power steering fluid SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1456 of 2053

POWER STEERING SYSTEM 6A-5

SSANGYONG MY2002

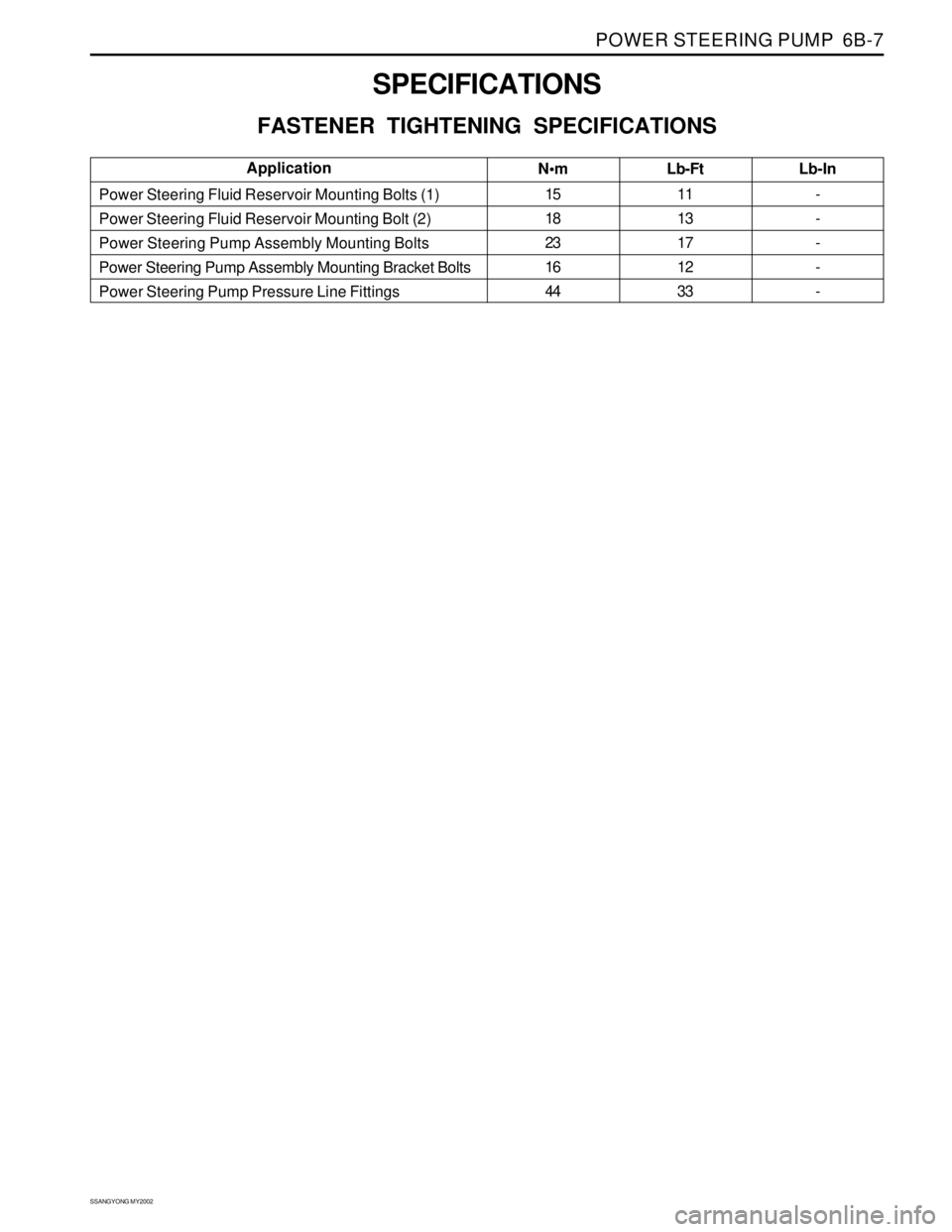

BLEEDING THE POWER

STEERING SYSTEM

1. Disconnect the fuel line. Using a starter motor,

crank the engine and turn the steering wheel from

lock to start 5 or 6 times.

