tow SKODA SUPERB 2016 3.G / (B8/3V) Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2016, Model line: SUPERB, Model: SKODA SUPERB 2016 3.G / (B8/3V)Pages: 336, PDF Size: 53.89 MB

Page 284 of 336

CAUTIONScrew the jack back to its starting position prior to putting it back in its box -

Otherwise, there is a risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

As far as possible, park the vehicle far away from the traffic flow - find a

place with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1st gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Switch on the parking brake.

›

Position the hazard warning system and the warning triangle at the prescri-

bed distance.

›

All the occupants should get out of the vehicle. The passengers should not

stand on the road (instead they should remain behind a crash barrier, for in-

stance) while the wheel is being changed.

›

Uncouple any trailers.

Changing a wheel

›

Remove the spare wheel » page 283.

›

Remove the full wheel trim » page 283 or caps » page 283 .

›

Loosen the wheel bolts » page 284 » .

›

Jack up the vehicle » page 284 until the wheel that needs changing is clear of

the ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“alter- nating crosswise”) » page 284.

›Replace the wheel trim

» page 283and the caps » page 283.

When fitting a wheel with a unidirectional tyre, ensure that the direction of ro-

tation is correct » page 276.

All bolts must be clean and must turn easily. If the screws are corroded and dif-

ficult to move, then these must be replaced.WARNING■ Undo the wheel bolts just a little (about one turn) while the vehicle is not

jacked up. Otherwise, the wheel could come off and fall down – there is a

risk of injury.■

Under no circumstances grease or oil the wheel bolts - risk of accident!

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure with a locking screw.

›

Stow the tool kit in the space provided and secure using the band.

›

Check and, if necessary, adjust the tyre pressure on the assembled wheel,

and, for vehicle with tyre pressure monitoring, save the tyre pressure values

in the system » page 249.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible. The prescribed tightening torque is 140 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

WARNINGA tightening torque which is too high can damage the bolts and threads

and this can result in permanent deformation of the contact surfaces on

the rim. Too low tightening torque, the wheels may fall off while driving -

risk of an accident. Drive cautiously and only at a moderate speed until the

tightening torque has been checked.282Do-it-yourself

Page 285 of 336

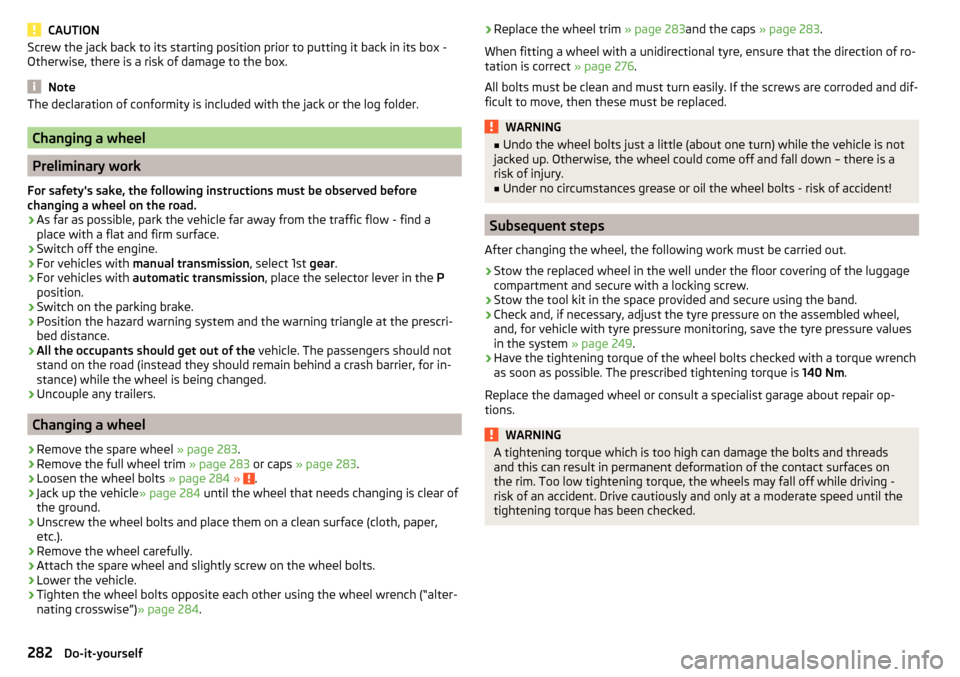

Removing /stowing the spare wheelFig. 332

Take out wheel

The spare wheel is located in a well under the floor covering in the luggage

compartment and is fixed in place with a fastening screw.

Take out wheel

›

Lift up the floor in the luggage compartment.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Unscrew the locking screw in the direction of arrow » Fig. 332 and the re-

move the wheel.

Store wheel away

›

Place the wheel into the wheel well with the wheel rim pointing downward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw the locking screw against the direction of arrow until it stops

» Fig. 332 .

›

Replace the box with the tool kit into the wheel and secure it with the tape.

›

Fold back the floor in the luggage compartment.

