ecm SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1181 of 2053

5A-86 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator pedal position etc. from ECM via CAN

without any additional sensors.

The DTC P1713 sets when the accelerator pedal signal

via CAN is out of range. The accelerator pedal signal

is greater than 254 steps.

Conditions for Setting the DTC

DTCs P1719 is not set.

The accelerator pedal signal is greater than 254

steps. The malfunction is triggered immediately

after this condition exists.

Action Taken When the DTC Sets

4th gear is inhibited.

Torque Converter Clutch (TCC) is inhibited.

Default value is adopted for shift point decisions.

Accelerator pedal is not used for P, R, or N B2

activation decisions.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred for 30 seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P1713

PEDAL SIGNAL ERROR

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring harness

while observing test equipment for a change.

When ECM finds a fault on the accelerator pedal

signals, ECM will adopt a default mode and send

the default value and trouble message to TCM via

CAN.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check if there are any DTCs related to the accelera-

tor pedal sensor on the ECM side.

4. Check for a poor connection at the ECM and TCM

connectors.

KAA5A5KA

Page 1182 of 2053

AUTOMATIC TRANSMISSION 5A-87

SSANGYONG MY2002

DTC P1713 Pedal Signal Error

1Perform a Transmission Control Module (TCM) Diag-

nostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1713?

Check if there are any DTCs related to the accelerator

pedal sensor on the ECM side.

Are any DTCs related to accelerator pedal sensor

found?

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

2

3

- Go to Step 5 - 4

- Go to Step 6 Go to Step 2 5

6

- Go to Step 2Go to “TCM

Diagnostic

System Check”

- Go to Step 3 Go to

“Diagnostic

Aids”

- Go to Section

1F, Engine

Controls Go to Step 4

-Go to

applicable

DTC tableSystem OK,

Check

Complete

Page 1185 of 2053

5A-90 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator etc. from ECM via CAN without any

additional sensors.

The DTC P1716 sets when the throttle signal via CAN

is out of range. The throttle is greater than 254 steps.

Conditions for Setting the DTC

The minimum & maximum throttle positions have

not been learnt by the TCU.

Action Taken When the DTC Sets

The minimum & maximum throttle positions are set

to their factory default values.

Incorrect sensitivity to driver demand.

Incorrect gear shift points.

DIAGNOSTIC TABLE CODE (DTC) 1716

THROTTLE NOT LEARNT ERROR

Conditions for Clearing the DTC

Throttle learns 0 % position. This value must be

greater than 0.2 V.

Diagnostic Aids

This fault indicates that the TCU has not learnt the

throttle position correctly since installation in the

vehicle or that the throttle setting have been cleared

by a diagnostic tool.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

4. The “Throttle Position Calibration Procedure” needs

to be carried out. This is given in this section.

KAA5A5U0

Page 1189 of 2053

5A-94 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator position etc. from ECM via CAN without

any additional sensors.

The DTC P1719 sets when the information required by

TCM is not available on the CAN. One or more CAN

messages used by the TCM is timed out, i.e. not re-

freshed for 1 second.

Conditions for Setting the DTC

One or more CAN messages used by the TCM are

timed out, i.e. not refreshed for 1 second.

Action Taken When the DTC Sets

TCM uses default values for all CAN dependent sig-

nals.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred for 30 seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P1719

CAN BUS ERROR

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring harness

while observing test equipment for a change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

6. Check for a poor connection at the ECM and TCM

connectors.

KAA5A3KA

Page 1190 of 2053

AUTOMATIC TRANSMISSION 5A-95

SSANGYONG MY2002

DTC P1719 CAN Bus Error

1Perform a Transmission Control Module (TCM) Diag-

nostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1719?

1. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Disconnect the Engine Control Module (ECM)

connector.

4. Check the wiring harness from ECM connector

terminal 38 to TCM connector terminal B23 for an

open or a short.

Is a problem found?

Repair the malfunctioning wiring harness.

Is a repair complete?

Check the wiring harness from ECM connector termi-

nal 37 to TCM connector terminal B24 for an open or a

short.

