lock SKODA SUPERB 2010 2.G / (B6/3T) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: SUPERB, Model: SKODA SUPERB 2010 2.G / (B6/3T)Pages: 287, PDF Size: 16.59 MB

Page 238 of 287

Breakdown assistance237

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

The spare wheel lies in a well under the floor covering of the luggage compartment and

is fixed in place using special screws

page 236, fig. 195 .

Before removing the spare wheel, you must take out the box with the vehicle tool kit

box page 236, fig. 194.

One should check the inflation pressure in the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap page 228) to ensure

that the spare wheel is always ready to use.

Temporary spare wheel

A warning label displayed on the rim of the temporary spare wheel indicates that your

vehicle is equippe d with a temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

The warning label must not be covered after installing the wheel.

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.

The inflation pressure for this spare wheel is identical to the inflation pressure of

the standard tyres. The temporary spare wheel R 18 must have an inflation pressure of

420 kPa (4.2 bar)!

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

No other summer or winter tyres must be mounted on the rim of the spare wheel

R 18.

Changing a wheelPreliminary workThe following steps should be carried ou t before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from

the traffic flow. The place you choose should be level.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (e.g. behind a crash barrier).

– Apply the handbrake firmly. –Engage

1st gear or if your vehicle is fitted with an automatic gearbox, position the

selector lever into position P .

– If a trailer is coupled, uncouple it.

–Take the vehicle tool kit page 236 and the spare wheel* page 236 out of the

luggage compartment.

WARNING

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescribed

distance from your vehicle while observin g all national legal provisions. In this

way you are protecting not only yourself but also other road users.

Never start the engine with the vehicle si tting on the raised jack - danger of

suffering injury.Caution

If you have to change a wheel on a slope fi rst block the opposite wheel with a stone or

similar object in order to secure the vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.Changing a wheelAlways change a wheel on a level surface as far as possible.

– Take off the full wheel trim* page 238 or the wheel trim cap page 239 or the

caps page 239.

– In the case of light alloy wheels remove the wheel trim cap page 239.

– First of all slacken the safety wheel bolt * and afterwards the other wheel bolts page 239.

– Jack up the vehicle until the wheel to be changed is clear of the ground

page 240.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

s3fg.2.book Page 237 Friday, April 30, 2010 12:17 PM

Page 239 of 287

Breakdown assistance

238

– Take off the wheel.

– Fit on the spare wheel and ti ghten the wheel bolts slightly.

–Lower the car.

– Tighten the wheel bolts firmly, alternately and diagonally using the wheel wrench (crosswise) and last the safety wheel bolt* page 239.

– Mount the full wheel trim/wheel trim cap or the caps.

Note

All bolts must be clean and must turn easily.

You must never grease or oil the wheel bolts!

When fitting on unidirectional tyres, ensu re that the tyres rotate in the correct

direction page 228.

Subsequent stepsAfter changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well using a special screw

page 236, fig. 195 .

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as possible.

– Have the tightening torque of the wheel bolts checked with a torque wrench as

soon as possible. Steel and light alloy wh eels must be tightened to a tightening

torque of 120 Nm .

– Change the damaged wheel or consult a specialist garage about possibilities for getting repairs done.

WARNING

It is necessary to observe the guidelines given on page 230 if the vehicle is

subsequently fitted with tyres which are different to those it was fitted with at

the works.

Note

If you find, when changing the wheel, that the wheel bolts are corroded and diffi-

cult to turn, the bolts must be replaced before checking the tightening torque.

Drive cautiously and only at a moderate speed to a workshop where the tightening

torque can be checked.

Full wheel trim*Pulling off– Hook the clamp found in the vehicle tool ki t into the reinforced edge of the full

wheel trim.

– Push the wheel key through the clamp, support the wheel key at the tyre and pull off the wheel trim.Installing– First press the full wheel trim onto the wheel at the valve opening provided. Then

press the full wheel trim into the wheel in such a way that its entire circumference

locks correctly in place.