Notice: Do bleeding with engine cranking. If bleed

with idling, there can be a air contact with oil.

2. Connect the fuel feed line and start the engine at

idle speed.

3. Turn the steering wheel from lock to lock until there

is no more air in oil reservoir.

4. Connect the oil level is within specification.

5. By turning the steering wheel left to right, check

the oil level change.

Notice: If oil is not changes more than 5 mm, do

bleeding again. If oil level rises suddenly when

stopped engine, again.

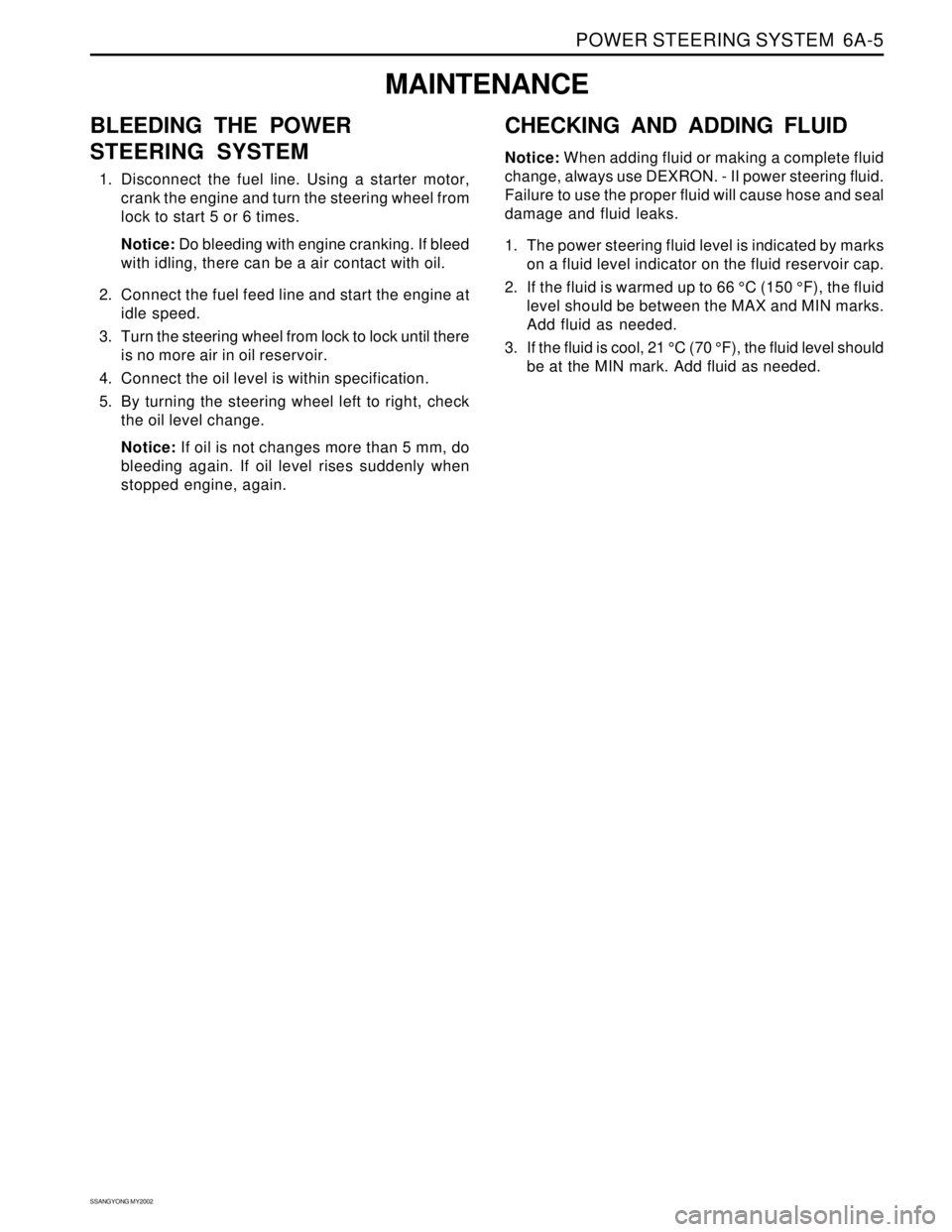

MAINTENANCE

CHECKING AND ADDING FLUID

Notice: When adding fluid or making a complete fluid

change, always use DEXRON. - II power steering fluid.