Is a problem found?

Check for a poor connection at the ECM connector or

TCM connector and repair the malfunctioning terminals

as necessary.

Is a repair necessary?

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

1. Turn the ignition OFF.

2. Replace the TCM with the original.

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

2

3

5

- Go to Step 8 - 6 4

- Go to Step 10 Go to Step 9 7

8

- Go to Step 11 Go to Step 2 9

10

- Go to Step 2Go to “TCM

Diagnostic

System Check”

-

Go to Step 4 Go to Step 5

- Go to Step 3 Go to

“Diagnostic

Aids”

11

-Go to

applicable

DTC tableSystem OK,

Check

Complete

- Go to Step 4 Go to Step 6

-Go to

Section 1F,

Engine Control-

- Go to Step 10 Go to Step 7

-

Go to Step 10-

Page 1193 of 2053

5A-98 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

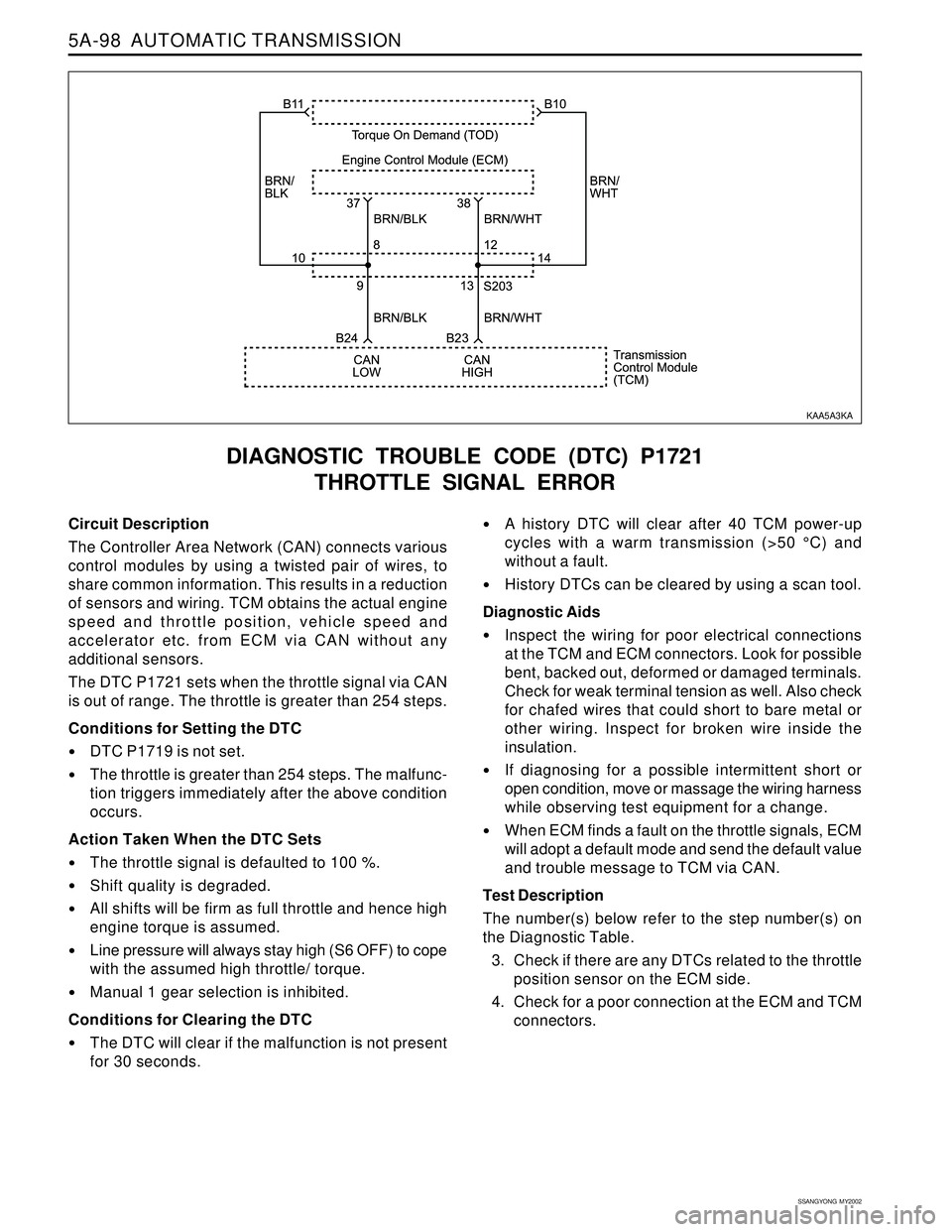

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator etc. from ECM via CAN without any

additional sensors.

The DTC P1721 sets when the throttle signal via CAN

is out of range. The throttle is greater than 254 steps.

Conditions for Setting the DTC

DTC P1719 is not set.

The throttle is greater than 254 steps. The malfunc-

tion triggers immediately after the above condition

occurs.

Action Taken When the DTC Sets

The throttle signal is defaulted to 100 %.

Shift quality is degraded.

All shifts will be firm as full throttle and hence high

engine torque is assumed.

Line pressure will always stay high (S6 OFF) to cope

with the assumed high throttle/ torque.

Manual 1 gear selection is inhibited.

Conditions for Clearing the DTC

The DTC will clear if the malfunction is not present

for 30 seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P1721

THROTTLE SIGNAL ERROR

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring harness

while observing test equipment for a change.

When ECM finds a fault on the throttle signals, ECM

will adopt a default mode and send the default value

and trouble message to TCM via CAN.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check if there are any DTCs related to the throttle

position sensor on the ECM side.

4. Check for a poor connection at the ECM and TCM

connectors.

