torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 2 of 2053

0B -- 2 GENERAL INFORMATION

D AEW OO M Y_2000

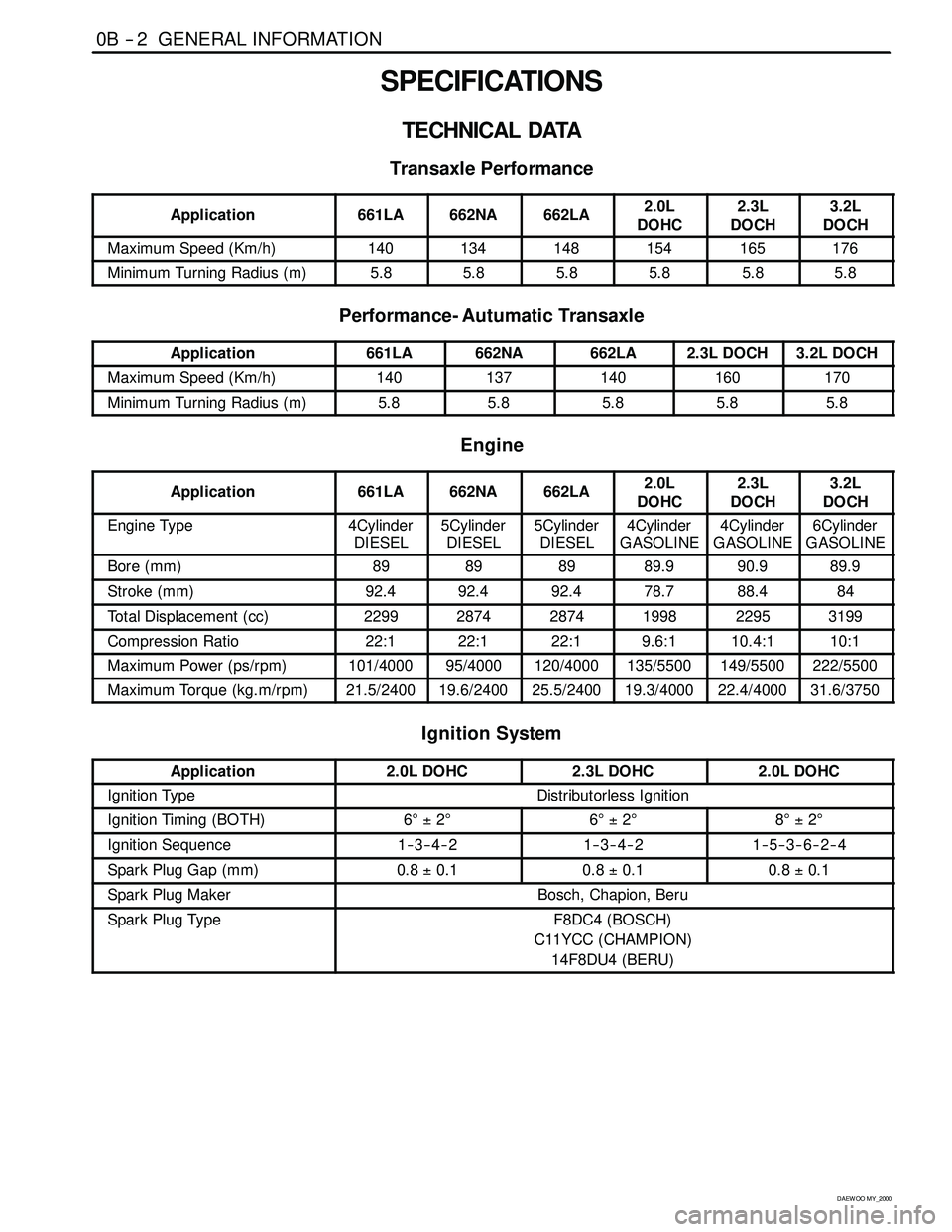

SPECIFICATIONS

TECHNICAL DATA

Transaxle Performance

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

Maximum Speed (Km/h)140134148154165176

Minimum Turning Radius (m)5.85.85.85.85.85.8

Performance- Autumatic Transaxle

Application661LA662NA662LA2.3L DOCH3.2L DOCH

Maximum Speed (Km/h)140137140160170

Minimum Turning Radius (m)5.85.85.85.85.8

Engine

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

Engine Type4Cylinder

DIESEL5Cylinder

DIESEL5Cylinder

DIESEL4Cylinder

GASOLINE4Cylinder

GASOLINE6Cylinder

GASOLINE

Bore (mm)89898989.990.989.9

Stroke (mm)92.492.492.478.788.484

Total Displacement (cc)229928742874199822953199

Compression Ratio22:122:122:19.6:110.4:110:1

Maximum Power (ps/rpm)101/400095/4000120/4000135/5500149/5500222/5500

Maximum Torque (kg.m/rpm)21.5/240019.6/240025.5/240019.3/400022.4/400031.6/3750

Ignition System

Application2.0L DOHC2.3L DOHC2.0L DOHC

Ignition TypeDistributorless Ignition

Ignition Timing (BOTH)6°±2°6°±2°8°±2°

Ignition Sequence1--3--4--21--3--4--21--5--3--6--2--4

Spark Plug Gap (mm)0.8±0.10.8±0.10.8±0.1

Spark Plug MakerBosch, Chapion, Beru

Spark Plug TypeF8DC4 (BOSCH)

