set clock SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 585 of 2053

1B3 -- 36 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Setting (with cylinder head installed)

1. Remove the prechamber of No. 1 cylinder.

2. Position the piston of No.1 cylinder at BTDC 10.

3. Install the measuring device into the prechamber

bore and position the dial gauge with a preload of

5mm.

Dial Gauge 001 589 53 21 00

Depth Gauge 601 589 07 21 00

4. Slowly rotate the crankshaft in the direction of en-

gine rotation until the large pointer on the dial gauge

stops (TDC position).

Notice

The position of TDC is when the large pointer on the

dial gauge is stopped before moving back.

5. Remove the reinstall the measuring device and

position the dial gauge scale at ’0’.

6. Slowly rotate the crankshaft in the direction of en-

gine rotation until the dial gauge has moved back

(counterclockwise) by 3.65mm.

7. Insert fixing device into the sensor bracket.

Notice

The pin on the vibration damper must engage into

the slot of the fixing device.

Fixing Device 667 589 01 21 00

8. If the pin does not engage, adjust the setting of the

sensor bracket by removing and tightening of the

sensor bracket bolts.

Tightening Torque10 N∙m(89lb-in)

Notice

The timing mark on the damper must be positioned

at ATDC 20.

Page 1446 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

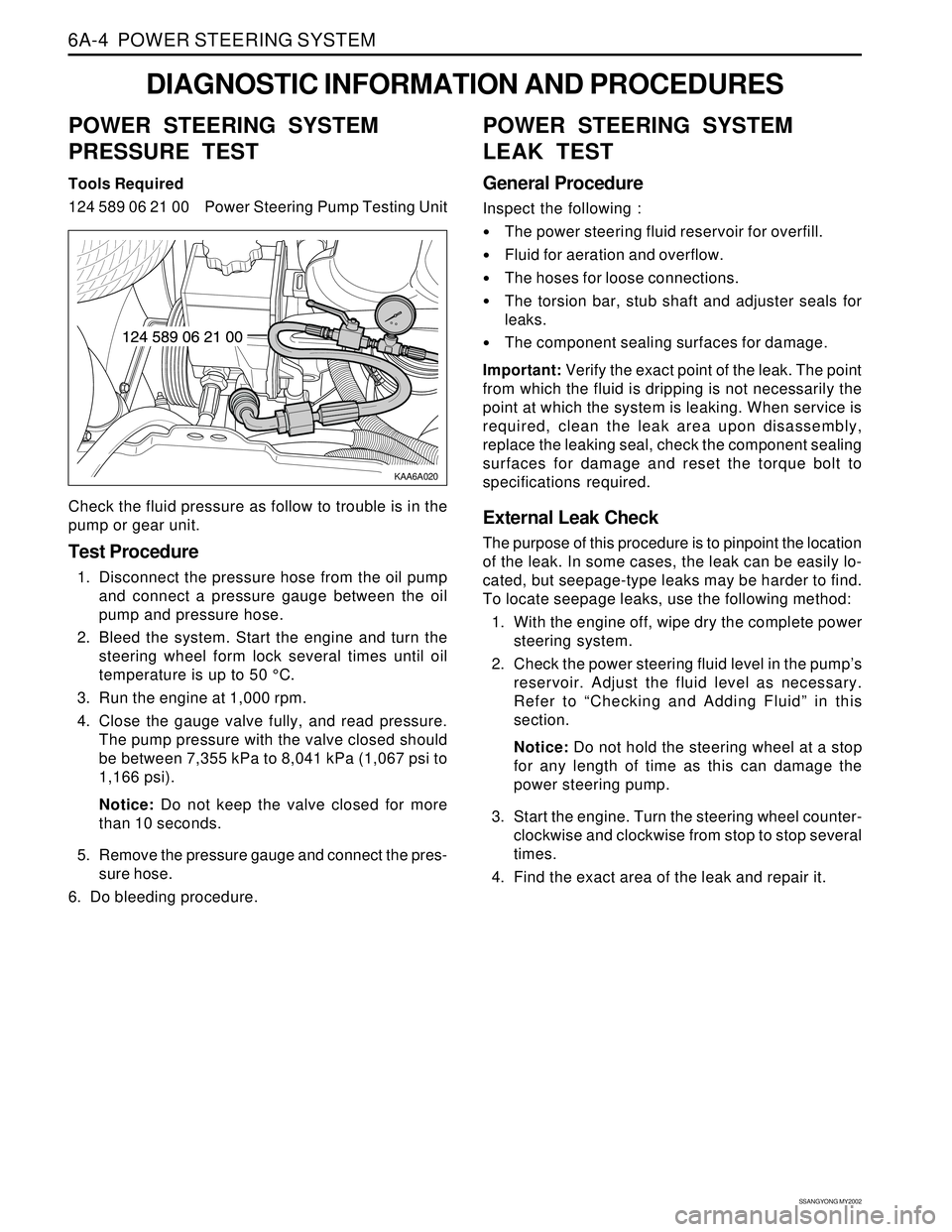

KAA6A020

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1455 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