KAA5A3KA

Page 1194 of 2053

AUTOMATIC TRANSMISSION 5A-99

SSANGYONG MY2002

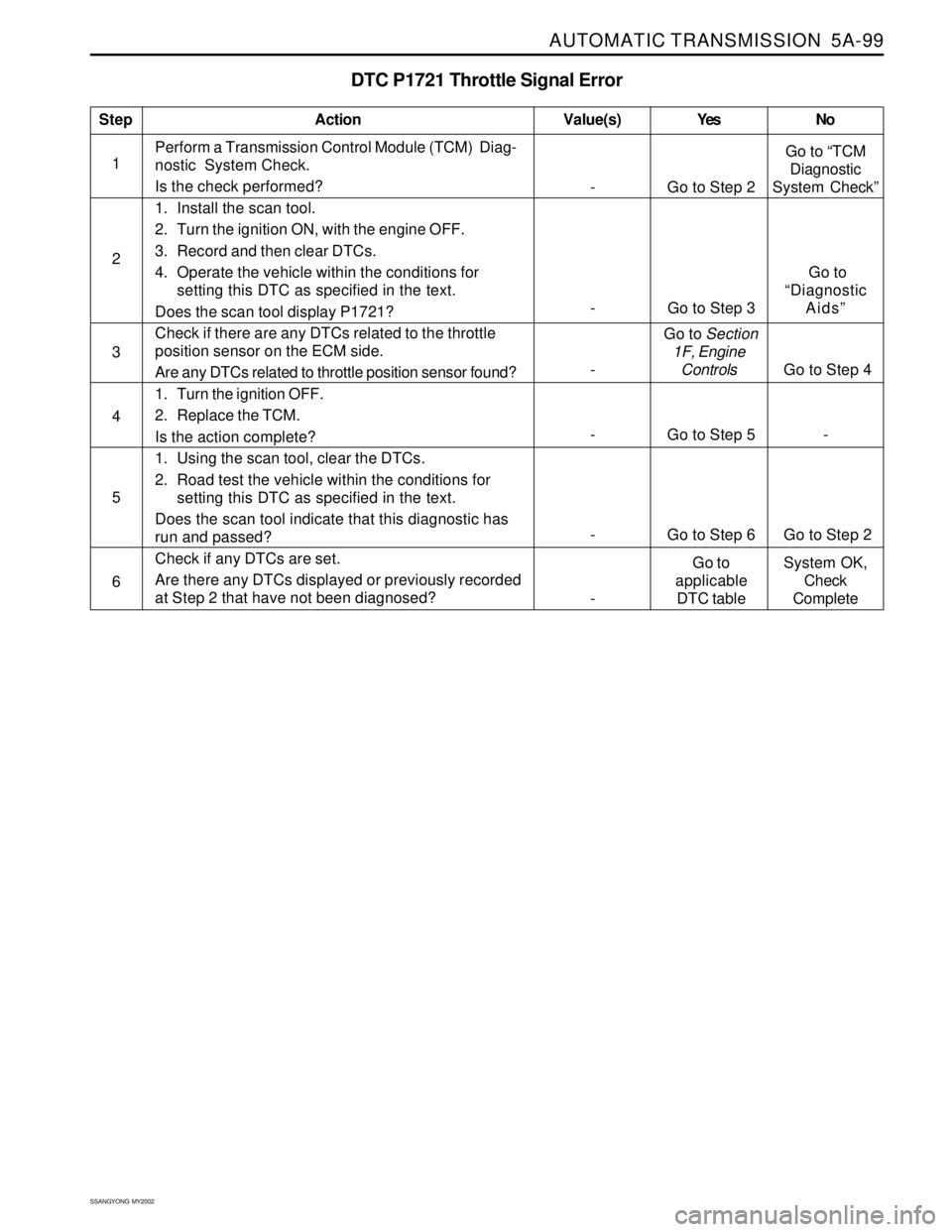

DTC P1721 Throttle Signal Error

1Perform a Transmission Control Module (TCM) Diag-

nostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1721?

Check if there are any DTCs related to the throttle

position sensor on the ECM side.

Are any DTCs related to throttle position sensor found?

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

2

3

- Go to Step 5 - 4

- Go to Step 6 Go to Step 2 5

6

- Go to Step 2Go to “TCM

Diagnostic

System Check”

- Go to Step 3 Go to

“Diagnostic

Aids”

