engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 804 of 2053

OM600 ENGINE CONTROLS 1F3 -- 47

D AEW OO M Y_2000

10. Install the assembly cage (29) and remove the bolt

(20) and pull off the washer (21).

Notice

Be careful that the bolt (20) is left hand thread.

Assembly Cage 601 589 05 14 00

11. Remove the chain tensioner (18) and seal (19).

12. Remove the bolt (12) and pull off the washer (11).

13. Remove the bolt (22) and pull off the square nut

(28).

14. Pull out the fuel injection pump (25) and seal (23).

Page 805 of 2053

1F3 -- 48 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

Installation Procedure

1. Remove the screw plug (27) and seal (26) and col-

lect oil in a vessel.

2. Insert flange (31) onto the injection pump camshaft

and turn until the cam of the governor is visible in the

hole.

Flange 601 589 00 08 00

3. Tighten the locking screw.

Locking Screw 601 589 05 21 00

4. Ensure that the No.1 cylinder is positioned at ATDC

15_.

Page 806 of 2053

OM600 ENGINE CONTROLS 1F3 -- 49

D AEW OO M Y_2000

5. Coat the new seal (23) with engine oil and install it.

6. Insert the fuel injection pump (25) and tighten the

bolts (22).

Tightening Torque23 N∙m (17 lb-ft)

7. Remove the locking screw (32).

8. Tighten the bolt(12).

Tightening Torque23 N∙m (17 lb-ft)

9. Insert the washer (21) and tighten the bolts (20) and

then remove the assembly cage (29).

Tightening Torque46 N∙m (34 lb-ft)

10. Connect the fuel pipes.

Return Line46 N∙m (34 lb-ft)

Fuel Injection Line18 N∙m (13 lb-ft)

Fuel feed Line13 N∙m (10 lb-ft)

Suction and Pressure Line13 N∙m (10 lb-ft)

Notice

Replace the seal.

Box Wrench Insert 000 589 77 03 00

Page 807 of 2053

1F3 -- 50 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

11. Assemble the plastic clip (8).

12. Connect the vacuum line (13, 14).

13. Connect the connecting rod (9).

14. Connect the accelerator control damper (10).

(Manual transmission vehicle)

