key SSANGYONG KORANDO 1997 Service Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1343 of 2053

MANUAL TRANSMISSION 5B-35

SSANGYONG MY2002

6. Remove the 2nd speed gear, bearing and spacer.

YAD5B880

YAD5B890

YAD5B910

YAD5B900

7. Using a screwdriver, remove the spiral retaining

ring.

8. Remove the thrust washer and three-piece 2nd

speed blocking ring assembly.

9. For correct reassembly, place an alignment mark

on the 1-2 synchronizer hub and sleeve.

10. Remove the 1-2 synchronizer sleeve from the hub

with following parts :

The anti-rattle ball and spring.

The three keys.

One of the 3 springs.

Page 1345 of 2053

MANUAL TRANSMISSION 5B-37

SSANGYONG MY2002

YAD5B960

YAD5B970

YAD5B990

15. Remove the tree-piece 1st speed blocking ring

assembly and remaining synchronizer spring.

16. Check and clean all removed parts and replace if

necessary.

Assembly Procedure

1. When assemble the synchronizer, make sure that

the hubs and sleeves are matched and the 3 keys

are installed properly. Also align blocking rings

with keys during installation.

Notice: Before assembly, coat all parts with

lubricant. In case of the paper-lined blocking rings,

soak them in DexronII/III before installation.

2. Assemble the following parts :

1st speed blocking ring.

Alignment pin and 1st speed gear bearing race.

1st speed gear and its bearing.

3. Install the rear bearing assembly to the main shaft.

YAD5B980

4. Using a hydraulic press and installer, press the

5th driven gear onto the main shaft. While the

main shaft is still on the press bed, install the 5th

driven gear snap ring. If the snap ring does not fit

completely, continue pressing the 5th driven gear.

Page 1346 of 2053

SSANGYONG MY2002

5B-38 MANUAL TRANSMISSION

5. Install the following parts :

2nd speed blocking ring assembly.

Thrust washer for the blocking ring inner cone.

Spiral retaining ring (Use special tools).

2nd speed gear spacer, bearing and gear.

2nd gear thrust washer and snap ring.

3rd speed gear spacer, bearing and gear.

3rd speed blocking ring.

YAD5B0A0

YAD5B0B0

YAD5B0D0

YAD5B0C0

6. Using a hydraulic press and installer, install the

3-4 synchronizer hub onto the main shaft.

Notice: Align the blocking ring with the

synchronizer keys while installing the hub.

INPUT SHAFT

Disassembly Procedure

1. Remove the following parts from the input shaft :

Main shaft thrust race and bearing.

Main shaft pilot bearing rollers (15 rollers).

2. Using a hydraulic press and puller plate, remove

the input shaft bearing assembly from the shaft.

Page 1382 of 2053

SSANGYONG MY2002

5D1-12 TRANSFER CASE

Both Speed Sensor Faulty

If both the front and rear speed sensors are faulty con

tinuously for 0.5 seconds the 4WD CHECK lamp is

illuminated. The TCCU then responds as follows:

1. If the system is in high range the TCCU sets the

EMC touch off level based on a vehicle speed of

0 and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum until the system is shifted out

of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

If both speed sensors recover continuously for 0.5 sec-

ond the TCCU will function normally. The 4WD CHECK

lamp is turned off but the fault code will remain in

memory.

Electro-Magnetic Clutch Test

The electromagnetic clutch (EMC) is tested for open

circuit or short circuit to ground. If a fault is detected

continuously for 0.8 second the 4WD CHECK lamp is

turned on and all TODTM activity is halted.

If the EMC recovers continuously for 0.8 second the

TCCU will function normally. The 4WD CHECK lamp is

turned off but the fault code will remain in memory.