- Go to Section

1F, Engine

Controls Go to Step 4

-Go to

applicable

DTC tableSystem OK,

Check

Complete

Page 1255 of 2053

5A-160 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

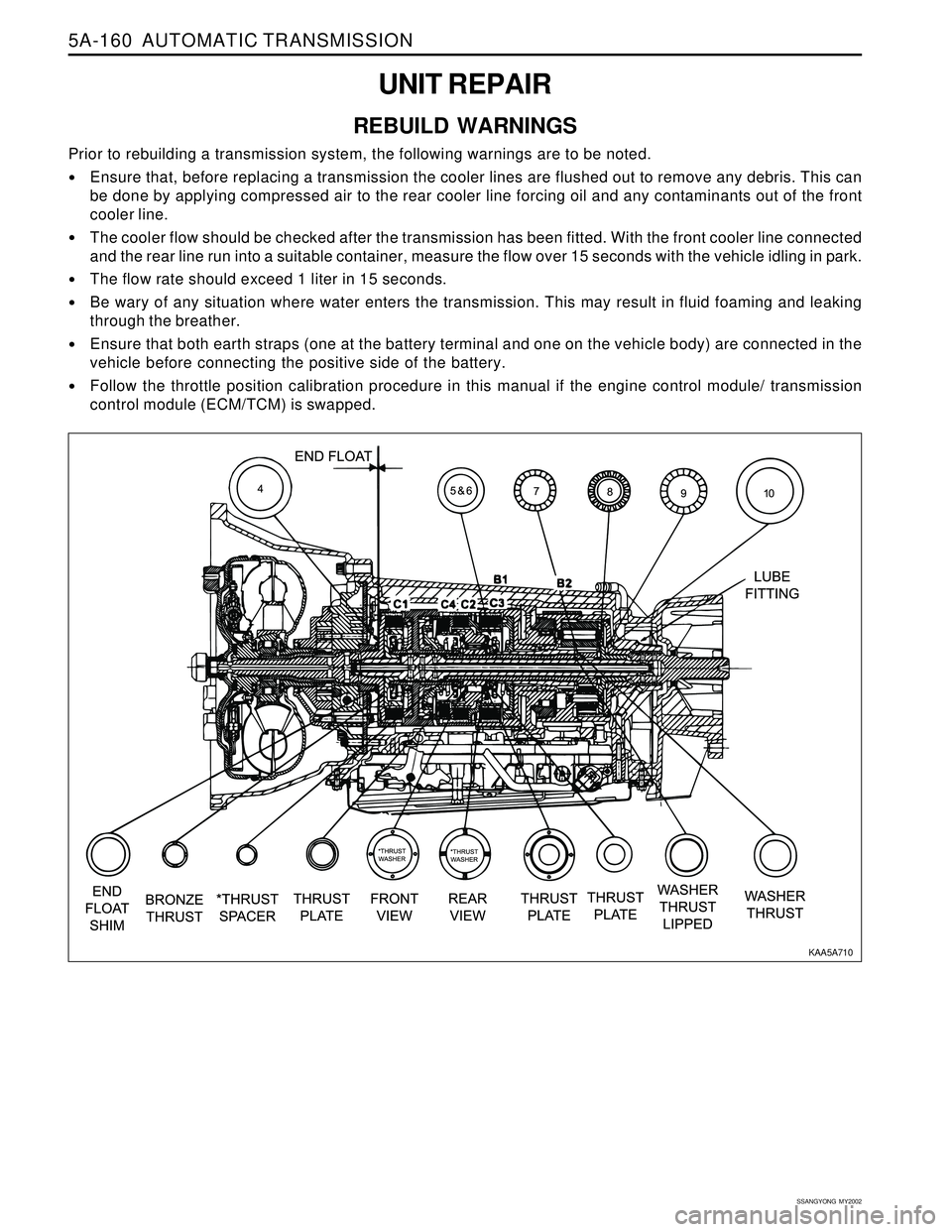

UNIT REPAIR

REBUILD WARNINGS

Prior to rebuilding a transmission system, the following warnings are to be noted.

Ensure that, before replacing a transmission the cooler lines are flushed out to remove any debris. This can

be done by applying compressed air to the rear cooler line forcing oil and any contaminants out of the front

cooler line.

The cooler flow should be checked after the transmission has been fitted. With the front cooler line connected

and the rear line run into a suitable container, measure the flow over 15 seconds with the vehicle idling in park.

The flow rate should exceed 1 liter in 15 seconds.

Be wary of any situation where water enters the transmission. This may result in fluid foaming and leaking

through the breather.

Ensure that both earth straps (one at the battery terminal and one on the vehicle body) are connected in the

vehicle before connecting the positive side of the battery.

Follow the throttle position calibration procedure in this manual if the engine control module/ transmission

control module (ECM/TCM) is swapped.

KAA5A710

Page 1375 of 2053

TRANSFER CASE 5D1-5

SSANGYONG MY2002

The motor reaches its destination.

The motor is on for 5 seconds without reaching its

destination. The shift has failed and the TCCU will

respond as default mode.

A fault occurs with either the motor or position

encoder. Refer to the diagnosis requirement.

When the motor is energized, the Ignition, 4H/4L

switch, propeller shaft speeds, and transmission

neutral inputs are ignored.