Caution

Use the pressure of your hand, do not knock on the full wheel trim! Heavy knocks

mainly on the points where the full wheel trim has not been inserted into the wheel,

can result in damage to the guide and centering elements of the full wheel trim.

Check for yourself that the safety wheel bolt is located in the hole in the area of the

valve before fitting the full wheel trim onto a steel wheel which is attached with a safety

wheel bolt page 240, “Securing wheels against being stolen*”.

s3fg.2.book Page 238 Friday, April 30, 2010 12:17 PM

Page 241 of 287

Breakdown assistance

240

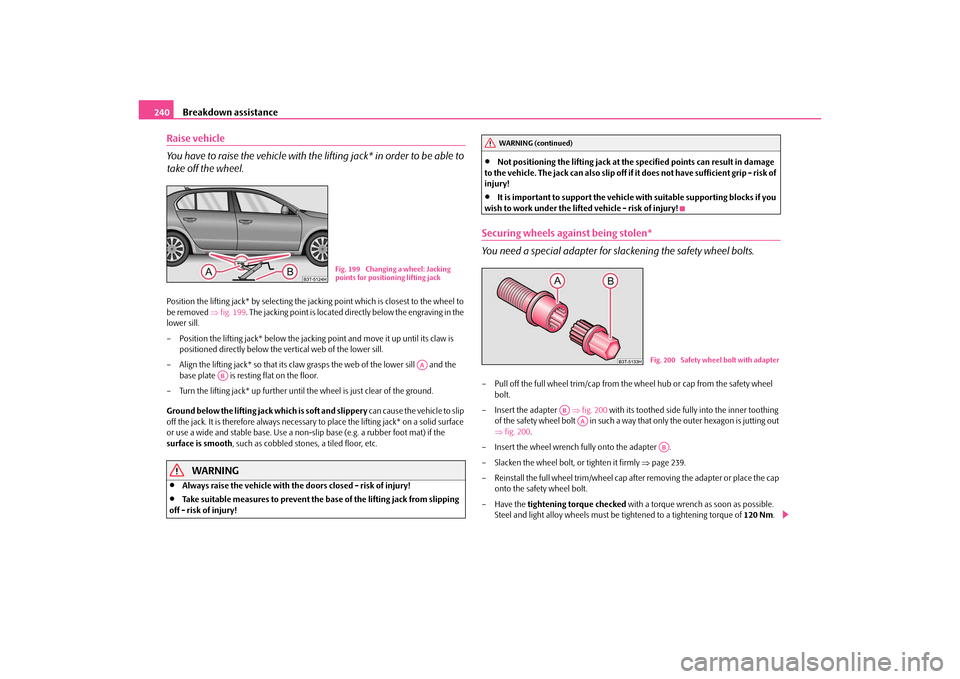

Raise vehicle

You have to raise the vehicle with the lifting jack* in order to be able to

take off the wheel.Position the lifting jack* by selecting the ja cking point which is closest to the wheel to

be removed fig. 199 . The jacking point is located directly below the engraving in the

lower sill.

– Position the lifting jack* below the jacking point and move it up until its claw is positioned directly below the vertical web of the lower sill.

– Align the lifting jack* so that its claw grasps the web of the lower sill and the

base plate is resting flat on the floor.

– Turn the lifting jack* up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the vehicle to slip

off the jack. It is therefore always necessary to place the lifting jack* on a solid surface

or use a wide and stable base. Use a non-sl ip base (e.g. a rubber foot mat) if the

surface is smooth , such as cobbled stones, a tiled floor, etc.

WARNING

Always raise the vehicle with the doors closed - risk of injury!

Take suitable measures to prevent the base of the lifting jack from slipping

off - risk of injury!

Not positioning the lifting jack at the specified points can result in damage

to the vehicle. The jack can al so slip off if it does not have sufficient grip - risk of

injury!

