wheel bolts SKODA SUPERB 2014 2.G / (B6/3T) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: SUPERB, Model: SKODA SUPERB 2014 2.G / (B6/3T)Pages: 246, PDF Size: 17.16 MB

Page 195 of 246

OperationOperating measureSetting the clock» page 30Data in the multifunction display are de-

leted.» page 41

Note

We recommend having the vehicle checked by a specialist garage in order to

ensure full functionality of all electrical systems.

Automatic load deactivation

Read and observe

and on page 190 first.

The vehicle voltage control unit automatically prevents the battery from dis-

charging when the battery is put under high levels of strain. This manifests it-

self by the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and

rear window heaters have their power limited or are shut off completely in

the event of an emergency.

CAUTION

■ Despite such intervention by the vehicle electric system management, the

vehicle battery may be drained. For example, when the ignition is switched on

a long time with the engine turned off or the side or parking lights are turned

on during longer parking.■

Consumers that are supplied via a 12-V power socket can cause the vehicle

battery to discharge when the ignition is switched off.

Note

Driving comfort is not impaired by consumers being deactivated. The driver is

often not aware of it having taken place.Wheels

Tyres and wheel rims

Introduction

This chapter contains information on the following subjects:

Service life of tyres

194

New tyres

195

Unidirectional tyres

196

Tyre pressure monitor

196

Spare and temporary spare wheel

197

Full wheel trim

198

Wheel bolts

198

Wheel bolts

198WARNINGThe national legal regulations must be observed for the use of tyres.WARNINGInstructions for the use of tyres■For the first 500 km, new tyres do not yet provide optimum grip, and ap-

propriate care should therefore be taken when driving – risk of accident!■

Only use radial tyres of the same type, size (rolling circumference) and

tread pattern on all four wheels.

■

For reasons of driving safety, do not replace tyres individually.

■

Never exceed the maximum permissible load bearing capacity for fitted

tyres – risk of accident!

■

Never exceed the maximum permissible speed for fitted tyres – risk of ac-

cident!

■

Incorrect wheel alignment at the front or rear impairs handling – risk of

accident!

■

Unusual vibrations or pulling of the vehicle to one side could be a sign of

tyre damage. If there is any doubt that a wheel is damaged, immediately re-

duce your speed and stop! If no external damage is evident, drive slowly

and carefully to the nearest specialist garage to have the vehicle checked.

■

Only use tyres or wheel rims that have been approved by ŠKODA for your

model of vehicle. Failure to observe this instruction may impair the road

safety of your vehicle – risk of accident!

193Wheels

Page 196 of 246

WARNINGInformation regarding tyre damage or wear■Never use tyres if you do not know anything about the condition and age.■

Never drive with damaged tyres – risk of accident!

■

Immediately replace damaged wheel rims or tyres.

■

You must have your tyres replaced with new ones at the latest when the

wear indicators have been worn down.

■

Worn tyres impair necessary adhesion to the road surface, particularly at

high speeds on wet roads. This could lead to “aquaplaning” (uncontrolled

vehicle movement – “swimming” on a wet road surface).

WARNINGInformation on tyre pressure■The tyre control display does not absolve the driver of the responsibility

to ensure the correct tyre inflation pressure. Check the tyre inflation pres-

sure at regular intervals.■

Insufficient or excessive inflation pressure impairs handling – risk of acci-

dent!

■

If the inflation pressure is too low, the tyre will have to overcome a higher

rolling resistance. This will cause a significant increase in the temperature

of the tyre, especially at higher speeds. This can result in tread separation

and a tyre blowout.

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rims

could come loose when the car is moving – risk of accident! A tightening

torque which is too high can damage the bolts and threads and this can re-

sult in permanent deformation of the contact surfaces on the rims.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving – risk of accident!

WARNINGInformation on the temporary spare wheel■Only use the temporary spare wheel when absolutely necessary.■

Never drive with more than one temporary spare wheel mounted.

■

The snow chains cannot be used on the temporary spare wheel.

CAUTION

■ If a spare wheel is used that is not identical to the fitted tyres, the following

must be observed » page 197, Spare and temporary spare wheel .■

Protect the tyres from contact with oil, grease and fuel.

■

Replace lost valve caps.