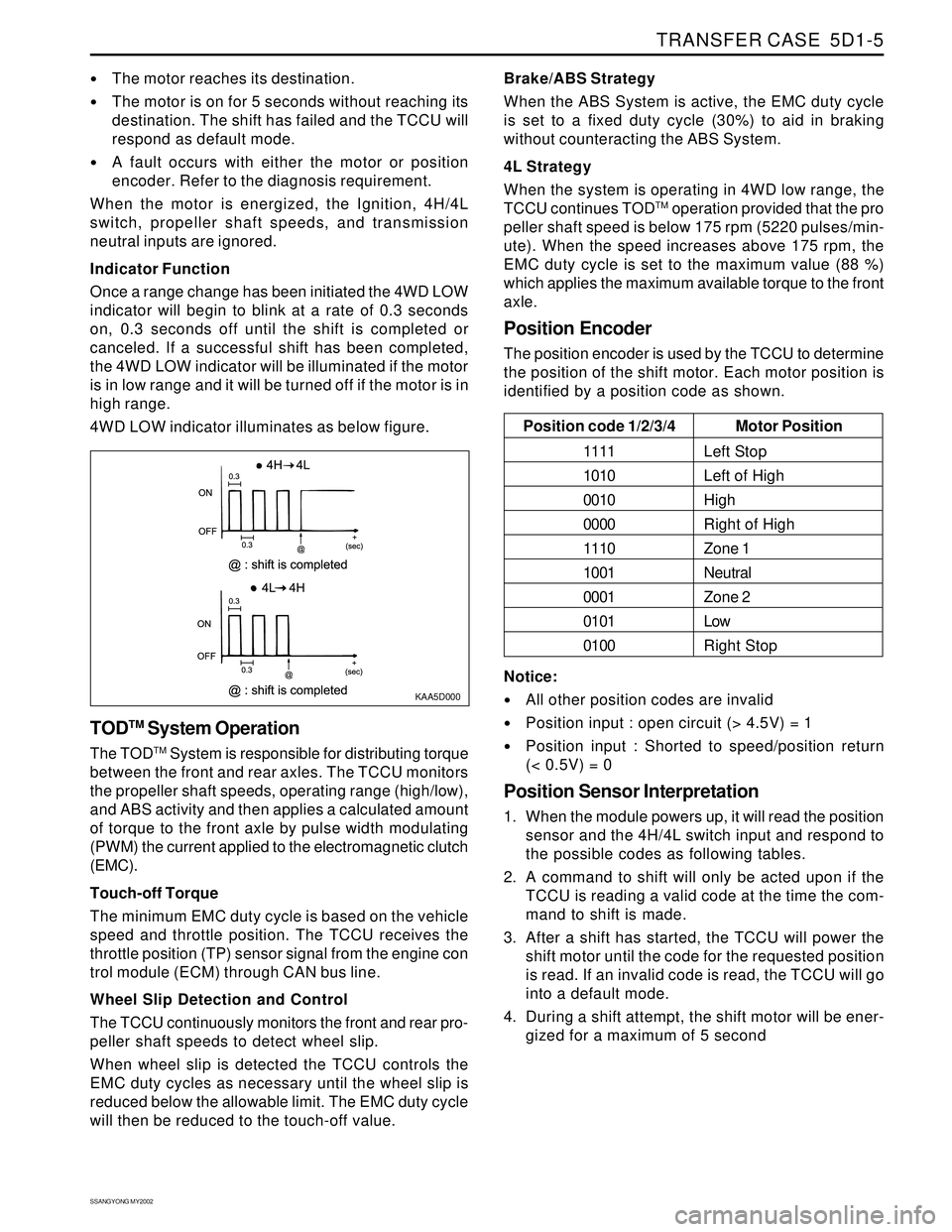

Indicator Function

Once a range change has been initiated the 4WD LOW

indicator will begin to blink at a rate of 0.3 seconds

on, 0.3 seconds off until the shift is completed or

canceled. If a successful shift has been completed,

the 4WD LOW indicator will be illuminated if the motor

is in low range and it will be turned off if the motor is in

high range.

4WD LOW indicator illuminates as below figure.

KAA5D000

TODTM System Operation

The TODTM System is responsible for distributing torque

between the front and rear axles. The TCCU monitors

the propeller shaft speeds, operating range (high/low),

and ABS activity and then applies a calculated amount

of torque to the front axle by pulse width modulating

(PWM) the current applied to the electromagnetic clutch

(EMC).

Touch-off Torque

The minimum EMC duty cycle is based on the vehicle

speed and throttle position. The TCCU receives the

throttle position (TP) sensor signal from the engine con

trol module (ECM) through CAN bus line.

Wheel Slip Detection and Control

The TCCU continuously monitors the front and rear pro-

peller shaft speeds to detect wheel slip.

