warning SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 13 of 2053

GENERAL INFORMATION 0B -- 13

D AEW OO M Y_2000

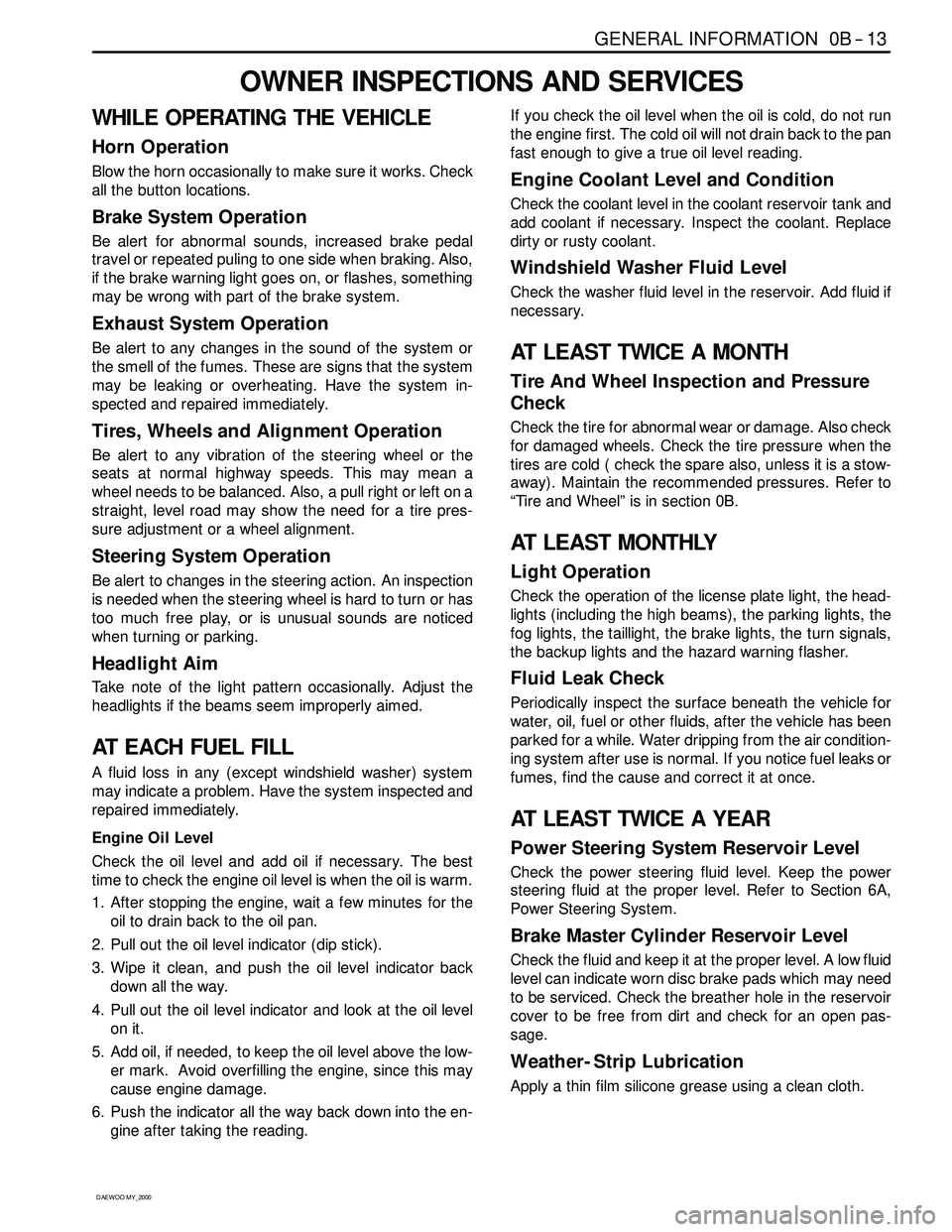

OWNER INSPECTIONS AND SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal

travel or repeated puling to one side when braking. Also,

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system.

