hood open SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 14 of 2053

0B -- 14 GENERAL INFORMATION

D AEW OO M Y_2000

EACH TIME THE OIL IS CHANGED

Brake System Inspection

This inspection should be done when the wheels are re-

moved for rotation. Inspect the lines and the hoses for

proper hookup, binding, leaks, cracks, chafing, etc. In-

spect the disc brake pads for wear. Inspect the rotors for

surface condition. Inspect other brake parts, the parking

brake, etc., at the same time. Inspect the brakes more

often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears or leakage. Replace

the seals if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the ex-

haust system. Look for broken, damaged, missing, or

out -- of -- position parts as well as open seams, holes,

loose connections, or other conditions which could

cause heat buildup in the floor pan or could let exhaust

fumes seep into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints

and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and

the accelerator pedal sliding face with suitable grease.

Check the throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper ten-

sion. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the sec-

ondary latch. It should keep the hood from opening all

the way when the primary latch is released. The hood

must close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops

and the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare

tire, all the jacking equipment, and the tools must be se-

curely stowed at all times. Oil the jack ratchet or the

screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the

latches, the glove box and the console doors, and any

folding seat hardware.

Underbody Flushing

Flushing the underbody will remove any corrosive mate-

rials used for ice and snow removal and dust control. At

least every spring clean the underbody. First, loosen the

sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the

fluid is dirty or rusty, drain, flush and refill the engine

cooling system with new coolant. Keep the coolant at

the proper mixture in order to ensure proper freeze

protection, corrosion protection and engine operating

temperature. Inspect the hoses. Replace the cracked,

swollen, or deteriorated hoses. Tighten the clamps.

Clean the outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure

test the cooling system and the cap in order to help en-

sure proper operation.