When wheel slip is detected the TCCU controls the

EMC duty cycles as necessary until the wheel slip is

reduced below the allowable limit. The EMC duty cycle

will then be reduced to the touch-off value.Brake/ABS Strategy

When the ABS System is active, the EMC duty cycle

is set to a fixed duty cycle (30%) to aid in braking

without counteracting the ABS System.

4L Strategy

When the system is operating in 4WD low range, the

TCCU continues TOD

TM operation provided that the pro

peller shaft speed is below 175 rpm (5220 pulses/min-

ute). When the speed increases above 175 rpm, the

EMC duty cycle is set to the maximum value (88 %)

which applies the maximum available torque to the front

axle.

Position Encoder

The position encoder is used by the TCCU to determine

the position of the shift motor. Each motor position is

identified by a position code as shown.

Motor Position

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right Stop Position code 1/2/3/4

1111

1010

0010

0000

1110

1001

0001

0101

0100

Notice:

All other position codes are invalid

Position input : open circuit (> 4.5V) = 1

Position input : Shorted to speed/position return

(< 0.5V) = 0

Position Sensor Interpretation

1. When the module powers up, it will read the position

sensor and the 4H/4L switch input and respond to

the possible codes as following tables.

2. A command to shift will only be acted upon if the

TCCU is reading a valid code at the time the com-

mand to shift is made.

3. After a shift has started, the TCCU will power the

shift motor until the code for the requested position

is read. If an invalid code is read, the TCCU will go

into a default mode.