■

If, in the event of a puncture, it is necessary to fit a spare wheel with a tyre

without a dedicated running direction or with the opposite direction of rota-

tion, drive carefully as the optimal characteristics of the tyre are no longer ap-

plicable in this situation.

For the sake of the environment

Tyres that are insufficiently inflated increase your fuel consumption.

Note

■ We recommend that any work on the wheels or tyres be carried out by a spe-

cialist garage.■

We recommend that you use wheel rims, tyres, full wheel trims and snow

chains from ŠKODA Original Accessories.

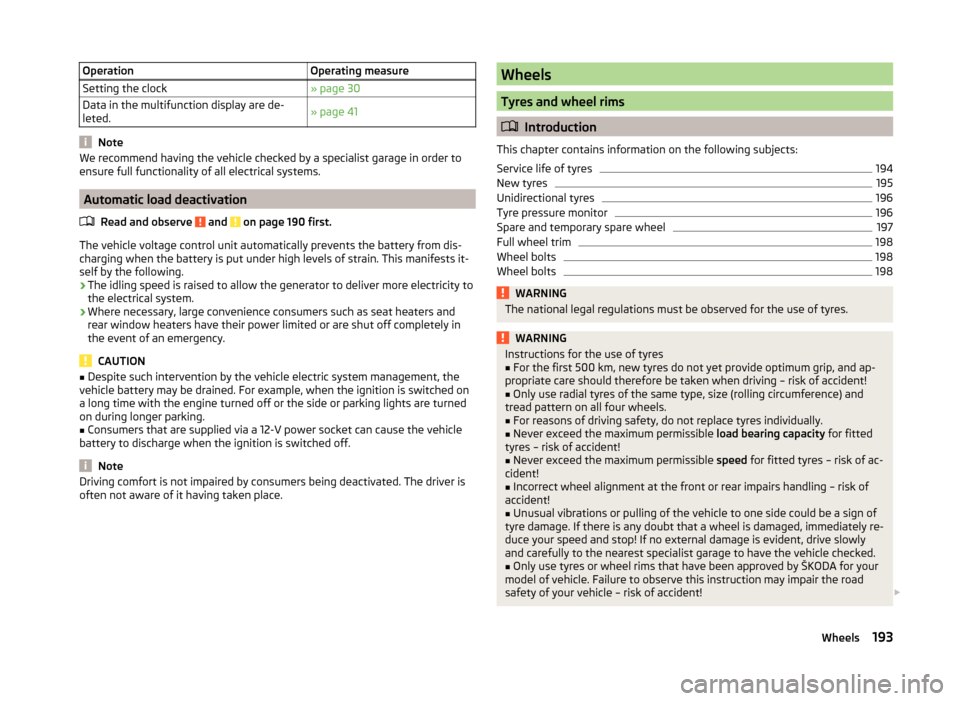

Service life of tyres

Fig. 168

Principle sketch: Tyre tread with wear indicators/open fuel filler

flap with a table detailing the tyre sizes and tyre inflation pressures

194General Maintenance

Page 200 of 246

Please note the following if you intend to use the temporary spare wheel.› The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The temporary spare wheel is inflated to the maximum inflation pressure for

the vehicle » Fig. 168 on page 194 .

› The tyre inflation pressure of the spare wheel R 18 is 420 kPa.

› Only use this temporary spare wheel to reach the nearest specialist garage,

as it is not intended for long-term use.WARNING■ Never drive with more than one temporary spare wheel mounted!■Never use the temporary spare wheel if it is damaged.■

If the dimensions or design of the temporary spare wheel differ from the

fitted tyres, never drive faster than 80 km/h (or 50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

CAUTION

Observe the instructions on the warning sign of the temporary spare wheel.

Full wheel trim

Read and observe

and on page 193 first.

Pulling off

›

Hook the clamp found in the vehicle tool kit » page 201 into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Fitting

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim. Avoid

heavy impacts when the trim has not yet been inserted into the wheel rim.

This could cause damage to the guide and centring elements of the trim.■

When using the anti-theft wheel bolt, ensure that it is in the hole in the

valve area » page 204 , Securing wheels against theft .

■

If wheel trims are retrofitted it must be ensured that an adequate flow of air

is assured to cool the brake system.

