heater SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1520 of 2053

HEATING AND VENTILATION SYSTEM 7A-19

SSANGYONG MY2002

CONTROL ASSEMBLY KNOB

LIGHTING

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Remove the heating and ventilation control (HVC)

controller assembly. Refer to “Controller Assembly

and Temperature Control Cable” in this section.

3. Remove the connector cover by sliding away.

4. Remove the connector from the temperature control

cable control mechanism.

5. Separate the temperature control cable control

mechanism.

6. Turn the bulb holder to the left and pull out the

bulb.

7. Installation should follow the removal procedure

in the reverse order.

KAA7A040

KAA7A050

KAA7A060

AIR INTAKE DOOR ACTUATOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Disconnect the connector to intake air control door

actuator.

4. Remove three screws that securing mode control

door actuator to heater/air distributor case.

5. Remove the mode control door actuator by gently

snapping the actuator.

6. Installation should follow the removal procedure

in the reverse order.

Page 1521 of 2053

SSANGYONG MY2002

7A-20 HEATING AND VENTILATION SYSTEM

MODE CONTROL DOOR

ACTUATOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Remove the driver knee bolster. Refer to Section

9E, Instrumentation/Driver Information.

3. Disconnect the connector to mode control door ac-

tuator.

4. Remove three sxrews that securing mode control

door actuator to heater/air distributor case.

5. Remove the mode control door actuator by gently

snapping the actuator.

6. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 5 Nm (44 lb-in)

KAA7A070

KAA7A080

HEATER/AIR DISTRIBUTOR CASE

ASSEMBLY

Removal and installation Procedure

1 .Disconnect the negative battery cable.

2. Drain the cooling system. Refer to Section 1D, En-

gine Cooling.

3. Remove the inlet and outlet heater hoses from the

firewall.

4. Remove the instrument panel carrier assembly.

Refer to Section 9E, Instrumentation/Driver

Information.

5. Remove upper four bolts and lower two bolts on I/

P centers bracket.

Installation Notice

6. Remove the I/P center bracket.

7. Remove one screw and the joint duct for heater/

air distributor-to-rear heater duct.

Page 1522 of 2053

HEATING AND VENTILATION SYSTEM 7A-21

SSANGYONG MY2002

8. Remove one bolt, one nut and two screws that se-

curing the heater/air distributor case-to-blower unit

duct.

9. Remove the heater/air distributor case-to-blower

unit duct.

KAA7A090

KAA7A100

KAA7A110

KAA7A120

10. Remove two bolts and the heater/air distributor

case-to-defroster duct.

Installation Notice

11. Remove electrical connector to the mode control

actuator.

12. Remove one bolt and two nuts that securing heater/

air distributor case.

Installation Notice

13. Remove the heater/air distributor case.

14. Installation should follow the removal procedure

in the reverse order.

Tightening TorqueBolt 5 Nm (44 lb-it)

Nut 5 Nm (44 lb-it)

BLOWER MOTOR

Removal and Installation Procedures

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Disconnect the blower motor electrical connector.

4. Remove the blower motor cooling hose.

5. Remove the screws that secure the motor to the

heater/air distributor case.

6. Remove the blower motor from the blower unit by

gently pulling the motor straight down and out.

Tightening Torque 5 Nm (44 lb-in)

Page 1523 of 2053

SSANGYONG MY2002

7A-22 HEATING AND VENTILATION SYSTEM

7. Installation should follow the removal procedure

in the reverse order.

Installation Notice: After install the blower motor

confirm that the blower motor operates properly.

KAA7A130

KAA7A140

BLOWER RESISTOR

Removal and Installation Procedures

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Disconnect the electrical connector at the resistor.

4. Remove two screws from the resistor.

5. Remove the resistor from the heater/air distributor

case by gently pulling the resistor.

6. Installation should follow the removal procedure

in the reverse order.

BLOWER UNIT

Removal and Installation Procedures

1. Disconnect the negative battery cable.

2. Remove the instrument panel carrier assembly.

Refer to Section 9E, Instrumentation/Driver

Information.

3. Remove one nut, one bolt and two screws that

securing the heater/air distributor case-to-blower

unit duct.

4. Remove the heater/air distributor case-to-blower

unit duct.