It is important to support the vehicle with suitable supporting blocks if you

wish to work under the lifted vehicle - risk of injury!

Securing wheels against being stolen*

You need a special adapter for sl ackening the safety wheel bolts.– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel

bolt.

– Insert the adapter fig. 200 with its toothed side full y into the inner toothing

of the safety wheel bolt in such a way that only the outer hexagon is jutting out

fig. 200 .

– Insert the wheel wrench fully onto the adapter .

– Slacken the wheel bolt, or tighten it firmly page 239.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap onto the safety wheel bolt.

– Have the tightening torque checked with a torque wrench as soon as possible.

Steel and light alloy wheels must be tightened to a tightening torque of 120 Nm.

Fig. 199 Changing a wheel: Jacking

points for positioning lifting jack

AA

AB

WARNING (continued)

Fig. 200 Safety wheel bolt with adapter

AB

AA

AB

s3fg.2.book Page 240 Friday, April 30, 2010 12:17 PM

Page 243 of 287

Breakdown assistance

242

– Attach the other end to the positive term inal of the battery supplying the power

.Connecting negative terminal and engine block– Attach one end to the negative termin al of the battery supplying the power .

– Attach the other end to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.Starting the engine– Start the engine of the vehicle providing current and run the engine at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start right

away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the reverse order they were

connected up.

WARNING

The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal of

the battery must not come into contact with electrically conducting parts of the

vehicle - risk of a short circuit!

Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

Do not bend over the batteries - risk of caustic burns!

The vent screws of the battery cells must be tightened firmly.

Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

Never jump-start the batteries which have a too low electrolyte level - risk

of explosion and caustic burns.

Jump-starting on vehicles with jump-starting pointFor vehicles with the 3.6 ltr./191 kW FSI engi nes, the positive terminal of the battery

supplying the power can only be connected to the jump-starting point in the engine

compartment of the vehicle which must be started by means of a jump-starting

cable fig. 202 !

– Open the protective cap of the jump-starting point in direction of arrow.

– Connect the positive termin al of the battery supplying the power with the jump-

starting point.

– Attach the negative terminal of the batte ry supplying the power to a solid metal

part which is connected firm ly to the engine block or to the engine block itself.

–Start the engine page 242.

– After the engine start, close the prot ective cap of the jump-starting point.Tow-starting and towing vehicleGeneralPlease pay attention to the following instru ctions if you are going to use a tow rope:Driver of the towing vehicle– Do not drive off until the tow rope is taught.

A2

AB

A3

AB

A4

Fig. 202 Detail of the engine compart-

ment: Jump-starting point

s3fg.2.book Page 242 Friday, April 30, 2010 12:17 PM

Page 244 of 287

Breakdown assistance243

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

– Release the clutch particularly gently wh

en starting off or depress the accelerator

particularly gently if your vehicle is fitted with an automatic gearbox.

Driver of the towed vehicle– Switch the ignition on so that the steeri ng wheel is not blocked and you can also

operate the turn signal lights, the headlight flasher, the windscreen wipers and

windscreen washer system.

– Take the vehicle out of gear or move the selector lever into position N if your

vehicle is fitted with an automatic gearbox.

– Note that the brake servo unit and power steering only operate if the engine is running. You will require significantly grea ter physical force to depress the brake

pedal and to steer th e vehicle if the engine is not running.

– Ensure that the tow rope is always kept taught.

Tow rope or tow bar

A tow bar is safest way of towing a vehicle an d also minimizes any shocks. You can use

a tow rope only if a suitable tow bar is not available.

The tow rope must be elastic to protect the vehicle. Thus one should only use plastic

fibre rope or a rope made out of a similarly elastic material.

Only attach the tow rope to the towing eyes provided for this purpose page 243

and page 244.

Driving style

Towing another vehicle requires a certain am ount of practice. Both drivers should be

familiar with the particular points about to wing a vehicle. Unskilled drivers should not

attempt to tow in another vehicle or to be towed in.