15. Install the chain tensioner.

16. Install the vacuum pump.

17. Check the start of delivery.

18. Adjust the idle speed.

Page 808 of 2053

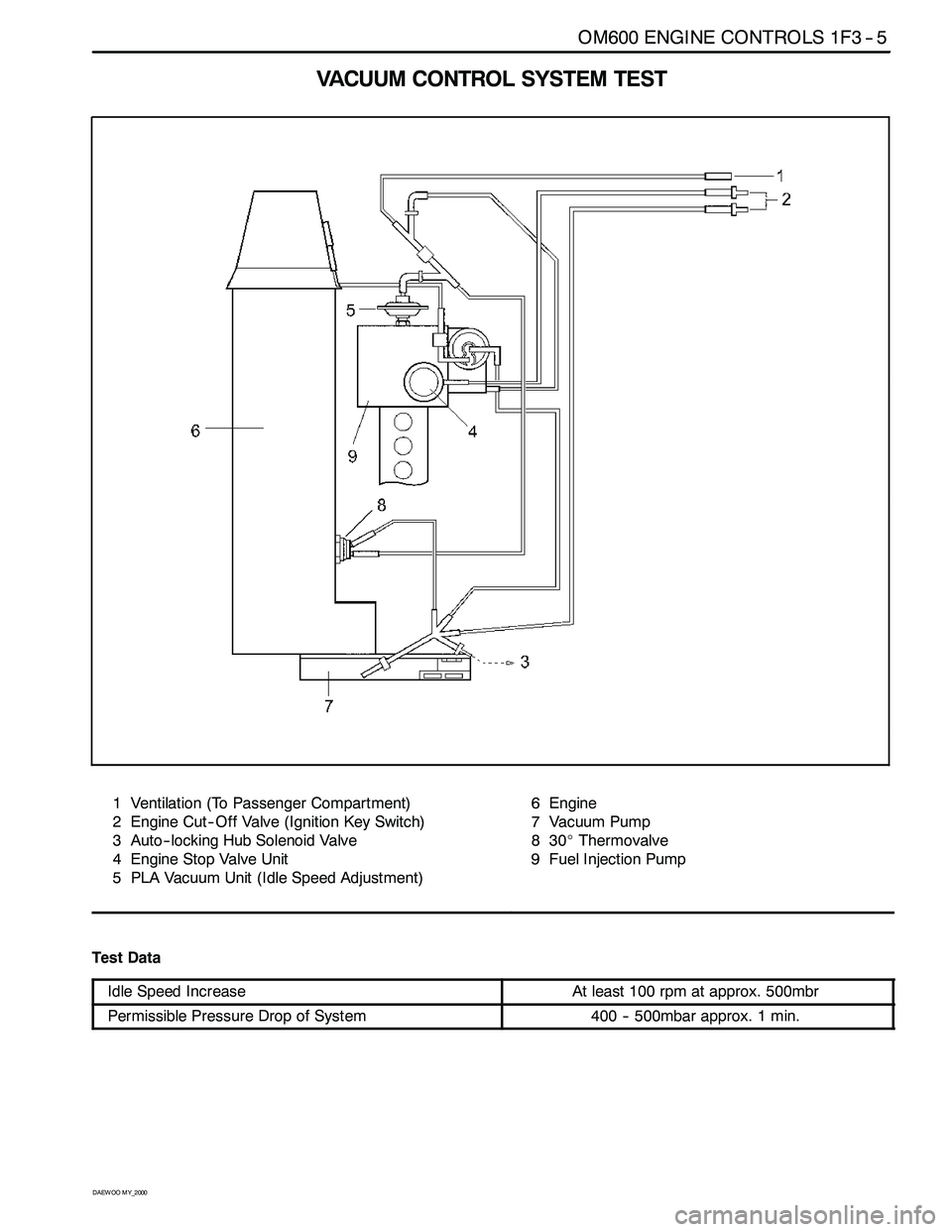

OM600 ENGINE CONTROLS 1F3 -- 5

D AEW OO M Y_2000

VACUUM CONTROLSYSTEM TEST

1 Ventilation (To Passenger Compartment)

2 Engine Cut -- Off Valve (Ignition Key Switch)

3 Auto-- locking Hub Solenoid Valve

4 Engine Stop Valve Unit

5 PLA Vacuum Unit (Idle Speed Adjustment)6Engine

7 Vacuum Pump

830_Thermovalve

9 Fuel Injection Pump

Test Data

Idle Speed IncreaseAt least 100 rpm at approx. 500mbr

Permissible Pressure Drop of System400 -- 500mbar approx. 1 min.

