roof SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 962 of 2053

SSANGYONG MY2002

4E-2 REAR BRAKES

DESCRIPTION AND OPERATION

DRUM BRAKE

This drum brake assembly is a leading/trailing shoe

design.

Both brake shoes are held against the wheel cylinder

pistons by the lower return spring and the fixed anchor

plate near the lower return spring. When the brakes

are applied, the wheel cylinder pistons move both

shoes out to contact the drum. With forward wheel

rotation, the forward brake shoe will wrap into the drum

and become selt-energized. With reverse wheel

rotation, brake shoes is transferred to the anchor plate

through the braking plate to the axle flange.

Adjustment is automatic and occurs on any service

brake application. Do not switch the position of shoes

that have been in service, as this may render the self-

adjustment feature inoperative and result in increased

pedal travel.

The brake drum must have high abrasion resistance,

heatproof, high stiffness, fatigue stiffness and strength

enough not to make any deformation. The temperature

of the drum surface comes up to 500 - 700 °C on brake

operation by the friction with the lining. When the

temperature of the drum surface continues to keep

high, the friction coefficient goes down and the ‘fade

development’ occurs. When the brake is applied often

on the hill, any accident may be occur.

YAD4C010

Wheel Cylinder

Both wheel cylinder diameters are same in order to

balance the friction forces of both shoes.

The hydraulic pressure from the master cylinder is

provided to the wheel cylinder and the piston in the

wheel cylinder allows to push both shoes toward the

drum resulted in generating the braking force.

Brake Lining

The brake lining is installed with the brake shoe and

pushed toward the drum for applying the brake pedal.

Thus, lining must have high-heat tolerance, abrasion

resistance and high friction coefficient.

Brake Lining and Drum Clearance Automatic

Control System

If the lining’s wear is excessive, the piston moves to

long distance and the pedal travel increases. The

clearance between the drum and the brake lining

should be adjusted.

Generally the drum brake must be adjusted regularly

and thus the clearance automatic control system

enables to adjust the clearance between the brake

lining and the drum resulting from brake lining wear.

YAD4C020

1 Cylinder Housing

2 Boot

3 Spring

4 Piston Cup

5 Piston

6 Air Bleeder1 Cylinder Housing

2 Boot

3 Spring

4 Piston Cup

5 Piston

6 Air Bleeder

Page 1652 of 2053

SECTION 9A

BODY WIRING SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

General Description.............................................9A-2

Wire Color Chart..................................................9A-2

Engine Room Fuse & Relay Box......................... 9A-3

Usage of Fuse in Engine Room Fuse Box.............9A-5

Passenger Room Fuse Box..................................9A-6

Usage of Fuse in Engine Room Fuse Box.............9A-7

Schematic and Routing Diagrams.......................9A-8

Engine Room Fuse & Relay Circuit.......................9A-8

Wiring Harness & Connector &

Ground Location................................................. 9A-11

W/H Engine Room.............................................9A-11W/H Main..........................................................9A-12