Failure to use the proper fluid will cause hose and seal

damage and fluid leaks.

1. The power steering fluid level is indicated by marks

on a fluid level indicator on the fluid reservoir cap.

2. If the fluid is warmed up to 66 °C (150 °F), the fluid

level should be between the MAX and MIN marks.

Add fluid as needed.

3. If the fluid is cool, 21 °C (70 °F), the fluid level should

be at the MIN mark. Add fluid as needed.

Page 1457 of 2053

SSANGYONG MY2002

6A-6 POWER STEERING SYSTEM

KAA6A040

3. Remove the power steering fluid reservoir

mounting bolts (1).

Removal Notice:

One power steering fluid reservoir mounting bolt

(2) is located in the fluid reservoir.

Installation Notice

KAA6A030

ON-VEHICLE SERVICE

POWER STEERING FLUID

RESERVOIR

Tools Required

DW310-021Power Steering Pump Pulley Remover/

Installer

Removal and Installation Procedure

1. Remove the power steering pump. Refer to

Section 6B, Power Steering Pump.

2. Remove the power steering pump pulley nut, using

the power steering pump pulley remover/installer

DW310-021.

Installation Notice

REPAIR INSTRUCTIONS

Tightening Torque 61 Nm (44 lb-ft)

15 Nm (11 lb-ft)

18 Nm (13 lb-ft)

Tightening

TorqueBolts (1)

Bolt (2)

4. Remove the power steering fluid reservoir upward.

After installing the power steering fluid reservoir,

bleed the power steering system. Refer to

“Bleeding the Power Steering System” in this

section.

5. Installation should follow the removal procedure

in the reverse order.

Page 1458 of 2053

POWER STEERING SYSTEM 6A-7

SSANGYONG MY2002

KAA6A050

KAA6A060

4. Disconnect the return line pipe from the power

steering gear outlet.

Installation Notice

KAA6A070

5. Disconnect the pressure line pipe from the power

steering gear inlet.

Installation Notice

POWER STEERING PUMP HOSES

AND PIPES

Removal and Installation Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Siphon the power steering fluid from the fluid reser-

voir.

3. Disconnect the pressure line pipe from the outlet

connection on the power steering pump and return

hose from the inlet connection on the power

steering fluid reservoir.

Installation Notice

Tightening Torque 44 Nm (33 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Tightening Torque 17 Nm (13 lb-ft)

Page 1459 of 2053

SSANGYONG MY2002

6A-8 POWER STEERING SYSTEM

KAA6A080

6. Remove the return line support clip from the front

frame.

Installation Notice

Tightening Torque 9 Nm (80 lb-in)

After installing the power steering fluid reservoir,

bleed the power steering system. Refer to

“Bleeding the Power Steering System” in this

section.

7. Installation should follow the removal procedure

in the reverse order.

Page 1460 of 2053

POWER STEERING SYSTEM 6A-9

SSANGYONG MY2002

SPECIFICATIONS

GENERAL SPECIFICATION

N•m

17

15

18

44

61

9Lb-Ft

13

11

13

33

44

- Power Steering Gear Inlet And Outlet Pipe Fitting

Power Steering Fluid Reservoir Mounting Bolts (1)

Power Steering Fluid Reservoir Mounting Bolt (2)