Full wheel trim

Removing the trim

›

The clamps for removing the full wheel trims hang on the edge of the full

wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing the trim

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

The back of the wheel trim supplied by the factory or from the ŠKODA Original

Accessories shows the position for the anti-theft wheel bolt. When using the

anti-theft wheel bolt, this is to be fitted in this point »

.

WARNINGWe recommend that you use hub caps from ŠKODA Original Accessories.

With other hub caps, a sufficient air supply for cooling the brake system

may not be guaranteed - There is risk of an accident.

CAUTION

■ If the wheel trim is set outside the position marked for the anti-theft wheel

bolt, there is a risk of damaging the wheel trim.■

Use only manual pressure and do not hit the full wheel trim – there is a risk

of damaging the trim.

Note

We recommend that you use hub caps from ŠKODA Original Accessories.

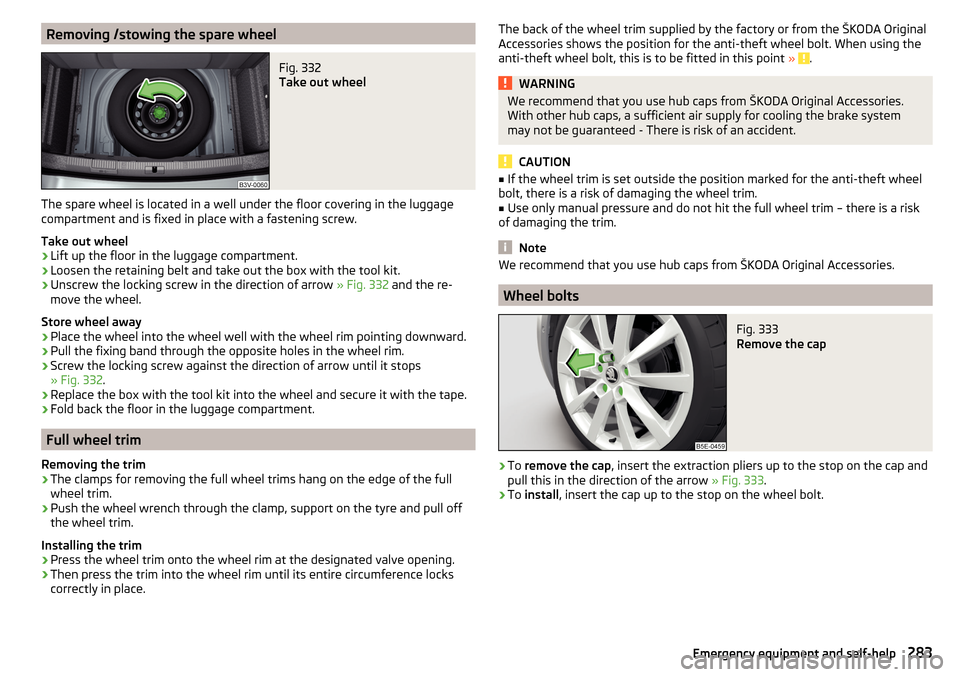

Wheel bolts

Fig. 333

Remove the cap

›

To remove the cap , insert the extraction pliers up to the stop on the cap and

pull this in the direction of the arrow » Fig. 333.

›

To install , insert the cap up to the stop on the wheel bolt.

283Emergency equipment and self-help

Page 290 of 336

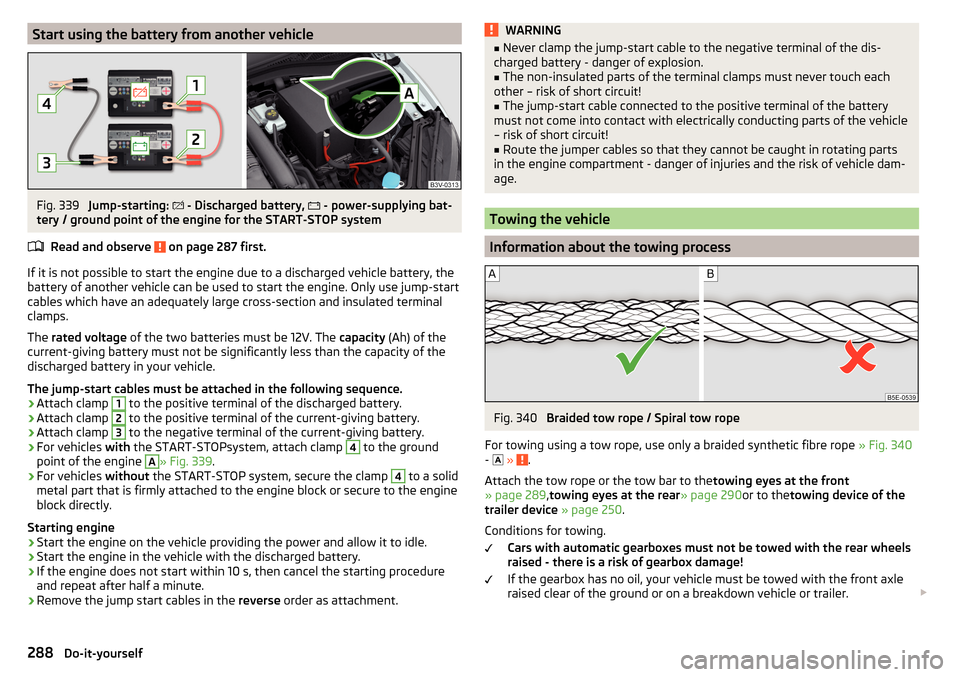

Start using the battery from another vehicleFig. 339

Jump-starting:

- Discharged battery,

- power-supplying bat-

tery / ground point of the engine for the START-STOP system

Read and observe

on page 287 first.