5. Disconnect the connector for air intake door

actuator and the connector for blower motor.

6. Remove three nuts that securing the blower unit.

Installation Notice

7. Remove the blower unit.

8. Installation should follow the removal procedure

in the reverse order.

Tightening Torque 5 Nm (44 lb-it)

Page 1524 of 2053

HEATING AND VENTILATION SYSTEM 7A-23

SSANGYONG MY2002

HEATER INLET HOSE

Removal and Installation Procedures

1. Partially drain the cooling system. Refer to Section

1D, Engine Cooling.

2. Remove the clip and slide rearward the inlet heater

hose clamp at the firewall.

3. Gently twist the hose from the left to right and

back again to loosen the bond between the hose

and the tube.

4. Remove the end of the hose from the tube.

KAA7A150

KAA7A160

KAA7A170

KAA7A180

5. Remove the clip and slide rearward the inlet heater

hose at the engine block.

6. Remove the inlet heater hose from the vehicle.

7. Installation should follow the removal procedure

in the reverse order.

HEATER OUTLET HOSE

Removal and Installation Procedures

1. Partially drain the cooling system. Refer to Section

1D, Engine Cooling.

2. Remove the clip and slide rearward the outlet

heater hose clamp at the firewall.

3. Gently twist the hose from the left to right and

back again to loosen the bond between the hose

and the tube.

4. Remove the end of the hose from the tube.

5. Remove the intake manifolds. Refer to Section 1C,

DOHC Engine Mechanical.

6. Remove the clip and slide rearward the outlet

heater hose at the thermostat housing.

7. Remove the outlet heater hose from the vehicle.

8. Installation should follow the removal procedure

in the reverse order.

Page 1525 of 2053

SSANGYONG MY2002

7A-24 HEATING AND VENTILATION SYSTEM

HEATER CORE

Removal and Installation Procedures

1. Disconnect the negative battery cable.

2. Remove the heater/air distribution case from the

vehicle. Refer to “Heater/Air Distribution Case

Assembly” in this section.

3. Remove the plastic holder and two screws that

secure the heater core to heater/air distributor case

assembly.

4. Slowly separate the heater/air distributor case as-

sembly and remove the heater core.

5. Installation should follow the removal procedure

in the reverse order.

REAR HEATER DUCT

This vehicle is equipped with rear seat heater ducts.

Should there be no airflow to the rear, look for any ob-

structions, such as items on the floor under the front

seats. Also check for air leaks between the heater/air

distributor assembly and the rear ducts.

KAA7A190

KAA7D130

KAA7D140

AIR FILTER

Removal and Installation Procedures

Notice: Replace earlier if air pollution is heavy.

1. Open the glove box and pull it inward to release

the upper left and right locking portion.

Notice: Remove the glove box by unscrewing

lower 2 screws, if necessary.

2. Press the 2 filter cover holds and remove the air

filter cover.

3. Remove the 2 air filters.

Notice: For installation, remember the installed

direction of the air filter before removal.