Power Steering Pump Pressure Line Fittings

Power Steering Pump Pulley Nut

Return Line Support Clip BoltLb-In

-

-

-

-

-

80Application

Description

1.0 Liter (1.06 qt)

Power Steering Fluid DEXRON .- I I Capacity

LubricantApplication

FASTENER TIGHTENING SPECIFICATIONS

Page 1464 of 2053

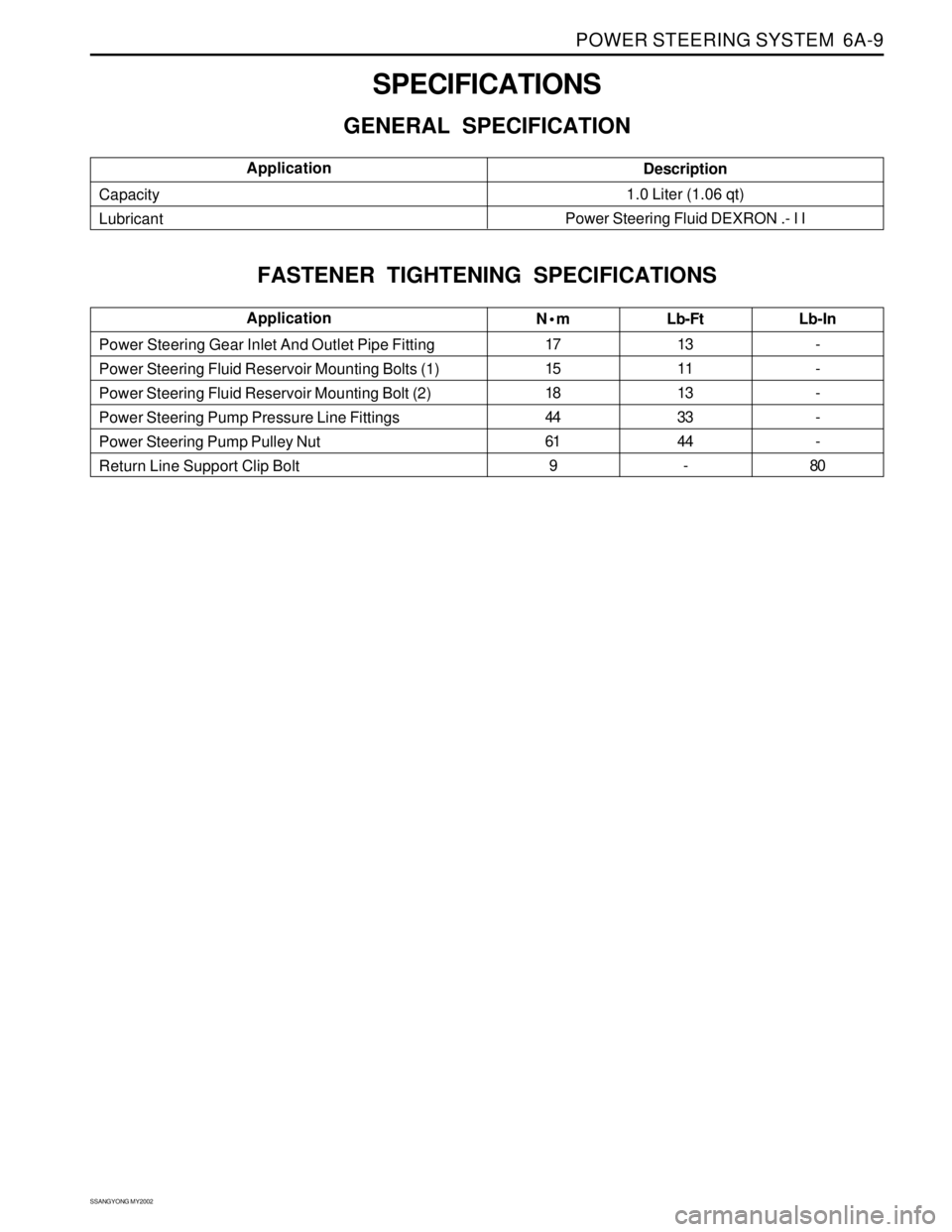

POWER STEERING PUMP 6B-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING PUMP DIAGNOSIS

Foaming or Milky Power Steering Fluid (Air in Fluid)

Low Pressure Due to Power Steering Pump

Check for a scored housing bore.

Check for leakage at the valve rings or the seals.ChecksActionReplace the housing bore.

Repair the leak.

Bleed the system.