If it is not possible to start the engine due to a discharged vehicle battery, the

battery of another vehicle can be used to start the engine. Only use jump-start

cables which have an adequately large cross-section and insulated terminal

clamps.

The rated voltage of the two batteries must be 12V. The capacity (Ah) of the

current-giving battery must not be significantly less than the capacity of the

discharged battery in your vehicle.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery.

›

Attach clamp

2

to the positive terminal of the current-giving battery.

›

Attach clamp

3

to the negative terminal of the current-giving battery.

›

For vehicles with the START-STOPsystem, attach clamp

4

to the ground

point of the engine

A

» Fig. 339 .

›

For vehicles without the START-STOP system, secure the clamp

4

to a solid

metal part that is firmly attached to the engine block or secure to the engine

block directly.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine in the vehicle with the discharged battery.

›

If the engine does not start within 10 s, then cancel the starting procedure

and repeat after half a minute.

›

Remove the jump start cables in the reverse order as attachment.

WARNING■

Never clamp the jump-start cable to the negative terminal of the dis-

charged battery - danger of explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – risk of short circuit!

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– risk of short circuit!

■

Route the jumper cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

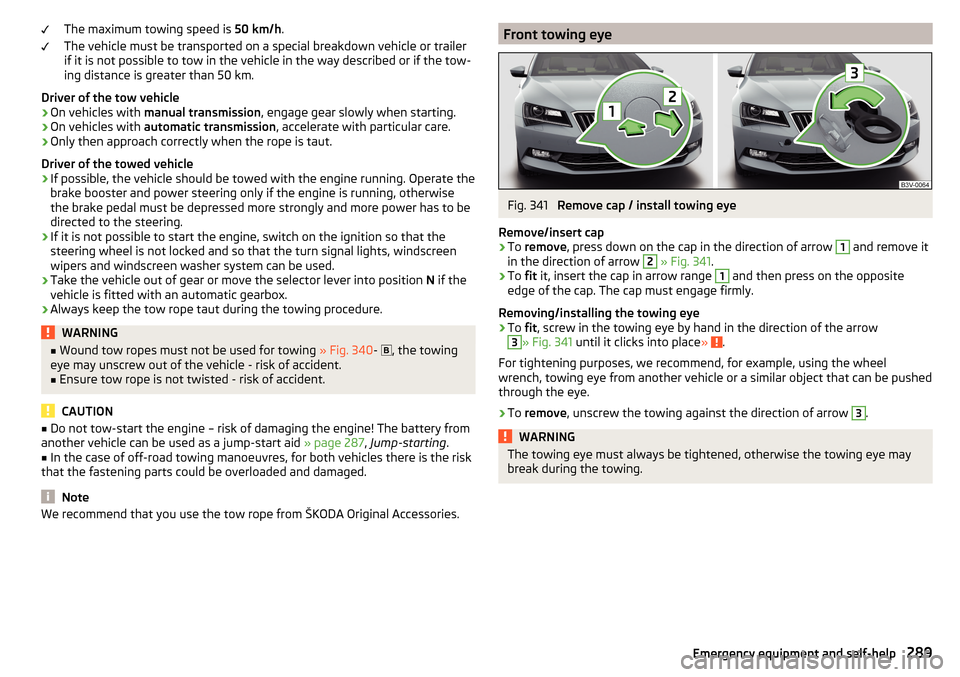

Fig. 340

Braided tow rope / Spiral tow rope

For towing using a tow rope, use only a braided synthetic fibre rope » Fig. 340

-

»

.

Attach the tow rope or the tow bar to the towing eyes at the front

» page 289 ,towing eyes at the rear » page 290or to thetowing device of the

trailer device » page 250 .

Conditions for towing. Cars with automatic gearboxes must not be towed with the rear wheels

raised - there is a risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

288Do-it-yourself

Page 291 of 336

The maximum towing speed is 50 km/h.

The vehicle must be transported on a special breakdown vehicle or trailer

if it is not possible to tow in the vehicle in the way described or if the tow-

ing distance is greater than 50 km.

Driver of the tow vehicle›

On vehicles with manual transmission , engage gear slowly when starting.

›

On vehicles with automatic transmission , accelerate with particular care.

›

Only then approach correctly when the rope is taut.

Driver of the towed vehicle

›

If possible, the vehicle should be towed with the engine running. Operate the

brake booster and power steering only if the engine is running, otherwise

the brake pedal must be depressed more strongly and more power has to be

directed to the steering.

›

If it is not possible to start the engine, switch on the ignition so that the

steering wheel is not locked and so that the turn signal lights, windscreen

wipers and windscreen washer system can be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

›

Always keep the tow rope taut during the towing procedure.

