torque SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 71 of 2053

M162 ENGINE MECHANICAL 1B1 -- 39

D AEW OO M Y_2000

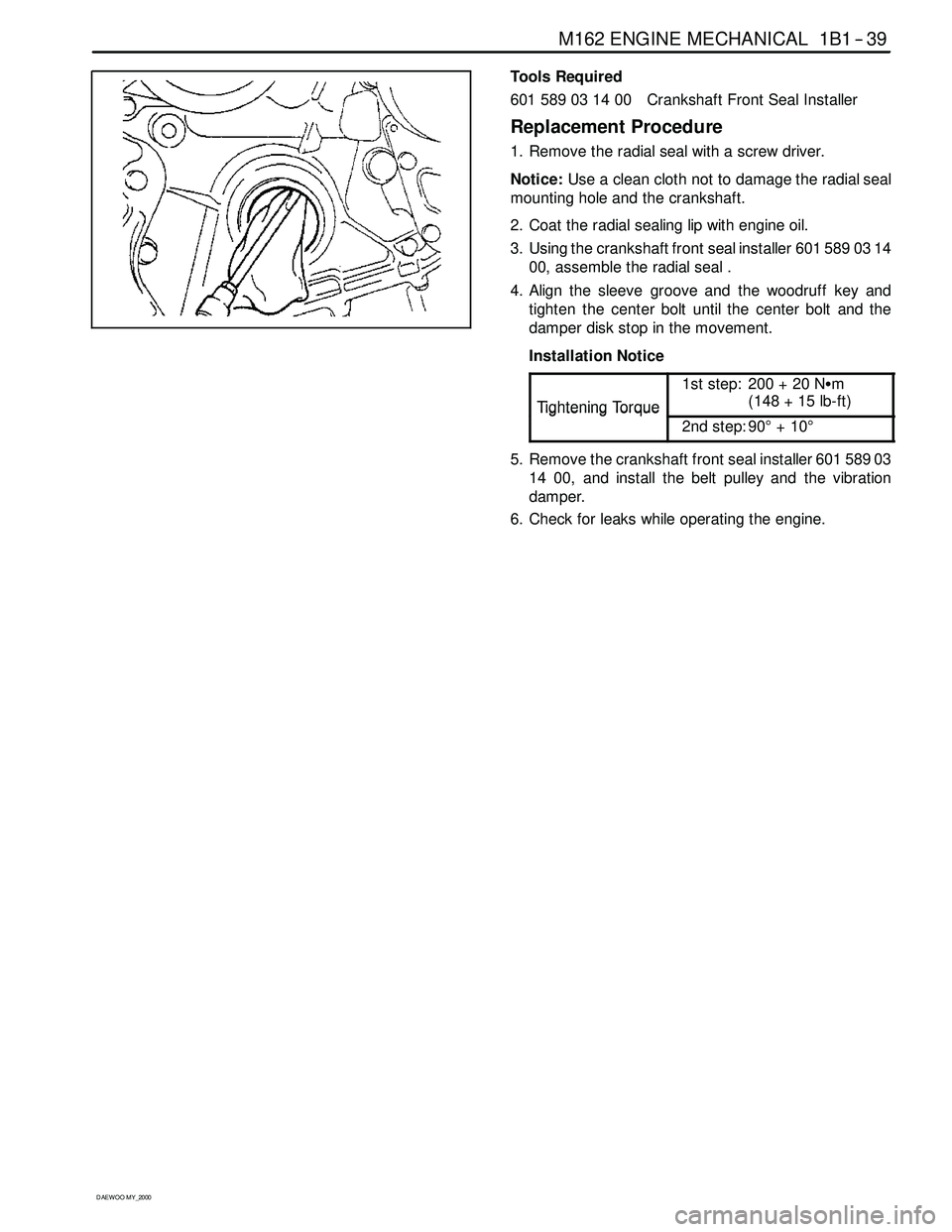

Tools Required

601 589 03 14 00 Crankshaft Front Seal Installer

Replacement Procedure

1. Remove the radial seal with a screw driver.

Notice:Use a clean cloth not to damage the radial seal

mounting hole and the crankshaft.

