trouble code connector SSANGYONG KORANDO 1997 Service Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1229 of 2053

5A-134 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The solenoid 2 is used to control fluid flow acting on

the 2 - 3 shift valve. The solenoid 2 is a normally open

ON/OFF type solenoid that is used in conjunction with

the solenoid 1 to allow four different shifting

combinations. Refer to Static Gear Status.

The solenoid is attached to the valve body within the

transmission. Voltage is supplied directly to the

solenoid through the Transmission Control Module

(TCM).

The DTC P1742 sets when the Solenoid 2 (S2) circuit

is shorted to ground. The solenoid 2’s driver

Integrated Chip (IC) status indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S2 is ON.

The solenoid 2’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 2 is always OFF.

TCM adopts a Limp Home Mode (LHM) operation.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

DIAGNOSTIC TROUBLE CODE (DTC) P1742

SOLENOID 2 CIRCUIT SHORT

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 2 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the pulse.

If the difference is outside the acceptable limits

the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check the

wiring or connectors that are common to the selected

solenoids, especially the earth connections.

Inspect the wiring for poor electrical connections

at the TCM and at the transmission 10-way

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short to bare metal or other wiring.

Inspect for broken wire inside the insulation.

KAC5A030

Page 1233 of 2053

5A-138 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The solenoid 3 is a normally open ON/OFF type sole-

noid that is used in conjunction with the solenoid 4 to

control the shift quality and sequencing.

The solenoid 3 switches the clutch regulator valve OFF

or ON and is attached to the valve body within the

transmission. Voltage is supplied directly to the

solenoid through the Transmission Control Module

(TCM).

The DTC P1743 sets when the Solenoid 3 (S3) circuit

is shorted to ground. The solenoid 3’s driver

Integrated Chip (IC) status indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S3 is ON.

The solenoid 3’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 3 is always OFF.

The 1 → 3, 1 → 4, 2 → 3, 2 → 4, 3 → 1, 3 → 2, 4 →

2 and 4 1 shift quality is degraded.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

DIAGNOSTIC TROUBLE CODE (DTC) P1743

SOLENOID 3 CIRCUIT SHORT

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 3 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the

pulse. If the difference is outside the acceptable

limits the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check

the wiring or connectors that are common to the

selected solenoids, especially the earth

connections.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short to bare metal or other wiring.

Inspect for broken wire inside the insulation.

KAC5A030

Page 1237 of 2053

5A-142 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The solenoid 4 is a normally open ON/OFF type sole-

noid that is used in conjunction with the solenoid 3 to

control the shift quality and sequencing.

The solenoid 4 switches the band regulator valve OFF

or ON and is attached to the valve body within the

transmission.

Voltage is supplied directly to the solenoid through

the Transmission Control Module (TCM).

The DTC P1744 sets when the Solenoid 4 (S4) circuit

is shorted to ground. The solenoid 4’s driver

Integrated Chip (IC) status indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S4 is ON.

The solenoid 4’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 4 is always OFF.

The 1 → 2, 1 → 4, 2 → 3, 2 → 4, 3 → 1, 3 → 2 (all

including manual), 3 → 4, 4 → 1 and 4 → 3 shift

quality is degraded.

DIAGNOSTIC TROUBLE CODE (DTC) P1744

SOLENOID 4 CIRCUIT SHORT

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 4 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the

pulse. If the difference is outside the acceptable

limits the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check

the wiring or connectors that are common to the

selected solenoids, especially the earth

connections.

KAC5A030

Page 1241 of 2053

5A-146 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The solenoid 5 is a variable force solenoid that ramps

the pressure during the gear changes and solenoid

switching, to enhance the transmission shift quality.

This solenoid provides the signal pressure to the clutch

and band regulator, there by controlling the shift

pressure.

The solenoid 5 is attached to the valve body within

the transmission. Voltage is supplied directly to the

solenoid through the Transmission Control Module

(TCM).

The DTC P1745 sets when the Solenoid 5 (S5) circuit

is shorted to ground. The solenoid 5’s driver

Integrated Chip (IC) status indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S5 is ON.