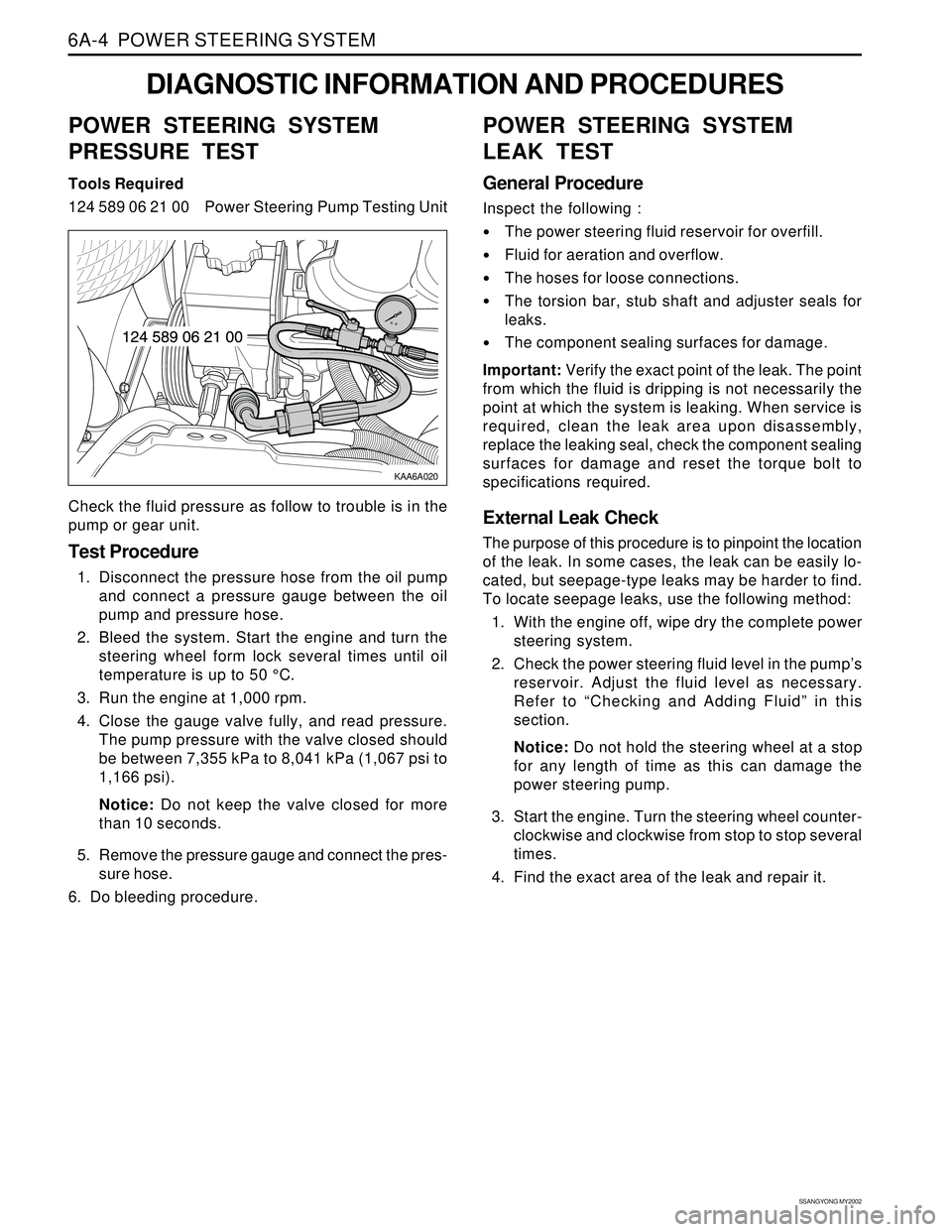

KAA6A020

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1618 of 2053

SSANGYONG MY2002

8B-34 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Upon

passing these tests ignition and deployment loop

voltages are measured to ensure that they are within

their respective normal voltage ranges. The SDM then

proceeds with resistance measurement test. Driver low

terminal 14 is grounded through a current sink. The

current source is connected to driver high terminal 13

to allow a known amount of the current flow. By

monitoring the voltage difference between drive high

and driver low, the SDM calculates the combined

resistance of the driver inflator module, the clock

spring, the harness wiring, and connector terminal

contacts.

DTC 17 Will Set When

DTC 17 will set when the resistance of the driver airbag

deployment loop is above specified value (4.5 ± 0.5 Ω).

DIAGNOSTIC TROUBLE CODE (DTC) 17

DRIVER DEPLOYMENT LOOP RESISTANCE HIGH

The test is run once each ignition cycle during the

resistance measurement test when the ignition voltage

is above a specified value.

Action Taken

The SDM will turn on the airbag indicator (blink mode

1) and set DTC 17. And driver airbag deployment loop

shutdown.

DTC 17 Will Clear When

The ignition switch is turned OFF or the scan tool

CLEAR CODES command is received.

Diagnostic Aids

All intermittent condition is likely to be the caused by

a poor connection from the driver airbag to the clock

spring or SDM terminal 13 or 14. The test for this DTCis

run only while the airbag indicator is performing the

start-up test. When a scan tool CLEAR CODES

command is issued and the malfunction is still present,

the DTC will not reappear until next ignition cycle.

KAA8B100

DTC 17 - Driver Deployment Loop Resistance High

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Page 1627 of 2053

SSANGYONG MY2002

8B-44 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Upon

passing these tests ignition and deployment loop

voltages are measured to ensure that they are within

their respective normal voltage ranges. The SDM then

proceeds with resistance measurement test. Driver low

terminal 14 is grounded through a current sink. The