2. Coat the radial sealing lip with engine oil.

3. Using the crankshaft front seal installer 601 589 03 14

00, assemble the radial seal .

4. Align the sleeve groove and the woodruff key and

tighten the center bolt until the center bolt and the

damper disk stop in the movement.

Installation Notice

Ti

ghteningTo rque

1st step: 200 + 20 NSm

(148 + 15 lb-ft)

TighteningTorque

2nd step: 90°+10°

5. Remove the crankshaft front seal installer 601 589 03

14 00, and install the belt pulley and the vibration

damper.

6. Check for leaks while operating the engine.

Page 76 of 2053

1B1 -- 44 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

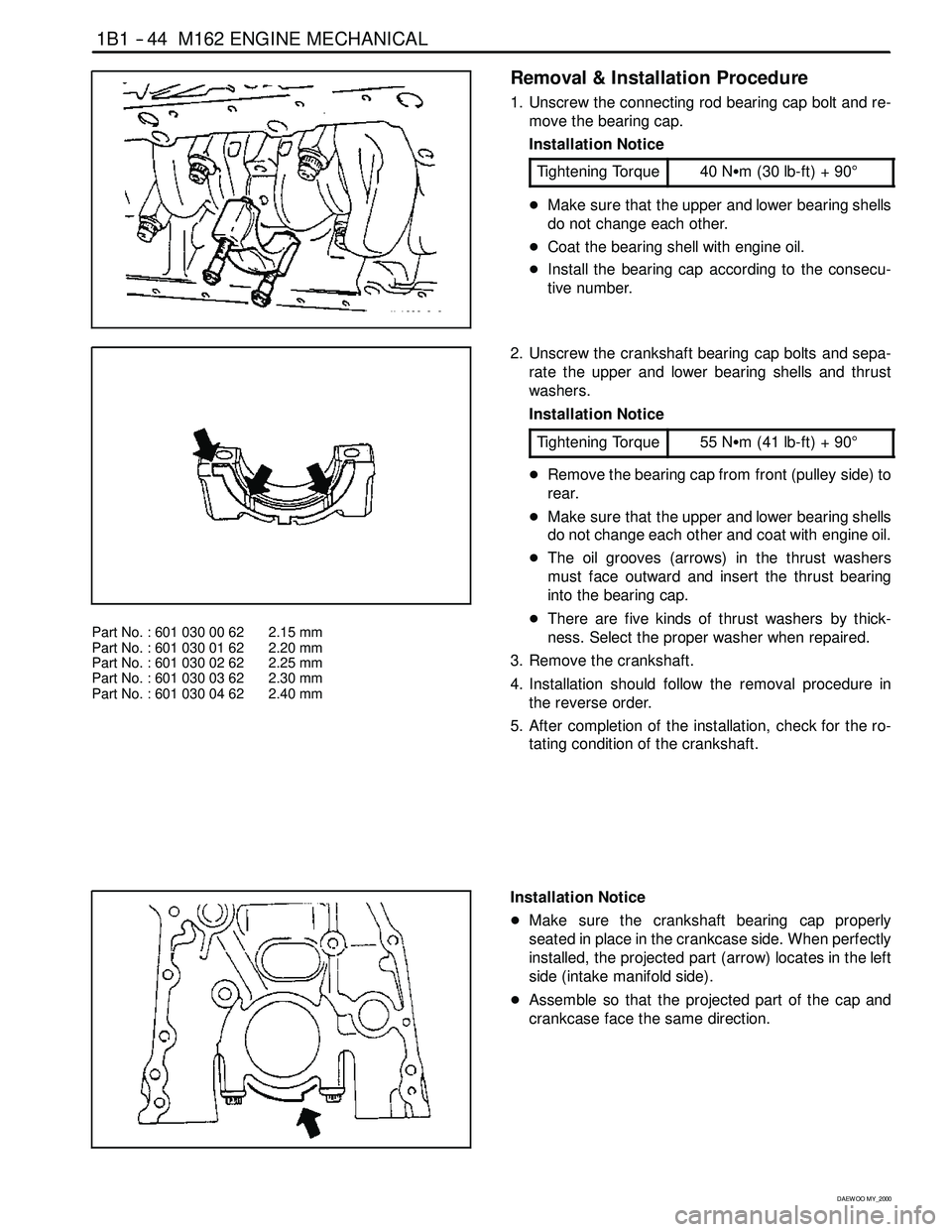

Removal & Installation Procedure

1. Unscrew the connecting rod bearing cap bolt and re-

move the bearing cap.

Installation Notice

Tightening Torque

40 NSm (30 lb-ft) + 90°

DMake sure that the upper and lower bearing shells

do not change each other.

DCoat the bearing shell with engine oil.

DInstall the bearing cap according to the consecu-

tive number.

Part No. : 601 030 00 62 2.15 mm

Part No. : 601 030 01 62 2.20 mm

Part No. : 601 030 02 62 2.25 mm

Part No. : 601 030 03 62 2.30 mm

Part No. : 601 030 04 62 2.40 mm

2. Unscrew the crankshaft bearing cap bolts and sepa-

rate the upper and lower bearing shells and thrust

washers.

Installation Notice

Tightening Torque

55 NSm (41 lb-ft) + 90°

DRemove the bearing cap from front (pulley side) to

rear.

DMake sure that the upper and lower bearing shells

do not change each other and coat with engine oil.

DThe oil grooves (arrows) in the thrust washers

must face outward and insert the thrust bearing

into the bearing cap.

DThere are five kinds of thrust washers by thick-

ness. Select the proper washer when repaired.

3. Remove the crankshaft.

4. Installation should follow the removal procedure in

the reverse order.

5. After completion of the installation, check for the ro-

tating condition of the crankshaft.

Installation Notice

DMake sure the crankshaft bearing cap properly

seated in place in the crankcase side. When perfectly

installed, the projected part (arrow) locates in the left

side (intake manifold side).

DAssemble so that the projected part of the cap and

crankcase face the same direction.