The solenoid 5’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

Solenoid 5 is disabled (always OFF)

The shift quality is degraded.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

DIAGNOSTIC TROUBLE CODE (DTC) P1745

SOLENOID 5 CIRCUIT SHORT

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

The current to solenoid 5 was outside acceptable

limits.

This fault results from a mismatch between the cur-

rent set point for solenoid 5 and the current

measured by the feedback within the TCM.

Typical causes would be a short circuit to ground

in the wiring to, from or within the solenoid.

It is also possible that there has been a fault in the

solenoid output circuit. But if this is the cause, the

fault should be continually present.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short to bare metal or other wiring.

Inspect for broken wire inside the insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

KAC5A030

Page 1248 of 2053

5A-150 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The solenoid 6 is a normally open ON/OFF type sole-

noid that is used to set the high/ low level of line pres-

sure.

The solenoid 6 (S6) OFF gives high pressure and the

S6 is attached to the valve body within the

transmission. Voltage is supplied directly to the

solenoid through the Transmission Control Module

(TCM).

The DTC P1746 sets when the Solenoid 6 (S6) circuit

is shorted to ground. The solenoid 6’s driver

Integrated Chip (IC) status indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S6 is ON.

The solenoid 6’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 6 is disabled (OFF) resulting in high

line pressure being applied continuously.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

DIAGNOSTIC TROUBLE CODE (DTC) P1746

SOLENOID 6 CIRCUIT SHORT

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 6 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the

pulse. If the difference is outside the acceptable

limits the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check

the wiring or connectors that are common to the

selected solenoids, especially the earth

connections.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short to bare metal or other wiring.

Inspect for broken wire inside the insulation.

KAC5A030

Page 1252 of 2053

5A-154 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DIAGNOSTIC TROUBLE CODE (DTC) P1747

SOLENOID 7 CIRCUIT SHORT

Circuit Description

The solenoid 7 is a normally open ON/OFF type sole-

noid that is used to control the application of the

Torque Converter Clutch (TCC).

The Solenoid 7 (S7) ON activates the TCC and is at-

tached to the pump body within the transmission. Volt-

age is supplied directly to the solenoid through the

Transmission Control Module (TCM).

The DTC P1747 sets when the solenoid 7, Torque

Converter Clutch Solenoid, circuit is shorted to ground.

The solenoid 7’s driver Integrated Chip (IC) status

indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S7 is ON.

The solenoid 7’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 7 is always disabled (OFF) resulting

in the TCC being unlocked continuously.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 7 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the

pulse. If the difference is outside the acceptable

limits the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check

the wiring or connectors that are common to the

selected solenoids, especially the earth

connections.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short tobare metal or other wiring. Inspect

for broken wire inside the insulation.

KAC5A030YAD1E080

Page 1382 of 2053

SSANGYONG MY2002

5D1-12 TRANSFER CASE

Both Speed Sensor Faulty

If both the front and rear speed sensors are faulty con

tinuously for 0.5 seconds the 4WD CHECK lamp is

illuminated. The TCCU then responds as follows:

1. If the system is in high range the TCCU sets the

EMC touch off level based on a vehicle speed of

0 and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum until the system is shifted out

of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

If both speed sensors recover continuously for 0.5 sec-

ond the TCCU will function normally. The 4WD CHECK

lamp is turned off but the fault code will remain in

memory.

Electro-Magnetic Clutch Test

The electromagnetic clutch (EMC) is tested for open

circuit or short circuit to ground. If a fault is detected

continuously for 0.8 second the 4WD CHECK lamp is

turned on and all TODTM activity is halted.

If the EMC recovers continuously for 0.8 second the

TCCU will function normally. The 4WD CHECK lamp is

turned off but the fault code will remain in memory.

