window SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1778 of 2053

WINDNOISE 9J-3

SSANGYONG MY2002

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

WINDNOISE REPAIR

Windnoise leak repairs are very similar to waterleak

repairs. Refer to Section 9I, Waterleaks. The actual

procedure depends on the type of seal being repaired.

Leaks around the door opening weatherstrips do not

al-ways indicate a faulty weatherstrip. A door or window

adjustment may resolve the condition. Refer to Section

9P, Doors or Section 9L, Glass and Mirrors.

Page 1783 of 2053

SECTION 9L

GLASS AND MIRRORS ON

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Description and Operation...................................9L-2

Stationary Glass..................................................9L-2

Inside Rearview Mirror.........................................9L-2

Outside Rearview Mirrors.....................................9L-2

Components Locator............................................9L-3

Glass and Mirror..................................................9L-3

Repair Instructions................................................9L-4

On-Vehicle Service Unit Repair................................9L-4

Windshield..........................................................9L-4

Rear Window Glass.............................................9L-6

Rear Window Defogger Braided Lead

Wire Repair......................................................9L-7Rear Window Defogger Grid Line Repair..............9L-8

Front Door Glass..................................................9L-9

Fixed Glass.........................................................9L-9

Inside Rearview Mirror ....................................... 9L-10

Outside Rearview Mirror..................................... 9L-10

Specifications.....................................................9L-11

Fastener Tightening Specifications..................... 9L-11

Schematic and Routing Diagram......................9L-12

Defroster........................................................... 9L-12

Inside Rear View Mirror (Dimming) &

Backup Lamp................................................. 9L-13

Page 1784 of 2053

SSANGYONG MY2002

9L-2 GLASS AND MIRRORS

DESCRIPTION AND OPERATION

STATIONARY GLASS

Stationary glass consists of all the glass on the vehicle

which is immovable within its frame, such as the wind

shield glass, the back glass, the quarter window, and

the inside rearview mirror.

INSIDE REARVIEW MIRROR

The inside rearview mirror can be manually adjusted

up/down, and left/right.