Page 40 of 2053

1B1 -- 8 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

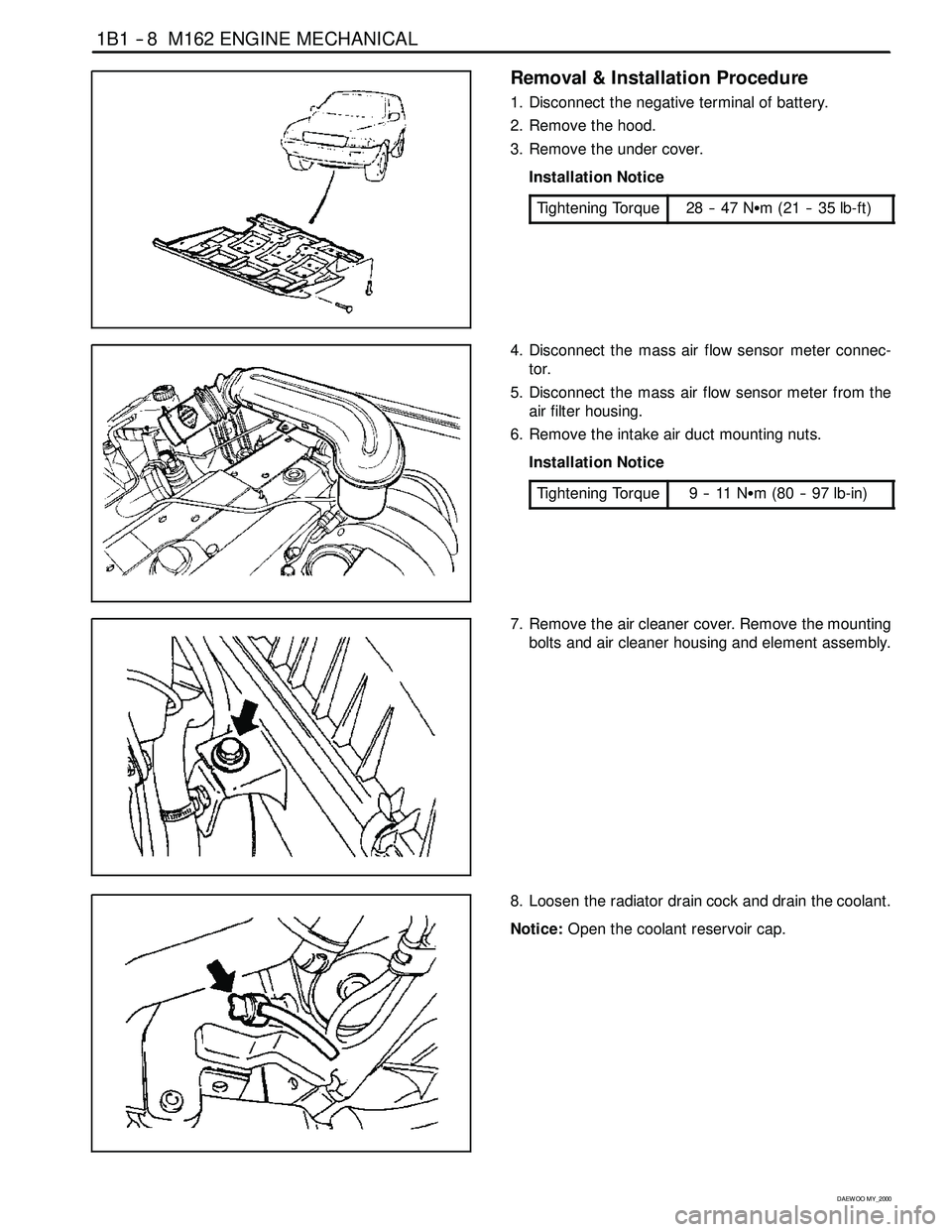

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque

28 -- 47 NSm (21 -- 35 lb-ft)

4. Disconnect the mass air flow sensor meter connec-

tor.

5. Disconnect the mass air flow sensor meter from the

air filter housing.

6. Remove the intake air duct mounting nuts.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

7. Remove the air cleaner cover. Remove the mounting

bolts and air cleaner housing and element assembly.

8. Loosen the radiator drain cock and drain the coolant.

Notice:Open the coolant reservoir cap.

Page 301 of 2053

1B2 -- 8 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque

28 -- 47 NSm (21 -- 35 lb-ft)

4. Disconnect the coupling of HFM sensor and remove

the air cleaner cross pipe.

5. Remove the air cleaner cover. Remove the mounting

bolts and air cleaner housing and element assembly.

6. Loosen the radiator drain cock and drain the coolant.

Notice:Open the coolant reservoir cap.