C11YCC (CHAMPION)

14F8DU4 (BERU)

Page 7 of 2053

GENERAL INFORMATION 0B -- 7

D AEW OO M Y_2000

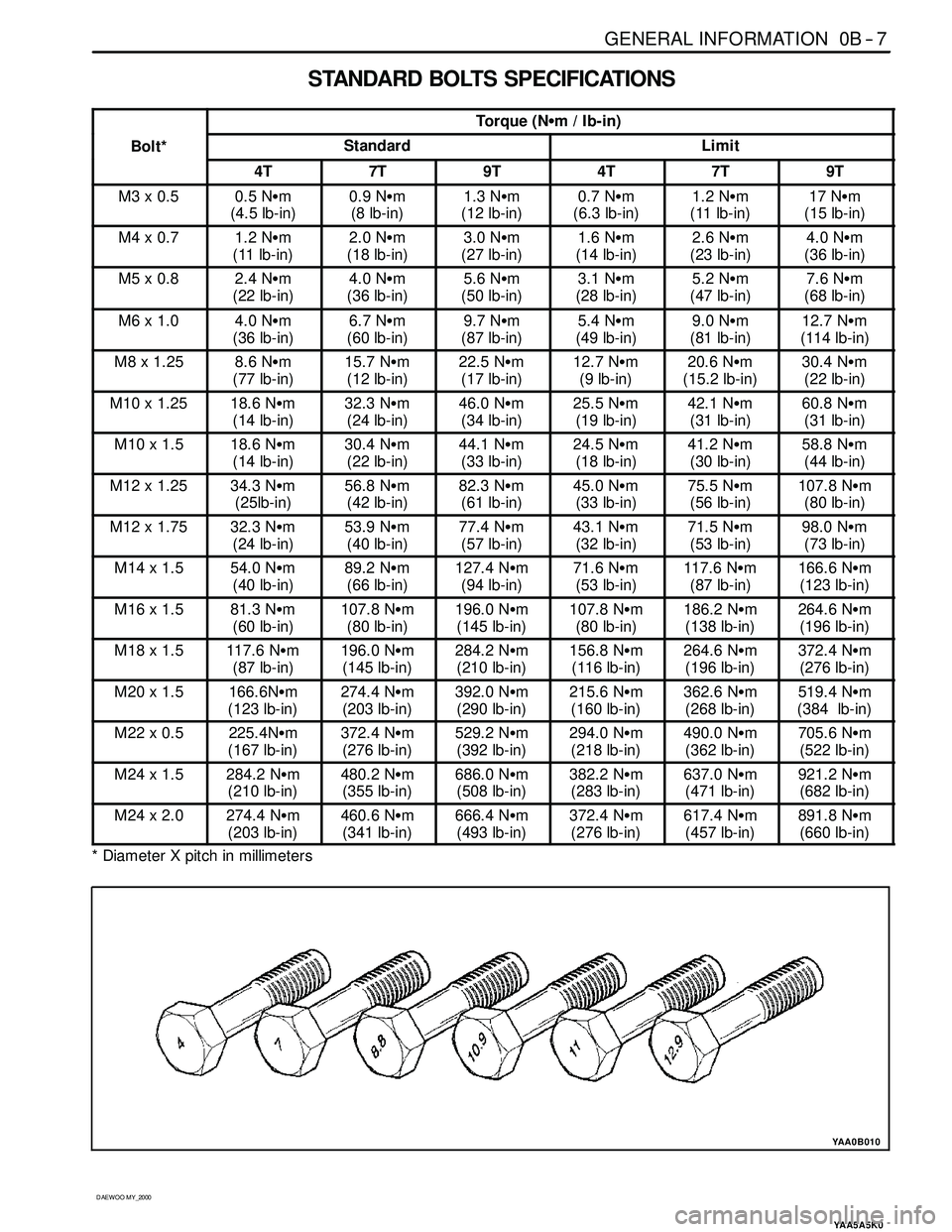

STANDARD BOLTSSPECIFICATIONS

Torque (NSm/Ib-in)

Bolt*StandardLimit

4T7T9T4T7T9T

M3 x 0.50.5 NSm

(4.5 lb-in)0.9 NSm

(8 lb-in)1.3 NSm

(12 lb-in)0.7 NSm

(6.3 lb-in)1.2 NSm

(11 lb-in)17 NSm

(15 lb-in)