WARNING■ Wound tow ropes must not be used for towing » Fig. 340- , the towing

eye may unscrew out of the vehicle - risk of accident.■

Ensure tow rope is not twisted - risk of accident.

CAUTION

■ Do not tow-start the engine – risk of damaging the engine! The battery from

another vehicle can be used as a jump-start aid » page 287, Jump-starting .■

In the case of off-road towing manoeuvres, for both vehicles there is the risk

that the fastening parts could be overloaded and damaged.

Note

We recommend that you use the tow rope from ŠKODA Original Accessories.Front towing eyeFig. 341

Remove cap / install towing eye

Remove/insert cap

›

To remove , press down on the cap in the direction of arrow

1

and remove it

in the direction of arrow

2

» Fig. 341 .

›

To fit it, insert the cap in arrow range

1

and then press on the opposite

edge of the cap. The cap must engage firmly.

Removing/installing the towing eye

›

To fit, screw in the towing eye by hand in the direction of the arrow

3

» Fig. 341 until it clicks into place » .

For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed

through the eye.

›

To remove , unscrew the towing against the direction of arrow

3

.

WARNINGThe towing eye must always be tightened, otherwise the towing eye may

break during the towing.289Emergency equipment and self-help

Page 292 of 336

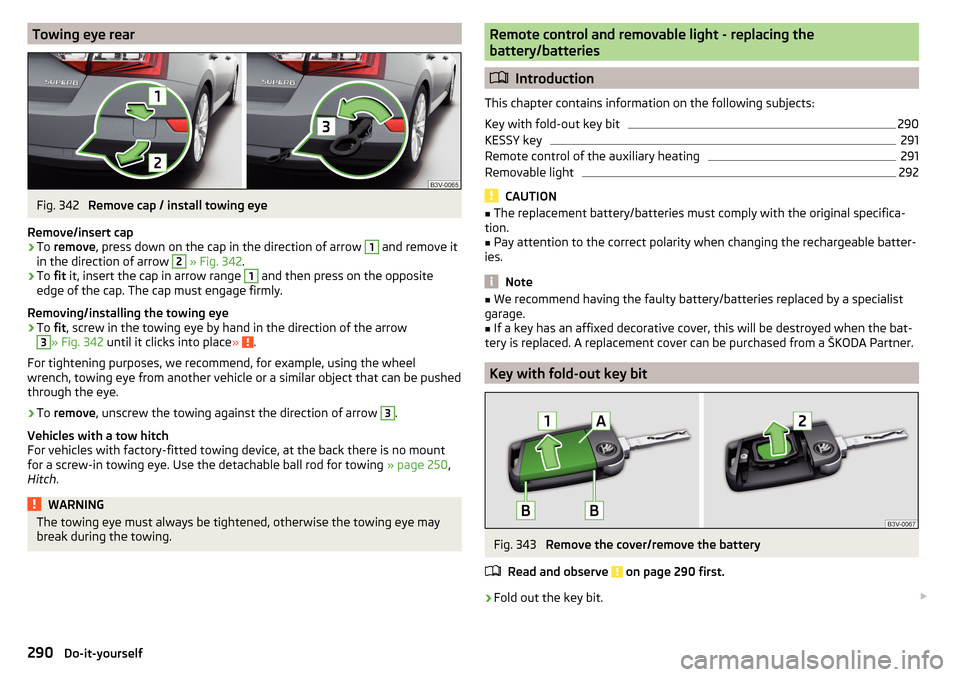

Towing eye rearFig. 342

Remove cap / install towing eye

Remove/insert cap

›

To remove , press down on the cap in the direction of arrow

1

and remove it

in the direction of arrow

2

» Fig. 342 .

›

To fit it, insert the cap in arrow range

1

and then press on the opposite

edge of the cap. The cap must engage firmly.

Removing/installing the towing eye

›

To fit, screw in the towing eye by hand in the direction of the arrow

3

» Fig. 342 until it clicks into place » .

For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed

through the eye.

›

To remove , unscrew the towing against the direction of arrow

3

.

Vehicles with a tow hitch

For vehicles with factory-fitted towing device, at the back there is no mount

for a screw-in towing eye. Use the detachable ball rod for towing » page 250,

Hitch .

WARNINGThe towing eye must always be tightened, otherwise the towing eye may

break during the towing.Remote control and removable light - replacing the

battery/batteries

Introduction

This chapter contains information on the following subjects:

Key with fold-out key bit

290

KESSY key

291

Remote control of the auxiliary heating

291

Removable light

292

CAUTION

■ The replacement battery/batteries must comply with the original specifica-

tion.■

Pay attention to the correct polarity when changing the rechargeable batter-

ies.

Note

■ We recommend having the faulty battery/batteries replaced by a specialist

garage.■

If a key has an affixed decorative cover, this will be destroyed when the bat-

tery is replaced. A replacement cover can be purchased from a ŠKODA Partner.

