four wheel drive SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 822 of 2053

WHEEL ALIGNMENT 2B-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

TIRE DIAGNOSIS

Irregular and Premature Wear

Irregular and premature tire wear has many causes.

Some of them are incorrect inflation pressures, lack of

regular rotation, poor driving habits, or improper wheel

alignment.

Rotate the tires if :

•The front tire wear is different from the rear.

The left and right front tire wear is unequal.

The left and right rear tire wear is unequal.

Check wheel alignment if :

The left and right front tire wear is unequal.

The wear is uneven across the tread of either front

tire.

The front tire treads are scuffed with “feather” edges

on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built-in tread wear in

dicators to show when the tires need replacement.

These indicators appear as bands when the tire tread

depth becomes shallow. Tire replacement is recom

mended when the indicators appear in three or more

grooves at six locations.

KAA2B010

Radial Tire Waddle

Waddle is side-to-side movement at the front or rear of

the vehicle. It is caused by the steel belt not being

straight within the tire, or by excessive lateral runout

of the tire or wheel.

The vehicle must be road tested to determine which

end of the vehicle has the faulty tire. The rear end of

the vehicle will shake from side to side or “waddle” if

the waddle tire is on the rear of the vehicle. From the

driver’s seat, it feels as though someone is pushing

on the side of the vehicle.

If the faulty tire is on the front of the vehicle, the waddle

is more visual. The front sheet meld appears to be mov-

ing back and forth, and the drivers seat feels like the

pivot point in the vehicle.

Waddle can be diagnosed using the method of substitut-

ing known good tire and wheel assemblies on the prob-

lem vehicle.

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle

in place of those on the offending end of the problem

vehicle. If the source of the waddle is not obvious,

change the rear tires.

3. Road test the vehicle. If there is improvement,

install the original tires to find the offending tire. If

there is no a straight improvement, install good tires

in place of all four offending tires.

KAA2B020

Page 987 of 2053

ABS AND TCS 4F-3

SSANGYONG MY2002

GENERAL DESCRIPTION AND SYSTEM OPERATION

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have

a basic knowledge of the following items. Without this

knowledge, it will be difficult to use the diagnostic

procedures contained in this section.

•Basic Electrical Circuits - You should understand

the basic theory of electricity and know the meaning

of voltage, current (amps), and resistance (ohms).

You should understand what happens in a circuit

with an open or shorted wire. You should be able to

read and understand a wiring diagram.

Use of Circuit Testing Tools - You should know

how to use a test light and how to bypass

components to test circuits using fused jumper

wires. You should be familiar with a digital

multimeter. You should be able to measure voltage,

resistance, and current, and be familiar with the

controls and how to use them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists

of a conventional hydraulic brake system plus antilock

components. The conventional brake system includes

a vacuum booster, master cylinder, front disc brakes,

rear disc brakes, interconnecting hydraulic brake pipes

and hoses, brake fluid level switch and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator

and the TCS indicator. See “ABS Component Locator”

in this section for the general layout of this system.

The hydraulic unit with the attached EBCM is located

between the surge tank and the bulkhead on the left

side of the vehicle.

The basic hydraulic unit configuration consists of hy-

draulic check valves, two solenoid valves for each

wheel, a hydraulic pump, and two accumulators. The

hydraulic unit controls hydraulic pressure to the front

calipers and rear calipers by modulating hydraulic

pressure to prevent wheel lockup.

Units equipped with TCS add two more valves for each

drive wheel for the purpose of applying the brake to a

wheel that is slipping. This is done with pressure from

the hydraulic pump in the unit. There is also a TCS

indicator lamp on the instrument panel to alert the driver

to the fact that the TCS system is active. The

components identified in the drawing are those added

to the basic ABS 5.3 system to provide traction control.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit withattached EBCM must be replaced. For more

information, refer to “Base Braking Mode” and

“Antilock Braking Mode” in this section.

TRACTION CONTROL SYSTEM

(TCS) DESCRIPTION

General Information

The traction control system (TCS) is a traction system

by means of brake intervention only, available in a low

speed range (< 60kph).

It workes on µ - split roads with sidewise different friction

coefficients.

The spinning driven wheel is braked and the drive

torque can be transferred to the wheel on the high-µ

side. During TCS active, the TCS information lamp is

blinking.

The temperature of the brakes is calculated by a mathe-

matical model and TCS is switched passive if the calcu-

lated temperature is greater than a threshold value (500

°C).