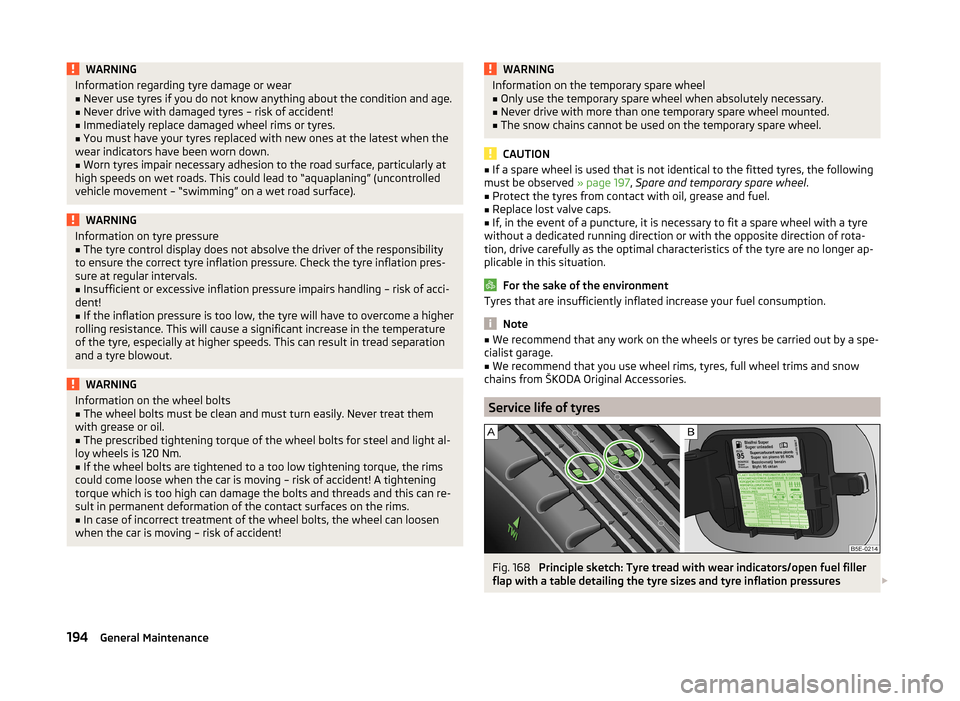

Wheel boltsFig. 172

Remove the cap

Read and observe and on page 193 first.

Pulling off

›

Push the extraction pliers » page 201 sufficiently far onto the cap until the

inner catches of the pliers are positioned at the collar of the cap.

›

Remove the cap in the direction of the arrow » Fig. 172.

Fitting

›

Push the cap onto the wheel bolt up to the stop.

The wheel bolt caps are housed in a plastic box in the spare wheel or in the

storage space for the spare wheel.

Wheel bolts

Read and observe

and on page 193 first.

Wheels and wheel bolts are matched to each other in terms of design. Each

time you fit other wheels rims, e.g. light alloy wheel rims or wheels with winter

tyres, you must also use the matching wheel bolts with the correct length and

dome shape. The right fastening of wheels depends on this.

Winter operation

Introduction

This chapter contains information on the following subjects:

Winter tyres

199

Snow chains

199198General Maintenance

Page 203 of 246

The fire extinguisher must be checked by an authorised person once a year.

The national legal requirements must be observed.WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