Page 79 of 2053

M162 ENGINE MECHANICAL 1B1 -- 47

D AEW OO M Y_2000

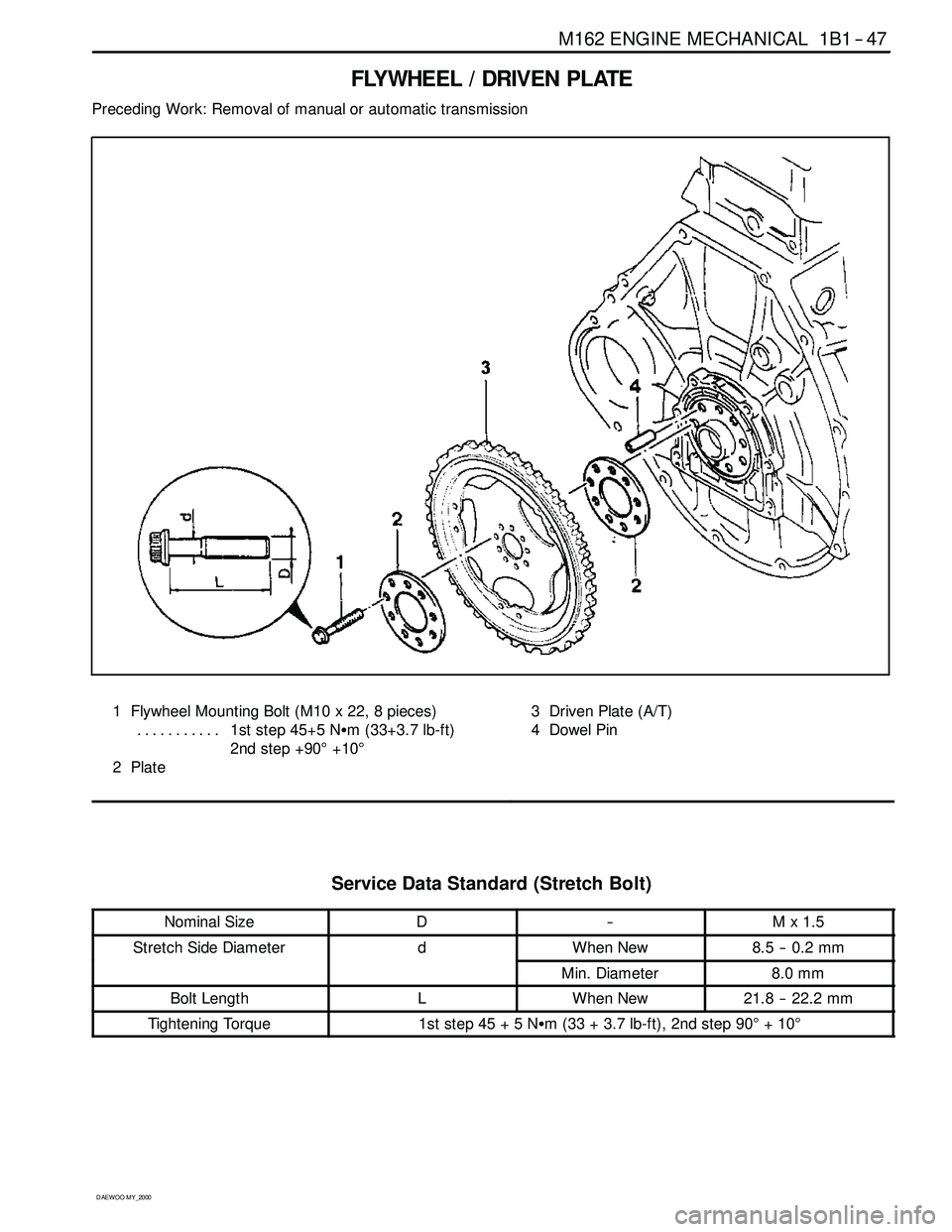

FLYWHEEL / DRIVEN PLATE

Preceding Work: Removal of manual or automatic transmission

1 Flywheel Mounting Bolt (M10 x 22, 8 pieces)

1st step 45+5 NSm (33+3.7 lb-ft) ...........

2nd step +90°+10°

2Plate3 Driven Plate (A/T)

4 Dowel Pin

Service Data Standard (Stretch Bolt)