Page 809 of 2053

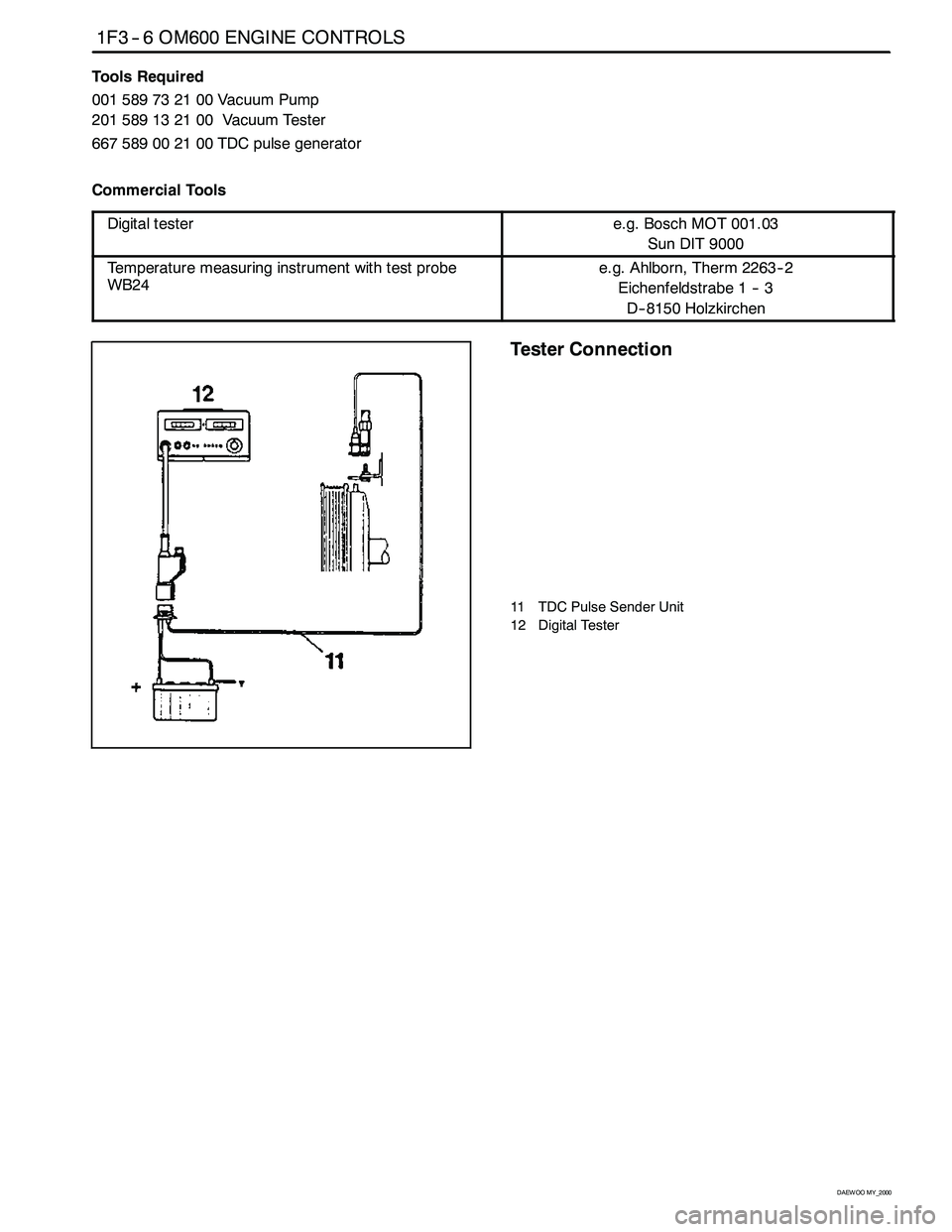

1F3 -- 6 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

Tools Required

001 589 73 21 00 Vacuum Pump

201 589 13 21 00 Vacuum Tester

667 589 00 21 00 TDC pulse generator

Commercial Tools

Digital testere.g. Bosch MOT 001.03

Sun DIT 9000

Temperature measuring instrument with test probe

WB24e.g. Ahlborn, Therm 2263 -- 2

Eichenfeldstrabe 1 -- 3

D-- 8150 Holzkirchen

Tester Connection

11 TDC Pulse Sender Unit

12 Digital Tester

Page 810 of 2053

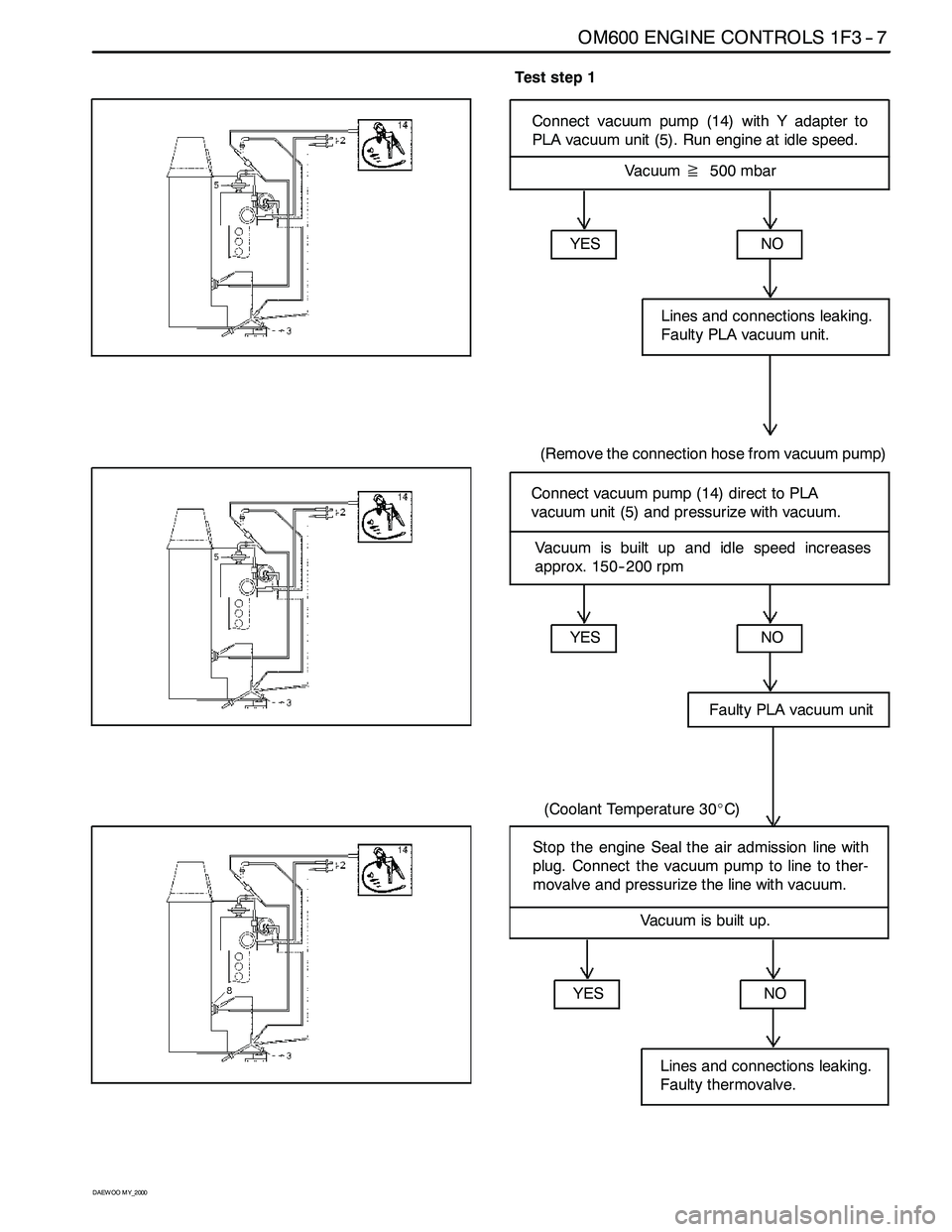

OM600 ENGINE CONTROLS 1F3 -- 7

D AEW OO M Y_2000

Test step 1

Connect vacuum pump (14) with Y adapter to

PLA vacuum unit (5). Run engine at idle speed.

Vacuum≧500 mbar

YES

NO

Faulty PLA vacuum unit

(Coolant Temperature 30_C)

Connect vacuum pump (14) direct to PLA

vacuum unit (5) and pressurize with vacuum.

YES

NO

Lines and connections leaking.

Faulty PLA vacuum unit.

(Remove the connection hose from vacuum pump)

Vacuum is built up and idle speed increases

approx. 150-- 200 rpm

YESNO

Lines and connections leaking.

Faulty thermovalve.

Stop the engine Seal the air admission line with

plug. Connect the vacuum pump to line to ther-

movalve and pressurize the line with vacuum.

Vacuum is built up.

Page 811 of 2053

1F3 -- 8 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

Detach line downstream of air admission filter

(13).

Vacuum drops

YES

NO

Faulty filter with restriction.

Fit the line onto air admission filter. Built up vacu-

um with vacuum pump. Detach the plug from air

admission line.