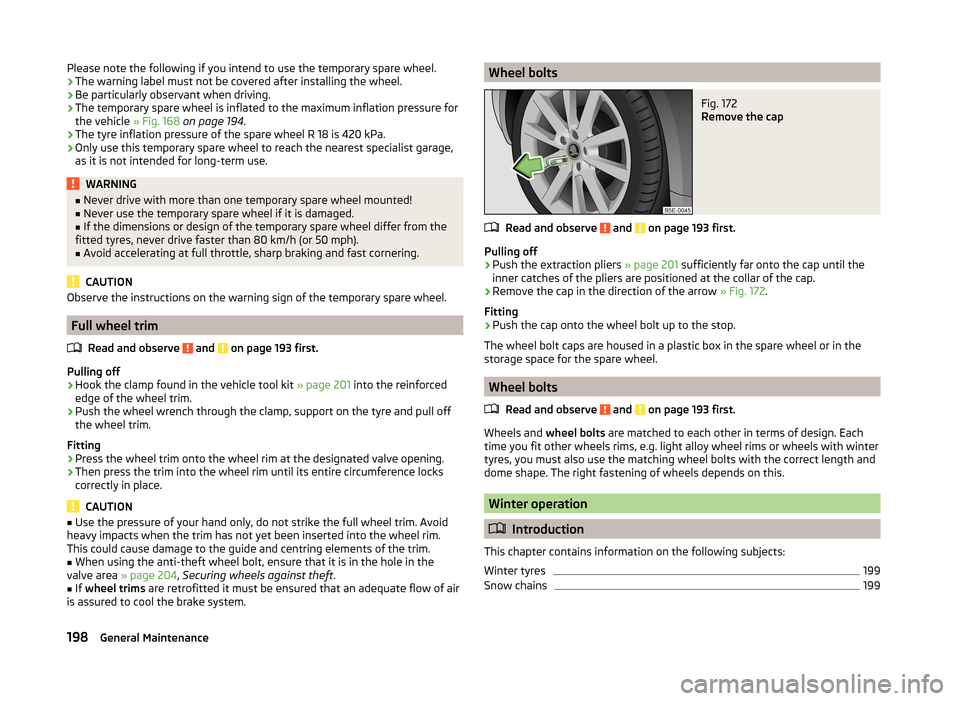

Vehicle tool kit

Fig. 176

Vehicle tool kit

The vehicle tool kit and the lifting jack are housed in a plastic box in the spare

wheel or in the storage space for the spare wheel. There is also space here for

the removable ball rod for the trailer towing device. The box is attached with a

strap on the spare wheel.

The components of the vehicle tool kit (if included in the vehicle) » Fig. 176.

Screwdriver

Key for removing and installing the tail light

Adapter for anti-theft wheel bolts

123Towing eye

Clamps for removing the wheel trims

Car jack

Crank for the jack

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb set

Screw the car jack back into its initial position after use in order to store it back

in the box with the vehicle tool kit.WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances use it to lift heavier vehicles or other loads – risk of

injury!■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

202

Changing a wheel

202

Follow-up work

202

Loosening/tightening wheel bolts

203

Raising the vehicle

203

Securing wheels against theft

204WARNING■ If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory-fitted ones » page 195,

New tyres .

45678910201Emergency equipment and self-help

Page 204 of 246

WARNINGNotes for vehicle lifting■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

Never start the engine when the vehicle is raised – risk of injury.

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rims

could come loose when the car is moving – risk of accident! A tightening

torque which is too high can damage the bolts and threads and this can re-

sult in permanent deformation of the contact surfaces on the rims.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving – risk of accident!

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 201 first.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

› Have

all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.›

Switch off the engine.

›

Move the gearshift lever into Neutral or move the selector lever for the auto-

matic gearbox into position P .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›

Remove the vehicle tool kit » page 201 and the spare wheel » page 197 from

the boot.

Changing a wheel

Read and observe

on page 201 first.

›

Remove the full wheel trim » page 198 or caps » page 198 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 203 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 203 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last » page 203.

›

Replace the wheel trim or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 193 .

Follow-up work

Read and observe

on page 201 first.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 197 .

202Do-it-yourself

Page 205 of 246

›Stow the tool kit in the space provided and secure using the band.›Check

the tyre pressure on the installed spare wheel as soon as possible.›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

