torque SSANGYONG KORANDO 1997 Service Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 121 of 2053

M162 ENGINE MECHANICAL 1B1 -- 95

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the bolt (1) from the oil pump drive sprocket

(2) and separate the gear and the oil pump drive

chain.

Installation Notice

Tightening Torque

29 -- 35 NSm (21 -- 26 lb-ft)

2. Unscrew the oil pump mounting bolts (3).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Tighten the baffle plate and the oil pump with the two

bolts in right side first, and then tighten the other bolt.

3. Remove the oil pump and oil strainer assembly.

4. Replace the strainer in oil pump if necessary.

5. Installation should follow the removal procedure in

the reverse order.

Page 122 of 2053

1B1 -- 96 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

OIL PRESSURE RELIEF VALVE

Preceding Work: Removal of oil pan

1 Screw Plug 50 NSm (37 lb-ft) ................

2 Compression Spring3 Guide Pin

4Piston

Removal & Installation Procedure

1. Remove the screw plug (1).

Installation Notice

Tightening Torque

50 NSm (37 lb-ft)

2. Remove the spring (2), guide pin (3) and the piston

(4).

3. Installation should follow the removal procedure in

the reverse order.

Notice:Don’t use the seal for the screw plug.

Page 124 of 2053

1B1 -- 98 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

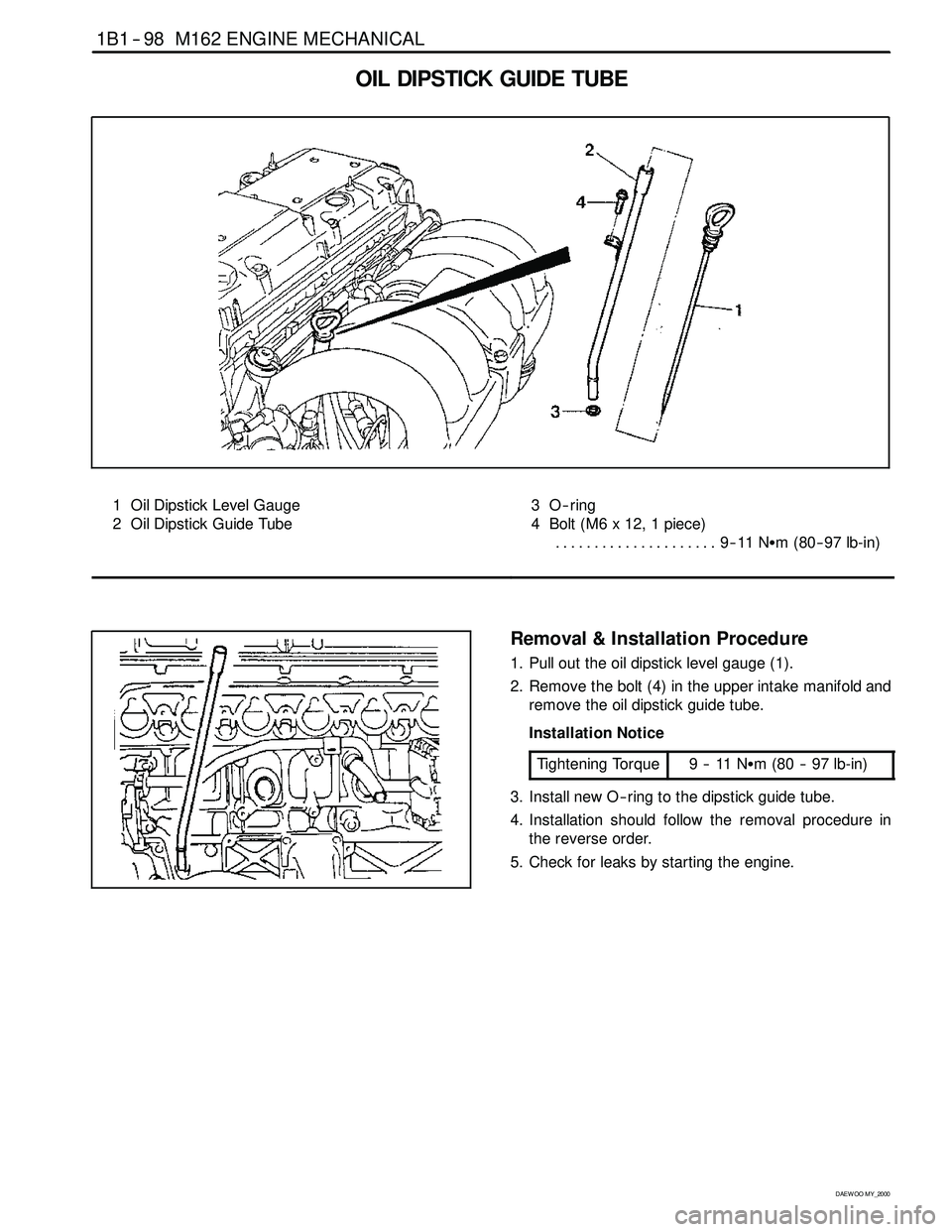

OIL DIPSTICK GUIDE TUBE

1 Oil Dipstick Level Gauge

2 Oil Dipstick Guide Tube3O--ring

4 Bolt (M6 x 12, 1 piece)

9--11 NSm (80-- 97 lb-in) .....................

Removal & Installation Procedure

1. Pull out the oil dipstick level gauge (1).

2. Remove the bolt (4) in the upper intake manifold and

remove the oil dipstick guide tube.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

3. Install new O -- ring to the dipstick guide tube.

4. Installation should follow the removal procedure in

the reverse order.