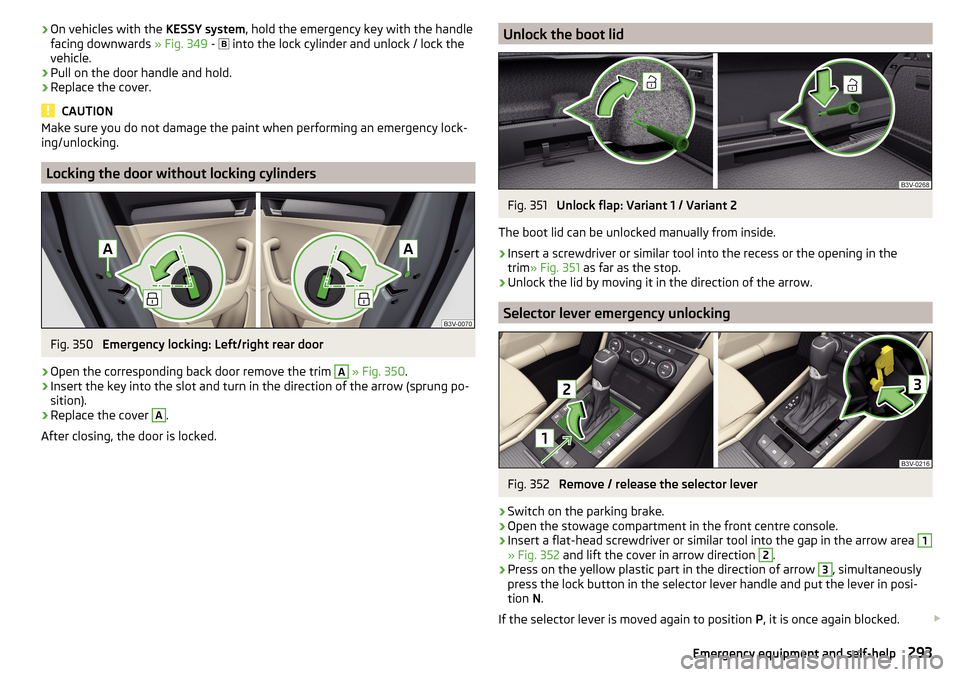

Key with fold-out key bit

Fig. 343

Remove the cover/remove the battery

Read and observe

on page 290 first.

›

Fold out the key bit.

290Do-it-yourself

Page 295 of 336

›On vehicles with the

KESSY system, hold the emergency key with the handle

facing downwards » Fig. 349 - into the lock cylinder and unlock / lock the

vehicle.›

Pull on the door handle and hold.

›

Replace the cover.

CAUTION

Make sure you do not damage the paint when performing an emergency lock-

ing/unlocking.

Locking the door without locking cylinders

Fig. 350

Emergency locking: Left/right rear door

›

Open the corresponding back door remove the trim

A

» Fig. 350 .

›

Insert the key into the slot and turn in the direction of the arrow (sprung po-

sition).

›

Replace the cover

A

.

After closing, the door is locked.

Unlock the boot lidFig. 351

Unlock flap: Variant 1 / Variant 2

The boot lid can be unlocked manually from inside.

›

Insert a screwdriver or similar tool into the recess or the opening in the

trim » Fig. 351 as far as the stop.

›

Unlock the lid by moving it in the direction of the arrow.

Selector lever emergency unlocking

Fig. 352

Remove / release the selector lever

›

Switch on the parking brake.

›

Open the stowage compartment in the front centre console.

›

Insert a flat-head screwdriver or similar tool into the gap in the arrow area

1

» Fig. 352 and lift the cover in arrow direction

2

.

›

Press on the yellow plastic part in the direction of arrow

3

, simultaneously

press the lock button in the selector lever handle and put the lever in posi-

tion N.

If the selector lever is moved again to position P, it is once again blocked.