Replacement Interval Every 10,000 km

Page 1526 of 2053

HEATING AND VENTILATION SYSTEM 7A-25

SSANGYONG MY2002

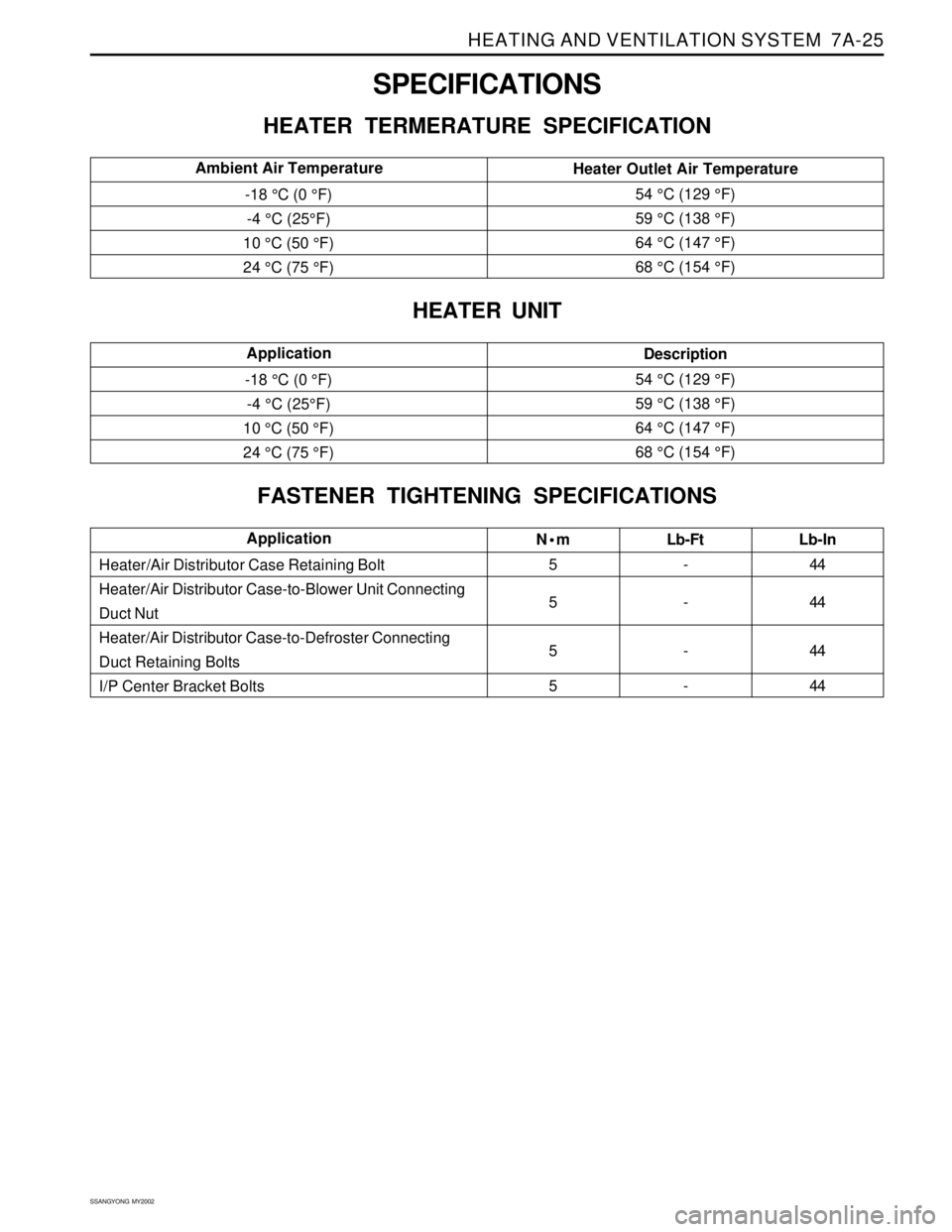

SPECIFICATIONS

HEATER TERMERATURE SPECIFICATION

Nm

5

5

5

5Lb-Ft

-

-

-

- Heater/Air Distributor Case Retaining Bolt

Heater/Air Distributor Case-to-Blower Unit Connecting

Duct Nut

Heater/Air Distributor Case-to-Defroster Connecting

Duct Retaining Bolts

I/P Center Bracket BoltsLb-In

44

44

44

44Application

Heater Outlet Air Temperature

54 °C (129 °F)

59 °C (138 °F)

64 °C (147 °F)

68 °C (154 °F) -18 °C (0 °F)

-4 °C (25°F)

10 °C (50 °F)

24 °C (75 °F)Ambient Air Temperature

FASTENER TIGHTENING SPECIFICATIONS

HEATER UNIT

Description

54 °C (129 °F)

59 °C (138 °F)

64 °C (147 °F)

68 °C (154 °F) -18 °C (0 °F)

-4 °C (25°F)

10 °C (50 °F)

24 °C (75 °F)Application

Page 1530 of 2053

SECTION 7C

MANUAL CONTROL / SEMIAUTO

TEMPERATURE CONTROL HEATING,

VENTILATION AND AIR CONDITIONING

SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when

a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless other-wise noted.