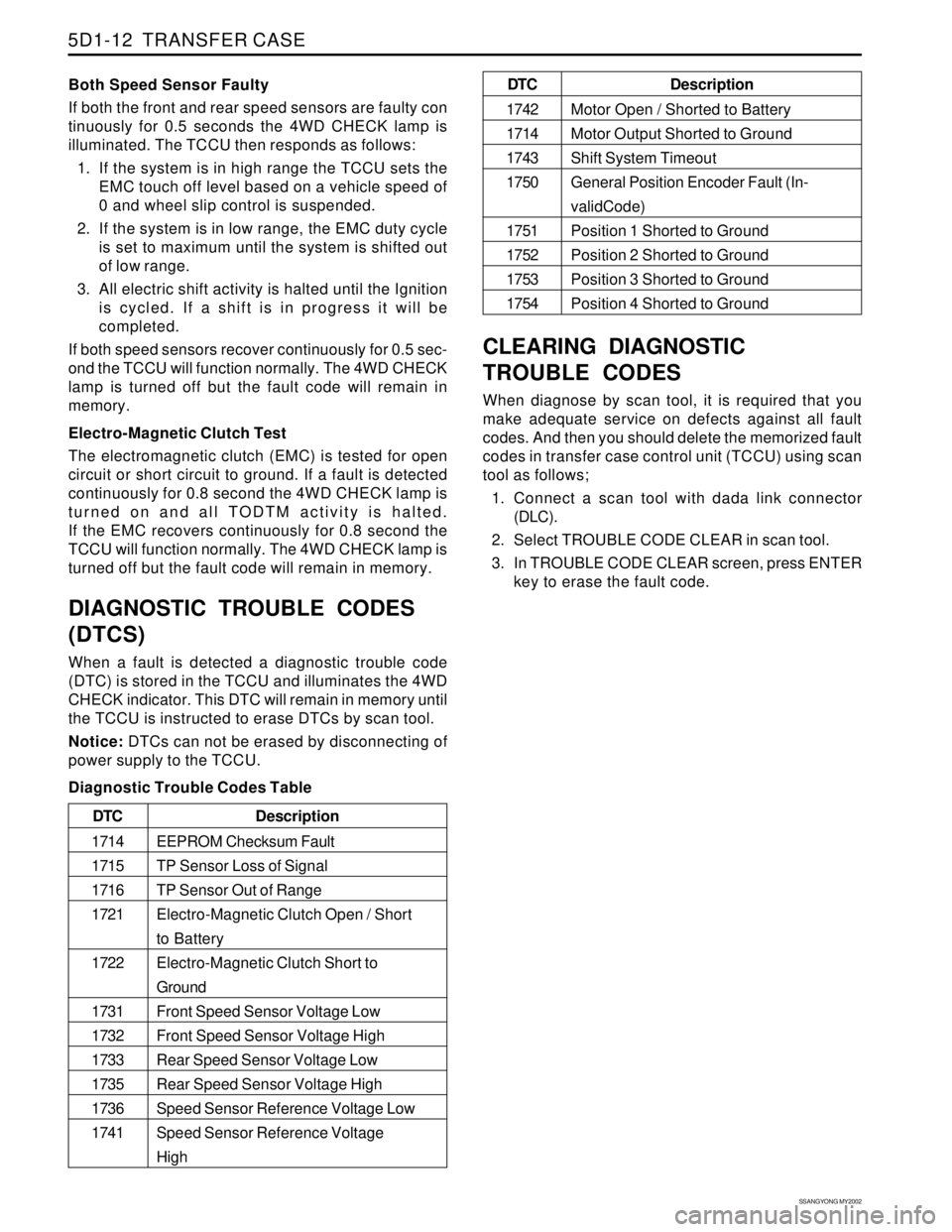

DIAGNOSTIC TROUBLE CODES

(DTCS)

When a fault is detected a diagnostic trouble code

(DTC) is stored in the TCCU and illuminates the 4WD

CHECK indicator. This DTC will remain in memory until

the TCCU is instructed to erase DTCs by scan tool.

Notice: DTCs can not be erased by disconnecting of

power supply to the TCCU.

Diagnostic Trouble Codes Table

CLEARING DIAGNOSTIC

TROUBLE CODES

When diagnose by scan tool, it is required that you

make adequate service on defects against all fault

codes. And then you should delete the memorized fault

codes in transfer case control unit (TCCU) using scan

tool as follows;

1. Connect a scan tool with dada link connector

(DLC).

2. Select TROUBLE CODE CLEAR in scan tool.

3. In TROUBLE CODE CLEAR screen, press ENTER

key to erase the fault code.

Description

EEPROM Checksum Fault

TP Sensor Loss of Signal

TP Sensor Out of Range

Electro-Magnetic Clutch Open / Short

to Battery

Electro-Magnetic Clutch Short to

Ground

Front Speed Sensor Voltage Low

Front Speed Sensor Voltage High

Rear Speed Sensor Voltage Low

Rear Speed Sensor Voltage High

Speed Sensor Reference Voltage Low

Speed Sensor Reference Voltage

High DTC

1714

1715

1716

1721

1722

1731

1732

1733

1735

1736

1741

Description

Motor Open / Shorted to Battery

Motor Output Shorted to Ground

Shift System Timeout

General Position Encoder Fault (In-

validCode)