W/H Main (Floor)............................................... 9A-14

W/H Roof..........................................................9A-15

W/H Seat Heater................................................9A-16

W/H Door..........................................................9A-17

W/H Tail Gate....................................................9A-18

W/H Air-Conditioner...........................................9A-19

W/H Engine Control (Gasoline)...........................9A-20

W/H Pre-Heating (Diesel)...................................9A-21

W/H Transmission..............................................9A-22

Page 1666 of 2053

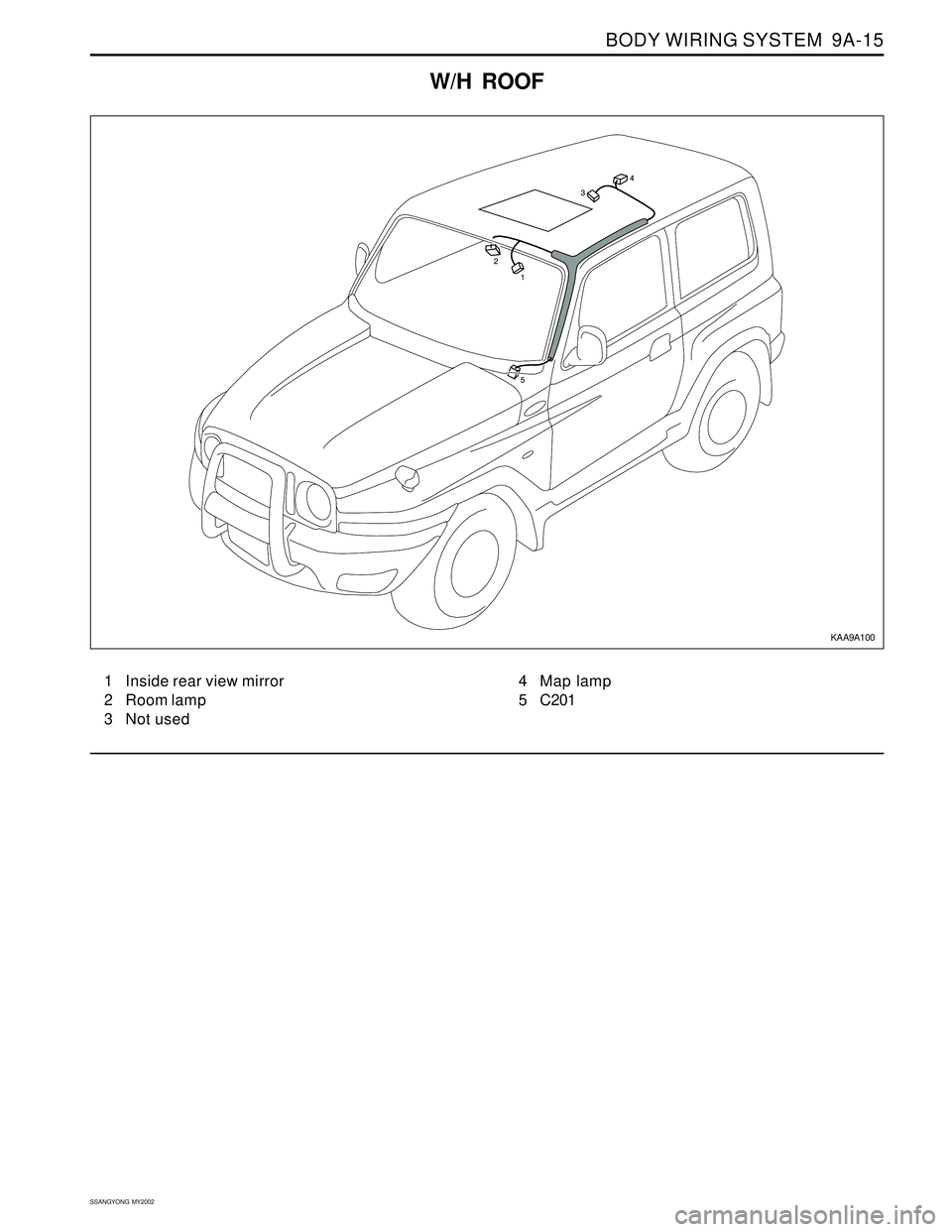

BODY WIRING SYSTEM 9A-15

SSANGYONG MY2002

W/H ROOF

1 Inside rear view mirror

2 Room lamp

3 Not used4 Map lamp

5 C201

KAA9A100

Page 1754 of 2053

INTERIOR TRIM 9G-5

SSANGYONG MY2002

EF

KAA9G060

KAA9G050

A-PILLAR TRIM PANEL

Removal and Installation Procedure

1. Remove the roof assist handle with the screws.

2. Remove the A-pillar trim panel.

3. Installation should follow the removal procedure

in the reverse order. 6. Disconnect the electrical connector.

7. Remove the door trim panel.

8. Installation should follow the removal procedure

in the reverse order.

KAA9G080

KAA9G070

3. Remove the upper quarter trim panel.

4. Installation should follow the removal procedure

in the reverse order.

UPPER QUARTER TRIM PANEL

Removal and Installation Procedure

1. Remove the roof assist handle with the screws.

2. Remove the seat belt anchor with the bolt.

Installation Notice

•Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

Tightening Torque 45 Nm (33 lb-ft)

Page 1755 of 2053

SSANGYONG MY2002

9G-6 INTERIOR TRIM

� �

�

y y

y

KAA9G100

KAA9G090

2. Remove the armrest. Refer to Section 9H “SEATS”.

3. Remove the ashtray and compartment lamp from

lower quarter trim panel.