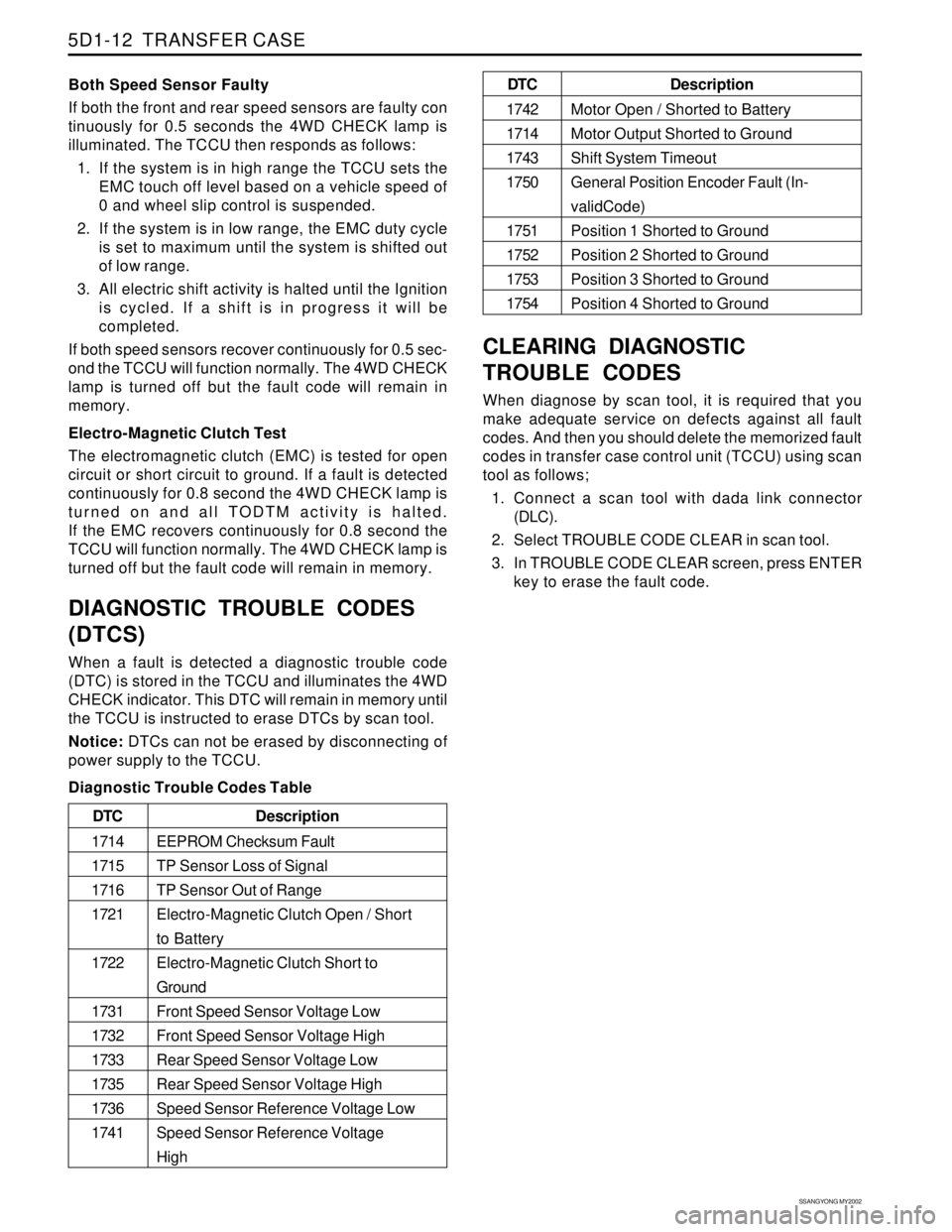

DIAGNOSTIC TROUBLE CODES

(DTCS)

When a fault is detected a diagnostic trouble code

(DTC) is stored in the TCCU and illuminates the 4WD

CHECK indicator. This DTC will remain in memory until

the TCCU is instructed to erase DTCs by scan tool.

Notice: DTCs can not be erased by disconnecting of

power supply to the TCCU.

Diagnostic Trouble Codes Table

CLEARING DIAGNOSTIC

TROUBLE CODES

When diagnose by scan tool, it is required that you

make adequate service on defects against all fault

codes. And then you should delete the memorized fault

codes in transfer case control unit (TCCU) using scan

tool as follows;

1. Connect a scan tool with dada link connector

(DLC).

2. Select TROUBLE CODE CLEAR in scan tool.

3. In TROUBLE CODE CLEAR screen, press ENTER

key to erase the fault code.