OUTSIDE REARVIEW MIRRORS

The outside rearview mirrors are equipped with a remote

control mirror. The electric control outside rearviewmirror

can be adjusted by an electric control switch on the

instrument panel

Page 1788 of 2053

SSANGYONG MY2002

9L-6 GLASS AND MIRRORS

KAA9L080

KAA9L090

KAA9L100

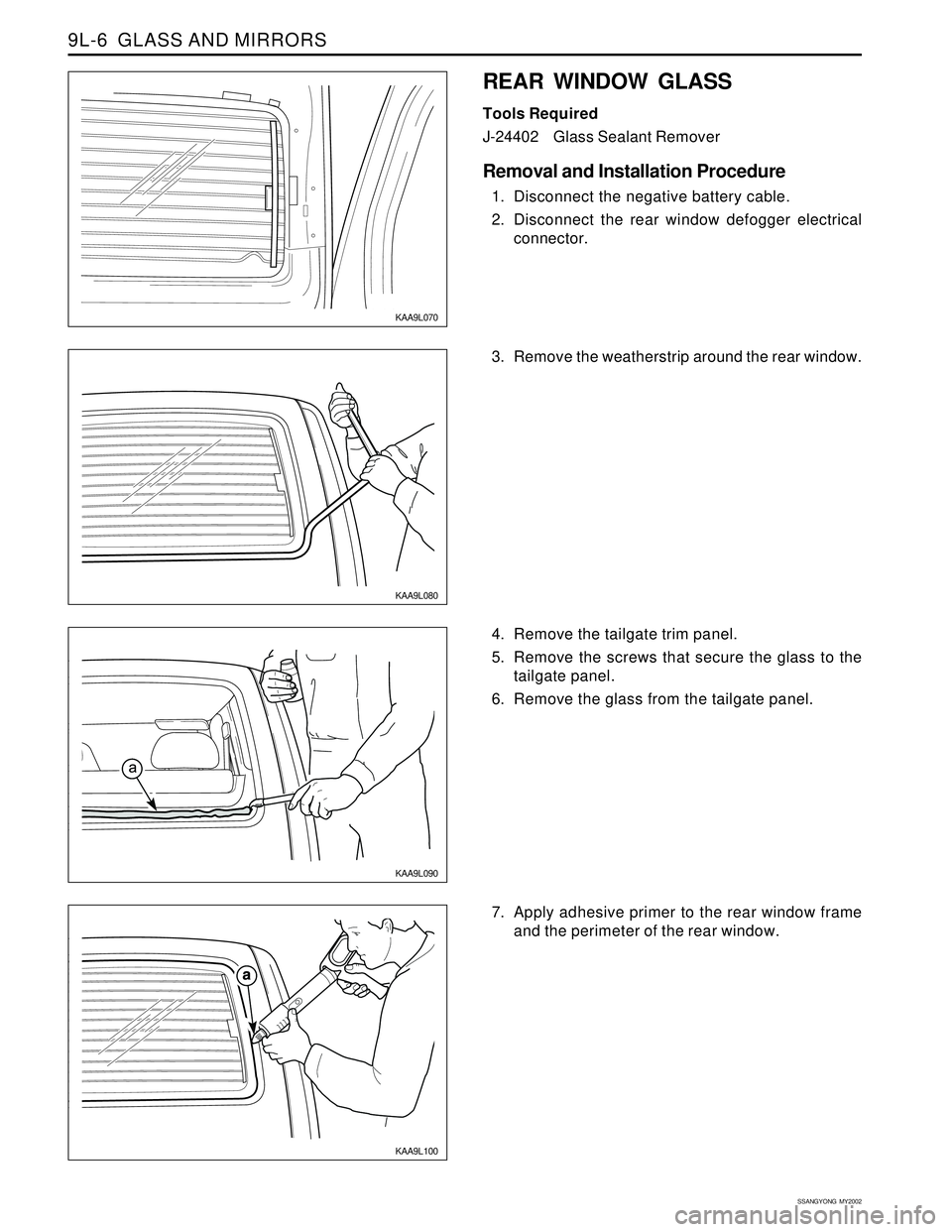

3. Remove the weatherstrip around the rear window.

7. Apply adhesive primer to the rear window frame

and the perimeter of the rear window.

KAA9L070

REAR WINDOW GLASS

Tools Required

J-24402Glass Sealant Remover

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the rear window defogger electrical

connector.

4. Remove the tailgate trim panel.

5. Remove the screws that secure the glass to the

tailgate panel.