5. Check for leaks by starting the engine.

Page 128 of 2053

1B1 -- 102 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Cleaning Procedure

1. Remove the screw plug (1) and the seal (2).

Installation Notice

Tightening Torque

15 NSm (11 lb-ft)

Replace the seal with new one.

2. Clean the oil gallery using the compressed air.

Sealing Procedure

1. Remove the screw plug (1) and the seal.

Installation Notice

Tightening Torque

15 NSm (11 lb-ft)

2. Remove the steel ball from the oil gallery (4), (5), (6)

and (7) using the round bar (12,φ6 x 700 mm).

3. Remove the plug (8) using the screw driver.

Page 141 of 2053

M162 ENGINE COOLING 1D1 -- 5

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

COOLANT DRAIN AND FILL UP

Draning & Filling up Procedure

1. Loosen the cap a little and release pressure and re-

move the cap.

Notice:For the risk of scalding, the cap must not be

opened unless the coolant temperature is below 90°C.

2. Loosen the radiator lower drain cock and drain the

coolant.

Notice:Collect the coolant by using a proper container.

3. Drain the coolant from the crankcase by inserting a

hose (dia. 14mm) onto the drain bolt on the side of

crankcase (exhaust manifold) and by loosening the

plug.

Notice

DJust loosen the drain plug to drain the coolant and do

not remove the plug completely.

DCollect the coolant by using the proper container.

4. After complete draining of the coolant, remove the

hose connector to drain plug and reinstall the drain

plug.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

5. Tighten the radiator lower drain cock.

Page 143 of 2053

M162 ENGINE COOLING 1D1 -- 7

D AEW OO M Y_2000

COOLANT CONNECTION FITTING

Preceding Work: Removal of cooling fan shroud

1 Bolt (M8 X 100, 2 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

2 Engine Hanger Bracket

3 Coolant Outlet Port4O--ring

5 Hose Mounting Clamp

6Hose

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the hose mounting clamp (5) and disconnect

the coolant hose (6).

3. Remove the two bolts (1), the engine hanger bracket

(2) and coolant outlet port (3).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Replace the O -- ring with new one.

4. Installation should follow the removal procedure in

the reverse order.

5. Fill up the coolant as specified.

6. Check the leaks in the cooling system.

Page 145 of 2053

M162 ENGINE COOLING 1D1 -- 9

D AEW OO M Y_2000

Removal & Installation Procedure

1. Drain the coolant.

2. Disconnect the water pump wire connector.

3. Loosen the hose clip and dsconnect all hoses from

the water pump.

4. Remove the oil cooler pipe line bolts (4) and then re-

move the coolant line (2).

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Replace the seal (3).

5. Remove the mounting bolts (11) and carefully pull out

water pump (10).

Installation Notice

Tightening Torque

21 NSm (15 lb-ft)

Notice:Replace the seal (13).

6. Installation should follow the removal procedure in

the reverse order.

7. Fill up coolant.

8. Do coolant system leakage test.

Page 146 of 2053

1D1 -- 10 M162 ENGINE COOLING

D AEW OO M Y_2000

THERMOSTAT

1 Thermostat Cover

2 Thermostat

3O--ring

4 Thermostat Cover Bracket5 Bolt (M6 X 25, 3 pieces)

9--11 NSm (80-- 97 lb-in) .....................

6 Hose Mounting Clamp

7HeaterHose

Removal & Installation Procedure

1. Drain the coolant from the radiator.

2. Loosen the hose mounting clamp (6) and remove the

heater hose (7).

3. Unscrew the three bolts (5) and remove the thermo-

stat cover bracket, thermostat cover and the thermo-

stat in order.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Do not separate the thermostat cover and thermo-

stat.

4. Replace the O -- ring if necessary.

5. Check the leakage in the cooling system.

Page 147 of 2053

M162 ENGINE COOLING 1D1 -- 11

D AEW OO M Y_2000

OIL COOLER PIPE LINE

Preceding Work: Removal of intake air duct

1 Bolt (M6 X 35, 1 piece)

9--11 NSm (80-- 97 lb-in) .....................

2 Bolt (M6 X 16, 2 pieces)

9--11 NSm (80-- 97 lb-in) .....................3 Oil Cooler Pipe Line

4 O -- ring Replace............................

Removal & Installation Procedure

1. Drain the coolant.

2. Unscrew the bolts (1, 2) and remove the oil cooler

pipe line (3).

Replace the O -- ring with new one.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

3. Installation should follow the removal procedure in

the reverse order.

4. Fill up the coolant as specified.

5. Check the leaks in the cooling system.

Page 149 of 2053

M162 ENGINE COOLING 1D1 -- 13

D AEW OO M Y_2000

Tools Required

603 589 00 40 00 Fan Clutch Holder

1. Remove the engine hanger bracket bolts.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

2. Remove the engine hanger bracket.

3. Remove the cooling fan bolts.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

4. Hold the cooling fan pulley using the fan clutch holder

603 589 00 40 00.

5. Remove the viscous clutch mounting bolts and vis-

cous clutch.

Installation Notice

Tightening Torque

40.5 -- 49.5 NSm

(29.8 -- 36.5 lb-ft)

Important:There are two chambers in the viscous

clutch. Be sure to make the viscous clutch stand on the

ground not to flow silicone oil into another chamber in

the viscous clutch. Do not lay down the clutch.

6. Installation should follow the removal procedure in

the reverse order.