4. During a shift attempt, the shift motor will be ener-

gized for a maximum of 5 second

Page 1664 of 2053

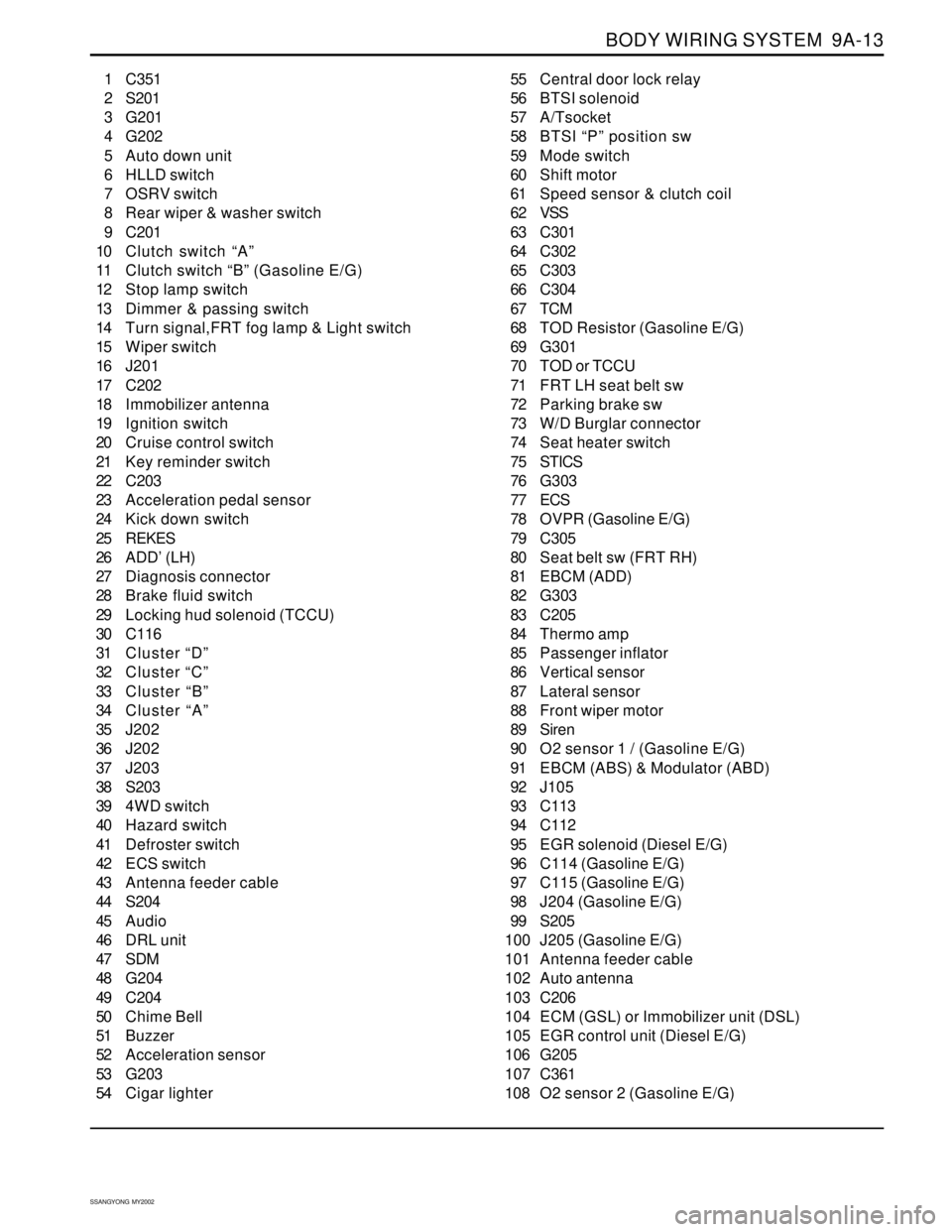

BODY WIRING SYSTEM 9A-13

SSANGYONG MY2002

1 C351

2 S201

3 G201

4 G202

5 Auto down unit

6 HLLD switch

7 OSRV switch

8 Rear wiper & washer switch

9 C201

10 Clutch switch “A”

11 Clutch switch “B” (Gasoline E/G)

12 Stop lamp switch

13 Dimmer & passing switch

14 Turn signal,FRT fog lamp & Light switch

15 Wiper switch

16 J201

17 C202

18 Immobilizer antenna

19 Ignition switch

20 Cruise control switch

21 Key reminder switch

22 C203

23 Acceleration pedal sensor

24 Kick down switch

25 REKES

26 ADD’ (LH)

27 Diagnosis connector

28 Brake fluid switch

29 Locking hud solenoid (TCCU)

30 C116

31 Cluster “D”

32 Cluster “C”

33 Cluster “B”

34 Cluster “A”

35 J202

36 J202

37 J203

38 S203

39 4WD switch

40 Hazard switch

41 Defroster switch

42 ECS switch

43 Antenna feeder cable

44 S204

45 Audio

46 DRL unit

47 SDM

48 G204

49 C204

50 Chime Bell

51 Buzzer