M4 x 0.71.2 NSm

(11 lb-in)2.0 NSm

(18 lb-in)3.0 NSm

(27 lb-in)1.6 NSm

(14 lb-in)2.6 NSm

(23 lb-in)4.0 NSm

(36 lb-in)

M5 x 0.82.4 NSm

(22 lb-in)4.0 NSm

(36 lb-in)5.6 NSm

(50 lb-in)3.1 NSm

(28 lb-in)5.2 NSm

(47 lb-in)7.6 NSm

(68 lb-in)

M6 x 1.04.0 NSm

(36 lb-in)6.7 NSm

(60 lb-in)9.7 NSm

(87 lb-in)5.4 NSm

(49 lb-in)9.0 NSm

(81 lb-in)12.7 NSm

(114 lb-in)

M8 x 1.258.6 NSm

(77 lb-in)15.7 NSm

(12 lb-in)22.5 NSm

(17 lb-in)12.7 NSm

(9 lb-in)20.6 NSm

(15.2 lb-in)30.4 NSm

(22 lb-in)

M10 x 1.2518.6 NSm

(14 lb-in)32.3 NSm

(24 lb-in)46.0 NSm

(34 lb-in)25.5 NSm

(19 lb-in)42.1 NSm

(31 lb-in)60.8 NSm

(31 lb-in)

M10 x 1.518.6 NSm

(14 lb-in)30.4 NSm

(22 lb-in)44.1 NSm

(33 lb-in)24.5 NSm

(18 lb-in)41.2 NSm

(30 lb-in)58.8 NSm

(44 lb-in)

M12 x 1.2534.3 NSm

(25lb-in)56.8 NSm

(42 lb-in)82.3 NSm

(61 lb-in)45.0 NSm

(33 lb-in)75.5 NSm

(56 lb-in)107.8 NSm

(80 lb-in)

M12 x 1.7532.3 NSm

(24 lb-in)53.9 NSm

(40 lb-in)77.4 NSm

(57 lb-in)43.1 NSm

(32 lb-in)71.5 NSm

(53 lb-in)98.0 NSm

(73 lb-in)

M14 x 1.554.0 NSm

(40 lb-in)89.2 NSm

(66 lb-in)127.4 NSm

(94 lb-in)71.6 NSm

(53 lb-in)117.6 NSm

(87 lb-in)166.6 NSm

(123 lb-in)

M16 x 1.581.3 NSm

(60 lb-in)107.8 NSm

(80 lb-in)196.0 NSm

(145 lb-in)107.8 NSm

(80 lb-in)186.2 NSm

(138 lb-in)264.6 NSm

(196 lb-in)

M18 x 1.5117.6 NSm

(87 lb-in)196.0 NSm

(145 lb-in)284.2 NSm

(210 lb-in)156.8 NSm

(116 lb-in)264.6 NSm

(196 lb-in)372.4 NSm

(276 lb-in)

M20 x 1.5166.6NSm

(123 lb-in)274.4 NSm

(203 lb-in)392.0 NSm

(290 lb-in)215.6 NSm

(160 lb-in)362.6 NSm

(268 lb-in)519.4 NSm

(384 lb-in)

M22 x 0.5225.4NSm

(167 lb-in)372.4 NSm

(276 lb-in)529.2 NSm

(392 lb-in)294.0 NSm

(218 lb-in)490.0 NSm

(362 lb-in)705.6 NSm

(522 lb-in)

M24 x 1.5284.2 NSm

(210 lb-in)480.2 NSm

(355 lb-in)686.0 NSm

(508 lb-in)382.2 NSm

(283 lb-in)637.0 NSm

(471 lb-in)921.2 NSm

(682 lb-in)

M24 x 2.0274.4 NSm

(203 lb-in)460.6 NSm

(341 lb-in)666.4 NSm

(493 lb-in)372.4 NSm

(276 lb-in)617.4 NSm

(457 lb-in)891.8 NSm

(660 lb-in)

* Diameter X pitch in millimeters

YAA5A5K0

YAA0B010

Page 16 of 2053

0B -- 16 GENERAL INFORMATION

D AEW OO M Y_2000

GENERAL DESCRIPTION AND SYSTEM OPERATION

GENERAL REPAIR INSTRUCTIONS

DIf a floor jack is used, the following precautions are

recommended.

DPark the vehicle on level ground, “block” the front or

rear wheels, set the jack against the frame, raise the

vehicle and support it with chassis stands and then

perform the service operation.

DBefore performing the service operation, disconnect

the negative battery cable in order to reduce the

chance of cable damaged and burning due to short --

cir cuiting.

DUse a cover on the body, the seats and the floor to

protect them against damage and contamination.

DHandle brake fluid and antifreeze solution with care

as they can cause paint damage.

DThe use of proper tools, and the recommended es-

sential and available tools where specified, are impor-

tant for efficient and reliable performance of the

service repairs.

DUse genuine DAEWOO parts.DDiscard used cotter pins, gaskets, O -- rings, oil seals,

lock washers and self -- locking nuts. Prepare new

ones for installation. Normal function of these parts

cannot be maintained if these parts are reused.