4. Remove the roof rear trim and back panel cover.

LOWER QUARTER TRIM PANEL

Removal and Installation Procedure

1. Lift up the rear seat from the floor.

KAA9G120

KAA9G110

COWL SIDE TRIM PANEL

Removal and Installation Procedure

1. Remove the cowl side trim panel. Refer to front

rocker trim panel in this section.

2. Remove the cowl side trim panel with the screws.

3. Installation should follow the removal procedure

in the reverse order. 5. Remove the lower quarter trim panel with the

screws.

6. Installation should follow the removal procedure

in the reverse order.

Page 1796 of 2053

Description and Operation..................................9M-2

Emblems and Lettering.......................................9M-2

Mud Guards.......................................................9M-2

Components Locator ...........................................9M-3

Exterior Trim.......................................................9M-3

Repair Instructions...............................................9M-4

On-Vehicle Service Unit Repair...............................9M-4

B-Pillar Molding..................................................9M-4

B-Pillar Cover......................................................9M-4

SECTION 9M

EXTERIOR TRIM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Air Extractor Grille...............................................9M-4

Door Molding......................................................9M-5

Front Wheel Molding...........................................9M-5

Rear Wheel Molding...........................................9M-5

Side Step...........................................................9M-6

C-Pillar Cover......................................................9M-6

Roof Molding......................................................9M-6

Specifications......................................................9M-7

Fastener Tightening Specifications......................9M-7

Page 1798 of 2053

EXTERIOR TRIM 9M-3

SSANGYONG MY2002

COMPONENTS LOCATOR

EXTERIOR TRIM

1 Rivet

2 B Pillar Cover

3 Air Extractor Grill

4 Air Extractor Grill Tape

5 Door Molding

6 Front Wheel Arch Molding

7 Rear Wheel Arch Molding

8 Side Step

9 Side Step Upper Cover

10 Bolt

11 Wheel Arch Clip12 Garnish Clip

13 Garnish Clip

14 Door Molding Clip

15 Door Molding Clip

16 Clip

17 “C” Pillar Cover

18 Clip

19 Tailgate Garnish

20 Roof Molding

21 Roof Molding Endcap

22 Clip

KAA9M010

Page 1801 of 2053

SSANGYONG MY2002

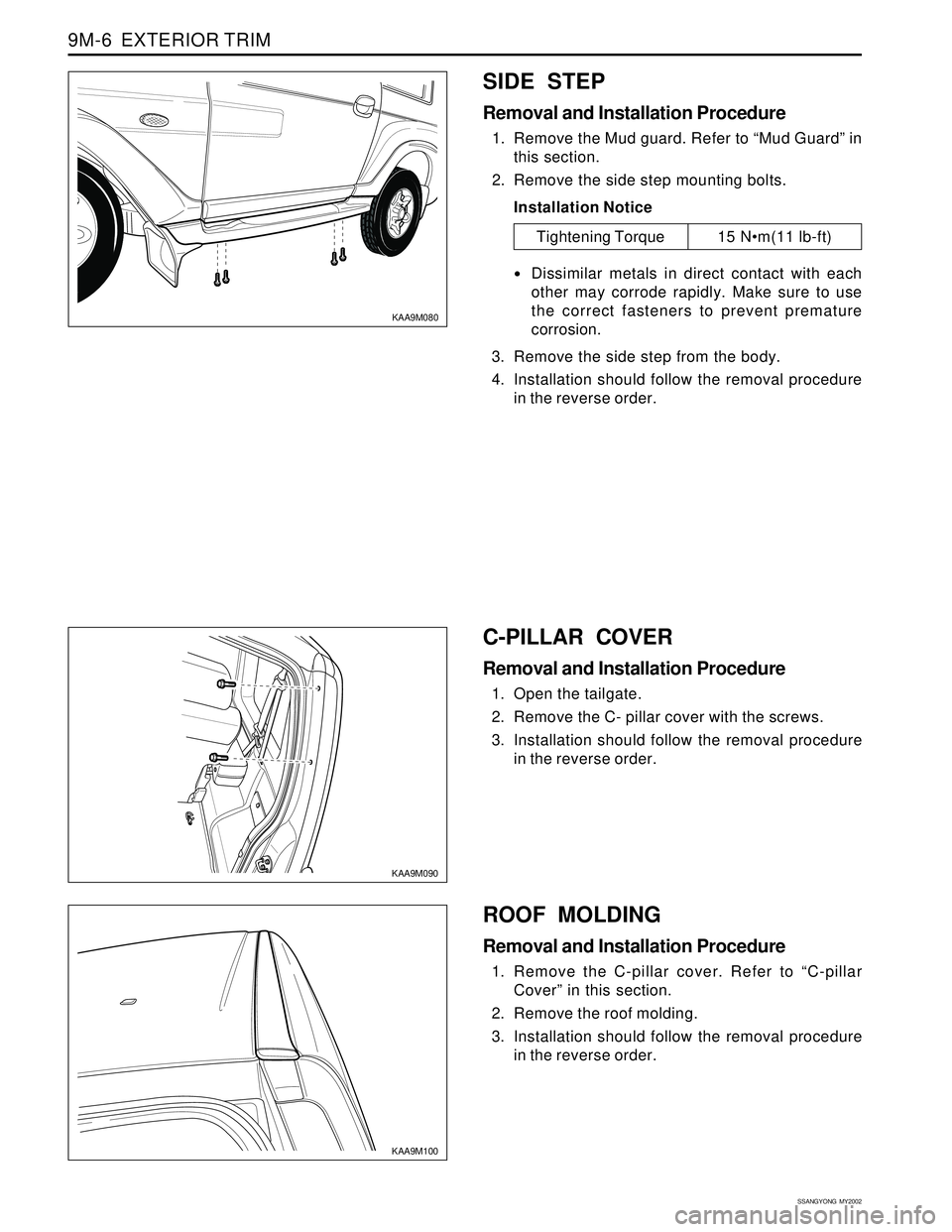

9M-6 EXTERIOR TRIM

KAA9M090

KAA9M100

C-PILLAR COVER

Removal and Installation Procedure

1. Open the tailgate.

2. Remove the C- pillar cover with the screws.

3. Installation should follow the removal procedure