Exhaust System Operation

Be alert to any changes inthe sound of the system or

the smell of the fumes. These are signs that the system

may be leaking or overheating. Have the system in-

spected and repaired immediately.

Tires, Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the

seats at normal highway speeds. This may mean a

wheel needs to be balanced. Also, a pull right or left on a

straight, level road may show the need for a tire pres-

sure adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn or has

too much free play, or is unusual sounds are noticed

when turning or parking.

Headlight Aim

Take note of the light pattern occasionally. Adjust the

headlights if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system

may indicate a problem. Have the system inspected and

repaired immediately.

Engine Oil Level

Check the oil level and add oil if necessary. The best

time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level

on it.

5. Add oil, if needed, to keep the oil level above the low-

er mark. Avoid overfilling theengine, since this may

cause engine damage.

6. Push the indicator all the way back down into the en-

gine after taking the reading.If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the pan

fast enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank and

add coolant if necessary. Inspect the coolant. Replace

dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH

Tire And Wheel Inspection and Pressure

Check

Check the tire for abnormal wear or damage. Also check

for damaged wheels. Check the tire pressure when the

tires are cold ( check the spare also, unless it is a stow-

away). Maintain the recommended pressures. Refer to

“Tire and Wheel” is in section 0B.

AT LEAST MONTHLY

Light Operation

Check the operation of the license plate light, the head-

lights (including the high beams), the parking lights, the

fog lights, the taillight, the brake lights, the turn signals,

the backup lights and the hazard warning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air condition-

ing system after use is normal. If you notice fuel leaks or

fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to Section 6A,

Power Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low fluid

level can indicate worn disc brake pads which may need

to be serviced. Check the breather hole in the reservoir

cover to be free from dirt and check for an open pas-

sage.

Weather- Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

Page 238 of 2053

M162 ENGINE CONTROLS 1F1 -- 75

D AEW OO M Y_2000

TRACTION CONTROLSYSTEM (TCS)

KAB1F310

Failure

CodeDescriptionTrouble AreaMaintenance Hint

150TCS input signal short

circuit to batteryTCS short circuit to powerDInspection the Engine Control Module

(ECM) pin 45 about short circuit or

openwithbadcontact

151TCS input signal short

circuit to ground or openTCS short circuit to ground or

open

openwithbadcontact

DInspection the TCS lamp of I/P cluster.

DInspection the ECM

Circuit Description

Battery voltage is supplied to the TCS warning lamp with the ignition in ON and START. The warning lamp can be

activated only by the Electrical Brake Control Module (EBCM) internally supplying ground to terminal 32. If the TCS

input circuit is open or short, this failure codewill be set.

Page 493 of 2053

M161 ENGINE CONTROLS 1F2 -- 75

D AEW OO M Y_2000

TRACTION CONTROLSYSTEM (TCS)

KAB1F310

Failure

CodeDescriptionTrouble AreaMaintenance Hint

150TCS input signal short

circuit to batteryTCS short circuit to powerDInspection the Engine Control Module

(ECM) pin 45 about short circuit or

openwithbadcontact

151TCS input signal short

circuit to ground or openTCS short circuit to ground or

open

openwithbadcontact

DInspection the TCS lamp of I/P cluster.

DInspection the ECM

Circuit Description

Battery voltage is supplied to the TCS warning lamp with the ignition in ON and START. The warning lamp can be

activated only by the Electrical Brake Control Module (EBCM) internally supplying ground to terminal 32. If the TCS

input circuit is open or short, this failure codewill be set.