TCS is permitted again, when the calculated tempera-

ture is less than 350 °C.

Control Algorithm

The input signals for the control algorithm are the

filtered wheel speed signals from the ABS speed

processing.

With the speed difference of the driven wheels, the

control deviation is calculated.

If the control deviation exceeds a certain threshold

value, the wheel with the greater slip is braked actively.

The threshold value depends on the vehicle speed:

It is reduced with increasing vehicle speed down to a

constant value.

KAA4F010

Page 1097 of 2053

AUTOMATIC TRANSMISSION 5A-3

SSANGYONG MY2002

N - Neutral allows the engine to be started and oper-

ated while driving the vehicle. The inhibitor switch

allows the engine to be started. There is no power

transferred through the transmission in Neutral. But

the final drive is not locked by the parking pawl, so

thewheels are free to rotate.

D - Overdrive range is used for all normal driving

conditions. 4th gear (overdrive gear) reduces the

fuel consumption and the engine noise. Engine

braking is applied with reduced throttle.

First to second (1 → 2), first to third (1 → 3), second

to third (2 → 3), second to fourth (2 → 4), third to

fourth (3 → 4), fourth to third (4 → 3), fourth to

second (4 → 2), third to second (3 → 2), third to

first (3 → 1) and second to first (2 → 1) shifts are

all available as a function of vehicle speed, throttle

position and the time change rate of the throttle

position.

Downshifts are available for safe passing by

depress-ing the accelerator. Lockup clutch may be

enabled in 3rd and 4th gears depending on vehicle

type.

3 - Manual 3 provides three gear ratios (first through

third) and prevents the transmission from operating

in 4th gear. 3rd gear is used when driving on long

hill roads or in heavy city traffic. Downshifts are

available by depressing the accelerator.

2 - Manual 2 provides two gear ratios (first and

second). It is used to provide more power when

climbing hills or engine braking when driving down

a steep hill or starting off on slippery roads.

1 - Manual 1 is used to provide the maximum engine

braking when driving down the severe gradients.When NORMAL mode is selected upshifts will occur

to maximize fuel economy. When POWER mode is se-

lected, upshifts will occur to give maximum

performance and the POWER mode indicator light is

switched ON.

When WINTER mode is selected, starting in second

gear is facilitated, the WINTER mode indicator light is

switched ON and the POWER mode indicator light is

switched OFF.

Indicator Light

The indicator light is located on the instrument panel.

Auto shift indicator light comes ON when the ignition

switch ON and shows the gear shift control lever

position.

POWER mode indicator light comes ON when the

POWER mode is selected and when the kickdown

switch is depressed.

WINTER mode indicator light comes ON when the

WINTER mode is selected.

CONTROL SYSTEMS

BTRA M74 4WD automatic transmission consists of

two control systems. One is the electronic control

system that monitors vehicle parameters and adjusts

the transmission performance. Another is the hydraulic

control system that implements the commands of the

electronic control system commands.

ELECTRONIC CONTROL SYSTEM

The electronic control system comprises of sensors, a

TCM and seven solenoids. The TCM reads the inputs

and activates the outputs according to values stored

in Read Only Memory (ROM).

The TCM controls the hydraulic control system. This

control is via the hydraulic valve body, which contains

seven electromagnetic solenoids. Six of the seven

solenoids are used to control the line pressure, operate

the shift valves and the torque converter lock-up clutch,

and to turn ON and OFF the two regulator valves that

control the shift feel.

The seventh solenoid is the proportional or Variable

Pressure Solenoid (VPS) which works with the two regu-

lator valves to control shift feel.

Transmission Control Module (TCM)

The TCM is an in-vehicle micro-processor based trans-

mission management system. It is mounted under the

driver’s side front seat in the vehicle cabin.

The TCM contains:

Processing logic circuits which include a central mi-

croprocessor controller and a back-up memory

system.

Input circuits.

Driving Mode Selector

The driving mode selector consists of a driving mode

selector switch and indicator light. The driving mode

selector is located on the center console and allows

the driver to select the driving mode.

The driving modes available to be selected vary with

vehicle types. Typically the driver should have the

option to select among NORMAL, POWER and

WINTER modes.