Low Pressure Due to Power Steering Gear

Check for internal leakage in the power steering pump,

causing an overflow.

Clean for a low fluid level.ChecksActionRepair the internal pump leakage.

Bleed the system.

Repair the internal pump leakage.

Bleed the system.

Cold temperatures will cause the air bubbles in the

system if the fluid level is low.

Check for an external leakage of the power steering

pump at the seals.

Check for a worn serpentine accessory drive belt.ChecksActionReplace the seals.

Repair the leak.

Bleed the system.

Replace the serpentine accessory drive belt.

Check for air in the power steering fluid.

Check for a low level of power steering fluid.

Check for a loose mounting of the power steering pump.ChecksActionPerform the checks listed in “Foaming or Milky Power

Steering Fluid (Air in Fluid)” above.

Repair any internal or external leaks.

Bleed the system.

Tighten the pump mounting to specifications.

Groaning Noise in the Power Steering Pump

Page 1466 of 2053

POWER STEERING PUMP 6B-5

SSANGYONG MY2002

KAA6B050

5. Remove the power steering pump assembly

mounting bolts.

Installation Notice

KAA6B040

3. Siphon the power steering fluid from the fluid reser-

voir.

4. Disconnect the pressure line pipe from the outlet

connectionon the power steering pump and return

hose from the inlet connection on the power

steering fluid reservoir.

Installation Notice

Tightening Torque 44 Nm (33 lb-ft)

KAA6B010

POWER STEERING PUMP

ASSEMBLY

Removal and Installation Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the

tension on the serpentine accessory drive belt.

Loosen the serpentine accessory drive belt.

Tightening Torque 25 Nm (17 lb-ft)

6. Remove the power steering pump assembly.

Page 1467 of 2053

SSANGYONG MY2002

6B-6 POWER STEERING PUMP

KAA6B060

KAA6B070

3. Remove the power steering fluid reservoir

mounting bolts (1).

Remove Notice:

One power steering fluid reservoir mounting bolt

(2) is located in the fluid reservoir.

Installation Notice

KAA6B080

5. Remove the power steering pump mounting

bracket bolts.

Installation Notice

UNIT REPAIR

PUMP

Tools Required

DW310-021Power Steering Pump Pulley Remover/

Installer

Disassembly and Assembly Procedure

Important: The power steering pump in this vehicle is

not serviceable. Replace, do not repair, a faulty power

steering pump. Refer to “Power Steering Pump

Diagnosis” in this section.

1. Remove the power steering pump assembly. Refer

to “Power Steering Pump Assembly” in this

section.

2. Remove the power steering pump pulley nut, using

the power steering pump pulley remover/installer

DW 310-021.

Tightening Torque 16 Nm (12 lb-ft)15 Nm (11 lb-ft)

18 Nm (13 lb-ft)

Tightening

TorqueBolts (1)

Bolt (2)

4. Remover the power steering fluid reservoir

upward.

6. Installation should follow the removal procedure

in the reverse order.