Page 921 of 2053

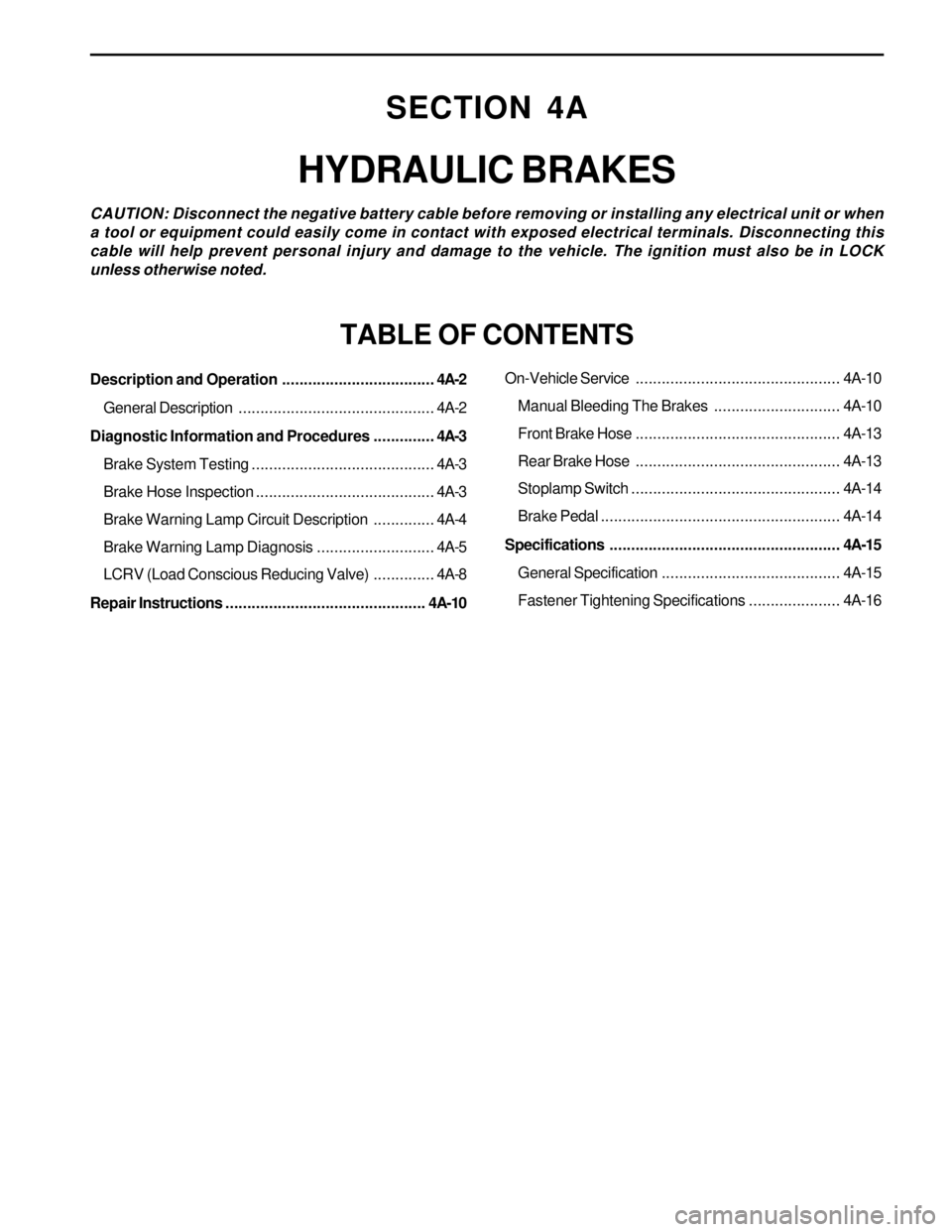

SECTION 4A

HYDRAULIC BRAKES

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when

a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

TABLE OF CONTENTS

Description and Operation...................................4A-2

General Description.............................................4A-2

Diagnostic Information and Procedures..............4A-3

Brake System Testing ..........................................4A-3

Brake Hose Inspection.........................................4A-3

Brake Warning Lamp Circuit Description..............4A-4

Brake Warning Lamp Diagnosis...........................4A-5

LCRV (Load Conscious Reducing Valve)..............4A-8

Repair Instructions..............................................4A-10On-Vehicle Service...............................................4A-10