Nominal SizeD--Mx1.5

Stretch Side DiameterdWhen New8.5 -- 0.2 mm

Min. Diameter8.0 mm

Bolt LengthLWhen New21.8 -- 22.2 mm

Tightening Torque1ststep45+5NSm (33 + 3.7 lb-ft), 2nd step 90°+10°

Page 80 of 2053

1B1 -- 48 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

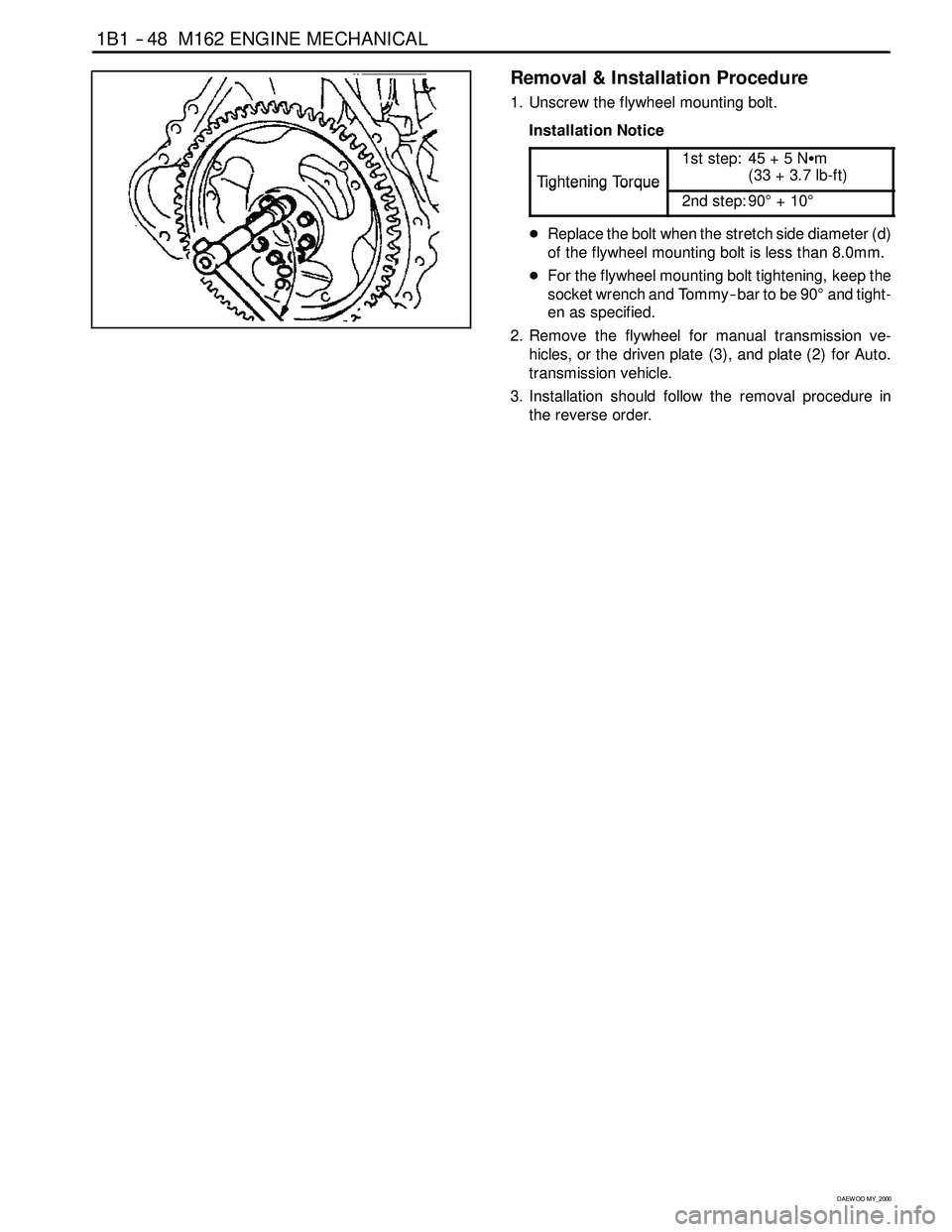

Removal & Installation Procedure

1. Unscrew the flywheel mounting bolt.

Installation Notice

Ti

ghteningTo rque

1st step: 45 + 5 NSm

(33+3.7lb-ft)

TighteningTorque

2nd step: 90°+10°

DReplace the bolt when the stretch side diameter (d)

of the flywheel mounting bolt is less than 8.0mm.

DFor the flywheel mounting bolt tightening, keep the

socket wrench and Tommy -- bar to be 90°and tight-

en as specified.

2. Remove the flywheel for manual transmission ve-

hicles, or the driven plate (3), and plate (2) for Auto.

transmission vehicle.

3. Installation should follow the removal procedure in

the reverse order.

Page 83 of 2053

M162 ENGINE MECHANICAL 1B1 -- 51

D AEW OO M Y_2000

Removal & Installation Procedure

1. Turn the crankshaft to the direction of engine rotation

and position the no.1 cylinder piston at TDC which the

camshaft is positioned at OT.