Page 562 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 13

D AEW OO M Y_2000

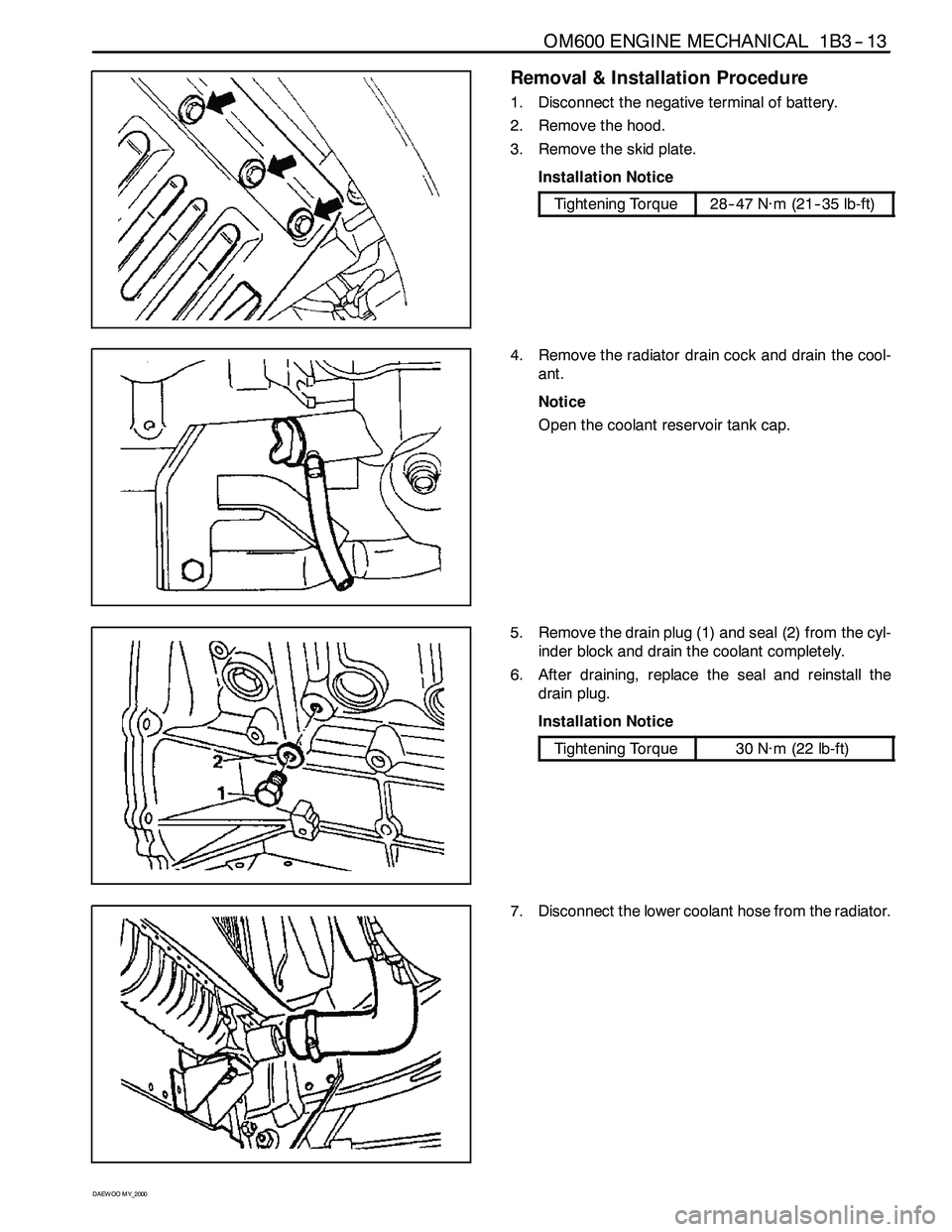

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the skid plate.

Installation Notice

Tightening Torque28-- 47 N∙m (21-- 35 lb-ft)

4. Remove the radiator drain cock and drain the cool-

ant.

Notice

Open the coolant reservoir tank cap.

5. Remove the drain plug (1) and seal (2) from the cyl-

inder block and drain the coolant completely.

6. After draining, replace the seal and reinstall the

drain plug.

Installation Notice

Tightening Torque30 N∙m (22 lb-ft)