current source is connected to driver high terminal 13

to allow a known amount of the current flow. By

monitoring the voltage difference between drive high

and driver low, the SDM calculates the combined

resistance of the driver inflator module, the clock

spring, the harness wiring, and connector terminal

contacts.

DTC 21 Will Set When

DTC 21 will set when the resistance of the driver airbag

deployment loop is below a specified value (1.4 ± 0.5 Ω).

DIAGNOSTIC TROUBLE CODE (DTC) 21

DRIVER AIRBAG DEPLOYMENT LOOP RESISTANCE LOW

The test is run once each ignition cycle during the

resistance measurement test when the ignition voltage

is above a specified value.

Action Taken

The SDM will turn on the airbag indicator (blink mode

1) and set DTC 21. And driver airbag deployment loop

shutdown.

DTC 21 Will Clear When

The ignition switch is turned OFF or the scan tool

CLEAR CODES command is received.

Diagnostic Aids

All intermittent condition is likely to be the caused by

a poor connection from the driver airbag to the clock

spring or SDM terminal 13 or 14. The test for this DTC

is run only while the airbag indicator is performing the

start-up test. When a scan tool CLEAR CODES

command is issued and the malfunction is still present,

the DTC will not reappear until next ignition cycle.

KAA8B100

DTC 21 - Driver Airbag Deployment Loop Resistance Low

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Page 1640 of 2053

SSANGYONG MY2002

8B-58 SUPPLEMENTAL RESTRAINTS SYSTEM

REPAIR INSTRUCTION

ON-VEHICLE SERVICE

SERVICE PRECAUTION

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioner for 0.15 seconds after the ignition

is OFF and the airbag fuse has been removed. If the

airbags or pretensioners are not disconnected, do

not begin service until one minute has passed after

disconnecting power to the SDM. If the airbag are

disconnected, service can begin immediately without

waiting for one-minute time period to expire. Failure

to temporarily disable the SRS during service can

result in unexpected deployment, personal injury,

and otherwise unneeded SRS repairs.

DISABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

1. Turn the steering wheel to the straight-ahead

position.