DKeep the disassembled parts neatly in groups to facil-

itate proper and smooth reassembly.

DKeep attaching bolts and nuts separated, as they

vary in hardness and design depending on the posi-

tion of the installation.

DClean the parts before inspection or reassembly.

DAlso clean the oil parts, etc. Use compressed air to

make certain they are free of restrictions.

DLubricate rotating and sliding faces of parts with oil or

grease before installation.

DWhen necessary, use a sealer on gaskets to prevent

leakage.

DCarefully observe all specifications for bolt and nut

torques.

DWhen service operation is completed, make a final

check to be sure service was done properly and the

problem was corrected.

Page 22 of 2053

1A1 -- 2 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

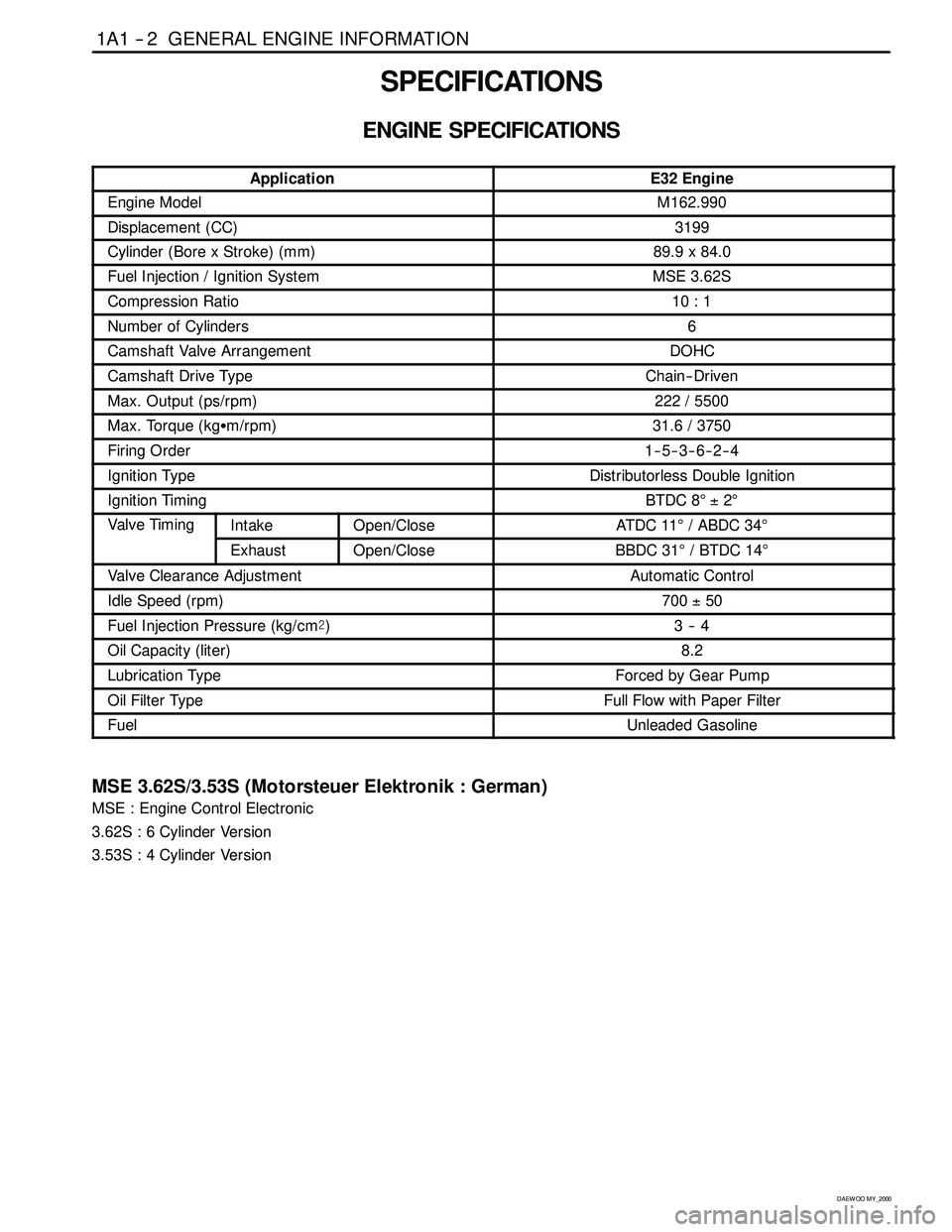

SPECIFICATIONS

ENGINE SPECIFICATIONS

ApplicationE32 Engine

Engine ModelM162.990

Displacement (CC)3199