KAA5A020

Page 1109 of 2053

AUTOMATIC TRANSMISSION 5A-15

SSANGYONG MY2002

3-4

OWC

X

X

X

X

X 1-2

OWC

X B2

X

X B1

X

X C4

X

X

X

Gear set-sprag-centre support

C1 -C2 -C3 -C4 clutch sub-assembly

Pump assembly

Valve body assembly

One, or a combination of selective washers are used

between the input shaft flange and the number 4

bearing to control the transmission end float. This

arrangement allows for extensive subassembly testing

and simplistic final assembly during production.

A general description of the operation of the Power

Train System is detailed below.

First gear is engaged by applying the C2 clutch and

locking the 1-2 One Way Clutch (1-2 OWC). The 1-2

shift is accomplished by applying the B1 band and

overrunning the 1-2 OWC. The 2-3 shift is

accomplished by applying the C1 clutch and releasingthe B1 band. The 3-4 shift is accomplished by re-

applying the B1 band and overrunning the 3-4 OWC.

Reverse gear is engaged by applying the C3 clutch

and the B2 band.

The C4 clutch is applied in the Manual 1, 2 and 3 ranges

to provide engine braking. In addition, the C4 clutch

is also applied in the Drive range for second and third

gears to eliminate objectionable freewheel coasting.

The B2 band is also applied in the Manual 1 range to

accomplish the low-overrun shift.

Both the front and rear servos are dual area designs

to allow accurate friction element matching without the

need for secondary regulator valves. All the friction

elements have been designed to provide low shift

energies and high static capacities when used with

the new low static co-efficient transmission fluids. Non-

asbestos friction materials are used throughout.

Gear

First

Second

Third

Fourth

Reverse

Manual 1Gear

Ratio

2.741

1.508

1.000

0.708

2.428

2.741C1

X

XC2

X

X

X

X

XC3

XLU

CLUTCH

X*

X ELEMENTS ENGAGED

* For Certain Vehicle Applications, Refer to the Owner's Manual.

KAA5A250

Page 1110 of 2053

5A-16 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Torque Converter

The torque converter consists of a turbine, stator pump,

impeller and a lock-up damper and piston assembly.

As in conventional torque converters, the impeller is

attached to the converter cover, the turbine is splined

to the input shaft and the stator is mounted on the

pump housing via a one way clutch (sprag).

The addition of the damper and piston assembly en-

ables the torque converter to lock-up under favorable

conditions. Lock-up is only permitted to occur in third

and fourth gears under specified throttle and vehicle

speed conditions.

Lock-up is achieved by applying hydraulic pressure

to the damper and piston assembly which couples the

turbine to the converter cover, locking-up the converter

and eliminating unwanted slippage. Whenever lock-

up occurs, improved fuel consumption is achieved.

Torsional damper springs are provided in the damper

and piston assembly to absorb any engine torque

fluctuations during lock-up.

Clutch Packs

There are four clutch packs. All clutch packs are com-

posed of multiple steel and friction plates.

C1 CLUTCH: When applied, this clutch pack allows

the input shaft to drive the planet carrier. This occurs

in third and fourth gears.

C2 CLUTCH: When applied this clutch pack allows

the input shaft to drive the forward sun gear via the 3-

4 OWC. This occurs in all forward gears.

C3 CLUTCH: When applied this clutch pack allows

the input shaft to drive the reverse sun gear. This only

occurs in reverse gear.

C4 CLUTCH: When applied this clutch provides engine

braking on overrun. This occurs in Manual 1, 2 and 3

and also Drive 2 and Drive 3 to prevent objectionable

free wheel coasting.

