transmission SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 3 of 2053

GENERAL INFORMATION 0B -- 3

D AEW OO M Y_2000

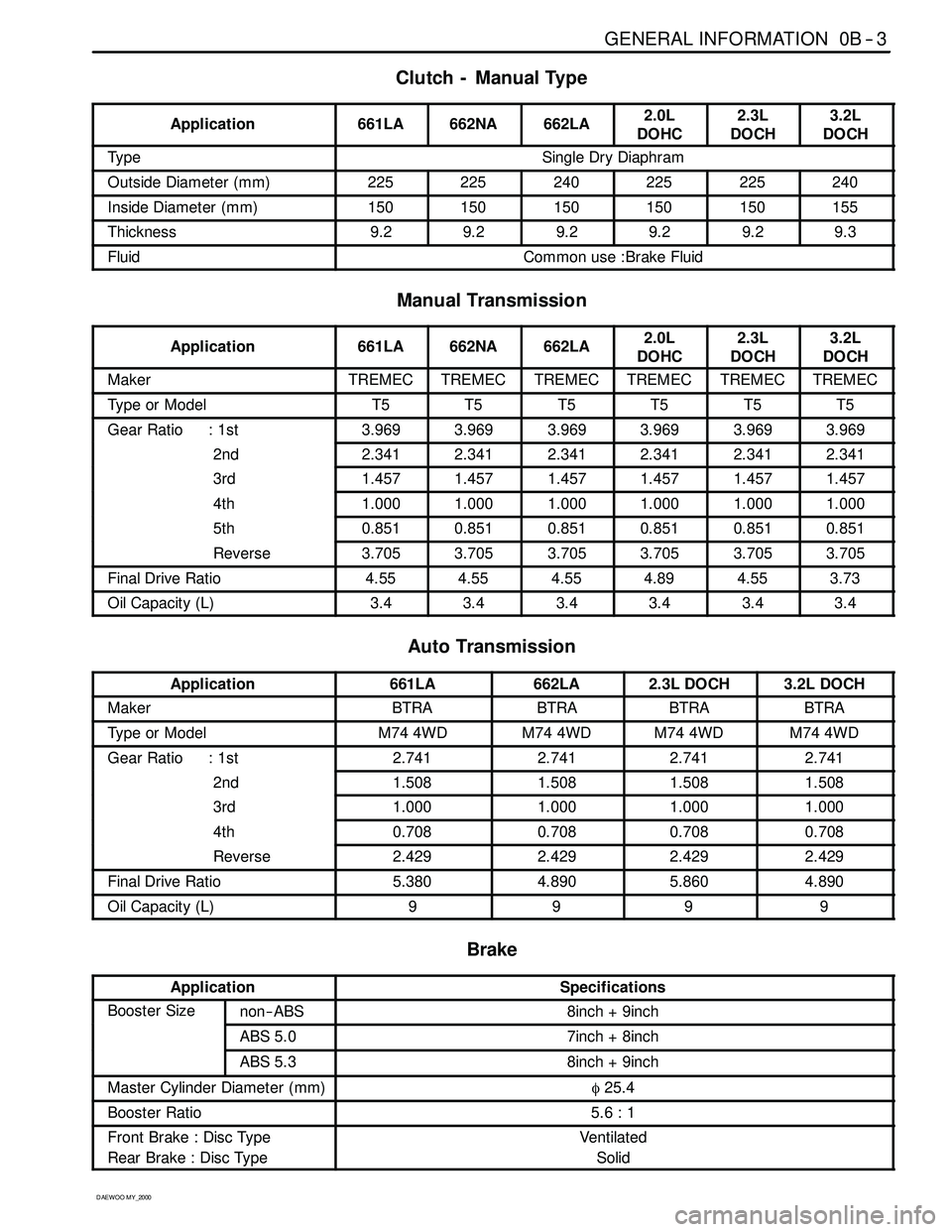

Clutch - Manual Type

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

Ty p eSingle Dry Diaphram

Outside Diameter (mm)225225240225225240

Inside Diameter (mm)150150150150150155

Thickness9.29.29.29.29.29.3

FluidCommon use :Brake Fluid

Manual Transmission

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

MakerTREMECTREMECTREMECTREMECTREMECTREMEC

Type or ModelT5T5T5T5T5T5

Gear Ratio : 1st3.9693.9693.9693.9693.9693.969

2nd2.3412.3412.3412.3412.3412.341

3rd1.4571.4571.4571.4571.4571.457

4th1.0001.0001.0001.0001.0001.000

5th0.8510.8510.8510.8510.8510.851

Reverse3.7053.7053.7053.7053.7053.705

Final Drive Ratio4.554.554.554.894.553.73

Oil Capacity (L)3.43.43.43.43.43.4

Auto Transmission

Application661LA662LA2.3L DOCH3.2L DOCH

MakerBTRABTRABTRABTRA

Type or ModelM74 4WDM74 4WDM74 4WDM74 4WD

Gear Ratio : 1st2.7412.7412.7412.741

2nd1.5081.5081.5081.508

3rd1.0001.0001.0001.000

4th0.7080.7080.7080.708

Reverse2.4292.4292.4292.429

Final Drive Ratio5.3804.8905.8604.890

Oil Capacity (L)9999

Brake

ApplicationSpecifications

Booster Sizenon-- ABS8inch + 9inch

ABS 5.07inch + 8inch

ABS 5.38inch + 9inch

Master Cylinder Diameter(mm)φ25.4

Booster Ratio5.6 : 1

Front Brake : Disc Type

Rear Brake : Disc TypeVentilated