›

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn

when changing the wheel, the bolts must be replaced before checking the

tightening torque.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

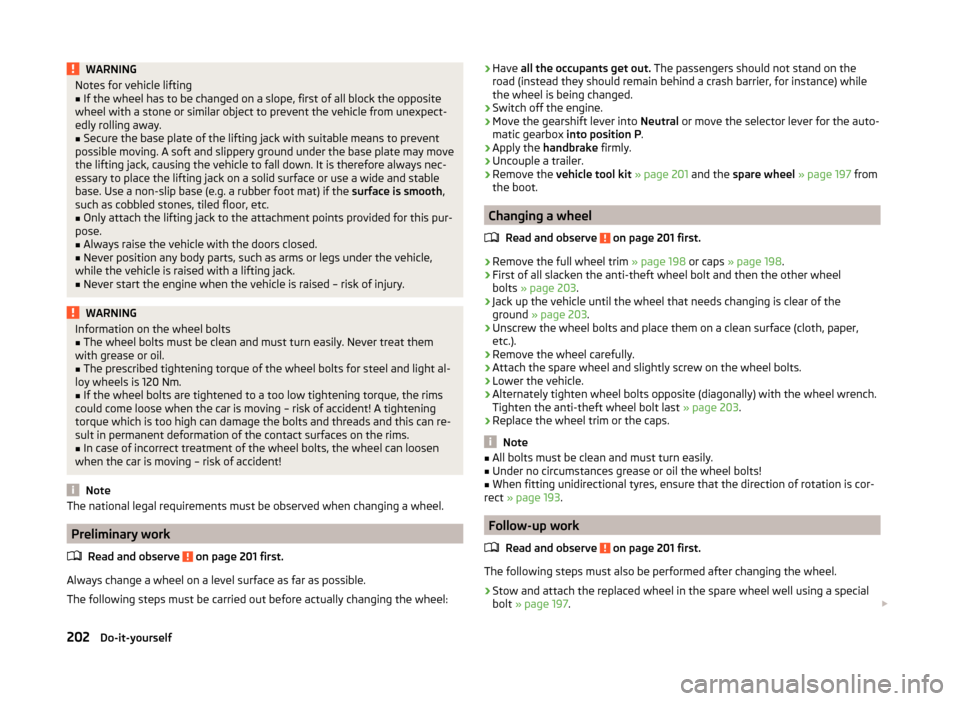

Loosening/tightening wheel bolts

Fig. 177

Changing a wheel: Loosening the

wheel bolts

Read and observe on page 201 first.

Releasing

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt about one turn in the direction of

the arrow » Fig. 177.

Tightening

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt against the direction of the ar-

row » Fig. 177 until it is tight.

WARNINGUndo the wheel bolts only a little (about one turn) provided that the vehicle

has not yet been jacked up. Otherwise the wheel could come off and fall

down – risk of injury!

Note

If it proves difficult to undo the bolts, carefully apply pressure to the end of the

wrench with your foodt. Keep hold of the vehicle when doing so, and make

sure you keep your footing.

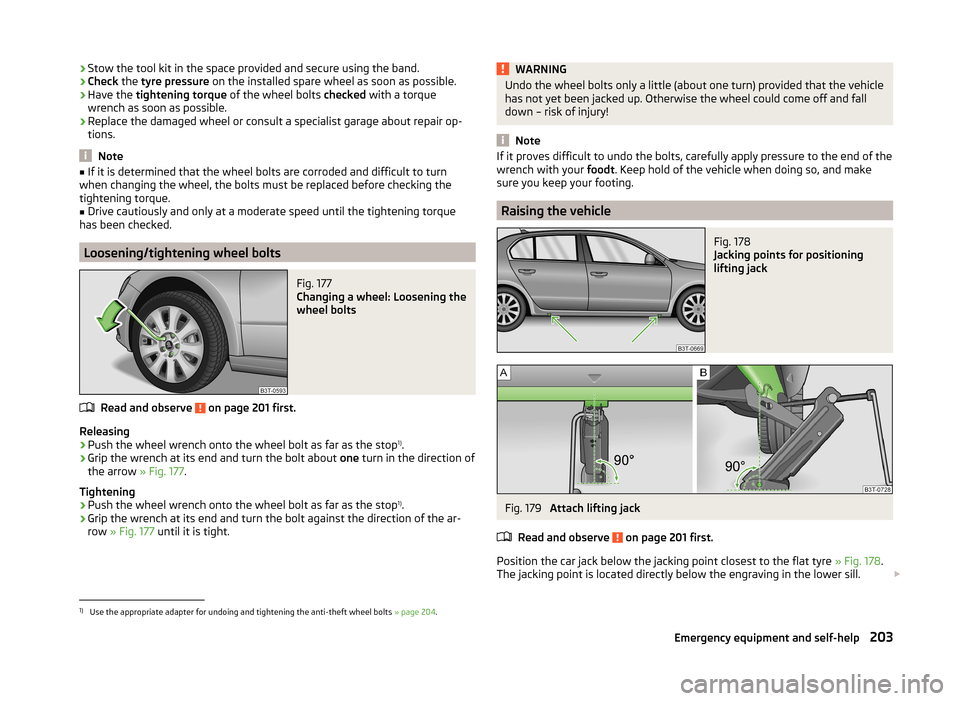

Raising the vehicle

Fig. 178

Jacking points for positioning

lifting jack

Fig. 179

Attach lifting jack

Read and observe

on page 201 first.