YES

NO

Faulty thermovalve

Vacuum drops

Go to test step 2

Page 812 of 2053

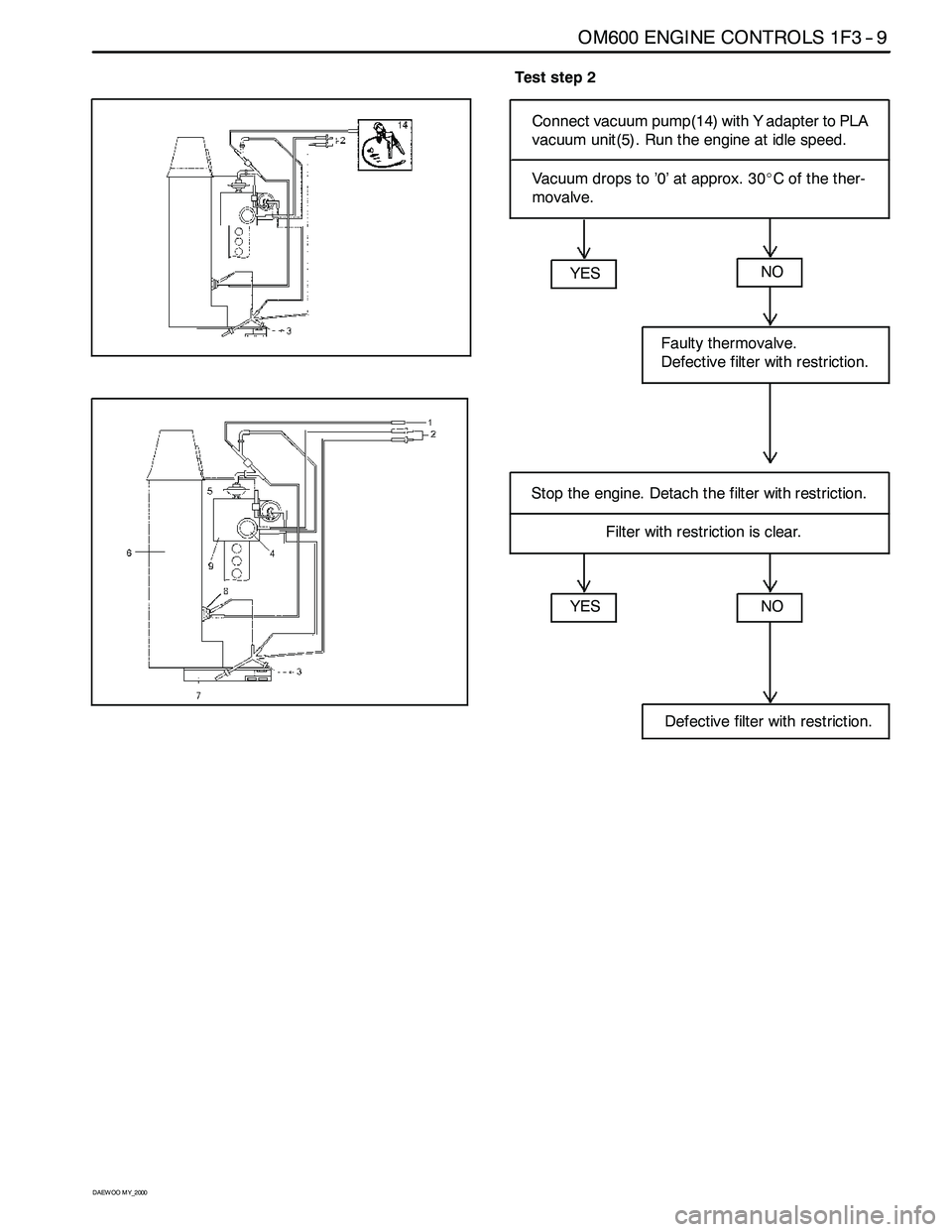

OM600 ENGINE CONTROLS 1F3 -- 9

D AEW OO M Y_2000

Test step 2

Connect vacuum pump(14) with Y adapter to PLA

vacuum unit(5). Run the engine at idle speed.

Vacuum drops to ’0’ at approx. 30_C of the ther-

movalve.

YES

NO

Defective filter with restriction.

Stop the engine. Detach the filter with restriction.

YES

NO

Faulty thermovalve.

Defective filter with restriction.

Filter with restriction is clear.

Page 821 of 2053

SSANGYONG MY2002

2B-2 WHEEL ALIGNMENT

FOUR WHEEL ALIGNMENT

The first responsibility of engineering is to design safe

steering and suspension systems. Each component

must be strong enough to withstand and absorb extreme

punishment. Both the steering system and the front

and the rear suspension must function geometrically

with the body mass.

The steering and the suspension systems require that

the front wheels self-return and that the tire rolling effor t

and the road friction be held to a negligible force in

order to allow the customer to direct the vehicle with

the least effort and the most comfort.

A complete wheel alignment check should include mea-

surements of the rear toe and camber.

Four-wheel alignment assures that all four wheels will

be running in precisely the same direction.

When the vehicle is geometrically aligned, fuel economy

and tire life are at their peak, and steering and perfor

mance are maximized.

TOE-IN

Toe-in is the turning in of the tires, while toe-out is the

turning out of the tires from the geometric centerline or

thrust line. The toe ensures parallel rolling of the wheels.

The toe serves to offset the small deflections of the

wheel support system which occur when the vehicle is

rolling forward. The specified toe angle is the setting

which achieves 0 degrees of toe when the vehicle is

moving.

Incorrect toe-in or toe-out will cause tire wear and re

duced fuel economy. As the individual steering and

sus-pension components wear from vehicle mileage,

additional toe will be needed to compensate for the

wear.

Always correct the toe dimension last.

CASTER

Caster is the tilting of the uppermost point of the steering

axis either forward or backward from the vertical when

viewed from the side of the vehicle. A backward tilt is

positive, and a forward tilt is negative. Caster influences

directional control of the steering but does not affect

tire wear. Weak springs or overloading a vehicle will

affect caster. One wheel with more positive caster will

pull toward the center of the car. This condition will

cause the car to move or lean toward the side with the

least amount of positive caster. Caster is measured in

degrees.

CAMBER

Camber is the tilting of the top of the tire from the

vertical when viewed from the front of the vehicle. When

the tires tilt outward, the camber is positive. When the

tires tilt inward, the camber is negative. The camber

angle is measured in degrees from the vertical. Camber

in-fluences both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too

much negative camber, the inside shoulder of the tire

will wear.

DESCRIPTION AND OPERATION