7. Disconnect the lower coolant hose from the radiator.

Page 1689 of 2053

LIGHTING SYSTEM 9B-15

SSANGYONG MY2002

REPAIR INSTRUCTIONS

KAA9B020

KAA9B030

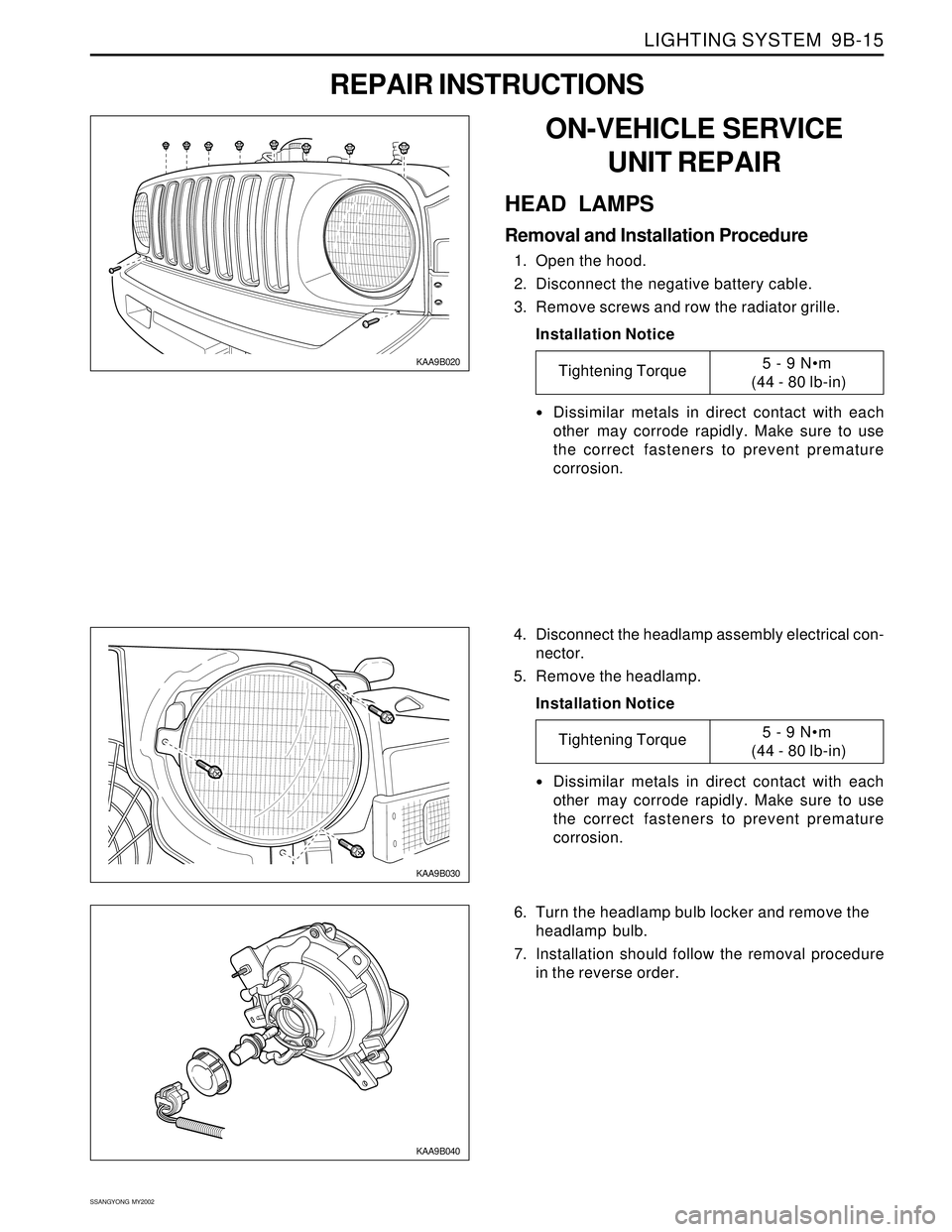

ON-VEHICLE SERVICE

UNIT REPAIR

HEAD LAMPS

Removal and Installation Procedure

1. Open the hood.

2. Disconnect the negative battery cable.

3. Remove screws and row the radiator grille.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

4. Disconnect the headlamp assembly electrical con-

nector.

5. Remove the headlamp.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

Tightening Torque5 - 9 Nm

(44 - 80 lb-in)

Tightening Torque5 - 9 Nm

(44 - 80 lb-in)

KAA9B040

6. Turn the headlamp bulb locker and remove the

headlamp bulb.

7. Installation should follow the removal procedure

in the reverse order.

Page 1713 of 2053

WIPER, WASHER SYSTEMS 9D-5

SSANGYONG MY2002

KAA9D050

KAA9D060

5. Remove nuts and the wiper motor.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

6. Installation should follow the removal procedure

in the reverse order.

WINDSHIELD WASHER

RESERVOIR

Removal and Installation Procedure

1. Open the hood.

2. Disconnect the negative battery cable.

3. Remove the coolant reservoir. Refer to Section 1D,

ENGING COOLING.

4. Disconnect the washer hose from the washer

pump.