Page 1468 of 2053

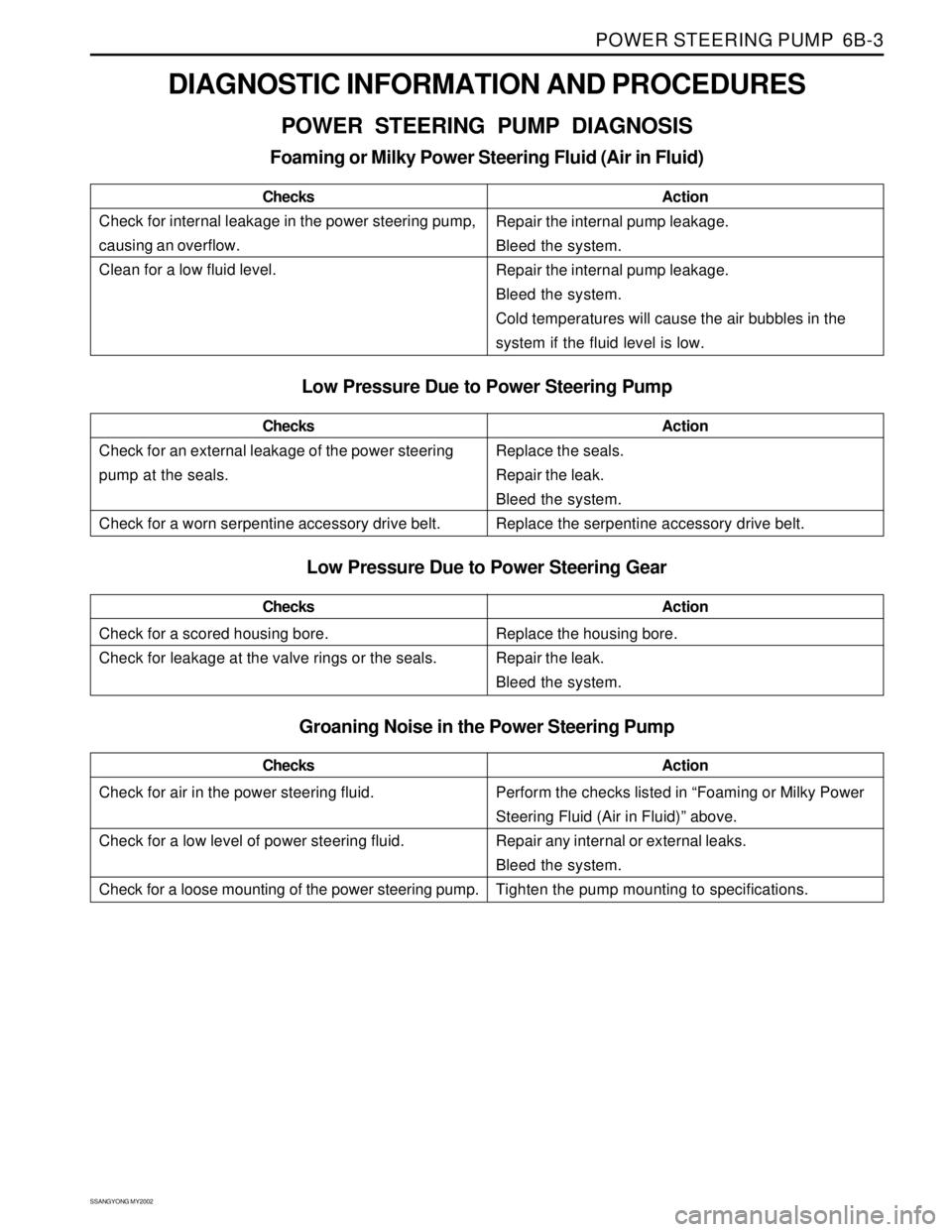

POWER STEERING PUMP 6B-7

SSANGYONG MY2002

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N•m

15

18

23

16

44Lb-Ft

11

13

17

12

33 Power Steering Fluid Reservoir Mounting Bolts (1)

Power Steering Fluid Reservoir Mounting Bolt (2)

Power Steering Pump Assembly Mounting Bolts

Power Steering Pump Assembly Mounting Bracket Bolts

Power Steering Pump Pressure Line FittingsLb-In

-

-

-

-

-Application

Page 1470 of 2053

SSANGYONG MY2002

6C-2 POWER STEERING GEAR

POWER RACK AND PINION

The power steering rack and pinion system has a rotary

control valve that directs hydraulic fluid coming from

the hydraulic pump to one side or the other side of the

rack piston. The integral rack piston is attached to the

rack. The rack piston converts hydraulic pressure to a

linear force that moves the rack left or right. That force

is then transmitted through the tie rods to the steering

knuckles, which turn the wheels.

DESCRIPTION AND OPERATION

If power rack and pinion steering is not available, manu-

al rack and pinion control is used; however, with this

system, more steering effort is required. The movement

of the steering wheel is transferred to the pinion. The

rotary movement of the pinion is then transferred

through the pinion threads, which mesh with teeth on

the rack, thereby causing the rack to move in a linear

direction.

A vane-type of hydraulic pump provides hydraulic pres-

sure for both steering systems.