Solid

Page 10 of 2053

0B -- 10 GENERAL INFORMATION

D AEW OO M Y_2000

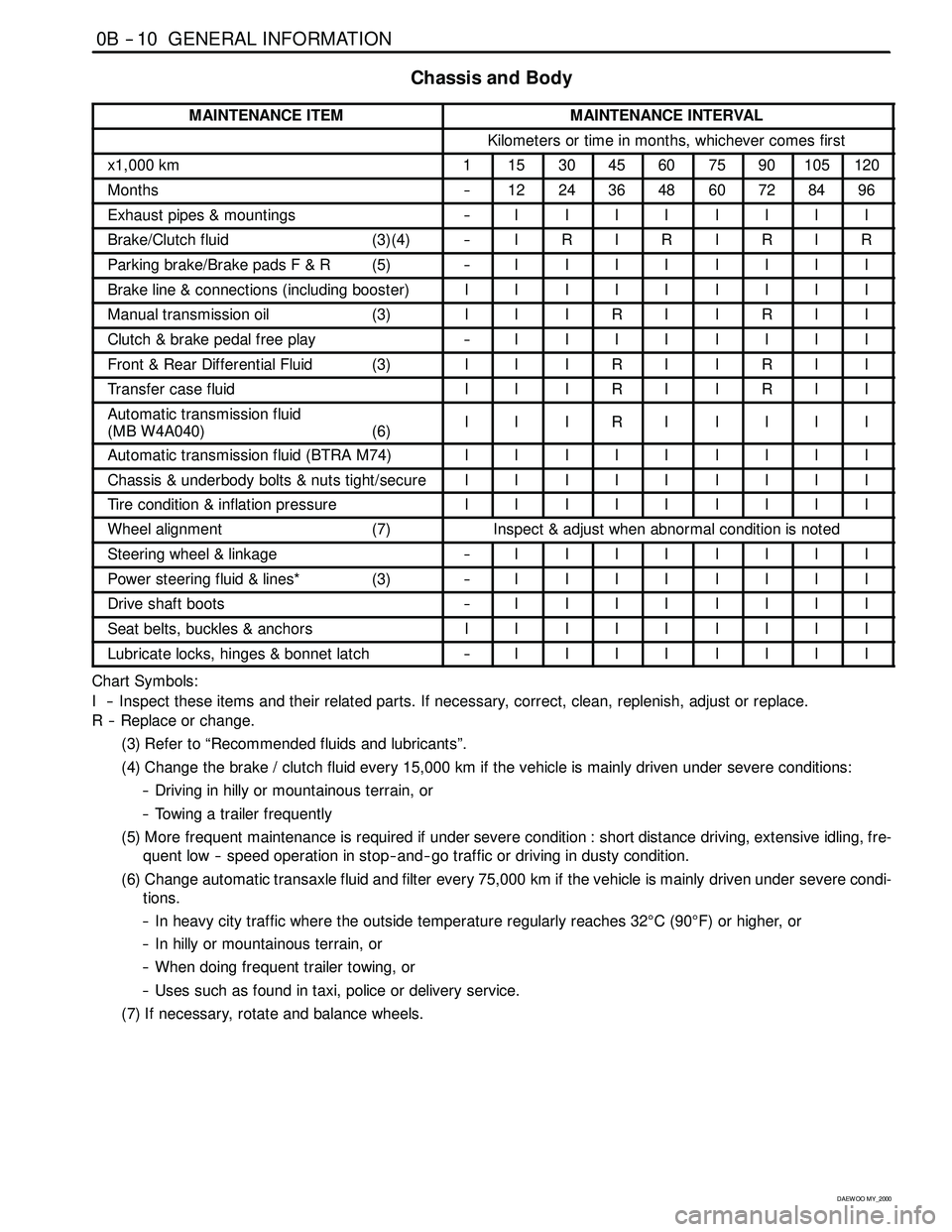

Chassis and Body

MAINTENANCE ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

x1,000 km1153045607590105120

Months--1224364860728496

Exhaust pipes & mountings--IIIIIIII

Brake/Clutch fluid (3)(4)--IRIRIRIR

Parking brake/Brake pads F & R (5)--IIIIIIII

Brake line & connections (including booster)IIIIIIIII

Manual transmission oil (3)IIIRIIRII

Clutch & brake pedal free play--IIIIIIII

Front & Rear Differential Fluid (3)IIIRIIRII

Transfer case fluidIIIRIIRII

Automatic transmission fluid

(MB W4A040) (6)IIIRIIIII

Automatic transmission fluid (BTRA M74)IIIIIIIII

Chassis & underbody bolts & nuts tight/secureIIIIIIIII

Tire condition & inflation pressureIIIIIIIII

Wheel alignment (7)Inspect & adjust when abnormal condition is noted

Steering wheel & linkage--IIIIIIII

Power steering fluid & lines* (3)--IIIIIIII

Drive shaft boots--IIIIIIII

Seat belts, buckles & anchorsIIIIIIIII

Lubricate locks, hinges & bonnet latch--IIIIIIII

Chart Symbols:

I -- Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R -- Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:

-- Driving in hilly or mountainous terrain, or

-- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, fre-

quent low -- speed operation in stop-- and-- go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe condi-

tions.