KAA5A260

KAA5A270

Page 1408 of 2053

SSANGYONG MY2002

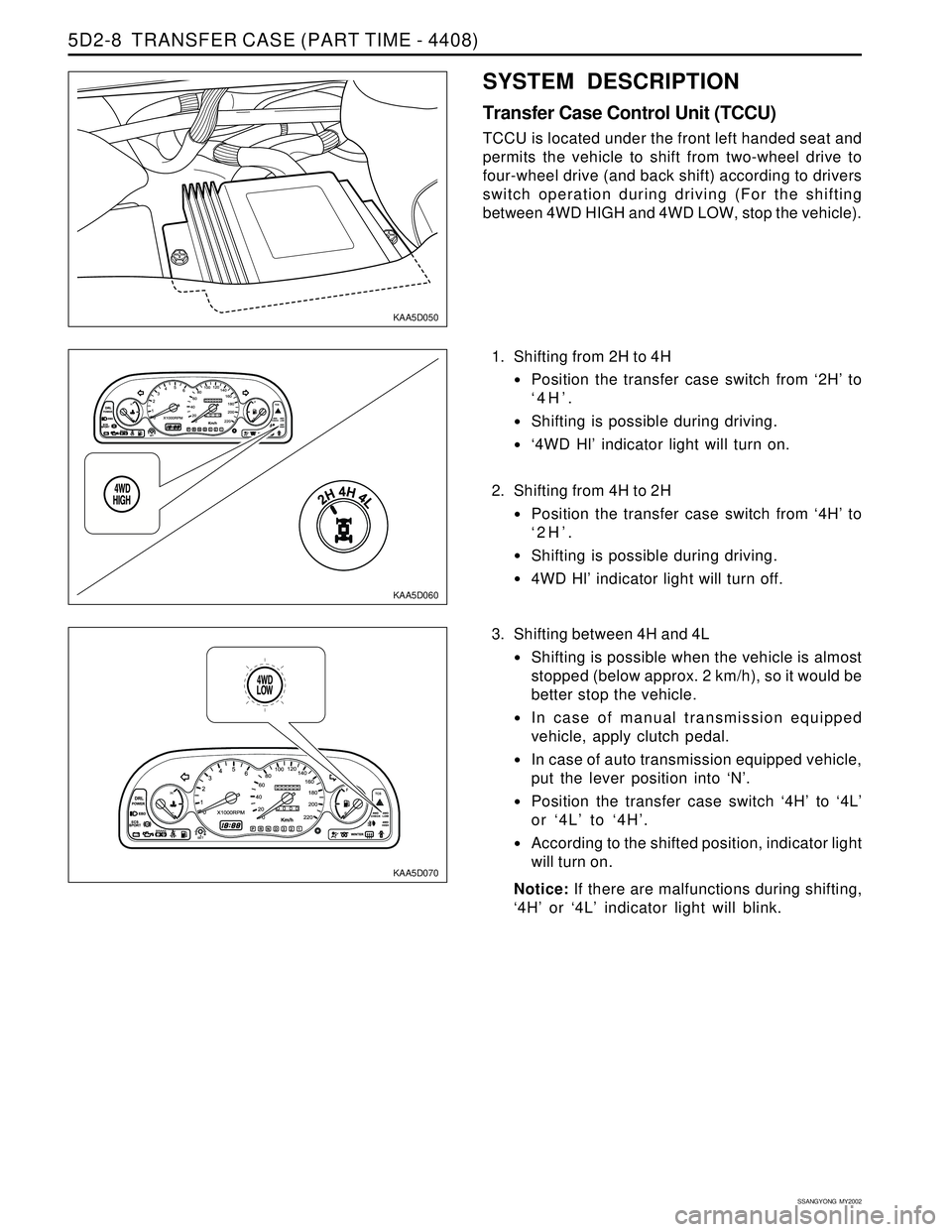

5D2-8 TRANSFER CASE (PART TIME - 4408)

KAA5D050

KAA5D060

KAA5D070

1. Shifting from 2H to 4H

Position the transfer case switch from ‘2H’ to

‘4H’.

Shifting is possible during driving.

‘4WD Hl’ indicator light will turn on.

2. Shifting from 4H to 2H

Position the transfer case switch from ‘4H’ to

‘2H’.

Shifting is possible during driving.

4WD Hl’ indicator light will turn off.

SYSTEM DESCRIPTION

Transfer Case Control Unit (TCCU)

TCCU is located under the front left handed seat and

permits the vehicle to shift from two-wheel drive to

four-wheel drive (and back shift) according to drivers

switch operation during driving (For the shifting

between 4WD HIGH and 4WD LOW, stop the vehicle).

3. Shifting between 4H and 4L

Shifting is possible when the vehicle is almost

stopped (below approx. 2 km/h), so it would be

better stop the vehicle.

In case of manual transmission equipped

vehicle, apply clutch pedal.

In case of auto transmission equipped vehicle,

put the lever position into ‘N’.

Position the transfer case switch ‘4H’ to ‘4L’

or ‘4L’ to ‘4H’.

According to the shifted position, indicator light

will turn on.

Notice: If there are malfunctions during shifting,

‘4H’ or ‘4L’ indicator light will blink.

Page 1588 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-3

SSANGYONG MY2002

SUPPLEMENTAL RESTRAINT

SYSTEM (SRS)

The supplemental restraint system (SRS) is safety de-

vice used in conjunction with the seat belts.

The air bag does not replace the function of the

seatbelt. The driver and the passengers must always

fasten their seat belts adjust them for a proper fit.