Position the car jack below the jacking point closest to the flat tyre » Fig. 178.

The jacking point is located directly below the engraving in the lower sill.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 204.

203Emergency equipment and self-help

Page 206 of 246

›Insert the crank into the mount on the car jack

» page 201.›Position the lifting jack below the jacking point with the crank and move it up

until its claw is positioned below the vertical web of the lower sill.›

Offer the jack up so that its claw encloses the web » Fig. 179 -

.

›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the point where

the claw encloses the web » Fig. 179 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ Only raise the vehicle at the attachment points.■Choose a flat and firm surface for jacking the vehicle.

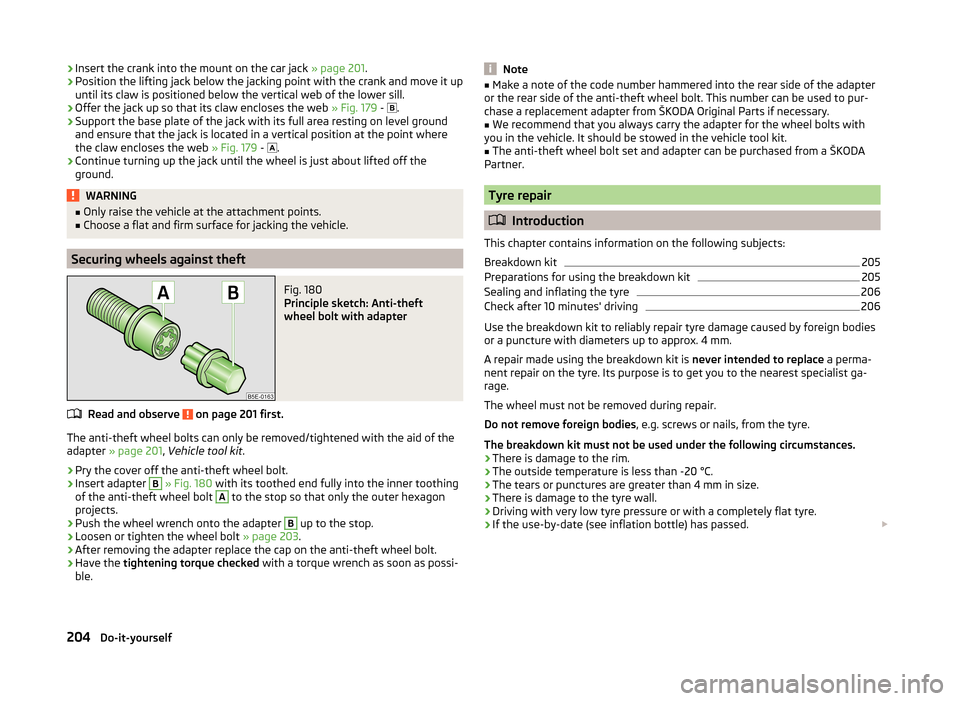

Securing wheels against theft

Fig. 180

Principle sketch: Anti-theft

wheel bolt with adapter

Read and observe on page 201 first.

The anti-theft wheel bolts can only be removed/tightened with the aid of the

adapter » page 201 , Vehicle tool kit .

›

Pry the cover off the anti-theft wheel bolt.

›

Insert adapter

B

» Fig. 180 with its toothed end fully into the inner toothing

of the anti-theft wheel bolt

A

to the stop so that only the outer hexagon

projects.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 203.

›

After removing the adapter replace the cap on the anti-theft wheel bolt.

›

Have the tightening torque checked with a torque wrench as soon as possi-

ble.

Note■ Make a note of the code number hammered into the rear side of the adapter

or the rear side of the anti-theft wheel bolt. This number can be used to pur-

chase a replacement adapter from ŠKODA Original Parts if necessary.■

We recommend that you always carry the adapter for the wheel bolts with

you in the vehicle. It should be stowed in the vehicle tool kit.

■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

Tyre repair

Introduction

This chapter contains information on the following subjects:

Breakdown kit

205

Preparations for using the breakdown kit

205

Sealing and inflating the tyre

206

Check after 10 minutes' driving

206

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

The wheel must not be removed during repair.

Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

204Do-it-yourself

Page 224 of 246

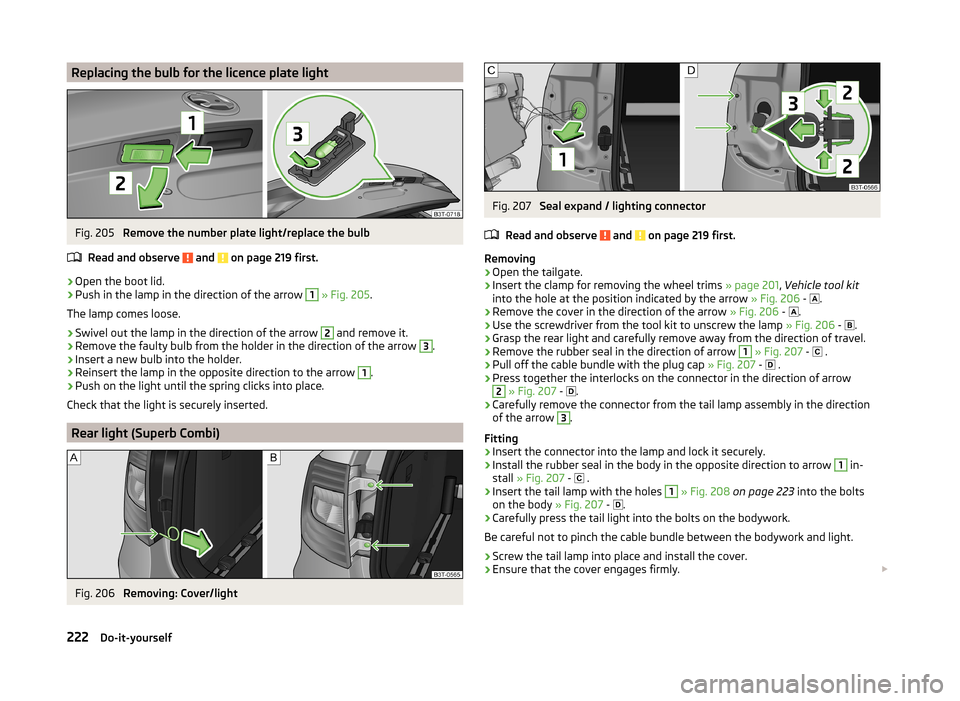

Replacing the bulb for the licence plate lightFig. 205

Remove the number plate light/replace the bulb

Read and observe

and on page 219 first.

›

Open the boot lid.

›

Push in the lamp in the direction of the arrow

1

» Fig. 205 .

The lamp comes loose.

›

Swivel out the lamp in the direction of the arrow

2

and remove it.

›

Remove the faulty bulb from the holder in the direction of the arrow

3

.

›

Insert a new bulb into the holder.

›

Reinsert the lamp in the opposite direction to the arrow

1

.

›

Push on the light until the spring clicks into place.

Check that the light is securely inserted.

Rear light (Superb Combi)

Fig. 206

Removing: Cover/light

Fig. 207

Seal expand / lighting connector

Read and observe

and on page 219 first.

Removing

›

Open the tailgate.

›

Insert the clamp for removing the wheel trims » page 201, Vehicle tool kit

into the hole at the position indicated by the arrow » Fig. 206 -

.

›

Remove the cover in the direction of the arrow

» Fig. 206 -

.

›

Use the screwdriver from the tool kit to unscrew the lamp

» Fig. 206 -

.

›

Grasp the rear light and carefully remove away from the direction of travel.

›

Remove the rubber seal in the direction of arrow

1

» Fig. 207 -

.

›

Pull off the cable bundle with the plug cap

» Fig. 207 -

.

›

Press together the interlocks on the connector in the direction of arrow

2

» Fig. 207 -

.

›

Carefully remove the connector from the tail lamp assembly in the direction

of the arrow

3

.

Fitting

›

Insert the connector into the lamp and lock it securely.

›

Install the rubber seal in the body in the opposite direction to arrow

1

in-

stall » Fig. 207 -

.

›

Insert the tail lamp with the holes

1

» Fig. 208 on page 223 into the bolts

on the body » Fig. 207 -

.

›

Carefully press the tail light into the bolts on the bodywork.