Cylinder (Bore x Stroke)(mm)89.9 x 84.0

Fuel Injection / Ignition SystemMSE 3.62S

Compression Ratio10 : 1

Number of Cylinders6

Camshaft Valve ArrangementDOHC

Camshaft Drive TypeChain-- Driven

Max. Output (ps/rpm)222 / 5500

Max. Torque (kgSm/rpm)31.6 / 3750

Firing Order1--5--3--6--2--4

Ignition TypeDistributorless Double Ignition

Ignition TimingBTDC 8°±2°

Valve TimingIntakeOpen/CloseAT DC 11°/ ABDC 34°g

ExhaustOpen/CloseBBDC 31°/BTDC14°

Valve Clearance AdjustmentAutomatic Control

Idle Speed (rpm)700±50

Fuel Injection Pressure (kg/cm@)3--4

Oil Capacity (liter)8.2

Lubrication TypeForced by Gear Pump

Oil Filter TypeFull Flow with Paper Filter

FuelUnleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 Cylinder Version

3.53S : 4 Cylinder Version

Page 35 of 2053

M162 ENGINE MECHANICAL 1B1 -- 3

D AEW OO M Y_2000

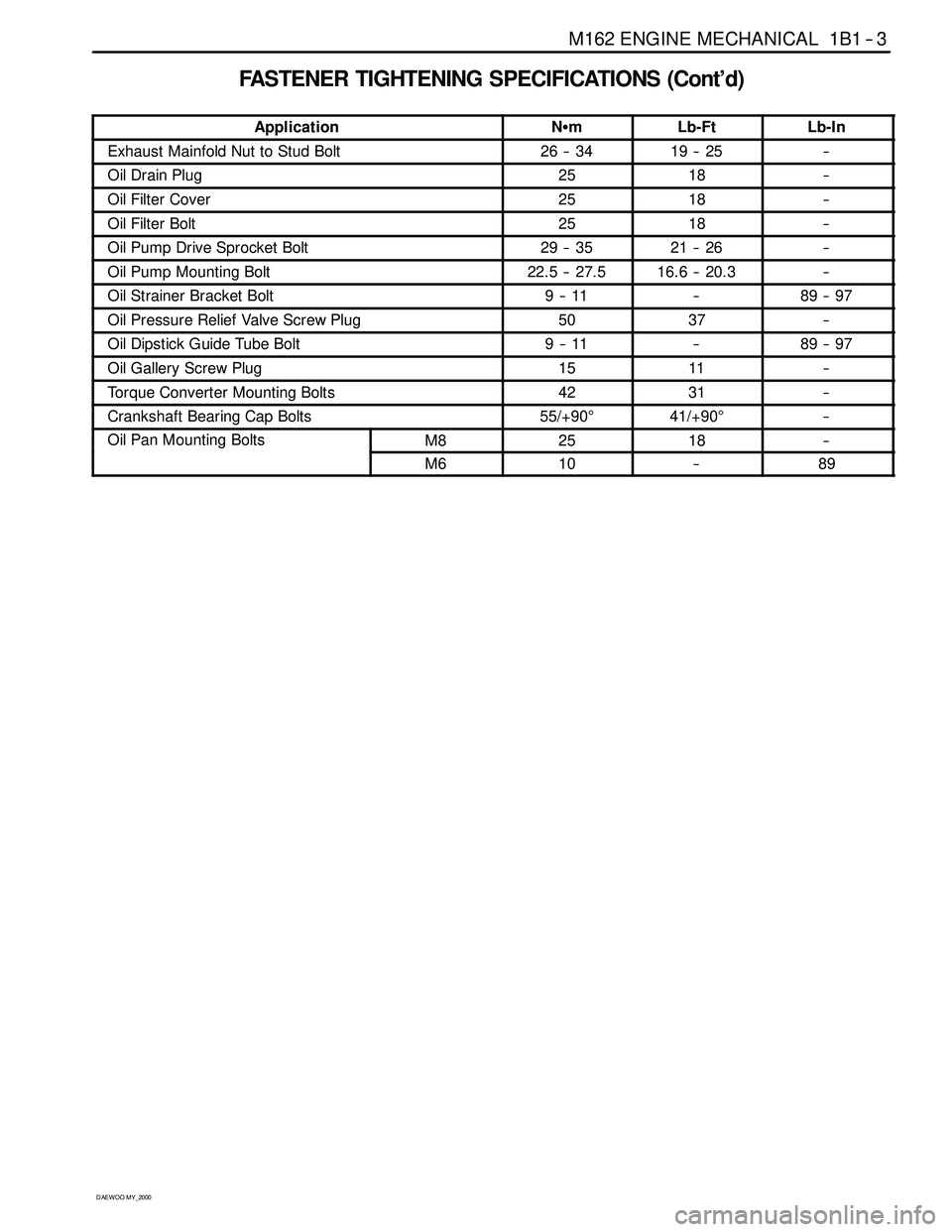

FASTENER TIGHTENING SPECIFICATIONS (Cont’d)