WINDSHIELD WIPER BLADE

Removal and Installation Procedure

1. Rotate the wiper blade on the arm.

2. While pressing the retainer clip, slide the wiper

blade down the wiper arm and remove the blade.

3. Installation should follow the removal procedure

in the reverse order.

Tightening Torque8 - 12 Nm

(71 - 106 lb-ft)

KAA9D070

5. Disconnect the reservoir pump electrical

connector.

6. Remove the bolt and the reservoir

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

7. Installation should follow the removal procedure

in the reverse order.

Tightening Torque5 - 9 Nm

(44 - 80 lb-in)

Page 1714 of 2053

SSANGYONG MY2002

9D-6 WIPER, WASHER SYSTEMS

KAA9D080

KAA9D090

KAA9D100

WINDSHIELD WASHER PUMP

Removal and Installation Procedure

1. Remove the windshield washer reservoir. Refer to

in this section “windshield washer reservoir”.

2. Remove the windshield washer pump.

3. Installation should follow the removal procedure

in the reverse order.

WINDSHIELD WASHER HOSES

Removal and Installation Procedure

1. Open the hood.

2. Disconnect the windshield washer hose from the

washer nozzles on the hood.

3. Disconnect the washer hose from the washer

reservoir.

4. Remove the washer hose.

5. Installation should follow the removal procedure

in the reverse order.

KAA9D110

REAR WIPER ARM

Removal and Installation Procedure

1. Remove the spare tire with wheel nuts.

2. Pry off the rear wiper arm cap.

3. Remove the rear wiper arm with the nut.

Installation Notice

Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct

fasteners to prevent premature corrosion.

4. Installation should follow the removal procedure

in the reverse order.

WINDSHIELD WASHER NOZZLES

Removal and Installation Procedure

1. Open the hood.

2. Disconnect the washer hose from the nozzle.

3. Remove the nozzle from the hood.

4. Installation should follow the removal procedure

in the reverse order.

Tightening Torque8 - 12 Nm

(71 - 106 lb-in)

Page 1840 of 2053

BODY FRONT END 9R-5

SSANGYONG MY2002

COWL VENT GRILLE

Removal and Installation Procedure

1. Open the hood.

2. Remove the wiper arms. Refer to Section 9D,

Wipers/Washer System.

3. Remove the cowl vent grille with the screws.

4. Installation should follow the removal procedure

in the reverse order.

KAA9R020

KAA9R030

HOOD

Removal and Installation Procedure

Important: Install protective coverings over the fenders

and the windshield to prevent damage to the paint,

the glass, and the moldings when removing and

installing the hood.

1. Open the hood.

2. Mark the position of the hinge to the hood to aid

in alignment during installation.

3. Remove the washer hoses from the hood.

4. Remove the hood gas spring. Refer to “Hood Gas

Spring” in this section.

5. Remove the bolts retaining the hood to both of

the hinges.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

6. With the aid of another technician, remove the hood

from the hinges.

7. Installation should follow the removal procedure

in the reverse order.

Tightening Torque7.84 - 11.76 Nm

(5.78 - 8.68 lb-ft)

Page 1841 of 2053

SSANGYONG MY2002

9R-6 BODY FRONT END

HOOD HINGES

Removal and Installation Procedure

1. Remove the hood. Refer to “Hood” in this section.

2. Remove the cowl vent grille. Refer to “Cowl Vent

Grille” in this section.

3. Remove the side cowl vent panel Refer to “Side

Cowl Vent Panel” in this section.

4. Remove the bolts and the hood hinges

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

5. Installation should follow the removal procedure

in the reverse order.

KAA9R040

HOOD GAS SPRING

Removal and Installation Procedure

1. Open the hood.

2. Remove the wiper arms. Refer to Section 9D,

Wipers/Washer System.

3. Remove the cowl vent grille with the screws.

4. Remove gas spring fix bolt and pull up the gas

spring from the ball stud by spreding the retainer

with screw driver.