Position 1 Shorted to Ground

Position 2 Shorted to Ground

Position 3 Shorted to Ground

Position 4 Shorted to Ground DTC

1742

1714

1743

1750

1751

1752

1753

1754

Page 1487 of 2053

SECTION 6E

POWER STEERING AND COLUMN

TABLE OF CONTENTS

Description and Operation...................................6E-2

General Description.............................................6E-2

Ignition Switch Keyhole Lamp..............................6E-2

Ignition Key Reminder .........................................6E-2

Component Locator.............................................6E-3

Diagnostic Information and Procedures..............6E-4

Steering Wheel Freeplay Inspection.....................6E-4

Steering Effort Inspection.....................................6E-4

Steering Column Diagnosis..................................6E-5

Repair Instructions................................................6E-9On-Vehicle Service.................................................6E-9

Headlamp/Turn Signal Switch and Lever...............6E-9

Wiper Switch and Lever.....................................6E-10

Steering Wheel With Sir.....................................6E-10

Ignition Lock Cylinder and Switch......................6E-11

Steering Column................................................6E-12

Specifications.....................................................6E-14

Fastener Tightening Specifications.....................6E-14

Special Tools and Equipment............................6E-15

Special Tools Table............................................6E-15

Page 1488 of 2053

SSANGYONG MY2002

6E-2 POWER STEERING AND COLUMN

GENERAL DESCRIPTION

Caution: To ensure the energy-absorbing action of

the steering column, it is important to use only the

specified screws, bolts, and nuts, tightened to the

specified torque.

In addition to the steering function, the steering column

provides safety and security.

The energy-absorbing column is designed to compress

in a front-end collision to lessen the chance of driver

injury.

The ignition switch and the lock are mounted on the

column, allowing the ignition and steering operations

to be locked to inhibit theft of the car.

The column levers trigger the turn signals, the headlight

beams, and the windshield washer and wipers.

A tilt steering column uses a spherical joint to allow

the steering wheel to tilt up and down. This enables

the driver to adjust the steering wheel to a comfortable

position.

Notice: Apply a thin coat of lithium grease to all friction

points when reassembling.

The column may be disassembled and reassembled

easily.

DESCRIPTION AND OPERATION

IGNITION SWITCH KEYHOLE LAMP

For description and lamp replacement information, Re-

fer to Section 9B, Lighting Systems.

IGNITION KEY REMINDER

The ignition key reminder alerts the driver that the key

is still in the ignition when the driver attempts to exit

the vehicle.

An internal switch in the ignition lock cylinder supplies

battery voltage to the reminder chime module when all

of the following conditions are true:

•The key is in the ignition switch.

The ignition is OFF.

The driver’s door is open.

For information on removal and installation of the re-

minder chime module, Refer to Section 9E, Instrumen-

tation/Driver Information.

Page 1497 of 2053

POWER STEERING AND COLUMN 6E-11

SSANGYONG MY2002

KAA6E040

KAA6E100

KAA6E090

4. Remove the steering wheel using the steering

wheel puller 661 589 00 33 00.

Installation Notice:

Align the match marks on the steering wheel

and the steering column shaft.

IGNITION LOCK CYLINDER AND

SWITCH

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower steering column

cover screws.

3. Remove the upper and the lower steering column

cover.

4. Remove the screws for illumination keyhole

connection.

5. With the key in the ignition turned to the position

designated ACC, remove the lock cylinder by

pressing down the detent spring with a 2.5 mm

allen wrench or other suitable tool, and pulling the

lock cylinder out of the cylinder housing.

Page 1581 of 2053

SEAT BELTS 8A-5

SSANGYONG MY2002

�� ��

��

yy yy

yy

ON-VEHICLE SERVICE

THREE-POINT FRONT SEAT BELT

WITH PRETENSIONER

Caution: the sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the air-

bags and pretensioner for 0.15 minutes after the

ignition is OFF and the fuse has been removed. If

the airbags or pretensioners are not disconnected,

do not begin service until one minute has passed

after disconnecting power to the SDM. Otherwise,

injury could result.

Removal and installation Procedure

1. Turn the ignition switch to LOCK and remove the

key.

2. Remove the plastic cap to reveal the lower B-pillar

seat belt anchor.

3. Remove the bolt and the lower B-pillar seat belt

anchor.

Installation Notice

KAA8A030

KAA8A040

4. Remove the lower quarter trim panel. Refer to Sec-

tion 9G, Interior Trim.

5. Disconnect the pretensioner connector.

6. Remove the bolt, screw and the seat belt retractor

(pretensioner).

Installation Notice

REPAIR PROCEDURES

Tightening Torque 45 Nm (33 lb-ft)

Tightening TorqueBolt 45 Nm (33 lb-ft)

Page 1596 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-11

SSANGYONG MY2002

SRS Diagnostic System Check

Caution: the sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Yes

Go to Step 5

Go to “Airbag

Warning Lamp

Stays on with

Ignition Switch

ON”

Go to Step 9

Go to Step 1

Go to Step 8

Go to Step 7

Refer to the

DTC chart for

any DTC that

was set or

internal fault.