ApplicationNSmLb-FtLb-In

Exhaust Mainfold Nut to Stud Bolt26 -- 3419 -- 25--

Oil Drain Plug2518--

Oil Filter Cover2518--

Oil Filter Bolt2518--

Oil Pump Drive Sprocket Bolt29 -- 3521 -- 26--

Oil Pump Mounting Bolt22.5 -- 27.516.6 -- 20.3--

Oil Strainer Bracket Bolt9--11--89 -- 97

Oil Pressure Relief Valve Screw Plug5037--

Oil Dipstick Guide Tube Bolt9--11--89 -- 97

Oil Gallery Screw Plug1511--

Torque Converter Mounting Bolts4231--

Crankshaft Bearing Cap Bolts55/+90°41/+90°--

Oil Pan Mounting BoltsM82518--g

M610--89

Page 40 of 2053

1B1 -- 8 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

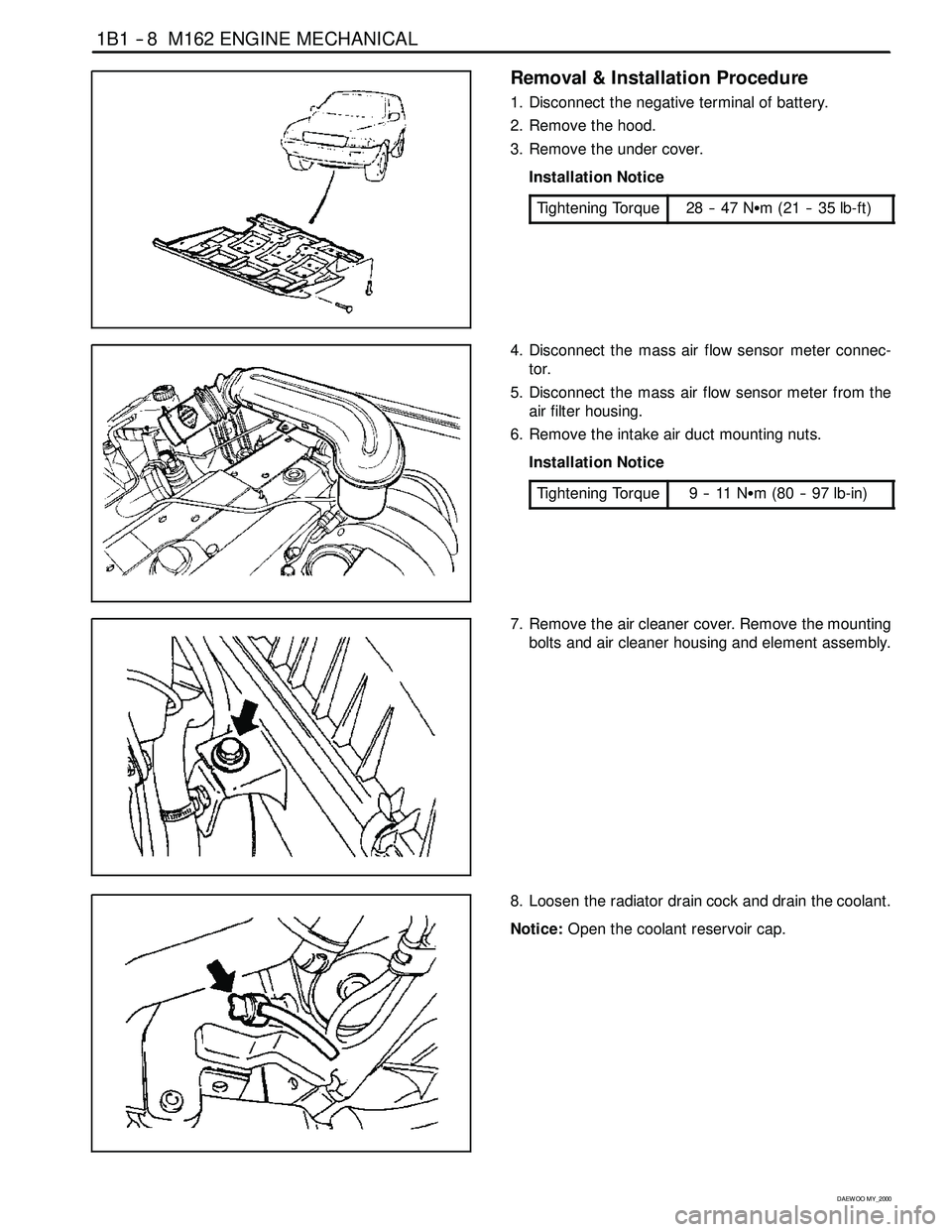

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque

28 -- 47 NSm (21 -- 35 lb-ft)

4. Disconnect the mass air flow sensor meter connec-

tor.

5. Disconnect the mass air flow sensor meter from the

air filter housing.

6. Remove the intake air duct mounting nuts.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

7. Remove the air cleaner cover. Remove the mounting

bolts and air cleaner housing and element assembly.

8. Loosen the radiator drain cock and drain the coolant.

Notice:Open the coolant reservoir cap.