2. Turn the ignition switch to LOCK and remove the key.

3. Remove the airbag fuse F31 in the I/P fuse block

and wait more than one minute for SRS capacitor to

discharge.

ENABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

Enabling the supplemental restraint system (SRS) is

reverse order of “Disabling the Supplemental Restraint

System (SRS)”.

Caution: Staying well away from the inflator

modules, turn the ignition key switch to ON, and

verify that the airbag indicator illuminates for 4.5

seconds and turns OFF. If it does not operate as

described, perform the “SRS Diagnostic System

Check” referring in this section.

HANDLING, INSTALLATION AND

DIAGNOSIS

Airbag modules should not be subjected to

temperature above 65°C (149°F)

An airbag module or sensing and diagnostic module

(SDM) should not be used if it has been dropped

from height of 0.9 meters (3 feet) or greater.

It is very important for the SDM to be installed flat

on the mounting surface, parallel to the vehicle’s

longitudinal axis.

To avoid setting diagnostic trouble codes (DTCs),

do not apply power to the SRS unless all components

are connected or a diagnostic chart request it.

The SRS Diagnostic System Check must be the

starting point of any SRS diagnostics. The SRS

Diagnostic System Check will verify proper airbag

indicator operation and will lead you to correct chart

to diagnose any SRS malfunctions. Bypassing

these procedures may result in extended diagnostic

time and incorrect parts replacements.

REPAIRS AND INSPECTIONS

REQUIRED AFTER AN ACCIDENT

Caution: any repairs to the vehicle’s structure must

return it to the original production configuration.

Deployment requires replacement of SDM, the

inflator modules, and a dimensional inspection of

the steering column.

If any SRS components are damaged, they must

be replaced. If SRS components mounting points

are damaged, they must be repaired or replaced.

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from

an authorized source.

Do not attempt to service the SDM, the clock spring,

or other airbag modules, these items must be

replaced if they are defective.

Verify the part number of replacement airbag

modules. Some inflator modules look identical but

contain different internal components.

ACCIDENT WITH DEPLOYMENT -

COMPONENTS REPLACEMENT

All SRS components must be replaced after frontal crash

involving airbag deployment. After deployment, a

powdery residue may be on the surface of the airbag.

The powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by-product of the deployment

reaction. The sodium hydroxide then quickly reacts with

atmospheric moisture and is converted to sodium

carbonate and sodium bicarbonate (also known as

baking soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. Replace

the following SRS components.

Caution: Wear gloves and safety glasses during the

disposal procedure. Refer to “Deployed Airbag

Module Disposal Procedure” in this section.

The SDM.

Airbag modules and pretensioners

SRS wiring

Clock spring

Page 1719 of 2053

SSANGYONG MY2002

9E-2 INSTRUMENTATION, DRIVER INFORMATION

DESCRIPTION AND OPERATION

CIGAR LIGHTER

The cigar lighter is located in the front portion of the

floor console. To use the lighter, push it in completely.

When the lighter is hot, it will release itsef from contact

with the heating element. The lighter and the heating

element can be damaged if the lighter does not fully

release itsef from the heating element.

ASHTRAY

The ashtray is located in the console. To access the

ashtray, pullit out of the ashtray housing. The ashtray

lamp will go on when the parking lamps or headlamps

are turned on.

INSTRUMENT PANEL VENTS

The center and the side vents in the instrument panel

can be adjusted up and down and from side to side.

The side vents can also be aimed toward the side

windows to defog them.

GLOVE BOX

The glove box can be opened by pulling upon the latch

handle.

DIGITAL CLOCK

The digital clock is located in the instrument cluster.

INSTRUMENT CLUSTER

The instrument cluster is located above the steering

column and in the instrument cluster trim panel. The

instrument cluster contains the instruments that

provide the driver with vehicle performance information.

The instrument cluster contains a speedometer, a

tachometer, an odometer, a trip odometer, a

temperature gauge, a fuel gauge, and several indicator

lamps. For replacement of the indicator lamp bulbs

contained in the instrument cluster, refer to “Instrument

Cluster Indicator Lamps Specifications” in the section.