The SRS is designed to protect the driver and the front

seat passenger in the event of a significant frontal im-

pact to the vehicle. The airbags deploy if the force is

applied from a direction within about 30 degrees of

the vehicle’s centerline.

The SRS system consists of the following components:

Driver side airbag module.

Passenger airbag module.

Driver’s and passengers front seat belt pretension-

ers.

Sensing and diagnostic module (SDM).

Clock spring.

Wire harness and connectors.

Airbag warning lamp on the instrument cluster.

There are there are for separate four separate deploy-

ment loops in the SRS system. The term “loop” is

used because current leaves the SDM and returns to

the SDM during deployment or testing. First loop is

the circuit from SDM to the driver airbag and back to

the SDM. Second loop is the circuit from the SDM to

the passenger airbag and back to the SDM. The third

and forth loops are for right and left pretensioners.

DESCRIPTION AND OPERATION

KAA8B010

deployment, the system will enter overall or partial

shutdown status and the airbag will not inflate. The

Diagnostic System Check reveals diagnostic trouble

codes (DTCs) through the use of scan tool. It also

checks for proper airbag warning lamp operation.

Battery Voltage Check

The SDM checks the battery voltage continuously and

if the voltage is out of normal operating range (9-16

volts), all system diagnosis stops and turns on the

warning warning lamp.

Deployment Line Check

The SDM checks not only low or high resistance in the

deployment loop but also short to battery or ground

condition to indicates defects in deployment loop. It

indicates the defects by blinking the airbag warning

warning lamp.

Safety Function Check

The SDM checks the operation of arming sensor. If

the arming sensor is shorted more than 2 seconds,

the SDM will enter overall shutdown mode.

AIRBAG MODULES

Driver Airbag Module

Caution: Tampering with driver side airbag module

creates the risk of an injury from unexpected de-

ployment. Therefore, the passenger airbag module

should never be disassembled.

The passenger airbag module is under the center pad

of the steering wheel. The driver airbag module contains

an igniter charge and a gas generator to inflate the

folded airbag.

The airbag contains a shorting bar, which short-circuit

the driver high circuit to driver low circuit when the

connector is disconnected. The shorting bar prevents

current from traveling through the driver airbag module

during servicing. The shorting bar is disengaged when

the connector is connected.

System Control

The sensing and diagnostic module (SDM) continuously

monitors and controls the supplemental restraint

system (SRS) function during ignition ON or driving.