-- In heavy city traffic where the outside temperature regularly reaches 32°C(90°F) or higher, or

-- In hilly or mountainous terrain, or

-- When doing frequent trailer towing, or

-- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 12 of 2053

0B -- 12 GENERAL INFORMATION

D AEW OO M Y_2000

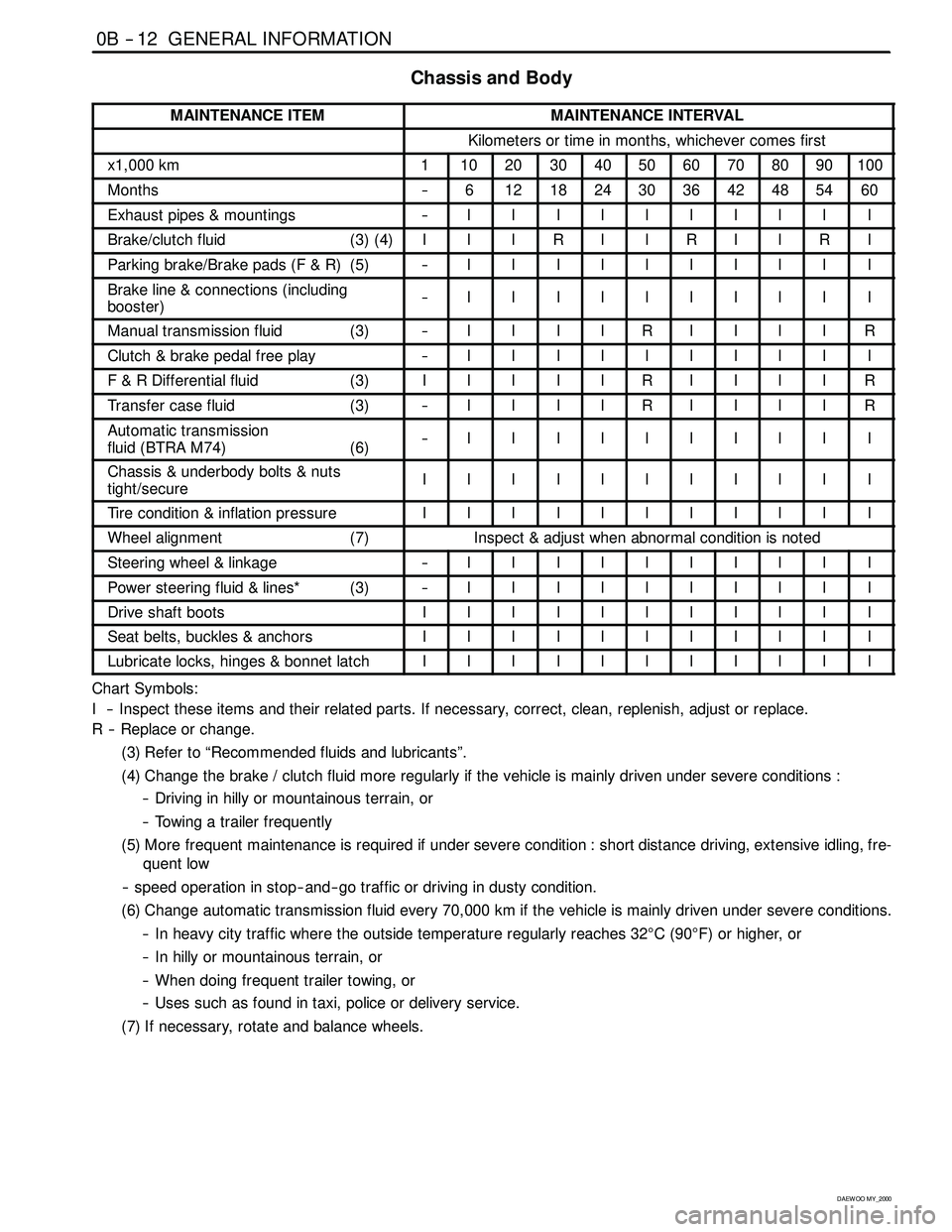

Chassis and Body

MAINTENANCE ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

x1,000 km1102030405060708090100

Months--6121824303642485460

Exhaust pipes & mountings--IIIIIIIIII

Brake/clutch fluid (3) (4)IIIRIIRIIRI

Parking brake/Brake pads (F & R) (5)--IIIIIIIIII

Brake line & connections (including

booster)--IIIIIIIIII

Manual transmission fluid (3)--IIIIRIIIIR

Clutch & brake pedal free play--IIIIIIIIII

F & R Differential fluid (3)IIIIIRIIIIR

Transfer case fluid (3)--IIIIRIIIIR

Automatic transmission

fluid (BTRA M74) (6)--IIIIIIIIII

Chassis & underbody bolts & nuts

tight/secureIIIIIIIIIII

Tire condition & inflation pressureIIIIIIIIIII

Wheel alignment (7)Inspect & adjust when abnormal condition is noted

Steering wheel & linkage--IIIIIIIIII

Power steering fluid & lines* (3)--IIIIIIIIII

Drive shaft bootsIIIIIIIIIII

Seat belts, buckles & anchorsIIIIIIIIIII

Lubricate locks, hinges & bonnet latchIIIIIIIIIII

Chart Symbols:

I -- Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R -- Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :

-- Driving in hilly or mountainous terrain, or

-- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, fre-

quent low

-- speed operation in stop-- and-- go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions.