Be careful not to pinch the cable bundle between the bodywork and light.

›

Screw the tail lamp into place and install the cover.

›

Ensure that the cover engages firmly.

222Do-it-yourself

Page 243 of 246

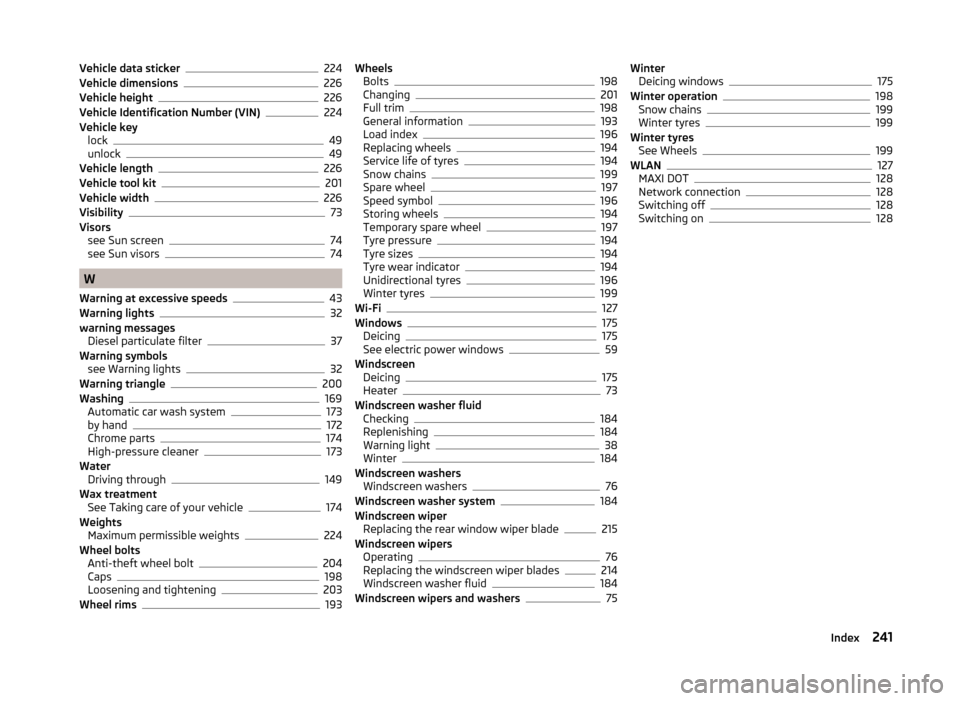

Vehicle data sticker224

Vehicle dimensions226

Vehicle height226

Vehicle Identification Number (VIN)224

Vehicle key lock

49

unlock49

Vehicle length226

Vehicle tool kit201

Vehicle width226

Visibility73

Visors see Sun screen

74

see Sun visors74

W

Warning at excessive speeds

43

Warning lights32

warning messages Diesel particulate filter

37

Warning symbols see Warning lights

32

Warning triangle200

Washing169

Automatic car wash system173

by hand172

Chrome parts174

High-pressure cleaner173

Water Driving through

149

Wax treatment See Taking care of your vehicle

174

Weights Maximum permissible weights

224

Wheel bolts Anti-theft wheel bolt

204

Caps198

Loosening and tightening203

Wheel rims193

Wheels Bolts198

Changing201

Full trim198

General information193

Load index196

Replacing wheels194

Service life of tyres194

Snow chains199

Spare wheel197

Speed symbol196

Storing wheels194

Temporary spare wheel197

Tyre pressure194

Tyre sizes194

Tyre wear indicator194

Unidirectional tyres196

Winter tyres199

Wi-Fi127

Windows175

Deicing175

See electric power windows59

Windscreen Deicing

175

Heater73

Windscreen washer fluid Checking

184

Replenishing184

Warning light38

Winter184

Windscreen washers Windscreen washers

76

Windscreen washer system184

Windscreen wiper Replacing the rear window wiper blade

215

Windscreen wipers Operating

76

Replacing the windscreen wiper blades214

Windscreen washer fluid184

Windscreen wipers and washers75

Winter Deicing windows175

Winter operation198

Snow chains199

Winter tyres199

Winter tyres See Wheels

199

WLAN127

MAXI DOT128

Network connection128

Switching off128

Switching on128

241Index