in the reverse order. 3. Remove the side step from the body.

4. Installation should follow the removal procedure

in the reverse order.

ROOF MOLDING

Removal and Installation Procedure

1. Remove the C-pillar cover. Refer to “C-pillar

Cover” in this section.

2. Remove the roof molding.

3. Installation should follow the removal procedure

in the reverse order.

SIDE STEP

Removal and Installation Procedure

1. Remove the Mud guard. Refer to “Mud Guard” in

this section.

2. Remove the side step mounting bolts.

Installation Notice

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

KAA9M080

Tightening Torque 15 Nm(11 lb-ft)

Page 1811 of 2053

FRAME AND UNDERBODY 9N-9

SSANGYONG MY2002

GENERAL DESCRIPTION AND SYSTEM OPERATION

GENERAL BODY CONSTRUCTION

This vehicle is constructed with a unitized body which

in-corporates integral front and rear frame side rails.

The front suspension lower control arms are bolted to

and retained by supports, one each on the right and

left sides. The front suspension lower control arm

supports are attached to the underbody with three bolts

at two locations. The engine is bolted to the integral

front side rails. The suspension strut towers must be

dimensionally correct in relation to the remainder of

the underbody in order to maintain specified

suspension strut and caster/camber angles.

Since the individual underbody parts contribute directly

to the overall strength of the body, it is essential to

observe proper welding techniques during servicerepair operations. The underbody parts should be

properly sealed and rustproofed whenever body repair

operations destroy or damage the original sealing and

rustproofing. When rustproofing critical underbody

parts, use a good-quality type of air-dry primer, such

as a corrosion-resistant chromate or an equivalent

material. Combination-type primer/surfacers are not

recommended.

ENGINE UNDER COVERS

The engine under covers are molded pieces of plastic

that serve as shields for the underside of the engine.

The covers help protect the engine from small rocks,

gravel and other objects that would otherwise come

into contact with the engine during normal driving

conditions.

Page 1812 of 2053

SSANGYONG MY2002

9O-6 BUMPERS AND FASCIAS

KAA9O070

REAR BUMPER IMPACT BAR

Removal and Installation Procedure

1. Remove the rear bumper fascia. Refer to Rear

Bumper Fascia in this section.

2. Remove the rear bumper impact bar.

3. Installation should follow the removal procedure

in the reverse order.

ROOF MOLDING

Removal and Installation Procedure

1. Remove the C-pillar cover. Refer to “C-pillar

Cover” in this section.

2. Remove the roof molding

3. Installation should follow the removal procedure

in the reverse order.