SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Page 764 of 2053

1F3 -- 2 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON -- VEHICLE SERVICE

FUEL SYSTEM

1 Fuel Injection Pump

2 Fuel Feed Pump

3 Overflow Valve

4 Injection Nozzle

5 Pre -- filter6 Fuel Retrun Hose

7 Injection Line

8 Fuel Tank

9 Fuel Filter

10 Choke Orifice

Page 765 of 2053

OM600 ENGINE CONTROLS 1F3 -- 3

D AEW OO M Y_2000

FUEL INJECTION PUMP CODING

Model Code

OM661 LA EnginePES 4M 55C 320 RS 167

OM662 LA EnginePES 5M 55C 320 RS 168

Fuel Injection Pump Code

Example) PES 5M 55C 320 RS 168

PPump

E Self -- Driven

S End Flange Mounting

5 Number of Cylinders (5EA)

MPumpSize

55 Element Diameter

C Modification Letter

320 Assembly Number

R Direction of Rotation (clockwise)

S188 Special Version

RSF Governor

R Governor

S Coil Spring

F Drive Governor

Component Location

1. Fuel Injection Pump

2. Vacuum Unit (Stop Unit)

3. Control Lever

4. PLA Vacuum Unit (Idle Speed Adjustment)

5. Governor

6. Fuel Pump

Page 766 of 2053

1F3 -- 4 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

FUEL TANK

1 Fuel Tank

2 The Sender of Fuel Tank

3 2-- way Check Valve

4 Pre Filter

5 Front Fuel Filler Neck

6 Rear Fuel Filler Neck

7 Fuel Supply Tube8 Fuel Return Tube

9 Filter Hose

10 Fuel Tank Hose

11 Fuel Filler Cap

12 Clip

13 Clip

Page 767 of 2053

1F3 -- 10 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

VACUUM PUMP TEST

1 Fuel Filter

2 Ancillaries Connection3 Vacuum Tester

Tools Required

201 589 13 21 00 Vacuum Tester

Page 768 of 2053

OM600 ENGINE CONTROLS 1F3 -- 11

D AEW OO M Y_2000

Test Procedure

1. Remove the fuel filter (1) and keep the filter not to be

damaged from running engine.

2. Remove the vacuum line from ancillaries connection

(2).

3. Connect the vacuum tester (3) to the ancillaries con-

nection (2).

Vacuum Tester 201 589 13 21 00

4. Run the engine at idle and check vacuum pressure

after 30 sec.

Standard>70mbar

Notice

If out of standard, replace the vacuum pump.

5. Remove the vacuum tester.

6. Connect the vacuum line to the ancillaries connec-

tion.

7. Install the fuel filter.

Page 769 of 2053

1F3 -- 12 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

VACUUM PUMP

Preceding Work : Remove the poly V-- belt

1 Bolt 10N∙m (89 lb-in) .....................

2 Vacuum Pump3 Vacuum Line

4 Gasket Replace..........................

Page 770 of 2053

OM600 ENGINE CONTROLS 1F3 -- 13

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the vacuum line.

2. Remove the bolts (1) evenly.

Notice

If necessary, rotate the engine until the pressure on

the tappet of the vacuum pump is released.

3. Remove the vacuum pump (2).

4. Install the vacuum pump (2).

Tightening Torque10 N∙m(89lb-in)

Notice

Clean the gasket residues of sealing surface of vac-

uum pump and replace the gasket(4).