293Emergency equipment and self-help

Page 298 of 336

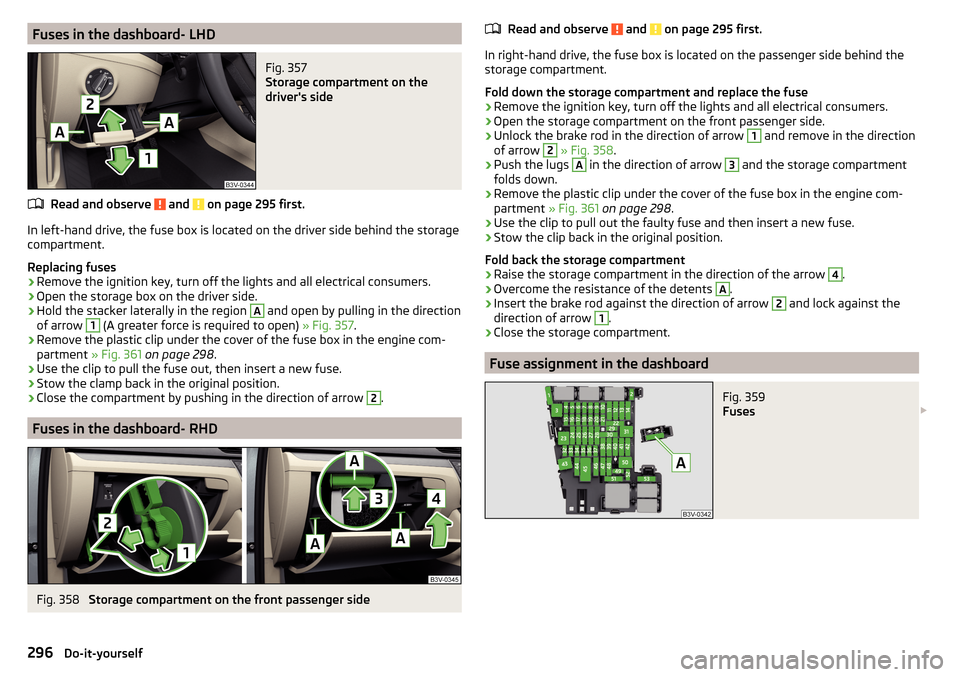

Fuses in the dashboard- LHDFig. 357

Storage compartment on the

driver's side

Read and observe and on page 295 first.

In left-hand drive, the fuse box is located on the driver side behind the storage compartment.

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Open the storage box on the driver side.

›

Hold the stacker laterally in the region

A

and open by pulling in the direction

of arrow

1

(A greater force is required to open) » Fig. 357.

›

Remove the plastic clip under the cover of the fuse box in the engine com-

partment » Fig. 361 on page 298 .

›

Use the clip to pull the fuse out, then insert a new fuse.

›

Stow the clamp back in the original position.

›

Close the compartment by pushing in the direction of arrow

2

.

Fuses in the dashboard- RHD

Fig. 358

Storage compartment on the front passenger side

Read and observe and on page 295 first.

In right-hand drive, the fuse box is located on the passenger side behind the

storage compartment.

Fold down the storage compartment and replace the fuse

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Open the storage compartment on the front passenger side.

›

Unlock the brake rod in the direction of arrow

1

and remove in the direction

of arrow

2

» Fig. 358 .

›

Push the lugs

A

in the direction of arrow

3

and the storage compartment

folds down.

›

Remove the plastic clip under the cover of the fuse box in the engine com-

partment » Fig. 361 on page 298 .

›

Use the clip to pull out the faulty fuse and then insert a new fuse.

›

Stow the clip back in the original position.

Fold back the storage compartment

›

Raise the storage compartment in the direction of the arrow

4

.

›

Overcome the resistance of the detents

A

.

›

Insert the brake rod against the direction of arrow

2

and lock against the

direction of arrow

1

.

›

Close the storage compartment.

Fuse assignment in the dashboard

Fig. 359

Fuses

296Do-it-yourself

Page 299 of 336

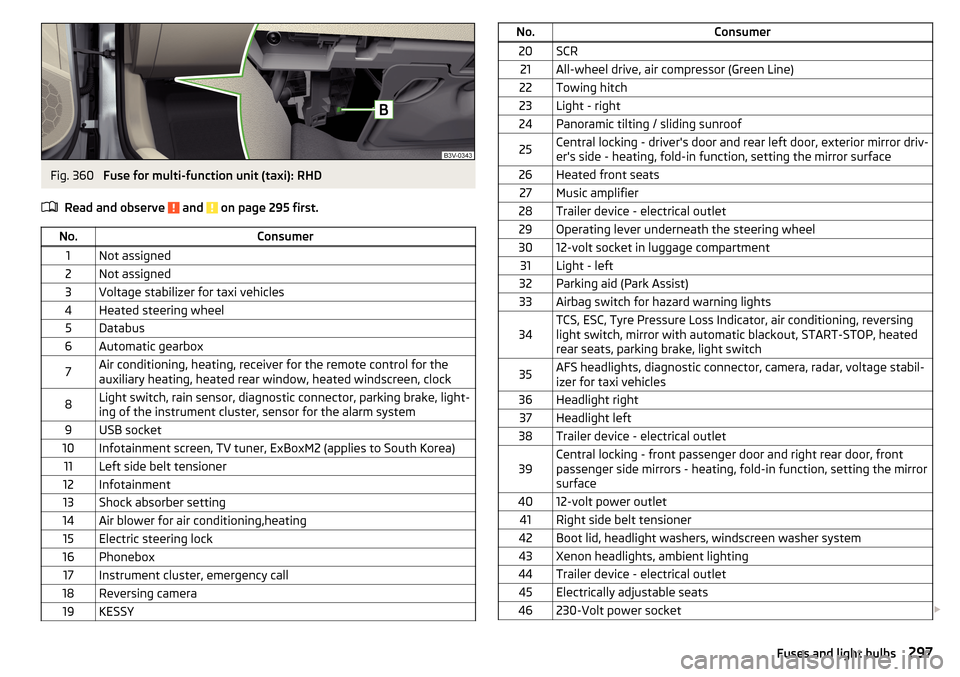

Fig. 360

Fuse for multi-function unit (taxi): RHD

Read and observe

and on page 295 first.