Manual Bleeding The Brakes.............................4A-10

Front Brake Hose...............................................4A-13

Rear Brake Hose...............................................4A-13

Stoplamp Switch................................................4A-14

Brake Pedal.......................................................4A-14

Specifications.....................................................4A-15

General Specification .........................................4A-15

Fastener Tightening Specifications.....................4A-16

Page 924 of 2053

SSAMGYONG MY2002

4A-4 HYDRAULIC BRAKES

KAA4A010

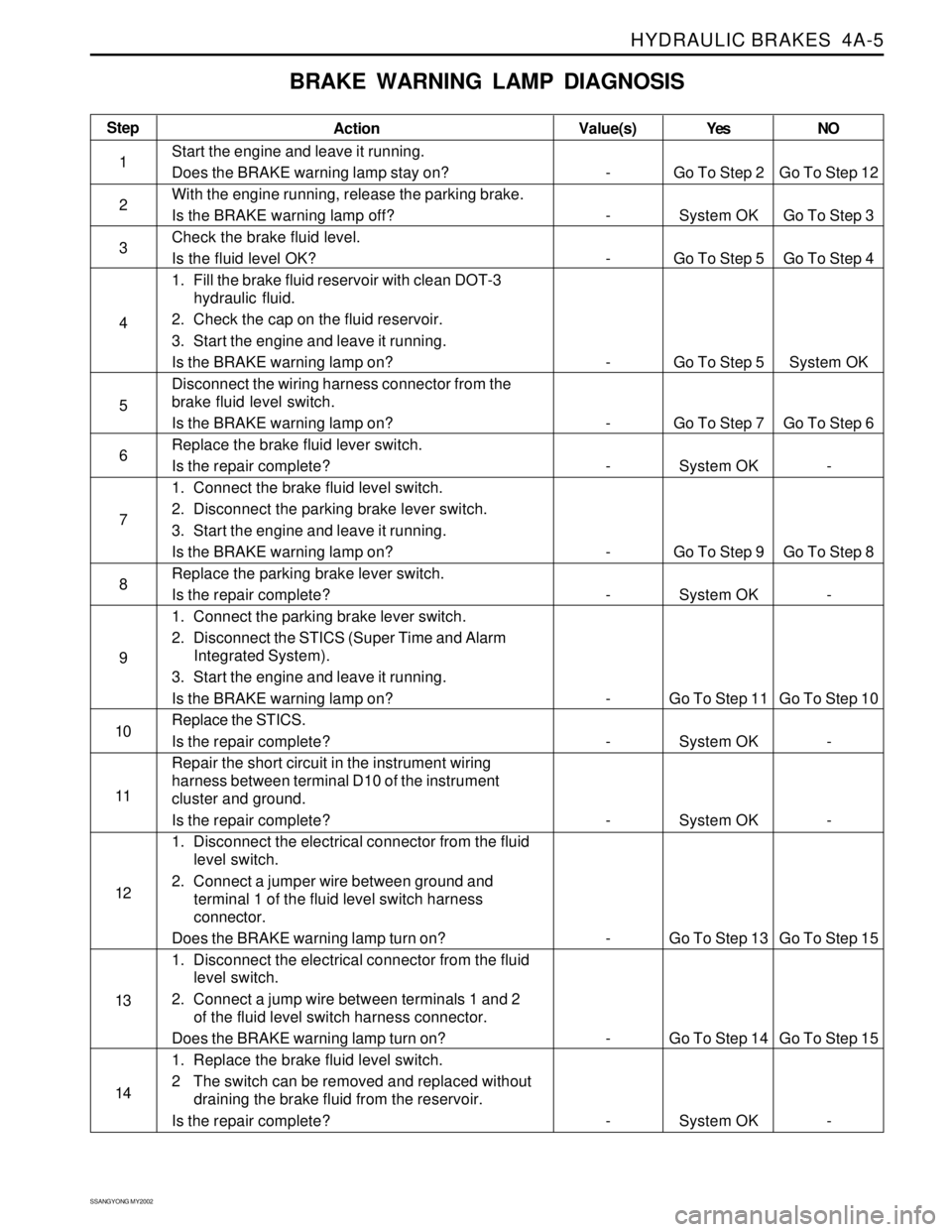

BRAKE WARNING LAMP CIRCUIT DESCRIPTION

Diagnostic Aids

The BRAKE lamp glows brightly when the ignition is

ON and either the parking brake lever switch or the

brake fluid level switch is closed.