Description

EEPROM Checksum Fault

TP Sensor Loss of Signal

TP Sensor Out of Range

Electro-Magnetic Clutch Open / Short

to Battery

Electro-Magnetic Clutch Short to

Ground

Front Speed Sensor Voltage Low

Front Speed Sensor Voltage High

Rear Speed Sensor Voltage Low

Rear Speed Sensor Voltage High

Speed Sensor Reference Voltage Low

Speed Sensor Reference Voltage

High DTC

1714

1715

1716

1721

1722

1731

1732

1733

1735

1736

1741

Description

Motor Open / Shorted to Battery

Motor Output Shorted to Ground

Shift System Timeout

General Position Encoder Fault (In-

validCode)

Position 1 Shorted to Ground

Position 2 Shorted to Ground

Position 3 Shorted to Ground

Position 4 Shorted to Ground DTC

1742

1714

1743

1750

1751

1752

1753

1754

Page 1571 of 2053

FATC-HAVC 7D-17

SSANGYONG MY2002

KAA7D150

KAA7D160

KAA7D170

KAA7D180

TROUBLESHOOTING

Check and Service

Incar sensor is a sensor that detects interior air

temperature and a thermistor that decreases its

resistance when temperature up and increases when

temperature down.

1. Check that there are incar sensor fault code (11,12)

by using self-diagnosis function.

2. Disconnect incar sensor 2-pin connector that

installed on inner lower instrument panel cover of

driver’s side and remove the sensor.

3. Check that measured resistance value among

incar sensor terminals is as shown in the right side

graph.

Notice: Measure resistance value by soaking the

sensor in the ice water and check changes in

resistance values after soaking it in the very hot

water.

4. If resistance value is out of specification, replace

the incar sensor.

5. Install the sensor and turn the ignition switch to

ON position and check that voltage between No.

12A terminal of incar sensor and body (-) is 5V.

6. Check current between the No. 12B and 12A

connector terminals of the incar sensor and the No.

1 and 5 connector terminals of the airconditioner

control unit and repair the wire if defective.

Page 1586 of 2053

SECTION 8B

SUPPLEMENTAL RESTRAINTS SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

other-wise noted.

TABLE OF CONTENTS

Description and Operation...................................8B-3

Supplemental Restraint System (SRS)..................8B-3

Airbag Modules...................................................8B-3

Front Seat Belt Pretensioners...............................8B-4

Sensing and Diagnostic Module (SDM)................8B-4

Airbag Warning Lamp ..........................................8B-5

Clock Spring........................................................8B-5

Wiring Harness Connectors..................................8B-5

Components Locator............................................8B-6

SRS Component and Wiring Location View...........8B-6

Diagnostic Information and Procedures..............8B-7

Diagnostic Trouble Codes (DTC)..........................8B-7

Scan Tool Diagnostics.........................................8B-7

Use of Special Tools............................................8B-7

Diagnostic Trouble Code Table............................8B-7

SRS Diagnostic System Check..........................8B-10

Sensing and Diagnostic Module (SDM)

Integrity Check...............................................8B-12

Airbag Warning Lamp Stays on with Ignition

Switch ON......................................................8B-14

DTCs - Internal Fault..........................................8B-16

DTCs 01 Driver Deployment Loop Shorted to

Voltage...........................................................8B-18

DTC 02 Passenger Deployment Loop Shorted to

Voltage...........................................................8B-20

DTC 03 Driver Seat Belt Pretensioner Shorted to

Voltage...........................................................8B-22

DTC 04 Passenger Seat Belt Pretensioner

Shorted to Voltage..........................................8B-24

DTC 05 Driver Deployment Loop Shorted to

Ground...........................................................8B-26

DTC 06 Passenger Deployment Loop Shorted to

Ground...........................................................8B-28

DTC 07 Driver Seat Belt Pretensioner Shorted to

Ground...........................................................8B-30DTC 08 Passenger Seat Belt Pretensioner