System OK

Go to Step 1No

Go to Step 2

Go to Step 3

Go to Step 4

-

Go to Step 6

System OK

-

Go to Step 9

- Value

-

-

-

-

-

-

-

-

-

Step

1

2

3

4

5

6

7

8

9Action

1. Turn the ignition switch to ON.

2. Observe the airbag indicator as the ignition is being

turned ON.

Does the indicator turn on for 4.5 seconds and go out?

Observe the airbag indicator after the ignition has been

turned ON.

Does the airbag indicator stay on?

1. Turn the ignition to LOCK and remove the key.

2. Disconnect the sensing and diagnostic module (SDM)

connector.

3. Check the airbag indicator bulb and circuit.

Are the bulb and bulb circuit in good condition?

1. Replace the bulb or repair the bulb circuit.

2. Connect SDM connector and ensure that all compo-

nents are properly mounted.

Is the repair complete?

Observe the airbag indicator after 4.5 seconds.

Does the indicator turn on again and stay?

Observe the airbag indicator after 4.5 seconds.

Does the indicator blink?

1. Turn the ignition to LOCK and remove the key.

2. Connect the scan tool to the data link connector (DLC).

Follow the directions given in the scan tool manual.

3. Turn the ignition to ON.

4. Request SRS DTC display with the scan tool.

Are any SRS DTCs displayed?

Check the bulb circuit for improper connections.

Is the repair complete?

1. Turn the ignition to LOCK and remove the key.

2. Disconnect the SDM connector.

3. Replace the SDM.

4. Reconnect SDM connector and ensure that all compo-

nents are properly mounted.

Is the repair complete?

Page 1597 of 2053

SSANGYONG MY2002

8B-12 SUPPLEMENTAL RESTRAINTS SYSTEM

Sensing and Diagnostic Module (SDM) Integrity Check

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS

operation. The SDM could be activated if it is

powered when it is not rigidly attached to the

vehicle, resulting in unexpected deployment and

possible injury.

Yes

Chear the SRS

DTCs and go

to “Diagnostic

system Check”

Go to Step 3No

Go to Step 2

Go to table for

the DTC

indicated Value

-

-

Step

1

2Action

1. Turn the ignition to LOCK and remove the key.

2. Connect all SRS components, and ensure that all

components are properly mounted.

3. Ensure that the ignition switch has been off for at least

30 seconds.

4. Observe the airbag indicator as the ignition is turned

ON.

Does the indicator lamp turn on for 4.5 seconds and then

turn off?

1. Turn the ignition to LOCK and remove the key.

2. Connect the scan tool to DLC. Follow the directions

given in the scan tool manual.

3. Turn the ignition to ON.

4. Request SRS DTC display with the scan tool.

Is the same DTC displayed that was previously occurring

when the SRS Diagnostic System Check was previously

performed?

SENSING AND DIAGNOSTIC MODULE (SDM) INTEGRITY CHECK

The following diagnostic chart must be used when all

circuitry outside the sensing and diagnostic module

(SDM) has been found to operate properly, as indicated

by following the appropriate diagnostic trouble code

(DTC) chart. The chart verifies the need for SDM

replacement.

Circuit Description

When the SDM recognizes ignition voltage greater then

9 volts at terminal 5 of the SDM, the airbag indicator is

turns on for 4.5 seconds to verify operation. At this

time the SDM performs start-up tests followed by

resistance measurement tests and continues

monitoring tests. When malfunction is detected, the

SDM sets a current DTC and illuminates or blinks the

airbag indicator. When the malfunction is no longer

detected and/or the ignition switch is cycled, the SDM

will clear current DTCs and move them to a history file,

except for the DTCs 18, 24, 51, 53 and sometimes 71.

DTCs 18, 24, 51 and 53 will not clear using a scan tool

because these codes require replacement of SDM. The

SDM must be replaced only after the malfunction that

set the DTC has been repaired.Diagnostic Aids

The order in which DTCs are diagnosed is very

important. Failure to diagnose the DTCs in the order

specified may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts replacement.

Test Description

The numbers below refer to steps on the diagnostic

table.

1. This test confirms a current malfunction. If no current

malefaction is occurring, refer to “Diagnostic Aids”

for the appropriate DTC. The SDM should not be

replaced for a historic DTC except when directed.

2. This test checks for a malfunction introduced into

the supplemental restraints system (SRS) during

the diagnostic procedure. It is extremely unlikely

that a malfunctioning SDM would cause a new

malfunction to occur during the diagnostic process.

4. See the caution below.