52 Acceleration sensor

53 G203

54 Cigar lighter55 Central door lock relay

56 BTSI solenoid

57 A/Tsocket

58 BTSI “P” position sw

59 Mode switch

60 Shift motor

61 Speed sensor & clutch coil

62 VSS

63 C301

64 C302

65 C303

66 C304

67 TCM

68 TOD Resistor (Gasoline E/G)

69 G301

70 TOD or TCCU

71 FRT LH seat belt sw

72 Parking brake sw

73 W/D Burglar connector

74 Seat heater switch

75 STICS

76 G303

77 ECS

78 OVPR (Gasoline E/G)

79 C305

80 Seat belt sw (FRT RH)

81 EBCM (ADD)

82 G303

83 C205

84 Thermo amp

85 Passenger inflator

86 Vertical sensor

87 Lateral sensor

88 Front wiper motor

89 Siren

90 O2 sensor 1 / (Gasoline E/G)

91 EBCM (ABS) & Modulator (ABD)

92 J105

93 C113

94 C112

95 EGR solenoid (Diesel E/G)

96 C114 (Gasoline E/G)

97 C115 (Gasoline E/G)

98 J204 (Gasoline E/G)

99 S205

100 J205 (Gasoline E/G)

101 Antenna feeder cable

102 Auto antenna

103 C206

104 ECM (GSL) or Immobilizer unit (DSL)

105 EGR control unit (Diesel E/G)

106 G205

107 C361

108 O2 sensor 2 (Gasoline E/G)