One should be constantly vigi lant not to allow impermissibly high towing forces or

jerky loadings. There is always a risk of excessive stresses and damage resulting at the

points to which you attach the tow rope or tow bar when you attempt to tow a vehicle

which is not standing on a paved road.

Caution

If the gearbox of your vehicle no longer contains any oil because of a defect, your

vehicle must only be towed in with the driven wheels raised clear of the ground, or on

a special vehicle transporter or trailer.

Note

Please comply with any national legal provisions particularly regarding the

switched on signal systems, when towi ng in or tow-starting another vehicle.

The tow rope must not be twisted as it may in certain circumstances result in the

front towing eye being unscrewed out of your vehicle.

Front towing eye

The towing eye is stored in th e box for the vehicle tool kit.Fig. 203 Front bumper: Removing the cover / installing the towing eye– Take the cover out of the front bumper fig. 203 - left.

– Screw in the towing eye by hand to the left up to the stop fig. 203 - right and

tighten it as much as po ssible. For tightening, we recommend that you use for

example the wheel wrench*, the lashing eye of another vehicle or a similar object

which you can push through the eye.

– Put the cover in place after screwing out the towing eye again and press into place.

The cover must engage firmly.

s3fg.2.book Page 243 Friday, April 30, 2010 12:17 PM

Page 248 of 287

Fuses and light bulbs247

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

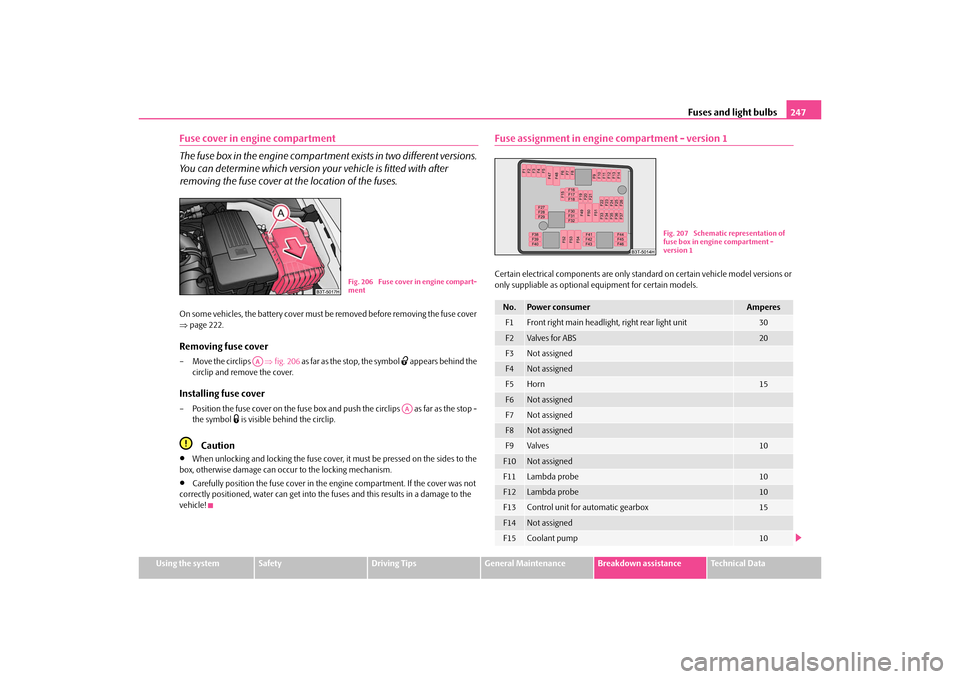

Fuse cover in engine compartment

The fuse box in the engine compartment exists in two different versions.

You can determine which version your vehicle is fitted with after

removing the fuse cover at the location of the fuses.On some vehicles, the battery cover must be removed before removing the fuse cover

page 222.Removing fuse cover– Move the circlips fig. 206 as far as the stop, the symbol

appears behind the

circlip and remove the cover.

