Timing sign SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 83 of 2053

M162 ENGINE MECHANICAL 1B1 -- 51

D AEW OO M Y_2000

Removal & Installation Procedure

1. Turn the crankshaft to the direction of engine rotation

and position the no.1 cylinder piston at TDC which the

camshaft is positioned at OT.

2. Remove the cylinder head front cover.

3. Paint the alignment marks (arrows) on the intake and

exhaust camshaft sprocket and the timing chain.

3 Bolt 13 Camshaft Sprocket

4 Amarture 18 Control Piston

6 Nut (M20 x 1.5) 22 Intake Camshaft

12 Seal Cover

4. Unscrew the bolt (3) from the armature (4) and re-

move the armature.

Installation Notice

Tightening Torque

35 NSm (26 lb-ft)

5. Unscrew the nut (6) and remove the ring and seal

cover (11).

Installation Notice

Tightening Torque

60 -- 70 NSm (44 -- 52 lb-ft)

6. Unscrew the sprocket bolt from the exhaust camshaft

and remove the sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so always replace with new one.

Page 84 of 2053

1B1 -- 52 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

7. Remove the camshaft sprocket (13) and adjust piston

(14), and remove the flange shaft (16) from the intake

camshaft (22) after removing the bolt (15).

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so always replace with new one.

8. Installation should follow the removal procedure in

the reverse order.

9. Adjust the camshaft timing.

CAMSHAFT SPROCKET BOLT

Intake Flange Shaft Bolt

TighteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The sprocket bolts are designed to be used only

once, so always replace with new one.

C. M7 x 13 Collar Bolt Torx -- T30

e. 6.8 mm

16. Flange Shaft

18. Control Piston

22. Intake Camshaft

Page 88 of 2053

M162 ENGINE MECHANICAL 1B1 -- 61

D AEW OO M Y_2000

10. Install the chain to the exhaust camshaft sprocket

and install it to the camshaft.

Installation Notice (Sprocket Bolt)

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so replace with new one.

11. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

12. Check the camshaft timing.

Page 181 of 2053

1F1 -- 18 M162 ENGINE CONTROLS

D AEW OO M Y_2000

IGNITION SYSTEM

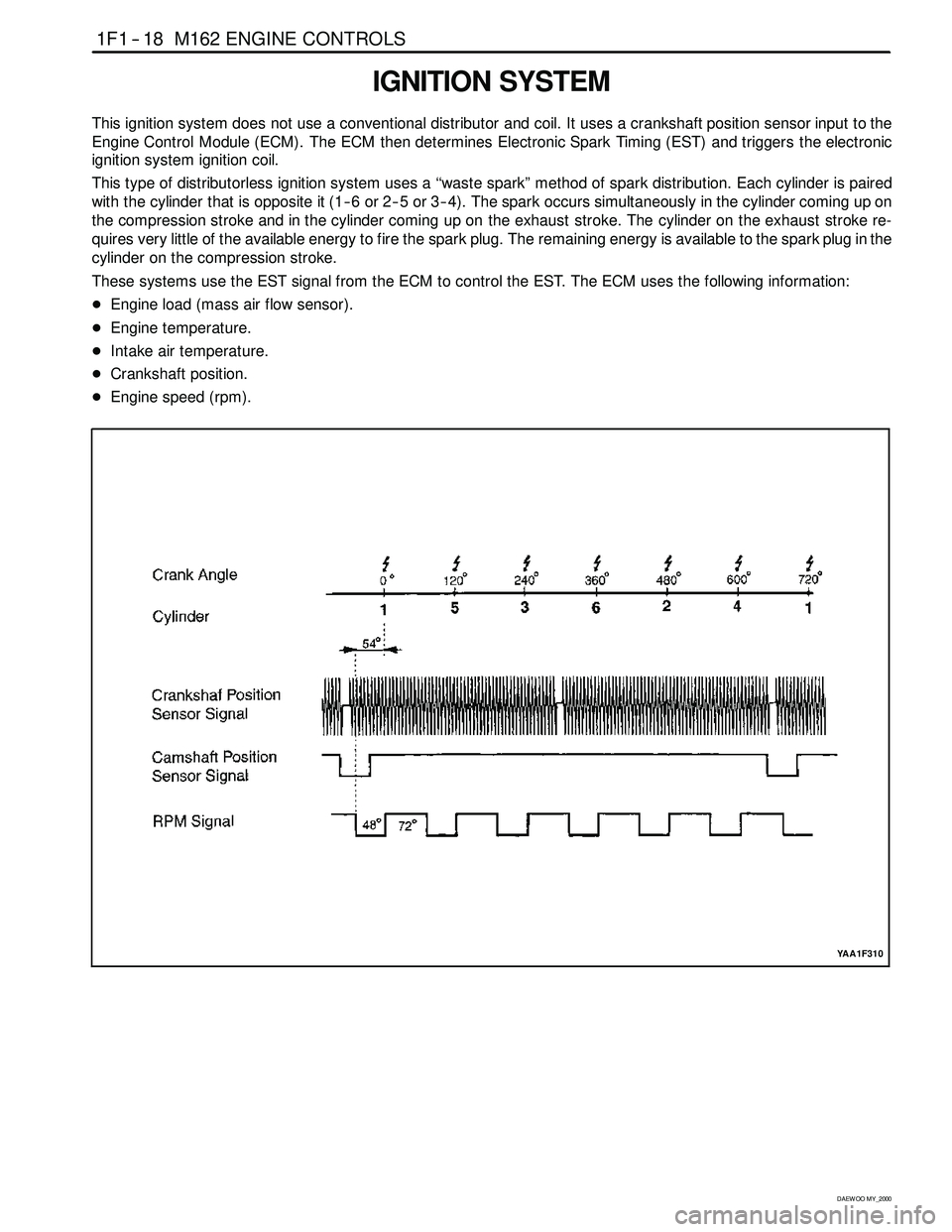

This ignition system does not use a conventional distributor andcoil. It uses a crankshaft position sensor input to the

Engine Control Module (ECM). The ECM then determines Electronic Spark Timing (EST) and triggers the electronic

ignition system ignition coil.

This type of distributorless ignition system uses a‘‘waste spark” method of spark distribution. Each cylinder is paired

with the cylinder that is opposite it (1 -- 6 or 2 -- 5 or 3 -- 4). The spark occurs simultaneously in the cylinder coming up on

the compression stroke and in the cylinder coming up on the exhaust stroke. The cylinder on the exhaust stroke re-

quires very little of the available energy to fire the spark plug. The remaining energy is available to the spark plug in the

cylinder on the compression stroke.

These systems use the EST signal from the ECM to control the EST. The ECM uses the following information:

DEngine load (mass air flow sensor).

DEngine temperature.

DIntake air temperature.

DCrankshaft position.

DEngine speed (rpm).

YAA1F310

Page 195 of 2053

1F1 -- 32 M162 ENGINE CONTROLS

D AEW OO M Y_2000

KNOCK SENSOR (KS)

YAA1F320

The Knock Sensor (KS) detects abnormal knocking in the engine. The two KS are mounted in the engine block near

the cylinders. The sensors produce an output voltage which increases with the severity of the knock. This signal is sent

to the Engine Control Module (ECM) via a shielded cable. The ECM then adjusts the ignition timing to reduce the spark

knock.