If neither switch is closed, the BRAKE lamp receives

a ground through the generator, and it glows dimly

when the ignition is ON and the engine is off. When

the engine starts, the generator creates voltage. With

voltage on both sides of the lamp, the lamp turns off.

Test Description

The numbers below refer to steps in the diagnostic

table.

1. This step begins the test sequence for a BRAKE

warning lamp that stays on when the engine is run-

ning.

2. This step begins the test sequence for a BRAKE

warning lamp that never turns on.

Page 925 of 2053

HYDRAULIC BRAKES 4A-5

SSANGYONG MY2002

Value(s)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

BRAKE WARNING LAMP DIAGNOSIS

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14Action

Start the engine and leave it running.

Does the BRAKE warning lamp stay on?

With the engine running, release the parking brake.

Is the BRAKE warning lamp off?

Check the brake fluid level.

Is the fluid level OK?

1. Fill the brake fluid reservoir with clean DOT-3

hydraulic fluid.

2. Check the cap on the fluid reservoir.

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Disconnect the wiring harness connector from the

brake fluid level switch.

Is the BRAKE warning lamp on?

Replace the brake fluid lever switch.

Is the repair complete?

1. Connect the brake fluid level switch.

2. Disconnect the parking brake lever switch.

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Replace the parking brake lever switch.

Is the repair complete?

1. Connect the parking brake lever switch.

2. Disconnect the STICS (Super Time and Alarm

Integrated System).

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Replace the STICS.

Is the repair complete?

Repair the short circuit in the instrument wiring

harness between terminal D10 of the instrument

cluster and ground.

Is the repair complete?

1. Disconnect the electrical connector from the fluid

level switch.

2. Connect a jumper wire between ground and

terminal 1 of the fluid level switch harness

connector.

Does the BRAKE warning lamp turn on?

1. Disconnect the electrical connector from the fluid

level switch.

2. Connect a jump wire between terminals 1 and 2

of the fluid level switch harness connector.

Does the BRAKE warning lamp turn on?

1. Replace the brake fluid level switch.

2 The switch can be removed and replaced without

draining the brake fluid from the reservoir.

