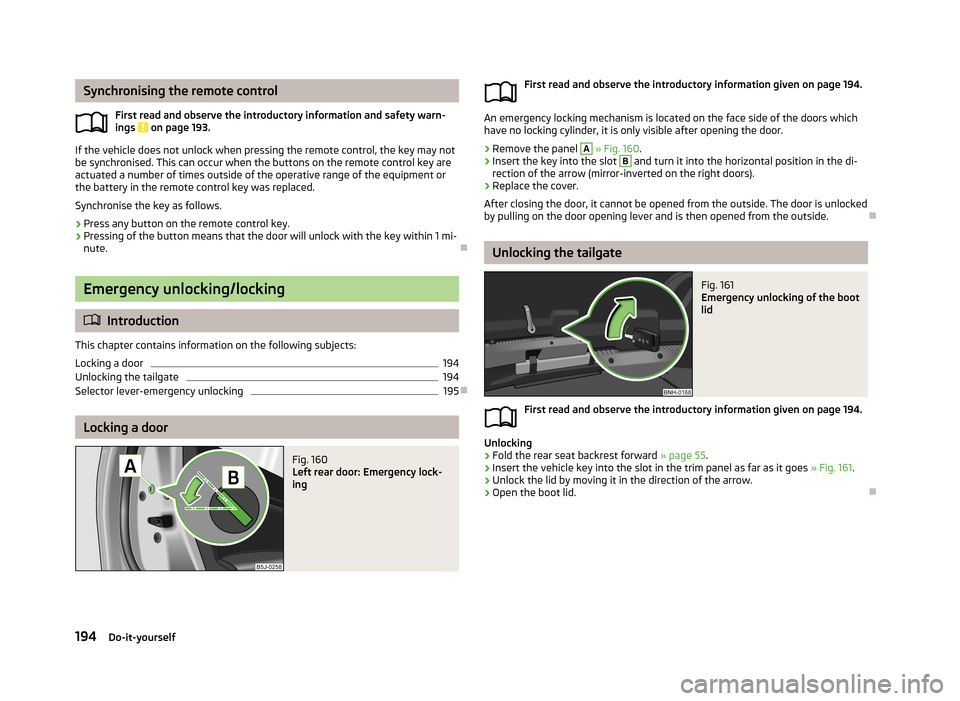

Locking a door

Fig. 160

Left rear door: Emergency lock-

ingFirst read and observe the introductory information given on page 194.

An emergency locking mechanism is located on the face side of the doors which

have no locking cylinder, it is only visible after opening the door.

›

Remove the panel

A

» Fig. 160 .

›

Insert the key into the slot

B

and turn it into the horizontal position in the di-

rection of the arrow (mirror-inverted on the right doors).

›

Replace the cover.

After closing the door, it cannot be opened from the outside. The door is unlocked by pulling on the door opening lever and is then opened from the outside.

Unlocking the tailgate

Fig. 161

Emergency unlocking of the boot

lid

First read and observe the introductory information given on page 194.

Unlocking

›

Fold the rear seat backrest forward » page 55.

›

Insert the vehicle key into the slot in the trim panel as far as it goes » Fig. 161

.

›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

194Do-it-yourself

Page 198 of 226

Selector lever-emergency unlockingFig. 162

Selector lever-emergency un-

locking

First read and observe the introductory information given on page 194.

›

Firmly apply the handbrake.

›

Carefully pull up the front left and right cover.

›

Pull up rear cover.

›

Press the yellow plastic part in the direction of the arrow » Fig. 162 using your

finger.

›

At the same time, press the locking button in the selector lever and move the selector lever to position N.

If the selector lever is moved again to position P, it is once again blocked.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the front windscreen wiper blades

195

Replacing the rear window glass wiper blades

196WARNINGReplace the windscreen wiper blades once or twice a year for safety reasons.

These can be purchased from a ŠKODA Partner.