-- In heavy city traffic where the outside temperature regularly reaches 32°C(90°F) or higher, or

-- In hilly or mountainous terrain, or

-- When doing frequent trailer towing, or

-- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 26 of 2053

1A1 -- 6 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

DIAGNOSIS

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may be

difficult to locate or repair. The following procedures may

help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid,

etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate loca-

tion of the leak by the drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-- type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating condi-

toins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer ’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil fill

tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid willappear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a gas-

ket is replaced, but the sealing flange is bent, the new

gasket will not repair the leak. Thebent flange must be

repaired also. Before attempting to repair a leak, check

for the following conditions and correct them as they

may cause a leak.

Gaskets

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe fasteners are tightened improperly or the threads

are dirty or damaged.

DThe flanges or the sealing surface is warped.

DThere are scratches, burrs or other damage to the

sealing surface.

DThe gasket is damaged or worn.

DThere is cracking or porosity of the component.

DAn improper seal was used (where applicable).

Seals

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe seal bore is damaged (scratched, burred or

nicked).

DThe seal is damaged or worn.

DImproper installation is evident.

DThere are cracks in the components.

DThe shaft surface is scratched, nicked or damaged.

DA loose or worn bearing is causing excess seal wear.

Page 34 of 2053

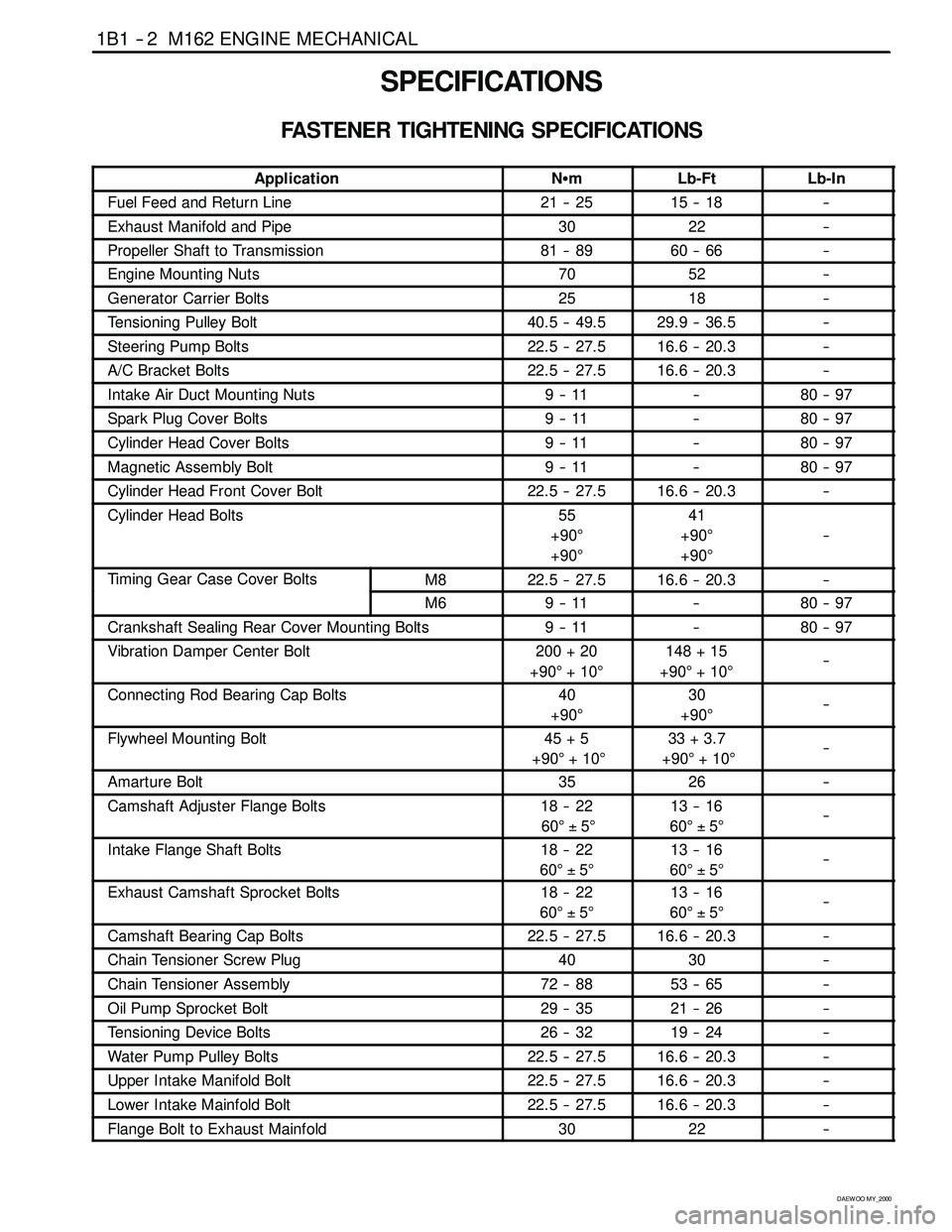

1B1 -- 2 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Fuel Feed and Return Line21 -- 2515 -- 18--