Page 41 of 2053

M162 ENGINE MECHANICAL 1B1 -- 9

D AEW OO M Y_2000

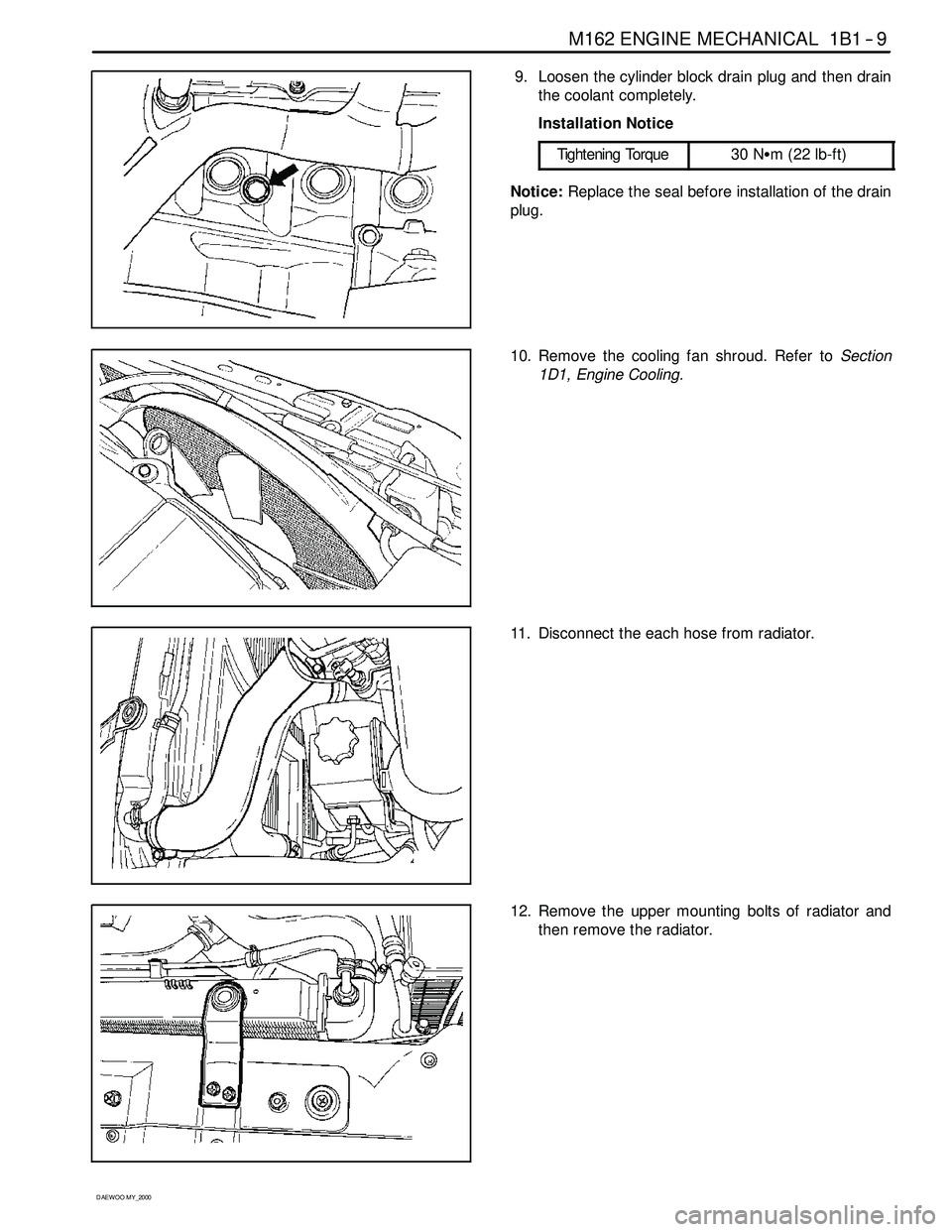

9. Loosen the cylinder block drain plug and then drain

the coolant completely.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

Notice:Replace the seal before installation of the drain

plug.

10. Remove the cooling fan shroud. Refer toSection

1D1, Engine Cooling.

11. Disconnect the each hose from radiator.

12. Remove the upper mounting bolts of radiator and

then remove the radiator.

Page 42 of 2053

1B1 -- 10 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

13. Remove the hydraulic pipe of power steering.

Notice:Completely drain the oil.

14. Discharge the refrigerant from A/C system, and dis-

connect the discharge pipe and suction pipe from

the compressor. Refer toSection 7B, Manual Con-

trol Heating, Ventilation, and Air Conditioning Sys -

tem.

15. Remove the fuel feed and return line.

Notice:Before removing the fuel lines, release the pres-

sure in the fuel system.