6. Remove the glass from the tailgate panel.

Page 1789 of 2053

GLASS AND MIRRORS 9L-7

SSANGYONG MY2002

KAA9L120

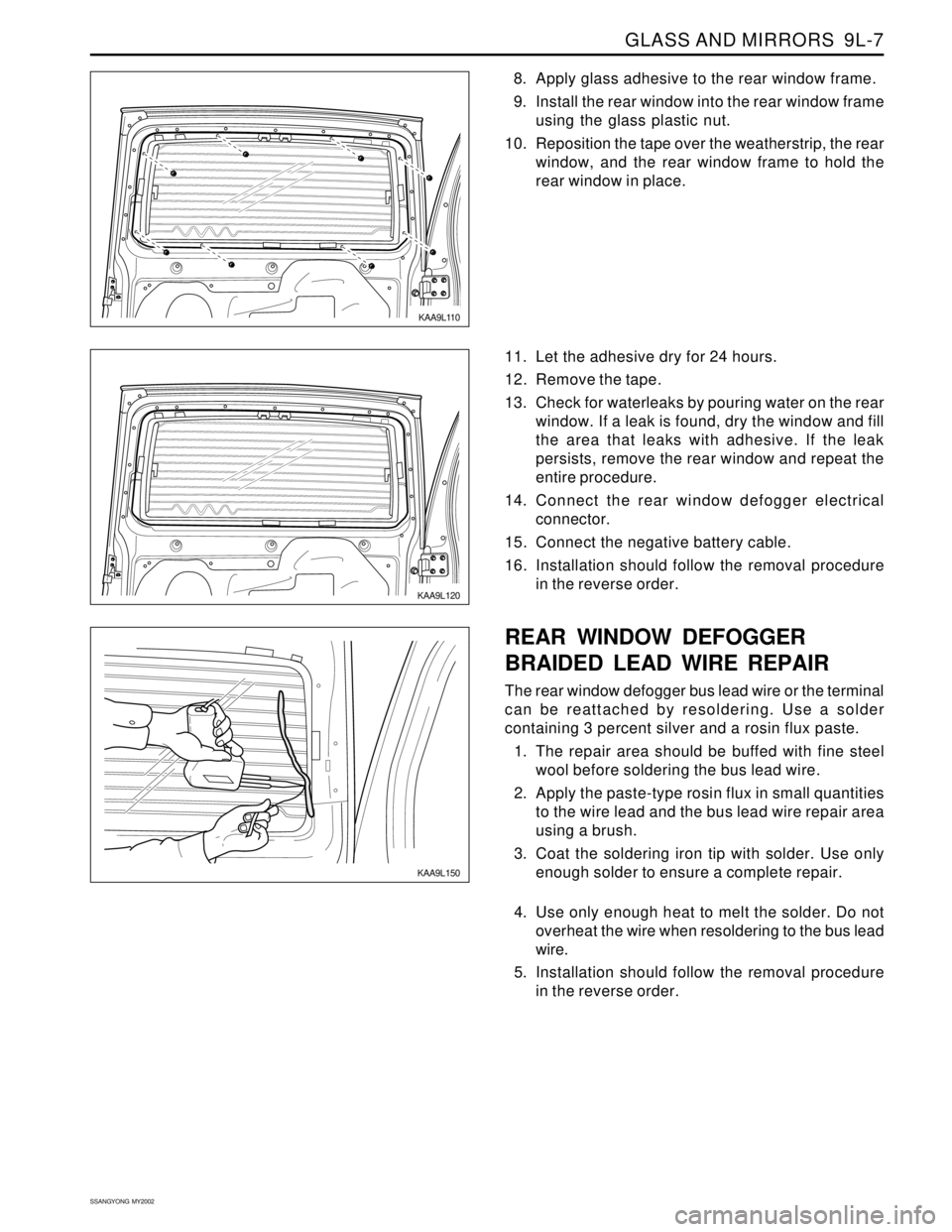

11. Let the adhesive dry for 24 hours.

12. Remove the tape.

13. Check for waterleaks by pouring water on the rear

window. If a leak is found, dry the window and fill

the area that leaks with adhesive. If the leak

persists, remove the rear window and repeat the

entire procedure.

14. Connect the rear window defogger electrical

connector.

15. Connect the negative battery cable.

16. Installation should follow the removal procedure

in the reverse order.

KAA9L110

8. Apply glass adhesive to the rear window frame.

9. Install the rear window into the rear window frame

using the glass plastic nut.

10. Reposition the tape over the weatherstrip, the rear

window, and the rear window frame to hold the

rear window in place.

KAA9L150

REAR WINDOW DEFOGGER

BRAIDED LEAD WIRE REPAIR

The rear window defogger bus lead wire or the terminal

can be reattached by resoldering. Use a solder

containing 3 percent silver and a rosin flux paste.

1. The repair area should be buffed with fine steel

wool before soldering the bus lead wire.

2. Apply the paste-type rosin flux in small quantities

to the wire lead and the bus lead wire repair area

using a brush.

3. Coat the soldering iron tip with solder. Use only

enough solder to ensure a complete repair.

4. Use only enough heat to melt the solder. Do not

overheat the wire when resoldering to the bus lead

wire.

5. Installation should follow the removal procedure

in the reverse order.

Page 1790 of 2053

SSANGYONG MY2002

9L-8 GLASS AND MIRRORS

KAA9L140

Notice: The grid line repair material must be cured

with heat. In order to avoid heat damage to the

interior trim, protect the trim near the repair area

where heat will be applied.

9. Heat the repair area for 1 to 2 minutes.

10. Hold the heat gun nozzle 25 mm (1 inch) from the

surface. A minimum temperature of 149°C (300°F)

is required.

11. Inspect the grid line repair area. If the repair

appears discolored, apply a coating of tincture of

iodine to the area using a pipe cleaner or a line

brush. Allow the iodine to dry for about 30

seconds. Carefully wipe off the excess iodine with

a lint-free cloth.

12. Test the operation of the rear window defogger in

order to verify that the repair was successful.

Important: At least 24 hours is required for

complete curing of the repair materials. The repair

area should not be physically disturbed until after

that time.

13. Installation should follow the removal procedure

in the reverse order.

KAA9L130

REAR WINDOW DEFOGGER GRID

LINE REPAIR

1. Disconnect the negative battery cable.

2. Disconnect the rear window defogger electrical

connector.

3. Inspect the rear window defogger grid lines.

4. Mark the grid line break on the outside of the glass

with a wax pencil or a crayon.

5. Buff the grid lines that are to be repaired with steel

wool. Wipe the lines clean using a cloth dampened

with alcohol. Buff and clean about 6 mm (0.25 inch)

beyond each side of the break in the grid line.

KAA9L130

6. Attach a grid line repair decal or two strips of tape

above and below the repair areas.

A repair decal or tape must be used in order to

control the width of the repair areas.