Exhaust Manifold and Pipe3022--

Propeller Shaft to Transmission81 -- 8960 -- 66--

Engine Mounting Nuts7052--

Generator Carrier Bolts2518--

Tensioning Pulley Bolt40.5 -- 49.529.9 -- 36.5--

Steering Pump Bolts22.5 -- 27.516.6 -- 20.3--

A/C Bracket Bolts22.5 -- 27.516.6 -- 20.3--

Intake Air Duct Mounting Nuts9--11--80 -- 97

Spark Plug Cover Bolts9--11--80 -- 97

Cylinder Head Cover Bolts9--11--80 -- 97

Magnetic Assembly Bolt9--11--80 -- 97

Cylinder Head Front Cover Bolt22.5 -- 27.516.6 -- 20.3--

Cylinder Head Bolts55

+90°

+90°41

+90°

+90°

--

Timing Gear Case Cover BoltsM822.5 -- 27.516.6 -- 20.3--g

M69--11--80 -- 97

Crankshaft Sealing Rear Cover Mounting Bolts9--11--80 -- 97

Vibration Damper Center Bolt200 + 20

+90°+10°148 + 15

+90°+10°--

Connecting Rod Bearing Cap Bolts40

+90°30

+90°--

Flywheel Mounting Bolt45 + 5

+90°+10°33 + 3.7

+90°+10°--

Amarture Bolt3526--

Camshaft Adjuster Flange Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Intake Flange Shaft Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Exhaust Camshaft Sprocket Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Camshaft Bearing Cap Bolts22.5 -- 27.516.6 -- 20.3--