SPEEDOMETER AND

TACHOMETER

The speedometer measures the speed of the vehicle

in km/h (with mph) or mph (with km/h). It consists of

an instrument cluster gauge connected to the vehicle

speed sensor on the transaxle output shaft. The

tachometer measures the engine’s speed in terms of

thousands of revolutions per minute. It consists of an

instrument cluster gauge connected to a sending unit

in the engine con-trol module. Do not operate the

engine in the red zone. Engine damage may occur.

TRIP ODOMETER

The trip odometer measures the distance the vehicle

has traveled since it was last reset. It consists of an

instrument cluster gauge connected to the sending unit

on the tasnsaxle output shaft. The trip oddometer can

be record the distance traveled from any starting point.

FUEL GAUGE

The fuel gauge consists of an instrument cluster gauge

connected to a sending unit in the fuel tank. The fuel

gauge indicates the quantity of fuel in the tank only

when the ignition is turned to ON or ACC. When the

ignition is turned to LOCK or START, the pointer may

come to rest at any position.

TEMPERATURE GAUGE

The temperature gauge consists of an instrument

cluster gauge connected to a temperature sensor that

is in con-tact with the circulating engine coolant. The

temperature gauge indicates the temperature of the

coolant. Prolonged driving or idling in very hot weather

may cause the pointer to move beyond the center of

the gauge. The engine is overheating if the pointer

moves into the red zone at the upper limit of the gauge.

INSTRUMENT CLUSTER

INDICATOR LAMPS

The instrument cluster contains indicator lamps that

indicatethe functioning of certain systems or the

existenceof potential problems with the operation of

the vehicle. The indicator lamps are replaceable. For

replacement of the indicator lamps contained in the

instrument cluster, refer to “instrument cluster indicator

lamps specifications” in this section.

CHIME MODULE

The chime module will sound to bring attention to one

or more of the following conditions:

The lights are on and the ignition not in ACC, ON,

or START.

The ignition key is in the ignition switch when the

driver’s side door is open.

The seat belt is unbuckled when the ignition is in

ACC, ON, or START.

Voltage is supplied at all times through the fuse block

to power the chime module.

Page 1723 of 2053

SSANGYONG MY2002

9E-6 INSTRUMENTATION, DRIVER INFORMATION

Digital Clock Inoperative (Cont’d)

Step

1

2

3

4

5

6

7

8Action

Repair the open power supply circuit for the fuse.

Is the repair complete?

1. Turn the ignition ON.

2. Use a voltmeter to check the battery voltage

available at the clock connector terminal D1.

Does the voltmeter indicate the value specified?

Repair the open circuit between the clock connector

terminal D1 and the fuse F4.

Is the repair complete?

Turn the ignition ON.

Is battery voltage available at the clock connector

terminal C13?

Repair the open circuit between the clock connector

terminal C13 and the fuse F4.

Is the repair complete?

Check continuity between the clock connector

terminal C13 and ground.

Does the multimeter indicate the value specified?

Replace the clock.

Is the repair complete?

Repair the open ground circuit between the clock

connector terminal C13 and the ground G201.

Is the repair complete?Yes

System OK

Go to Step 7

System Ok

Go to Step 9

System OK

Go to Step 10

System OK

System OKNo

−

Go to Step 6

-

Go to Step 8

-

Go to Step 11

-

- Value(s)

−

11 - 14 v

-

-

-

0 Ω

-

-

SPEEDO METER

Speedometer Is Inoperative

Step

1

2

5

6

7

8Action

Check fuse F28, and F30.

Is fuse F28 and F30 blown?

1. Check for a short circuit and repair if necessary.

2. Replace the fuse F28, and F30.

Is the repair complete?

1. Turn the ignition ON.

2. Check the voltage at fuse F28 and F30.

Is the voltage equal to the specified value?

1. connect a scan tool.

2. Check for engine control diagnostic trouble codes

(DTCs).

Is a vehicle speed sensor DTC set?

1. Remove the instrument cluster.

2. Turn the ignition ON.

3. Check the voltage at instrument cluster connector

terminal A1.

Is the voltage equal to the specified value?

Repair the open circuit between fuse F30 and the

instrument cluster.

Is the repair complete?Yes

Go to Step 7

System OK

Go to Step 5

Go to Section

2F, Engine

Controls

Go to Step 8

System OKNo

Go to Step 3

-

Go to Step 4

Go to Step 6

Go to Step 7

- Value(s)

-

-

11 - 14 v

-

11 - 14 v

-