If a decal is used, the die-cut metered slot must

be the same width as the grid line.

7. Apply the grid repair material to the repair area

using a small wooden stick or a spatula. The grid

repair material should be at room temperature.

8. Carefully remove the decal or the tape.

Page 1791 of 2053

GLASS AND MIRRORS 9L-9

SSANGYONG MY2002

KAA9L160

KAA9L170

FRONT DOOR GLASS

Removal Procedure

1. Remove the door seal trim. Refer to Section 9P,

Doors.

2. Remove the screws that secure the glass to the

window regulator.

3. Remove the glass from the door.

4. Removal procedure should follow the installation

procedure in the reverse order.

Installation Procedure

1. Install the glass in the door and position the glass

within the window regulator.

Notice: Dissimilar metals in direct contact with

each other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Install the glass to the window regulator with the

screws.

Installation Notice

3. Install the door seal trim. Refer to Section 9P,

Doors.

4. Removal procedure should follow the installation

procedure in the reverse order.

Tightening Torque1.96 - 2.94 Nm

(17.50 - 26.25 lb-in)

KAA9L180

FIXED GLASS

Removal and Installation Procedure

1. Remove the exterior B-pillar molding. Refer to

Section 9M, Exterior Trim.

2. Remove the screws that secure the glass to the

window regulator.

3. Remove the glass from the door.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

4. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 7 Nm (62 lb-in)

Page 1819 of 2053

SECTION 9P

DOORS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Description and Operation...................................9P-2

Power Door Locks................................................9P-2

Power Windows...................................................9P-2

Door Lock Striker.................................................9P-2

Components Locator............................................9P-3

Doors ..................................................................9P-3

Repair Instructions................................................9P-4

On-Vehicle Service Unit Repair................................9P-4

Door Glass Run...................................................9P-4

Door Side Opening Weatherstrip..........................9P-4

Door Lock Striker.................................................9P-4

Door Lock Striker Adjustment...............................9P-5

Front Door Lock...................................................9P-6

Inside Door Handle..............................................9P-7

Outside Door Handle ...........................................9P-7Door Lock Cylinder..............................................9P-7

Power Window Regulator.....................................9P-8

Front Door Assembly ...........................................9P-8

Tail Gate Assembly.............................................9P-8

Door Hinge..........................................................9P-9

Door Hold Open Link ...........................................9P-9

Outside Channel Molding.....................................9P-9

Door Weatherstrip................................................9P-9

Door Seal Trim...................................................9P-10

Specifications.....................................................9P-11

Fastener Tightening Specifications.....................9P-11

Schematic and Routing Diagrams.....................9P-12

Central Door Locks System................................9P-12

Power Windows.................................................9P-13

Page 1820 of 2053

SSANGYONG MY2002

9P-2 DOORS

DESCRIPTION AND OPERATION

POWER DOOR LOCKS

The power door locks use a solenoid that is contained

in each door lock assembly. The door locks are

activated by the actuator on the inside door handle or

by the lock cylinder on the driver’s side door only.

When the driver’s side door is locked or unlocked by

the actuator or lock cylinder, all doors are locked or

unlocked accordingly.

POWER WINDOWS

The power windows are controlled by electrical

switches on the door trim center upper panel and areoperated by a motor at each window regulator. The

windows are lowered by pressing the switch and are

raised by pulling up on the switch. The window will

stop movement when the switch is released or when

the windowis completely open or closed.

DOOR LOCK STRIKER

The front door lock strikers each consist of a striker

with two screws threaded into a floating cage plate in

the B-pillars. The door lock fork snaps over and engages

the striker.

Page 1821 of 2053

SSANGYONG MY2002

9P-4 DOORS

DOOR LOCK STRIKER

Removal and Installation Procedure

1. Remove the screws and the door lock striker.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Installation should follow the removal procedure

in the reverse order.

KAA9P020

ON-VEHICLE SERVICE

UNIT REPAIR

DOOR GLASS RUN

Removal and Installation Procedure

1. Lower the window.

2. Remove the glass from the door.

3. Remove the front door glass run.

4. Installation should follow the removal procedure

in the reverse order.

REPAIR INSTRUCTIONS

KAA9P030

DOOR SIDE OPENING

WEATHERSTRIP

Removal and Installation Procedure

1. Remove the side opening weatherstrip.

2. Installation should follow the removal procedure

in the reverse order.

Tightening Torque9.8 - 18.62 Nm

(7.23 - 13.74 lb-ft)

KAA9P040