Chain Tensioner Screw Plug4030--

Chain Tensioner Assembly72 -- 8853 -- 65--

Oil Pump Sprocket Bolt29 -- 3521 -- 26--

Tensioning Device Bolts26 -- 3219 -- 24--

Water Pump Pulley Bolts22.5 -- 27.516.6 -- 20.3--

Upper Intake Manifold Bolt22.5 -- 27.516.6 -- 20.3--

Lower Intake Mainfold Bolt22.5 -- 27.516.6 -- 20.3--

Flange Bolt to Exhaust Mainfold3022--

Page 44 of 2053

1B1 -- 12 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

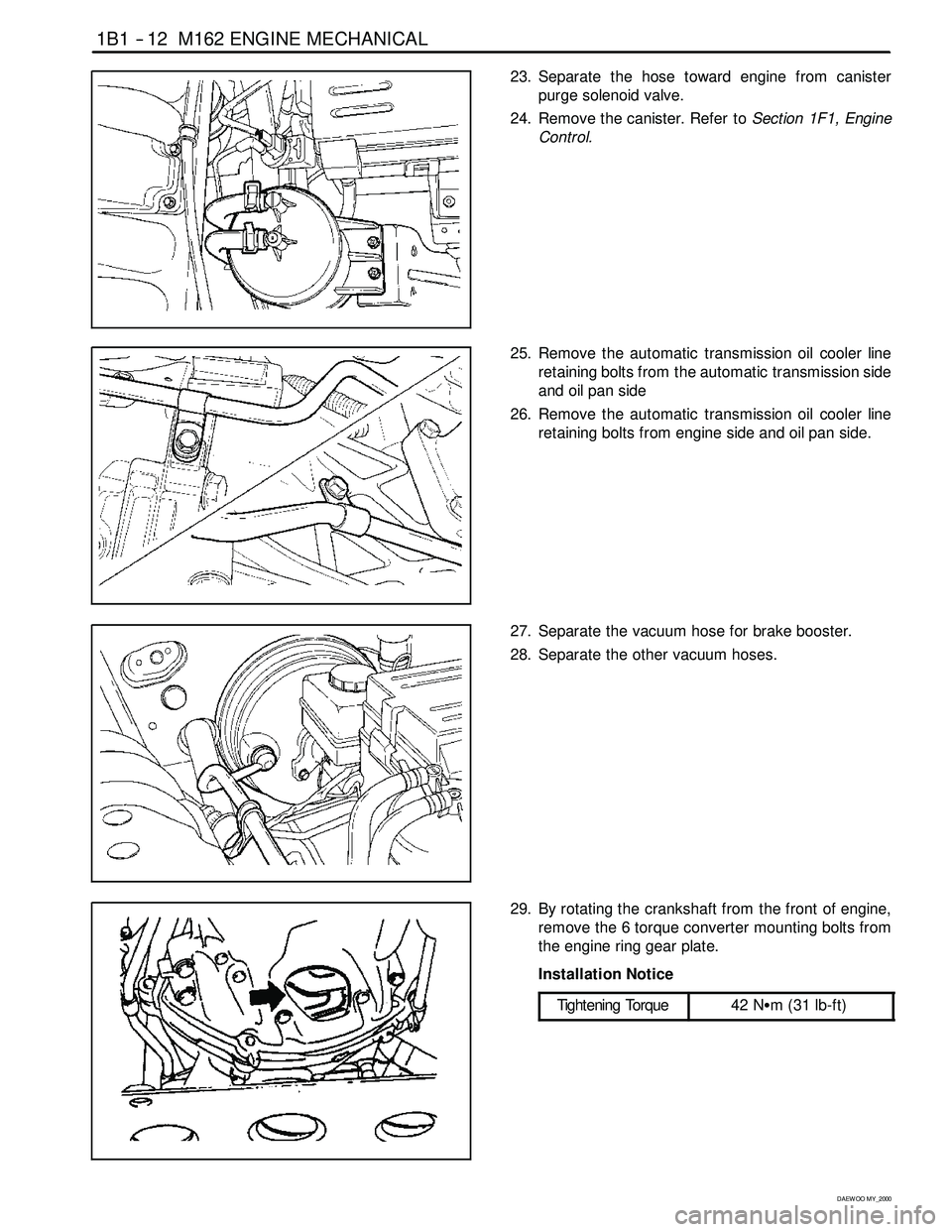

23. Separate the hose toward engine from canister

purge solenoid valve.

24. Remove the canister. Refer toSection 1F1, Engine

Control.

25. Remove the automatic transmission oil cooler line

retaining bolts from the automatic transmission side

and oil pan side

26. Remove the automatic transmission oil cooler line

retaining bolts from engine side and oil pan side.

27. Separate the vacuum hose for brake booster.

28. Separate the other vacuum hoses.

29. By rotating the crankshaft from the front of engine,

remove the 6 torque converter mounting bolts from

the engine ring gear plate.

Installation Notice

Tightening Torque

42 NSm (31 lb-ft)

Page 45 of 2053

M162 ENGINE MECHANICAL 1B1 -- 13

D AEW OO M Y_2000

30. Remove the exhaust manifold and exhaust pipe.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

31. Remove the transmission.Refer to Section 5A, Au-

tomatic Transmission.

32. Install a chain to the bracket of engine, by using a

hoist or crane.

33. Remove the engine mount nuts.

Installation Notice

Tightening Torque

70 NSm (52 lb-ft)

34. Carefully separate the engine assembly from the ve-

hicle.

35. Installation should follow the removal procedure in

the reverse order.