No.Consumer1Not assigned2Not assigned3Voltage stabilizer for taxi vehicles4Heated steering wheel5Databus6Automatic gearbox7Air conditioning, heating, receiver for the remote control for the

auxiliary heating, heated rear window, heated windscreen, clock8Light switch, rain sensor, diagnostic connector, parking brake, light-

ing of the instrument cluster, sensor for the alarm system9USB socket10Infotainment screen, TV tuner, ExBoxM2 (applies to South Korea)11Left side belt tensioner12Infotainment13Shock absorber setting14Air blower for air conditioning,heating15Electric steering lock16Phonebox17Instrument cluster, emergency call18Reversing camera19KESSYNo.Consumer20SCR21All-wheel drive, air compressor (Green Line)22Towing hitch23Light - right24Panoramic tilting / sliding sunroof25Central locking - driver's door and rear left door, exterior mirror driv-

er's side - heating, fold-in function, setting the mirror surface26Heated front seats27Music amplifier28Trailer device - electrical outlet29Operating lever underneath the steering wheel3012-volt socket in luggage compartment31Light - left32Parking aid (Park Assist)33Airbag switch for hazard warning lights34TCS, ESC, Tyre Pressure Loss Indicator, air conditioning, reversing

light switch, mirror with automatic blackout, START-STOP, heated

rear seats, parking brake, light switch35AFS headlights, diagnostic connector, camera, radar, voltage stabil-

izer for taxi vehicles36Headlight right37Headlight left38Trailer device - electrical outlet39Central locking - front passenger door and right rear door, front

passenger side mirrors - heating, fold-in function, setting the mirror

surface4012-volt power outlet41Right side belt tensioner42Boot lid, headlight washers, windscreen washer system43Xenon headlights, ambient lighting44Trailer device - electrical outlet45Electrically adjustable seats46230-Volt power socket 297Fuses and light bulbs

Page 300 of 336

No.Consumer47Rear window wiper48Blind spot detection49Engine starting, clutch pedal switch50Opening the boot lid51Heating of the rear seats52Heated front seats53Heated rear windowA

» Fig. 359Multifunctional unit for taxi vehicles - LHD

B

» Fig. 36 0Multifunctional unit for taxi vehicles - RHD

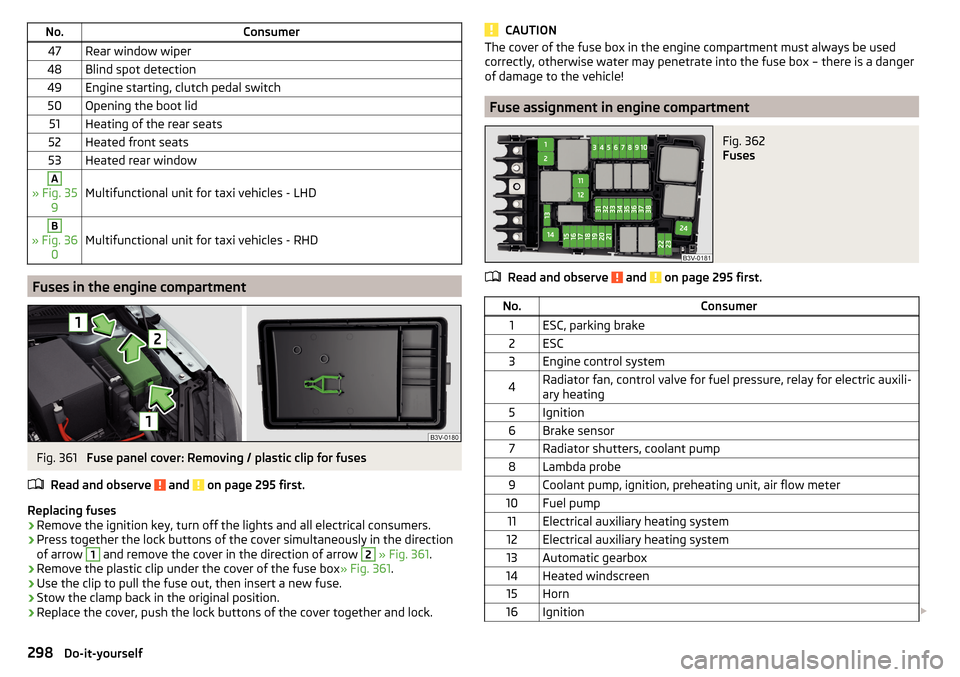

Fuses in the engine compartment

Fig. 361

Fuse panel cover: Removing / plastic clip for fuses

Read and observe

and on page 295 first.

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Press together the lock buttons of the cover simultaneously in the direction

of arrow

1

and remove the cover in the direction of arrow

2

» Fig. 361 .

›

Remove the plastic clip under the cover of the fuse box » Fig. 361.

›

Use the clip to pull the fuse out, then insert a new fuse.

›

Stow the clamp back in the original position.

›

Replace the cover, push the lock buttons of the cover together and lock.

CAUTIONThe cover of the fuse box in the engine compartment must always be used

correctly, otherwise water may penetrate into the fuse box – there is a danger

of damage to the vehicle!

Fuse assignment in engine compartment

Fig. 362

Fuses

Read and observe and on page 295 first.