Is the repair complete?Yes

Go To Step 2

System OK

Go To Step 5

Go To Step 5

Go To Step 7

System OK

Go To Step 9

System OK

Go To Step 11

System OK

System OK

Go To Step 13

Go To Step 14

System OKNO

Go To Step 12

Go To Step 3

Go To Step 4

System OK

Go To Step 6

-

Go To Step 8

-

Go To Step 10

-

-

Go To Step 15

Go To Step 15

-

Page 926 of 2053

SSAMGYONG MY2002

4A-6 HYDRAULIC BRAKES

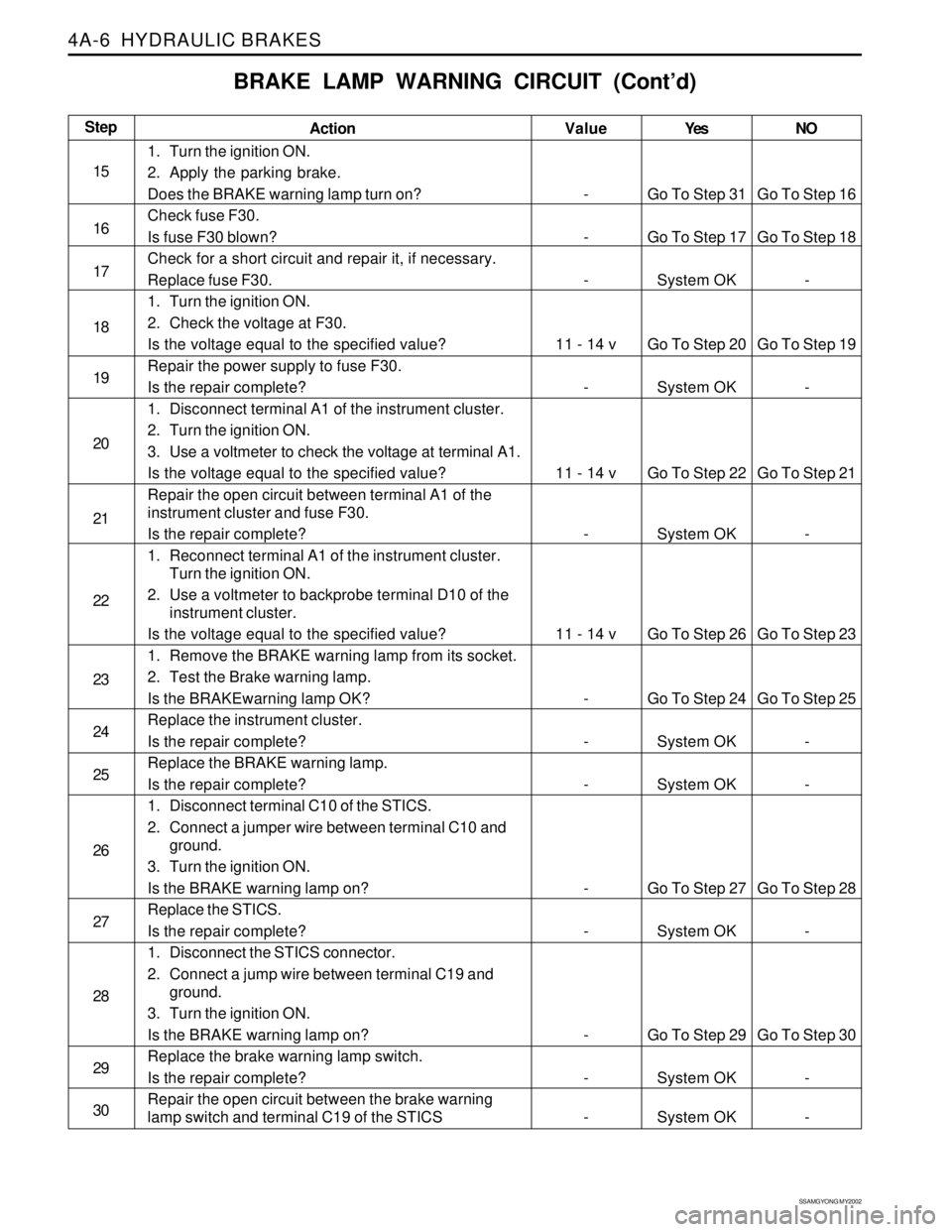

Action

1. Turn the ignition ON.

2. Apply the parking brake.

Does the BRAKE warning lamp turn on?

Check fuse F30.

Is fuse F30 blown?

Check for a short circuit and repair it, if necessary.

Replace fuse F30.

1. Turn the ignition ON.

2. Check the voltage at F30.

Is the voltage equal to the specified value?

Repair the power supply to fuse F30.

Is the repair complete?

1. Disconnect terminal A1 of the instrument cluster.

2. Turn the ignition ON.

3. Use a voltmeter to check the voltage at terminal A1.

Is the voltage equal to the specified value?

Repair the open circuit between terminal A1 of the

instrument cluster and fuse F30.

Is the repair complete?

1. Reconnect terminal A1 of the instrument cluster.

Turn the ignition ON.

2. Use a voltmeter to backprobe terminal D10 of the

instrument cluster.

Is the voltage equal to the specified value?

1. Remove the BRAKE warning lamp from its socket.

2. Test the Brake warning lamp.

Is the BRAKEwarning lamp OK?

Replace the instrument cluster.

Is the repair complete?

Replace the BRAKE warning lamp.

Is the repair complete?

1. Disconnect terminal C10 of the STICS.

2. Connect a jumper wire between terminal C10 and

ground.

3. Turn the ignition ON.

Is the BRAKE warning lamp on?

Replace the STICS.

Is the repair complete?

1. Disconnect the STICS connector.

2. Connect a jump wire between terminal C19 and

ground.