5. Remove ball stud from hood. (or not)

Installation Notice

6. Installation should follow the removal procedure

in the reverse order.

KAA9R050

Tightening Torque12.74 - 25.48 Nm

(9.4 - 18.8 lb-ft)

Tightening

Torque9 - 11 Nm

(6.63 - 8.11 lb-ft)

16 - 23 Nm

(11.8 - 16.96 lb-ft)

Spring fix

bolt

Ball stud

bolt

Page 1849 of 2053

SSANGYONG MY2002

9T1-2 REMOTE KEYLESS ENTRY AND ANTI-THEFT SYSTEM

DESCRIPTION AND OPERATION

REMOTE KEYLESS ENTRY AND

ANTI-THEFT SYSTEM

The remote keyless entry and anti-theft system can

perform the following functions:

•Remotely lock and unlock the vehicle doors by

means of a hand-held, high-frequency transmitter.

Sense intrusion into the vehicle through the doors

or the hood.

Activate a warning if an intrusion is detected.

Automatically relock the doors if thedoor or the

tail gate is not opened within 30 seconds after the

vehicle has been unlocked by remote keyless

entry.

Help the driver find the vehicle in a parking area.

The remote keyless entry system consist of the

following components:

STICS.

Remote keyless entry system receiver.

Hand-held transmitter.

Tailgate open switch.

Door contact switch.

Siren.

Hood open switch

Key reminder switch.

Antenna.

STICS can perform the following functions:

1. Wiper INT sening vehicle speed.

By operating INT tiem control volume, variable

time will be changed within 1.5-20 seconds

2. Washer relating wiper.

3. Dimming room lamp.

When room lamp is coupled with door, it truns on

if door is opened. After closing the door it

maintains 2 seconds of lighting and dims off

whithin 3 seconds.

4. Time delayed power window control.

Power window can be operated within 30 seconds

after truning the IGN 1 switch from ON to OFF. If

driver/passenger’s door is opened within the 30

seconds from that moment.

5. Rear defogger timer.

The rear defogger will be operated for 12 min. by

turning ON the defogger switch while engine is

running.

Defogger will be stopped by pushing the switch

again.

The defogger will be operated 6 mim, if push ON

the switch within 10 min. after 12 min. of operation.6. Seat belt waring.

The warning lamp will be turned on for about 6

sec. With an intermittent chime bell when the IGN.

Switch is ON unless fastening the seat belt.

7. parking brake warning.

The indicator lamp will flash if drive while the

parking brake is applied.

8. Tail lamp lighting warning.

When the driver’s door is opened while the tail

lamp is still ON, the buzzer operates intermittently.

In this condition, the door will be automatically

unlock when it locked.

9. Door ajar warning.

The indicator lamp will be blinking when the door

is not closed completely and driving.

10. IGN key reminder.

The chime will be operated intermittently if the

driver’s door is opened while the IGN key is still

remain-ing in the ignition switch. In this condition,

the door will be automatically unlocked when it

locked.

11. Central door lock.

All doors will be locked/unlocked by locking/

unlocking the driver’s or passenger’s door.

12. coupled with REKES.

Being coupled with REKES (remote keyless entry

system), all doors will be locked/unlocked

according to signals of transmitter when the

ignition key is not inserted.

13. iginition key hole illumination.

coupled with door switch, ignition key hole

illumination lamp will trun on when the driver ’s

door is opened and will dim off after 10 sec. After

closing the door.

14. Auto door lock.

All doors will be locked automatically if the vehicle

speed reaches 50 km/h though the doors are in

unlock.

15. Auto door unlock.

All doors will be automatically unlock if the vehicle

crashes while driving (over 15km/h).

Operate the burglar alarm.

1. Burglar alarm must operate immediately when the

door, tailgate or hood is opened with improper

ways after all doors and hood were closed and

continued this status for 1 seconds.

2. If the tailgate is opened by key when the system

is on the burglar alarm cindition, the sysem must

be changed to the second burglar alarm condition

frim normal condition.