When SDM detects any problem it turns on or blink

the airbag warning lamp and keeps the diagnostic

trouble codes (DTCs). If there is a danger of improper

KAA8B020

Page 1590 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-5

SSANGYONG MY2002

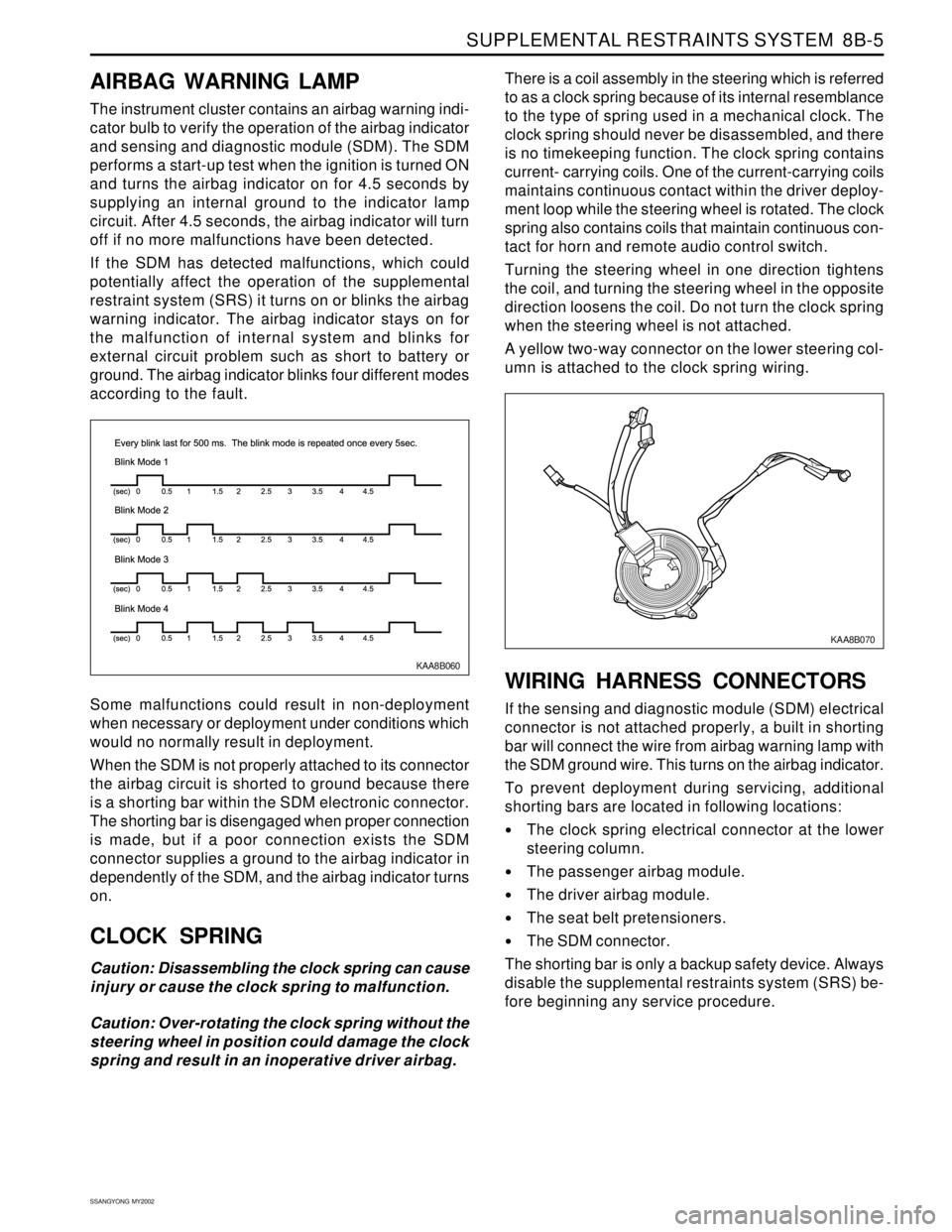

KAA8B060

AIRBAG WARNING LAMP

The instrument cluster contains an airbag warning indi-

cator bulb to verify the operation of the airbag indicator

and sensing and diagnostic module (SDM). The SDM

performs a start-up test when the ignition is turned ON

and turns the airbag indicator on for 4.5 seconds by

supplying an internal ground to the indicator lamp

circuit. After 4.5 seconds, the airbag indicator will turn

off if no more malfunctions have been detected.

If the SDM has detected malfunctions, which could

potentially affect the operation of the supplemental

restraint system (SRS) it turns on or blinks the airbag

warning indicator. The airbag indicator stays on for

the malfunction of internal system and blinks for

external circuit problem such as short to battery or

ground. The airbag indicator blinks four different modes

according to the fault.

Some malfunctions could result in non-deployment

when necessary or deployment under conditions which

would no normally result in deployment.

When the SDM is not properly attached to its connector

the airbag circuit is shorted to ground because there

is a shorting bar within the SDM electronic connector.

The shorting bar is disengaged when proper connection

is made, but if a poor connection exists the SDM

connector supplies a ground to the airbag indicator in

dependently of the SDM, and the airbag indicator turns

on.

CLOCK SPRING

Caution: Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

Caution: Over-rotating the clock spring without the

steering wheel in position could damage the clock

spring and result in an inoperative driver airbag.There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance

to the type of spring used in a mechanical clock. The

clock spring should never be disassembled, and there

is no timekeeping function. The clock spring contains

current- carrying coils. One of the current-carrying coils

maintains continuous contact within the driver deploy-

ment loop while the steering wheel is rotated. The clock

spring also contains coils that maintain continuous con-

tact for horn and remote audio control switch.

Turning the steering wheel in one direction tightens

the coil, and turning the steering wheel in the opposite

direction loosens the coil. Do not turn the clock spring

when the steering wheel is not attached.

A yellow two-way connector on the lower steering col-

umn is attached to the clock spring wiring.

WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical

connector is not attached properly, a built in shorting

bar will connect the wire from airbag warning lamp with

the SDM ground wire. This turns on the airbag indicator.

To prevent deployment during servicing, additional

shorting bars are located in following locations:

The clock spring electrical connector at the lower

steering column.

The passenger airbag module.

The driver airbag module.

The seat belt pretensioners.

The SDM connector.

The shorting bar is only a backup safety device. Always

disable the supplemental restraints system (SRS) be-

fore beginning any service procedure.

KAA8B070