3. Turn the ignition ON.

Is the BRAKE warning lamp on?

Replace the brake warning lamp switch.

Is the repair complete?

Repair the open circuit between the brake warning

lamp switch and terminal C19 of the STICS

BRAKE LAMP WARNING CIRCUIT (Cont’d)

Yes

Go To Step 31

Go To Step 17

System OK

Go To Step 20

System OK

Go To Step 22

System OK

Go To Step 26

Go To Step 24

System OK

System OK

Go To Step 27

System OK

Go To Step 29

System OK

System OKNO

Go To Step 16

Go To Step 18

-

Go To Step 19

-

Go To Step 21

-

Go To Step 23

Go To Step 25

-

-

Go To Step 28

-

Go To Step 30

-

-Step

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30Value

-

-

-

11 - 14 v

-

11 - 14 v

-

11 - 14 v

-

-

-

-

-

-

-

-

Page 927 of 2053

HYDRAULIC BRAKES 4A-7

SSANGYONG MY2002

BRAKE LAMP WARNING CIRCUIT (Cont’d)

Action

1. Disconnect the brake fluid level switch.

2. Use an ohmmeter to check the resistance between

terminal 2 of the switch connector and ground.

Is the resistance equal to the specified value?

Repair the open circuit between ground and the brake

fluid level switch.

Is the repair complete?

Repair the open circuit between terminal 1 of the brake

fluid level switch and terminal D10 of the instrument

cluster.

Is the repair complete?Yes

Go To Step 32

System OK

System OKNO

Go To Step 33

-

-Step

31

32

33Value(s)

≈ 0 Ω

-

-

Page 988 of 2053

SSANGYONG MY2002

4F-4 ABS AND TCS

Pressure Modulation

Depending on the control deviation and the wheel accel-

eration of the spinning wheel, pressure increase, hold

and decrease are made.

The pressure modulation is done with the conventional

control with the valves. Prime valve, pilot valve, inlet

valve and outlet valve according to the following table:

Speed Range

TCS is available in the speed range ≤ 60 kph.

Above 60 kph vehicle speed, TCS is passive.

It is possible to initiate TCS operation up to a vehicle

speed of 55 kph.

Prime Valve

Pilot Valve

Inlet Valve

Outlet Valve

Increase

Open

Closed

Open

ClosedHold

Open

Closed

Closed

ClosedDecrease

Open

Closed

Closed

Open

System Failure (EBD,

ABS or TCS are Not

Distinguished)

ABS Warning

LampIgnition ONABS

OperationTCS

OperationTCS Passive Due to

Temperature Model

2 second on

for lamp

checkOFF OFF ON OFF

TCS Info

Lamp2 second on

for lamp

checkOFFBlinking

(FLASHING)OFF ON

EBD Warning

Lamp2 second on

for lamp

checkEBD

operation/OFFOFF ON OFF

Temperature Model

TCS operation is a high thermal load for the brakes.

To avoid any damages at the brakes, the disk tempera-

ture is calculated with a mathematical model for each

driven wheel separately. After ignition on, the

calculation starts with 30°C and then three different

phases are evaluated separately and added:

TCS operation, braking and coling phase.

If the temperature is highter than 500°C, TCS is dis-

abled for this wheel.

It is permitted again, if the model has calculated down

the 350°C.

Lamp Concepts

The system is equipped with an TCS information lamp,

which is blinking during TCS operation.

The activation of the EBD, TCS warning lamp and the

TCS info lamp issummarized in thefollowing table:

Page 997 of 2053

SSANGYONG MY2002

4F-14 ABS AND TCS

COMPONENT LOCATOR

ABS, ABS/TCS 5.3

1 ABS/TCS Hydraulic Unit

(with EBCM in case of ABS only)

2 ABS/TCS EBCM Unit (in case of TCS)

3 Rear Wheel Speed Sensor

KAA4F100

4 ABS Warning Indicator Light

5 Diagnosis Connector

6 Front Wheel Speed Sensor

7 Acceleration Sensor