Installing fuse cover– Position the fuse cover on the fuse box and push the circlips as far as the stop -

the symbol

is visible behind the circlip.

Caution

When unlocking and locking the fuse cover, it must be pressed on the sides to the

box, otherwise damage can occur to the locking mechanism.

Carefully position the fuse cover in the engine compartment. If the cover was not

correctly positioned, water can get into the fuses and this results in a damage to the

vehicle!

Fuse assignment in engine compartment - version 1Certain electrical components are only stan dard on certain vehicle model versions or

only suppliable as optional equipment for certain models.

Fig. 206 Fuse cover in engine compart-

ment

AA

AA

No.

Power consumer

Amperes

F1

Front right main headlight, right rear light unit

30

F2

Valves for ABS

20

F3

Not assigned

F4

Not assigned

F5

Horn

15

F6

Not assigned

F7

Not assigned

F8

Not assigned

F9

Valves

10

F10

Not assigned

F11

Lambda probe

10

F12

Lambda probe

10

F13

Control unit for automatic gearbox

15

F14

Not assigned

F15

Coolant pump

10

Fig. 207 Schematic representation of

fuse box in engine compartment -

version 1

s3fg.2.book Page 247 Friday, April 30, 2010 12:17 PM

Page 251 of 287

Fuses and light bulbs

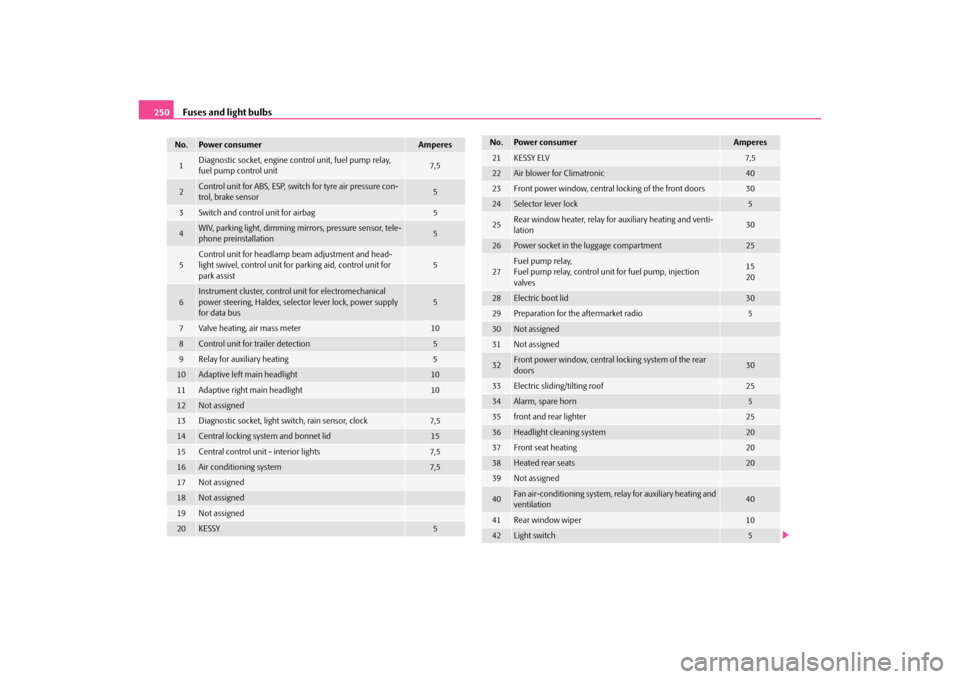

250No.