Page 65 of 2053

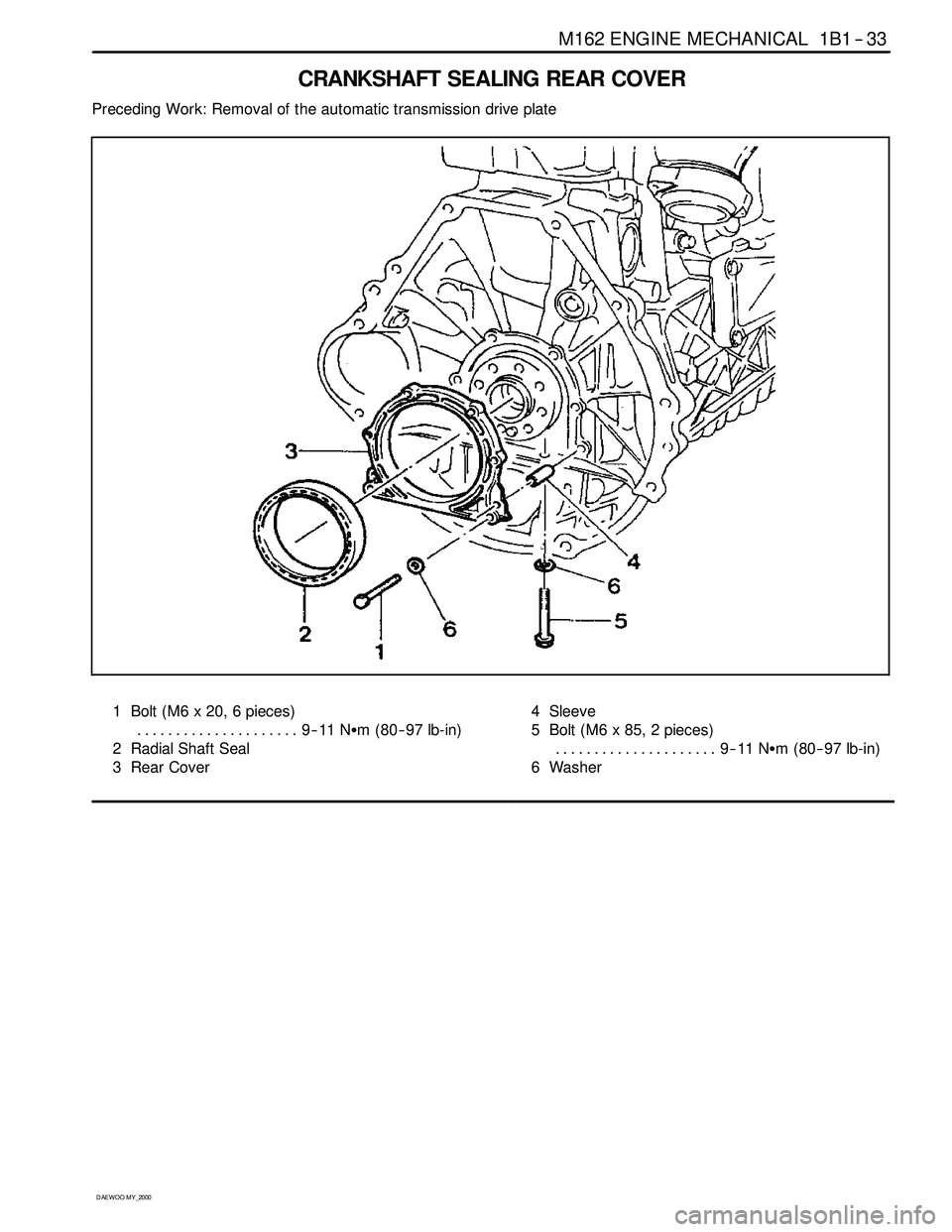

M162 ENGINE MECHANICAL 1B1 -- 33

D AEW OO M Y_2000

CRANKSHAFT SEALING REAR COVER

Preceding Work: Removal of the automatic transmission drive plate

1 Bolt (M6 x 20, 6 pieces)

9--11 NSm (80-- 97 lb-in) .....................

2 Radial Shaft Seal

3 Rear Cover4 Sleeve

5 Bolt (M6 x 85, 2 pieces)

9--11 NSm (80-- 97 lb-in) .....................

6Washer

Page 79 of 2053

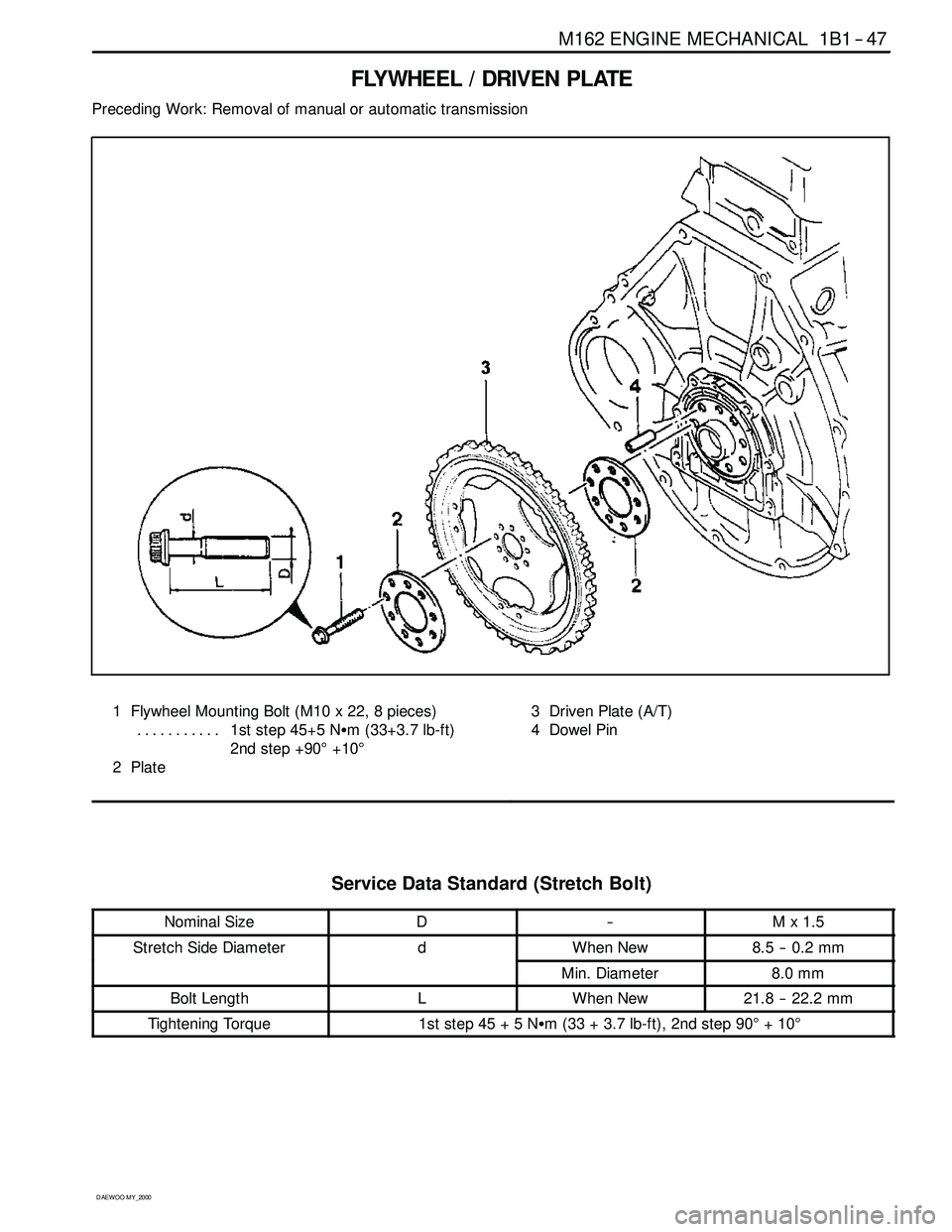

M162 ENGINE MECHANICAL 1B1 -- 47

D AEW OO M Y_2000

FLYWHEEL / DRIVEN PLATE

Preceding Work: Removal of manual or automatic transmission

1 Flywheel Mounting Bolt (M10 x 22, 8 pieces)

1st step 45+5 NSm (33+3.7 lb-ft) ...........