Installation Notice

Tightening Torque

21 -- 25 NSm (15 -- 18 lb-ft)

16. Disconnect the terminals from the generator.

Page 44 of 2053

1B1 -- 12 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

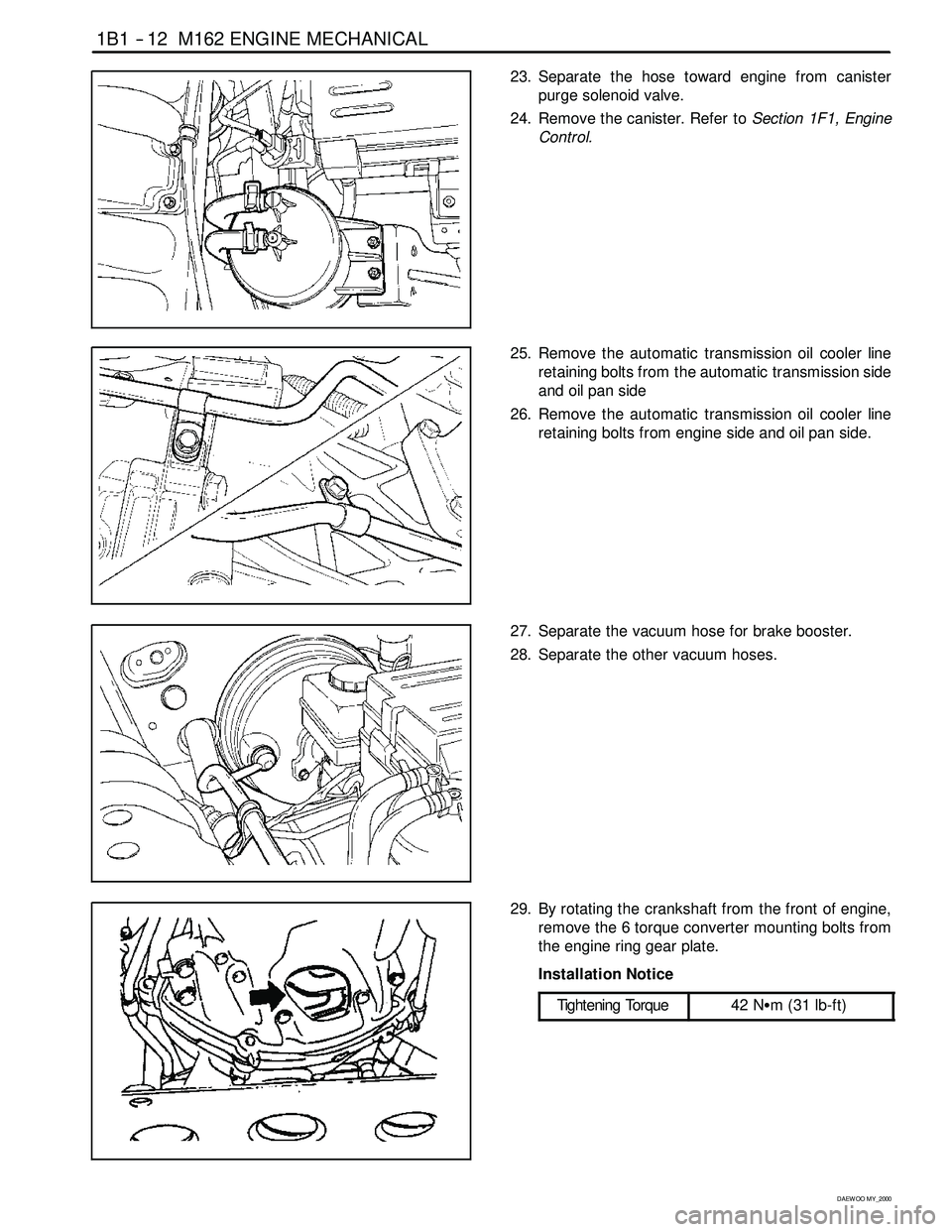

23. Separate the hose toward engine from canister

purge solenoid valve.

24. Remove the canister. Refer toSection 1F1, Engine

Control.

25. Remove the automatic transmission oil cooler line

retaining bolts from the automatic transmission side

and oil pan side

26. Remove the automatic transmission oil cooler line

retaining bolts from engine side and oil pan side.

27. Separate the vacuum hose for brake booster.

28. Separate the other vacuum hoses.

29. By rotating the crankshaft from the front of engine,

remove the 6 torque converter mounting bolts from

the engine ring gear plate.

Installation Notice

Tightening Torque

42 NSm (31 lb-ft)

Page 45 of 2053

M162 ENGINE MECHANICAL 1B1 -- 13

D AEW OO M Y_2000

30. Remove the exhaust manifold and exhaust pipe.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

31. Remove the transmission.Refer to Section 5A, Au-

tomatic Transmission.

32. Install a chain to the bracket of engine, by using a

hoist or crane.

33. Remove the engine mount nuts.

Installation Notice

Tightening Torque

70 NSm (52 lb-ft)

34. Carefully separate the engine assembly from the ve-

hicle.

35. Installation should follow the removal procedure in

the reverse order.