Power consumer

Amperes

1

Diagnostic socket, engine control unit, fuel pump relay,

fuel pump control unit

7,5

2

Control unit for ABS, ESP, switch for tyre air pressure con-

trol, brake sensor

5

3

Switch and control unit for airbag

5

4

WIV, parking light, dimming mirrors, pressure sensor, tele-

phone preinstallation

5

5

Control unit for headlamp beam adjustment and head-

light swivel, control unit for parking aid, control unit for

park assist

5

6

Instrument cluster, control unit for electromechanical

power steering, Haldex, selector lever lock, power supply

for data bus

5

7

Valve heating, air mass meter

10

8

Control unit for trailer detection

5

9

Relay for auxiliary heating

5

10

Adaptive left main headlight

10

11

Adaptive right main headlight

10

12

Not assigned

13

Diagnostic socket, light switch, rain sensor, clock

7,5

14

Central locking system and bonnet lid

15

15

Central control unit - interior lights

7,5

16

Air conditioning system

7,5

17

Not assigned

18

Not assigned

19

Not assigned

20

KESSY

5

21

KESSY ELV

7,5

22

Air blower for Climatronic

40

23

Front power window, central locking of the front doors

30

24

Selector lever lock

5

25

Rear window heater, relay for auxiliary heating and venti-

lation

30

26

Power socket in the luggage compartment

25

27

Fuel pump relay,

Fuel pump relay, control unit for fuel pump, injection

valves

15

20

28

Electric boot lid

30

29

Preparation for the aftermarket radio

5

30

Not assigned

31

Not assigned

32

Front power window, central locking system of the rear

doors

30

33

Electric sliding/tilting roof

25

34

Alarm, spare horn

5

35

front and rear lighter

25

36

Headlight cleaning system

20

37

Front seat heating

20

38

Heated rear seats

20

39

Not assigned

40

Fan air-conditioning system, re lay for auxiliary heating and

ventilation

40

41

Rear window wiper

10

42

Light switch

5

No.

Power consumer

Amperes

s3fg.2.book Page 250 Friday, April 30, 2010 12:17 PM

Page 255 of 287

Fuses and light bulbs

254

– For the installation, first of all insert the fog light with the interlock to the side far

away from the marking of the vehicle.

– Press into place the headlight onto the si de facing the marking. The spring bolt

must engage firmly.

– In order to reinstall the cover, first of all insert one part of the cover starting on the side facing the fog light. Then press the cover closed on the side facing the marking.

The cover must engage firmly.

- bulb for daylight driving lights*.

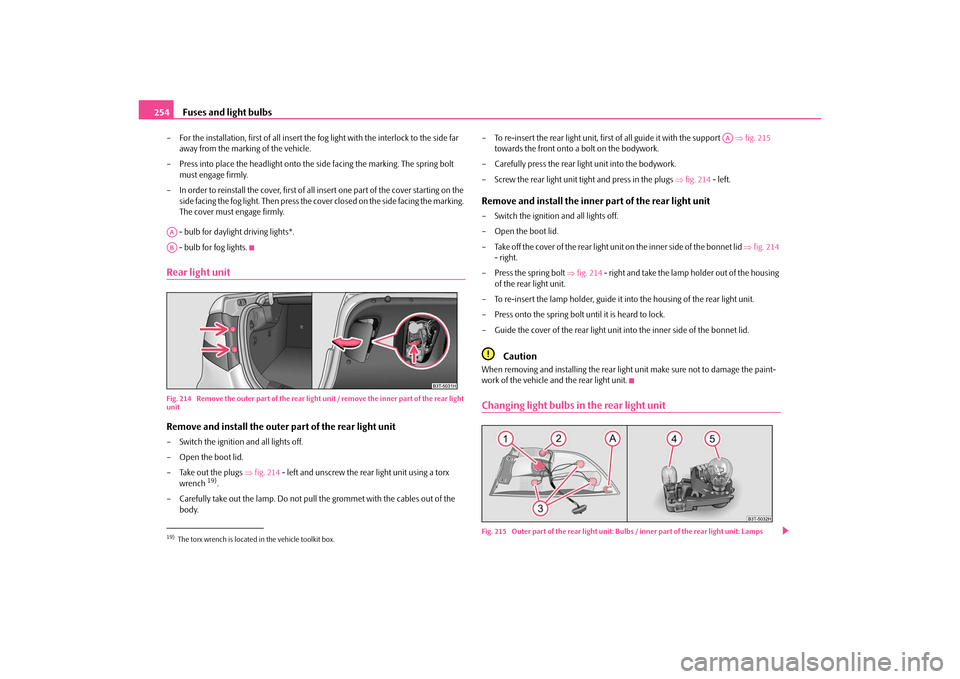

- bulb for fog lights.Rear light unitFig. 214 Remove the outer part of the rear light unit / remove the inner part of the rear light