2nd step +90°+10°

2Plate3 Driven Plate (A/T)

4 Dowel Pin

Service Data Standard (Stretch Bolt)

Nominal SizeD--Mx1.5

Stretch Side DiameterdWhen New8.5 -- 0.2 mm

Min. Diameter8.0 mm

Bolt LengthLWhen New21.8 -- 22.2 mm

Tightening Torque1ststep45+5NSm (33 + 3.7 lb-ft), 2nd step 90°+10°

Page 80 of 2053

1B1 -- 48 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

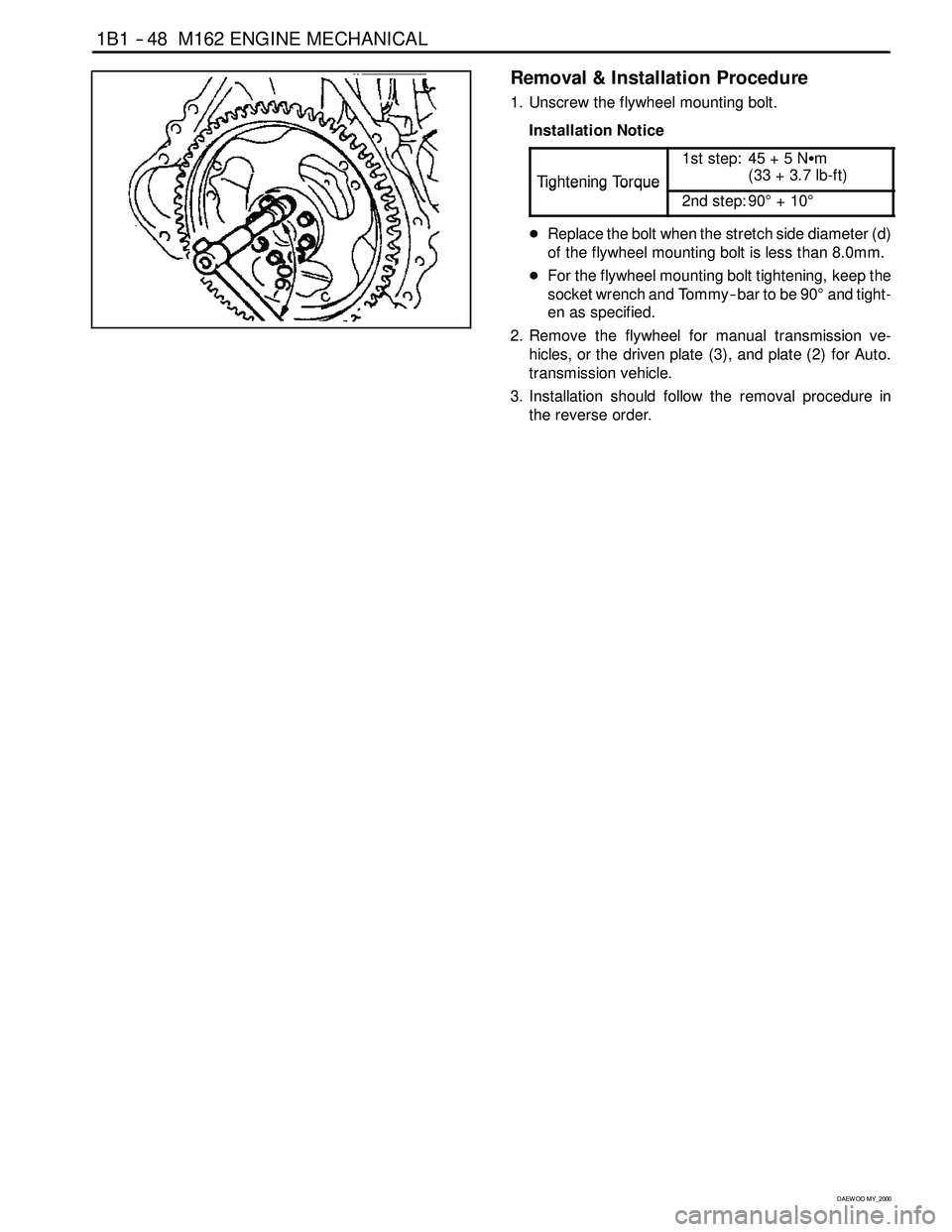

Removal & Installation Procedure

1. Unscrew the flywheel mounting bolt.

Installation Notice

Ti

ghteningTo rque

1st step: 45 + 5 NSm

(33+3.7lb-ft)

TighteningTorque

2nd step: 90°+10°

DReplace the bolt when the stretch side diameter (d)

of the flywheel mounting bolt is less than 8.0mm.

DFor the flywheel mounting bolt tightening, keep the

socket wrench and Tommy -- bar to be 90°and tight-

en as specified.

2. Remove the flywheel for manual transmission ve-

hicles, or the driven plate (3), and plate (2) for Auto.

transmission vehicle.

3. Installation should follow the removal procedure in

the reverse order.