5. Connect the vacuum line.

Page 771 of 2053

1F3 -- 14 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

VACUUM UNIT REPLACEMENT

1 Bracket

2Bolt

3 Vacuum Unit

4 Vacuum Line

5 Seal Replace.............................

Page 772 of 2053

OM600 ENGINE CONTROLS 1F3 -- 15

D AEW OO M Y_2000

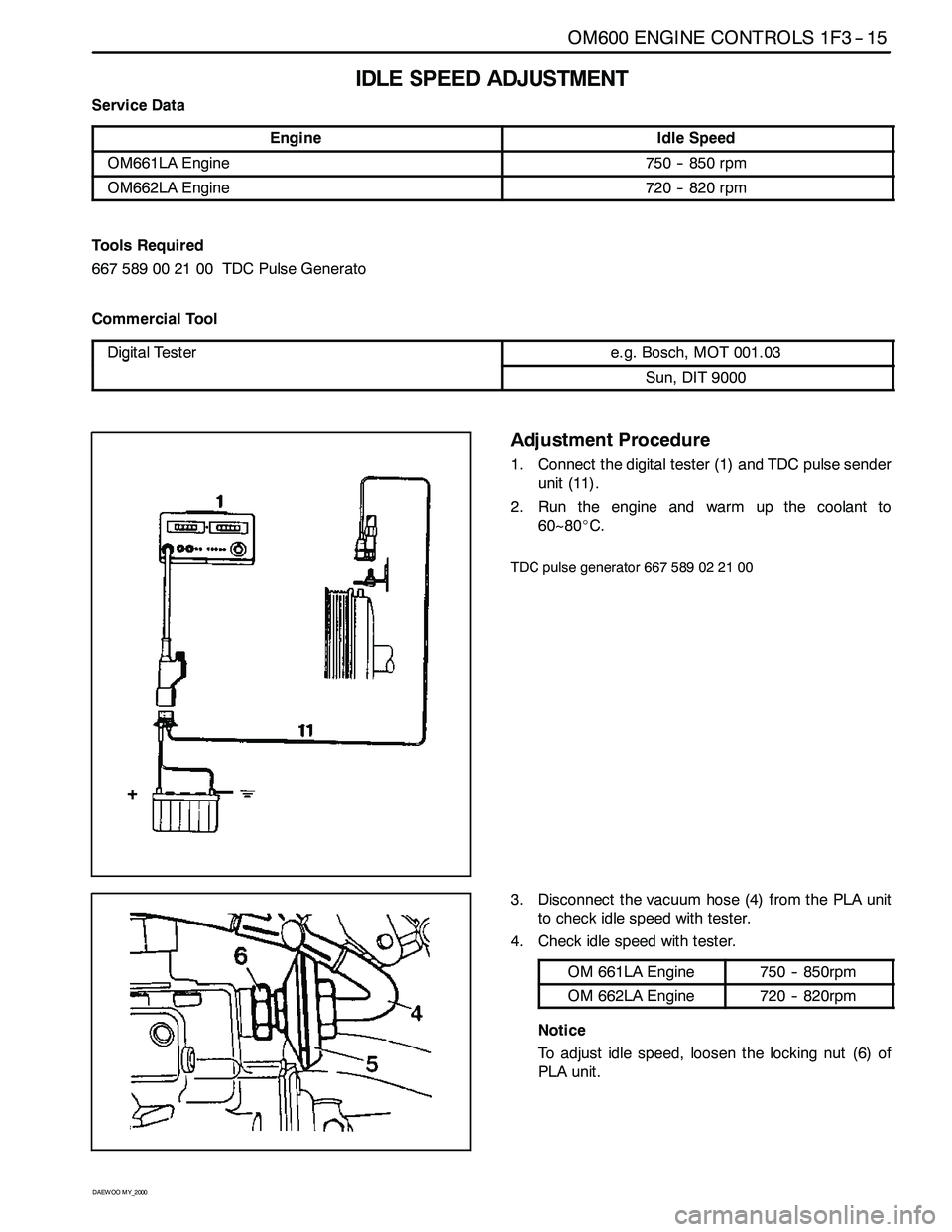

IDLE SPEED ADJUSTMENT

Service Data

EngineIdle Speed

OM661LA Engine750 -- 850 rpm

OM662LA Engine720 -- 820 rpm

Tools Required

667 589 00 21 00 TDC Pulse Generato

Commercial Tool

Digital Testere.g. Bosch, MOT 001.03g

Sun, DIT 9000

Adjustment Procedure

1. Connect the digital tester (1) and TDC pulse sender

unit (11).

2. Run the engine and warm up the coolant to

60~80_C.

TDC pulse generator 667 589 02 21 00

3. Disconnect the vacuum hose (4) from the PLA unit

to check idle speed with tester.

4. Check idle speed with tester.

OM 661LA Engine750 -- 850rpm

OM 662LA Engine720 -- 820rpm

Notice

To adjust idle speed, loosen the locking nut (6) of

PLA unit.

Page 773 of 2053

1F3 -- 16 OM600 ENGINE CONTROLS

D AEW OO M Y_2000

5. Ensure not to damage the idle spring in the governor

and adjust idle speed by turning the PLA unit (5)

slowly.

ClockwiseRPM Decrease

CounterclockwiseRPM Increase

Notice

Do not rotate the PLA unit over 1/2 turn from the

position marking. If do, idle spring in the governor

will be severely damaged.

6. After adjustment, tighten the locking nut and place

the position marking with different color of paint.

Notice

If there are no changes in idle speed with PLA unit

adjustment, perform the service at a BOSCH Ser-

vice Center.

7. Connect the vacuum pump to the PLA vacuum unit

and build up vacuum approx. 500mbar. If engine

rpm increases by approx. 100rpm, It is normal.

Vacuum Pump 001 589 73 21 00

8. Connect the vacuum line (4).

9. Switch on all ancillaries and check the idle speed.