Shorted to Ground ..........................................8B-32

DTC 17 Driver Deployment Loop

Resistance High.............................................8B-34

DTC 18 Passenger Deployment Loop

Resistance High.............................................8B-38

DTC 19 Driver Seat Belt Pretensioner

Deployment Loop resistance High...................8B-40

DTC 20 Passenger Seat Belt Pretensioner

Deployment Loop Resistance High.................8B-42

DTC 21 Driver Airbag Deployment Loop

Resistance Low..............................................8B-44

DTC 22 Passenger Airbag Deployment Loop

Resistance Low..............................................8B-48

DTC 23 Driver Seat Belt Pretensioner

Deployment Loop resistance Low....................8B-50

DTC 24 Passenger Seat Belt Pretensioner

Deployment Loop Resistance Low..................8B-52

DTC 46 Airbag Warning Lamp Circuit Open or

Short to Ground/Battery..................................8B-54

DTC 47 Battery Voltage is Out of

Specification...................................................8B-56

Repair Instruction...............................................8B-58

On-Vehicle Service...............................................8B-58

Service Precaution.............................................8B-58

Disabling the Supplemental Restraint

System (SRS).................................................8B-58

Enabling the Supplemental Restraint

System (SRS).................................................8B-58

Handling, Installation and Diagnosis..................8B-58

Repairs and Inspections Required After an

Accident ........................................................8B-58

Accident with Deployment - Components

Replacement..................................................8B-58

Accident without Deployment - Component

Inspection......................................................8B-59

Page 1588 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-3

SSANGYONG MY2002

SUPPLEMENTAL RESTRAINT

SYSTEM (SRS)

The supplemental restraint system (SRS) is safety de-

vice used in conjunction with the seat belts.

The air bag does not replace the function of the

seatbelt. The driver and the passengers must always

fasten their seat belts adjust them for a proper fit.

The SRS is designed to protect the driver and the front

seat passenger in the event of a significant frontal im-

pact to the vehicle. The airbags deploy if the force is

applied from a direction within about 30 degrees of

the vehicle’s centerline.

The SRS system consists of the following components:

Driver side airbag module.

Passenger airbag module.

Driver’s and passengers front seat belt pretension-

ers.

Sensing and diagnostic module (SDM).

Clock spring.

Wire harness and connectors.

Airbag warning lamp on the instrument cluster.

There are there are for separate four separate deploy-

ment loops in the SRS system. The term “loop” is

used because current leaves the SDM and returns to

the SDM during deployment or testing. First loop is

the circuit from SDM to the driver airbag and back to

the SDM. Second loop is the circuit from the SDM to

the passenger airbag and back to the SDM. The third

and forth loops are for right and left pretensioners.

DESCRIPTION AND OPERATION

KAA8B010

deployment, the system will enter overall or partial

shutdown status and the airbag will not inflate. The

Diagnostic System Check reveals diagnostic trouble

codes (DTCs) through the use of scan tool. It also

checks for proper airbag warning lamp operation.

Battery Voltage Check

The SDM checks the battery voltage continuously and

if the voltage is out of normal operating range (9-16

volts), all system diagnosis stops and turns on the

warning warning lamp.

Deployment Line Check

The SDM checks not only low or high resistance in the

deployment loop but also short to battery or ground

condition to indicates defects in deployment loop. It

indicates the defects by blinking the airbag warning

warning lamp.

Safety Function Check

The SDM checks the operation of arming sensor. If

the arming sensor is shorted more than 2 seconds,

the SDM will enter overall shutdown mode.

AIRBAG MODULES

Driver Airbag Module

Caution: Tampering with driver side airbag module

creates the risk of an injury from unexpected de-

ployment. Therefore, the passenger airbag module

should never be disassembled.

The passenger airbag module is under the center pad

of the steering wheel. The driver airbag module contains

an igniter charge and a gas generator to inflate the

folded airbag.

The airbag contains a shorting bar, which short-circuit

the driver high circuit to driver low circuit when the

connector is disconnected. The shorting bar prevents

current from traveling through the driver airbag module

during servicing. The shorting bar is disengaged when

the connector is connected.

System Control

The sensing and diagnostic module (SDM) continuously

monitors and controls the supplemental restraint

system (SRS) function during ignition ON or driving.

When SDM detects any problem it turns on or blink

the airbag warning lamp and keeps the diagnostic

trouble codes (DTCs). If there is a danger of improper

KAA8B020