unitRemove and install the outer part of the rear light unit– Switch the ignition and all lights off.

– Open the boot lid.

– Take out the plugs fig. 214 - left and unscrew the rear light unit using a torx

wrench

19).

– Carefully take out the lamp. Do not pull the grommet with the cables out of the

body. – To re-insert the rear light unit, first of all guide it with the support

fig. 215

towards the front onto a bolt on the bodywork.

– Carefully press the rear li ght unit into the bodywork.

– Screw the rear light unit tight and press in the plugs fig. 214 - left.

Remove and install the inner part of the rear light unit– Switch the ignition and all lights off.

– Open the boot lid.

– Take off the cover of the rear light unit on the inner side of the bonnet lid fig. 214

- right.

– Press the spring bolt fig. 214 - right and take the lamp holder out of the housing

of the rear light unit.

– To re-insert the lamp holder, guide it into the housing of the rear light unit.

– Press onto the spring bolt until it is heard to lock.

– Guide the cover of the rear light unit into the inner side of the bonnet lid.

Caution

When removing and installing the rear ligh t unit make sure not to damage the paint-

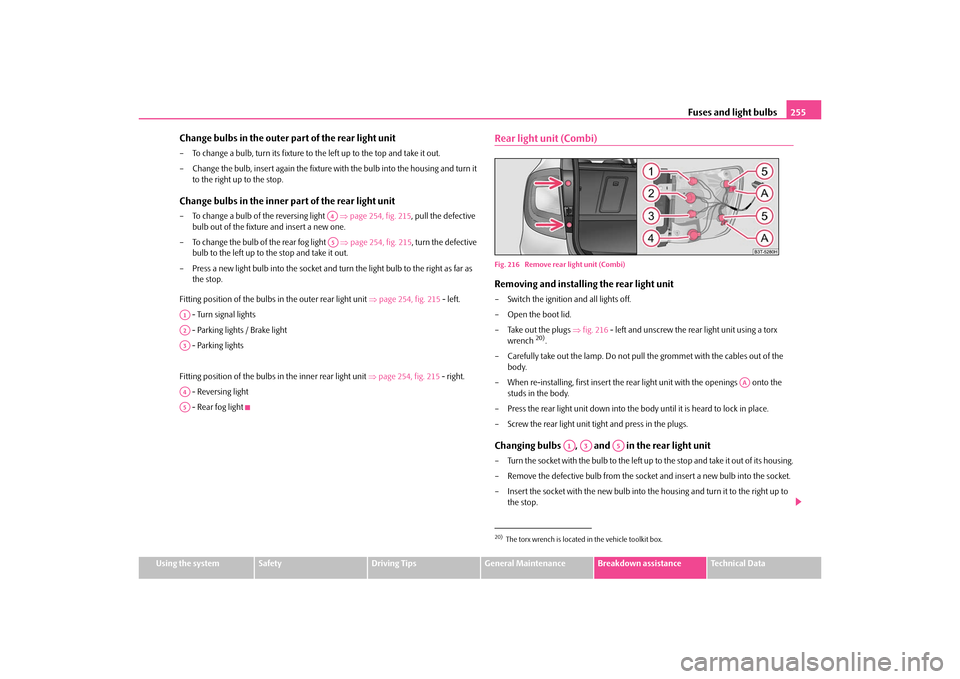

work of the vehicle and the rear light unit.Changing light bulbs in the rear light unitFig. 215 Outer part of the rear light unit: Bulbs / inner part of the rear light unit: Lamps

19)The torx wrench is located in the vehicle toolkit box.AAAB

AA

s3fg.2.book Page 254 Friday, April 30, 2010 12:17 PM

Page 256 of 287

Fuses and light bulbs255

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Change bulbs in the outer part of the rear light unit– To change a bulb, turn its fixture to the left up to the top and take it out.