2. Remove the cylinder head front cover.

3. Paint the alignment marks (arrows) on the intake and

exhaust camshaft sprocket and the timing chain.

3 Bolt 13 Camshaft Sprocket

4 Amarture 18 Control Piston

6 Nut (M20 x 1.5) 22 Intake Camshaft

12 Seal Cover

4. Unscrew the bolt (3) from the armature (4) and re-

move the armature.

Installation Notice

Tightening Torque

35 NSm (26 lb-ft)

5. Unscrew the nut (6) and remove the ring and seal

cover (11).

Installation Notice

Tightening Torque

60 -- 70 NSm (44 -- 52 lb-ft)

6. Unscrew the sprocket bolt from the exhaust camshaft

and remove the sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so always replace with new one.

Page 84 of 2053

1B1 -- 52 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

7. Remove the camshaft sprocket (13) and adjust piston

(14), and remove the flange shaft (16) from the intake

camshaft (22) after removing the bolt (15).

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so always replace with new one.

8. Installation should follow the removal procedure in

the reverse order.

9. Adjust the camshaft timing.

CAMSHAFT SPROCKET BOLT

Intake Flange Shaft Bolt

TighteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The sprocket bolts are designed to be used only

once, so always replace with new one.

C. M7 x 13 Collar Bolt Torx -- T30

e. 6.8 mm

16. Flange Shaft

18. Control Piston

22. Intake Camshaft

Page 85 of 2053

M162 ENGINE MECHANICAL 1B1 -- 53

D AEW OO M Y_2000

Exhaust Camshaft Sprocket Bolt

TighteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The sprocket bolts are designed to be used only

once, so always replace with new one.

E. M7 x 13 Collar Bolt Torx -- T30

e. 6.8 mm

13a. Camshaft Sprocket

22a. Exhaust Camshaft

Page 88 of 2053

M162 ENGINE MECHANICAL 1B1 -- 61

D AEW OO M Y_2000

10. Install the chain to the exhaust camshaft sprocket

and install it to the camshaft.

Installation Notice (Sprocket Bolt)

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so replace with new one.

11. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

12. Check the camshaft timing.

Page 90 of 2053

M162 ENGINE MECHANICAL 1B1 -- 63

D AEW OO M Y_2000

Tools Required

111 589 01 59 00 Supporting Bar

111 589 18 61 00 Lever Pusher

111 589 25 63 00 Thrust Piece

602589004000 EngineLock

DW110-- 090 Connecting Hose

DW110-- 100 Valve Tappet Remover

Removal & Installation Procedure

1. Place the supporting bar 111 589 01 59 00 (a) at the

camshaft bearing cap and tighten them with the bear-

ing cap bolt.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

2. Turn the crankshaft to position the each cylinder pis-

ton at TDC.

Mark on The Vibration Damper

Cylinder

OT1, 6

120°2, 5

240°3, 4

Notice

DRemove the valve spring only at TDC.

DAlways rotate the crankshaft by holding the chain to

prevent from timing chain damage and tangling, and

for smooth rotation.

Page 95 of 2053

1B1 -- 68 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

4. Carefully unscrew the screw plug (1), and remove the

seal (2).

Notice

DFor the removal of screw plug, be careful that it can

be jumped out due to the force of compression

spring.

DRemove the screw plug only when the seal and com-

pression spring are damaged.

5. Carefully remove the filler pin (3), compression spring

(4), snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal

(8).

Installation Procedure

1. Connect the thrust pin (6) and the snap ring (5) to the

chain tensioner housing (7).

Notice:When connecting the thrust pin, push in the

thrust pin far enough so that it doesn’t protrude at the

chain tensioner housing.

2. Install the chain tensioner housing (7), thrust pin (6),

snap ring (5), and the seal (8).

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

3. Insert the compression spring (4) with the filler pin (3)

into chain tensioner housing.