TABLE OF CONTENTS

Specifications.......................................................7C-2

Refrigerant..........................................................7C-2

Evaporator Unit....................................................7C-2

Blower Unit..........................................................7C-2

Compressor.........................................................7C-2

Condenser...........................................................7C-2

Receiver Drier......................................................7C-2

Pressure Switch...................................................7C-3

Air Filter...............................................................7C-3

Heater Unit..........................................................7C-3

Fastener Tightening Specifications.......................7C-3

Diagnosis..............................................................7C-4

Defectives in Fan Motor Circuit.............................7C-5

Defectives in Compressor Circuit.........................7C-6

Diagnosis Using the Manifold Gauge...................7C-7Component Locator.............................................7C-9

Ventilation............................................................7C-9

Heater System ................................................... 7C-11

Air Conditioner System...................................... 7C-12

Diesel Engine .................................................... 7C-12

Gasoline Engine................................................ 7C-13

Maintenance and Repair................................... 7C-14

Refrigerant Charging .......................................... 7C-14

Compressor Oil Replacement............................ 7C-18

Repair Instructions.............................................. 7C-19

On-Vehicle Service............................................... 7C-19

Condener.......................................................... 7C-19

Receiver Drier.................................................... 7C-21

Air - Conditioner Compressor............................. 7C-23

Heater and Air Conditioner Control Box.............. 7C-24

Air Filter............................................................. 7C-25

Page 1532 of 2053

MANUAL & SEMIAUTO-HVAC 7C-3

SSANGYONG MY2002

PRESSURE SWITCH

Type

High (OFF)

Low (ON)ApplicationDescriptionDirect

OFF : 32 ± 2 Kgf/cm

2, DIFF : 6 ± 2 Kgf/cm2

OFF : 2.0 ± 0.2 Kgf/cm2, ON : 2.1 ± 0.2 Kgf/cm2

AIR FILTER

ReplacementApplicationDescriptionEvery 12,000 km (replace earlier if air pollution is heavy)

HEATER UNIT

Heater Core Type

Heating Capacity

Heater Core Size (L x W x T)ApplicationDescription2-ROW

4,600 Kcal/h (AT 300 CMH)

219.5 x 151.8 x 52

FASTENER TIGHTENING SPECIFICATIONS

N•m

4 - 6

4 - 6

4 - 6

5 - 8

4 - 6

20 - 30

20 - 26Lb-Ft

2.9 - 4.4

2.9 - 4.4

2.9 - 4.4

3.7 - 5.9

2.9 - 4.4

14.7 - 22.1

14.7 - 19.1 Condenser Bolt

Condenser Fan Nut

Condenser Bolt

Receiver Drier Pipe Bolt

Receiver Drier Pipe Bolt (Condenser)

Pressure Pipe Bolt

Pressure Mounting BoltLb-In

35.4 - 53.1

35.4 - 53.1

35.4 - 53.1

44.2 - 70.8

35.4 - 53.1

177.0 - 265.5

177.0 - 230.1Application

Page 1533 of 2053

SSANGYONG MY2002

7C-4 MANUAL & SEMIAUTO-HVAC

DIAGNOSIS

Insufficient

cooling

Check blowing outlet

Normal outlet

Check outlet temperature

Check fan motor operation

Motor operates

with poor outletFan motor does

not operate

Blown fuse

Check for motor control circuit

Poor outlet or no

outlet

Intake grille is

cloggedFrosted evaporatorHigh temperatureNormal temperature

Check the case

Check heater Check

compressor

operation Warmeaporator

(A/C S/W off, Fan

‘4’)

Check with sight

glass

Check thermo amp Remove

cloggings

Normal compressorFaulty compressor

Check belt

Tension is normal

Check

magnetic

clutch

Check clutch

connection

Check wire Adjust tension

Bubble is not foundBubble is found

Check refrigerant

volume and air in

system Check

pressure

Loosened tension

Bubble is not foundBubble is found

Check refrigerant Check pressure

Faulty magnetic

electricFaulty clutchFaulty compressor operation

Check battery voltage

Check control switch

Check ground

Normal high/low pressureHigh high/low pressureHigh pressure : low

Low pressure : high

Check intake

and outlet

temperature Faulty A/C system

Faulty A/C mix door

Faulty vent, intake door Excessive refrigerant

Dirty cond., fan

Excessive oil in system

- No diffence in

temperature

- Fast pressure balanceLow intake temperature

Faulty comp. outlet Faulty evaporatorNoise

CompressorBeltOthers

Excessive oil

Faulty bearing

Faulty clutch Identify the place

Faulty belt

Belt line is correct

Check belt tension