– Change the bulb, insert again the fixture with the bulb into the housing and turn it

to the right up to the stop.Change bulbs in the inner part of the rear light unit– To change a bulb of the reversing light page 254, fig. 215 , pull the defective

bulb out of the fixture and insert a new one.

– To change the bulb of the rear fog light page 254, fig. 215 , turn the defective

bulb to the left up to the stop and take it out.

– Press a new light bulb into the socket and turn the light bulb to the right as far as

the stop.

Fitting position of the bulbs in the outer rear light unit page 254, fig. 215 - left.

- Turn signal lights

- Parking lights / Brake light

- Parking lights

Fitting position of the bulbs in the inner rear light unit page 254, fig. 215 - right.

- Reversing light

- Rear fog light

Rear light unit (Combi)Fig. 216 Remove rear light unit (Combi)Removing and installing the rear light unit– Switch the ignition and all lights off.

– Open the boot lid.

– Take out the plugs fig. 216 - left and unscrew the rear light unit using a torx

wrench

20).

– Carefully take out the lamp. Do not pull the grommet with the cables out of the

body.

– When re-installing, first insert the rear light unit with the openings onto the studs in the body.

– Press the rear light unit down into the body until it is heard to lock in place.

– Screw the rear light unit tight and press in the plugs.

Changing bulbs , and in the rear light unit– Turn the socket with the bulb to the left up to the stop and take it out of its housing.

– Remove the defective bulb from the socket and insert a new bulb into the socket.

– Insert the socket with the new bulb into the housing and turn it to the right up to the stop.

A4A5

A1A2A3A4A5

20)The torx wrench is located in the vehicle toolkit box.

AA

A1

A3

A5

s3fg.2.book Page 255 Friday, April 30, 2010 12:17 PM

Page 259 of 287

Technical Data

258Gearbox code, paint number, interior eq uipment number, engine output, engine

code.

Partial description of the vehicle.

7GG, 7MB, 7MG - vehicles with DPF page 193.

Vehicle identification number (VIN)

The vehicle identification number - VIN (veh icle body number) is stamped into the

engine compartment on the right hand sh ock absorber dome. This number is also

located on a sign on the lowe r left hand edge below the windscreen (together with a

VIN bar code).

Engine number

The engine number is stam ped into the engine block.

Type plate (production plate)

It is located on the left middle pillar of the body.

Sticker on inside of fuel filler flap

The stickers are affixed to the inside of the fuel filler flap. They contain the following

data:

The prescribed types of fuel,

Ty re s i z e ,

Tyre pressure.

Fuel consumption according to the ECE standards and EU guidelinesDepending on the range of the special equipment, style of driving, traffic situation,

weather influences and vehicl e condition, the consumption values which in practice

result when using the vehicle can deviate from the indicated values.

Urban traffic

The consumption measurement in urban traffic begins with starting of the cold engine.

Afterwards the normal ur ban traffic is simulated. Non-urban traffic

For the consumption measurement in non-ur

ban traffic the vehicle, as in daily

motoring, is accelerated and braked severa l times in all gears. The vehicle speed

changes within the range from 0 to 120 km/h.

Combined traffic

The consumption value in the combined traffic consists of 37% from the value for the

urban traffic and of 63% from th e value for the non-urban traffic.

Note

Please note that the information stated in the official vehicle registration docu-

ments always takes priority.

A3A4A5s3fg.2.book Page 258 Friday, April 30, 2010 12:17 PM