No.Consumer1ESC, parking brake2ESC3Engine control system4Radiator fan, control valve for fuel pressure, relay for electric auxili-

ary heating5Ignition6Brake sensor7Radiator shutters, coolant pump8Lambda probe9Coolant pump, ignition, preheating unit, air flow meter10Fuel pump11Electrical auxiliary heating system12Electrical auxiliary heating system13Automatic gearbox14Heated windscreen15Horn16Ignition 298Do-it-yourself

Page 306 of 336

The approved tyres and rim sizes for your vehicle are listed in the vehicle's

technical documentation (the so called COC document) and this also states the

declaration of conformity.

Type plate

The rating plate » Fig. 370 is located at the bottom of the B-column on the

right-hand driver's side.

The type plate contains the following data. Vehicle manufacturers

Vehicle identification number (VIN)

Maximum permissible gross weight

Maximum permissible towed weight (towing vehicle and trailer)

Maximum permissible front axle load

Maximum permissible rear axle load

Vehicle identification number (VIN)

The vehicle identification number - VIN (vehicle body number) is stamped into

the engine compartment on the right hand suspension strut dome. This num-

ber is also located on a sign on the lower left hand edge below the windscreen

(together with a VIN bar code), and on the type plate.

The VIN number can also be displayed in Infotainment in the

→

→

serv-ice

menu.

Engine number

The engine number (three-digit identifier and serial number) is stamped on the

engine block.

Supplementary Information (applies to Russia)

The full type approval number of the means of transport is indicated in the

registration documents, field 17.

Maximum permissible towed weight

The listed maximum allowable trailer weight is only valid for altitudes up to

1000 m above sea level.

The engine output falls as altitude increases, as does the vehicle's climbing

power. Therefore, for every additional 1000 m in height (or part), the maximum

permissible towed weight must be reduced by 10%.

The towed weight is made up of the actual weights of the loaded towing vehi-

cle and the loaded trailer.

123456WARNINGDo not exceed the specified maximum permissible weights – risk of acci-

dent and damage!

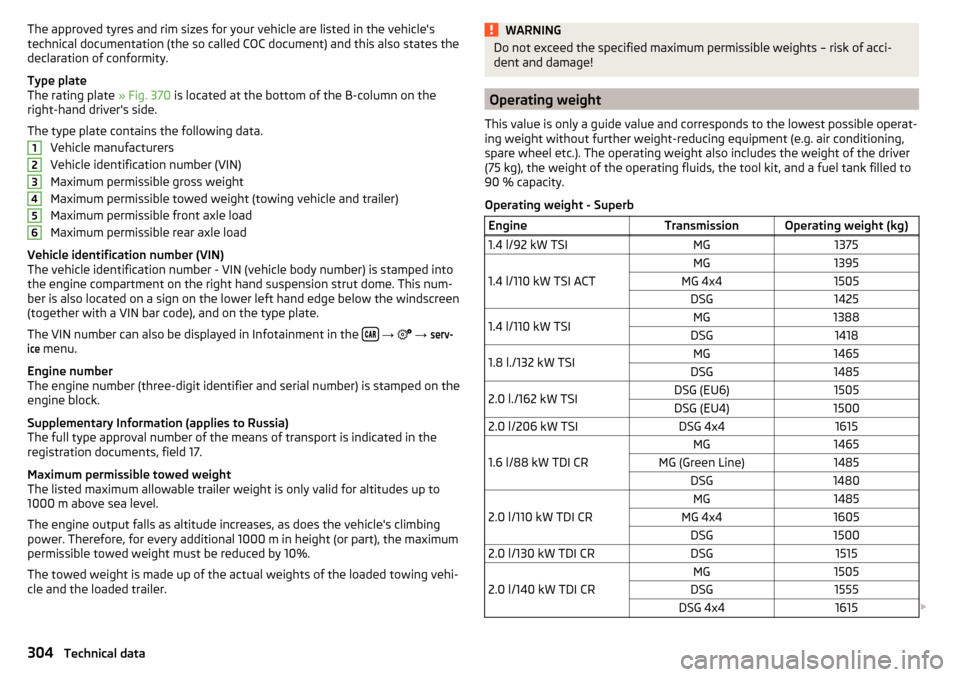

Operating weight

This value is only a guide value and corresponds to the lowest possible operat-

ing weight without further weight-reducing equipment (e.g. air conditioning,

spare wheel etc.). The operating weight also includes the weight of the driver

(75 kg), the weight of the operating fluids, the tool kit, and a fuel tank filled to

90 % capacity.

Operating weight - Superb

EngineTransmissionOperating weight (kg)1.4 l/92 kW TSIMG1375

1.4 l/110 kW TSI ACT

MG1395MG 4x41505DSG14251.4 l/110 kW TSIMG1388DSG14181.8 l./132 kW TSIMG1465DSG14852.0 l./162 kW TSIDSG (EU6)1505DSG (EU4)15002.0 l/206 kW TSIDSG 4x41615

1.6 l/88 kW TDI CR

MG1465MG (Green Line)1485DSG1480

2.0 l/110 kW TDI CR

MG1485MG 4x41605DSG15002.0 l/130 kW TDI CRDSG1515

2.0 l/140 kW TDI CR

MG1505DSG1555DSG 4x41615 304Technical data