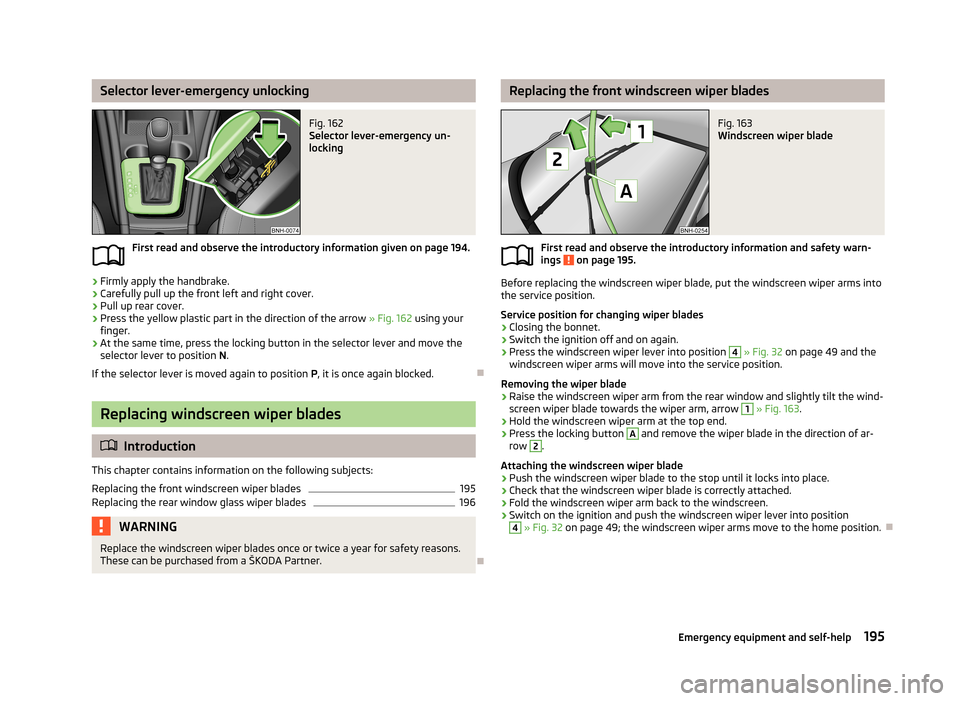

Replacing the front windscreen wiper bladesFig. 163

Windscreen wiper blade

First read and observe the introductory information and safety warn- ings on page 195.

Before replacing the windscreen wiper blade, put the windscreen wiper arms into

the service position.

Service position for changing wiper blades

›

Closing the bonnet.

›

Switch the ignition off and on again.

›

Press the windscreen wiper lever into position

4

» Fig. 32 on page 49 and the

windscreen wiper arms will move into the service position.

Removing the wiper blade

›

Raise the windscreen wiper arm from the rear window and slightly tilt the wind-

screen wiper blade towards the wiper arm, arrow

1

» Fig. 163 .

›

Hold the windscreen wiper arm at the top end.

›

Press the locking button

A

and remove the wiper blade in the direction of ar-

row

2

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

›

Switch on the ignition and push the windscreen wiper lever into position

4

» Fig. 32 on page 49; the windscreen wiper arms move to the home position.

195Emergency equipment and self-help

Page 199 of 226

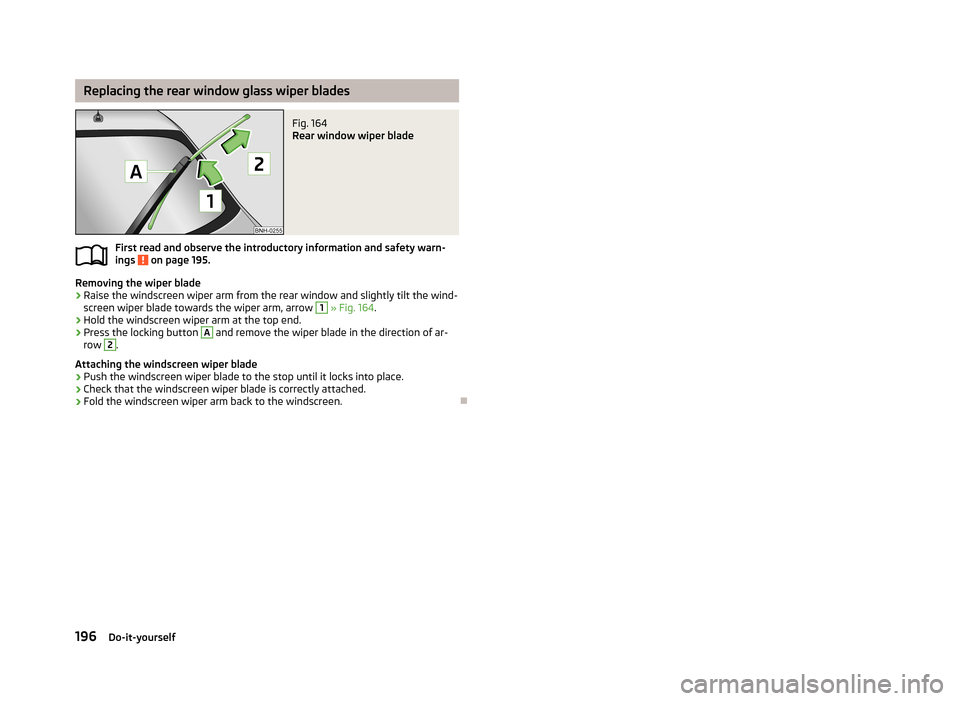

Replacing the rear window glass wiper bladesFig. 164

Rear window wiper blade

First read and observe the introductory information and safety warn-ings on page 195.

Removing the wiper blade

›

Raise the windscreen wiper arm from the rear window and slightly tilt the wind-

screen wiper blade towards the wiper arm, arrow

1

» Fig. 164 .

›

Hold the windscreen wiper arm at the top end.

›

Press the locking button

A

and remove the wiper blade in the direction of ar-

row

2

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

196Do-it-yourself