Page 196 of 2053

M162 ENGINE CONTROLS 1F1 -- 33

D AEW OO M Y_2000

KAB1F170

Failure

CodeDescriptionTrouble AreaMaintenance Hint

56No. 1 knock sensor

signal failure

When recognition in more

than control gain threshold at

normal operational condition

of other system during over

75 and 3,000 rpm running

area (cylinder 1, 2, 3)DInspection the ECM pin 118, 117 about

short circuit or open with bad contact

DInspection the KS 1 malfunction

DInspection the ECM

57No. 2 knock sensor

signal failure

When recognition in more

than control gain threshold at

normal operational condition

of other system during over

75 and 3,000 rpm running

area (cylinder 4, 5, 6)DInspection the ECM pin 115, 114 about

short circuit or open with bad contact

DInspection the KS 2 malfunction

DInspection the ECM

Circuit Description

The KS system is used to detect engine detonation, allowing the ECM to retard the ignition control spark timing based

on the KS signal being received. The KS signal’s amplitude and frequency depend upon the amount of knock being

experienced. The ECM monitors the KS signal and can diagnose the KS sensor and circuitry.

Knock Sensor Resistance Inspection

1. Disconnect the coupling from ECM while the ignition switch is in “OFF” position.

2. Measure the resistance between the coupling terminal pin No. 118 and No. 117 and terminal pin No. 115 and No.

114usingamultimeter.

Specified Value

>10 MΩ

Notice:Replace the KS if the measured values is out of the specified values. Check the connector and wire connec-

tion between ECM and the KS if the measured values are normal.

Page 324 of 2053

M161 ENGINE MECHANICAL 1B2 -- 31

D AEW OO M Y_2000

Tools Required

617589001000 AllenWrenchSocket

116 589 20 33 00 Sliding Hammer

116 589 01 34 00 Threaded Pin

111 589 03 15 00 Holding Pin

Removal & Installation Procedure

1. Rotate the crankshaft so that the piston of number 1

cylinder is at ATDC 20.

2. Put the holding pin 111 589 03 15 00 into the cam-

shaft bearing cap (number 1, 6).

3. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

4. Remove the chain tensioner.

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

5. Remove the exhaust camshaft sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

Page 328 of 2053

M161 ENGINE MECHANICAL 1B2 -- 35

D AEW OO M Y_2000

Tools Required

116 589 20 33 00 Sliding Hammer

116 589 01 34 00 Threaded Pin

Removal & Installation Procedure

1. Remove the power steering belt pulley and A/C com-

pressor bracket.

2. Remove the oil line from power steering pump.

3. Rotate the crankshaft so that the piston of number,

cylinder is at ATDC20°.

4. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

5. Remove the chain tensioner.

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

6. Remove the intake and exhaust camshaft sprocket

(remove the camshaft adjuster assembly in E23 en-

gine).

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

7. Remove the guide rail pin using the sliding hammer

116 589 20 33 00 (02) and the threaded pin 116 589

01 34 00 (03).

Notice:Apply the sealant on guide rail pin when installa-

tion.

Page 348 of 2053

M161 ENGINE MECHANICAL 1B2 -- 55

D AEW OO M Y_2000

Removal & Installation Procedure

1. Turn the crankshaft and position the no.1 cylinder pis-

ton at ATDC 20°.

Notice:Turn the crankshaft in the direction of engine

rotation.

2. Remove the cylinder head front cover.

3. Put the alignment marks (arrows) on the camshaft

sprocket and the timing chain.

4. Insert the holding pin 111 589 03 15 00 into the no.1

and no.6 bearing cap hole on camshaft to secure in-

take and exhaust camshaft.

5. Remove the chain tensioner.

6. Unscrew the exhaust sprocket bolt and remove the

exhaust camshaft sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

Page 349 of 2053

1B2 -- 56 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

7. Unscrew the bolt (3) from the armature (4) and re-

move the roll pin, and remove the armature.

Installation Notice

Tightening Torque

35 NSm (26 lb-ft)

8. Unscrew the nut (6) and remove the seal cover (7).

Installation Notice

Tightening Torque

60 -- 70 NSm (44 -- 52 lb-ft)

Notice:Put the locking slot of nut toward armarture.

9. Take off the timing chain from intake camshaft

sprocket.

10. Remove the adjuster piston (9) and conical spring

(10) from intake camshaft sprocket.

11. Unscrew the bolt (11) and remove the flange shaft.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

12. Installation should follow the removal procedure in

the reverse order.

13. Check and adjust the camshaft timing.