heater SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 194 of 1336

0000-00

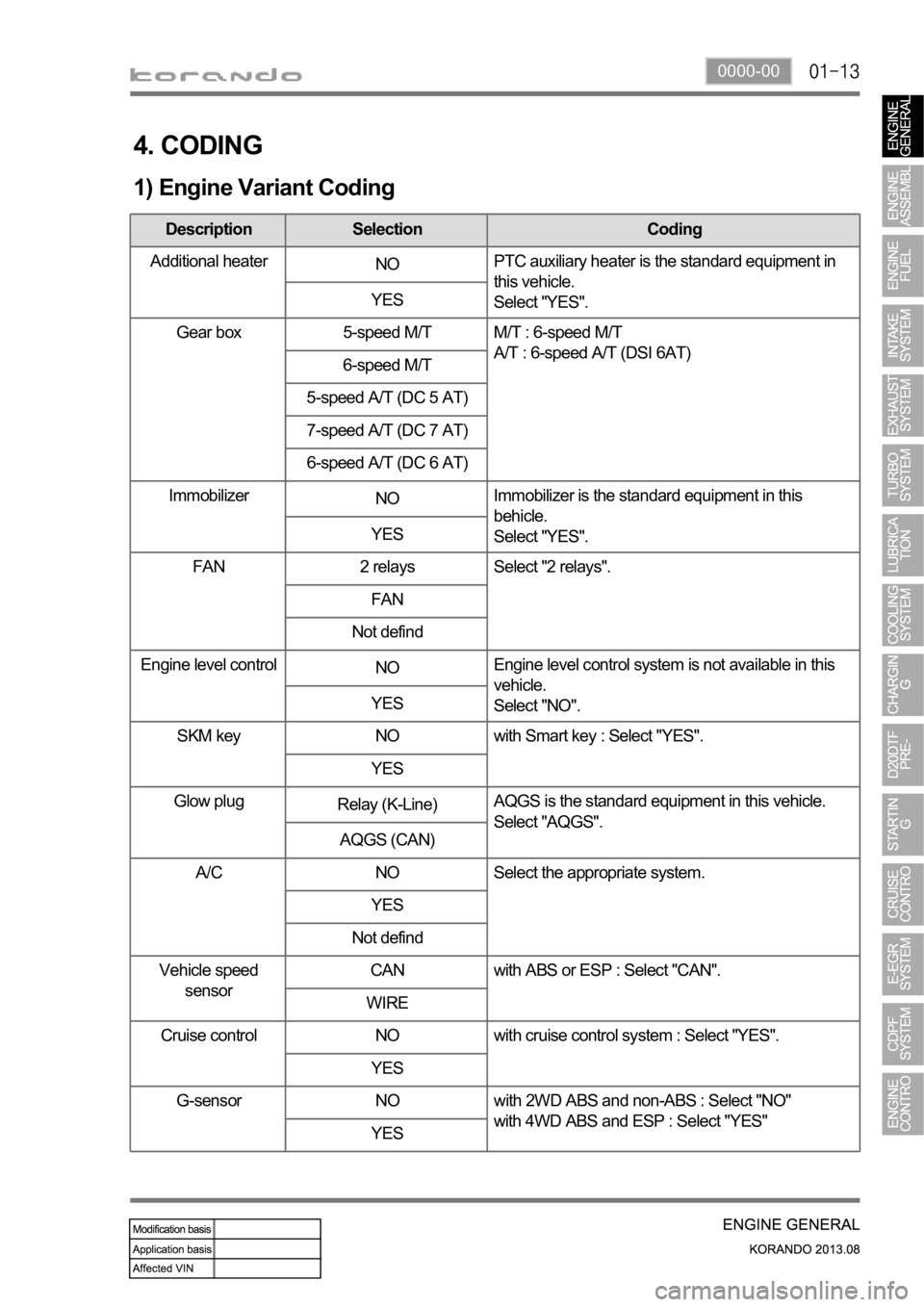

4. CODING

1) Engine Variant Coding

Description Selection Coding

Additional heater

NOPTC auxiliary heater is the standard equipment in

this vehicle.

Select "YES". YES

Gear box 5-speed M/T M/T : 6-speed M/T

A/T : 6-speed A/T (DSI 6AT)

6-speed M/T

5-speed A/T (DC 5 AT)

7-speed A/T (DC 7 AT)

6-speed A/T (DC 6 AT)

Immobilizer

NOImmobilizer is the standard equipment in this

behicle.

Select "YES". YES

FAN 2 relays Select "2 relays".

FAN

Not defind

Engine level control

NOEngine level control system is not available in this

vehicle.

Select "NO". YES

SKM key NO with Smart key : Select "YES".

YES

Glow plug

Relay (K-Line)AQGS is the standard equipment in this vehicle.

Select "AQGS".

AQGS (CAN)

A/C NO Select the appropriate system.

YES

Not defind

Vehicle speed

sensorCAN with ABS or ESP : Select "CAN".

WIRE

Cruise control NO with cruise control system : Select "YES".

YES

G-sensor NO with 2WD ABS and non-ABS : Select "NO"

with 4WD ABS and ESP : Select "YES"

YES

Page 227 of 1336

0000-00

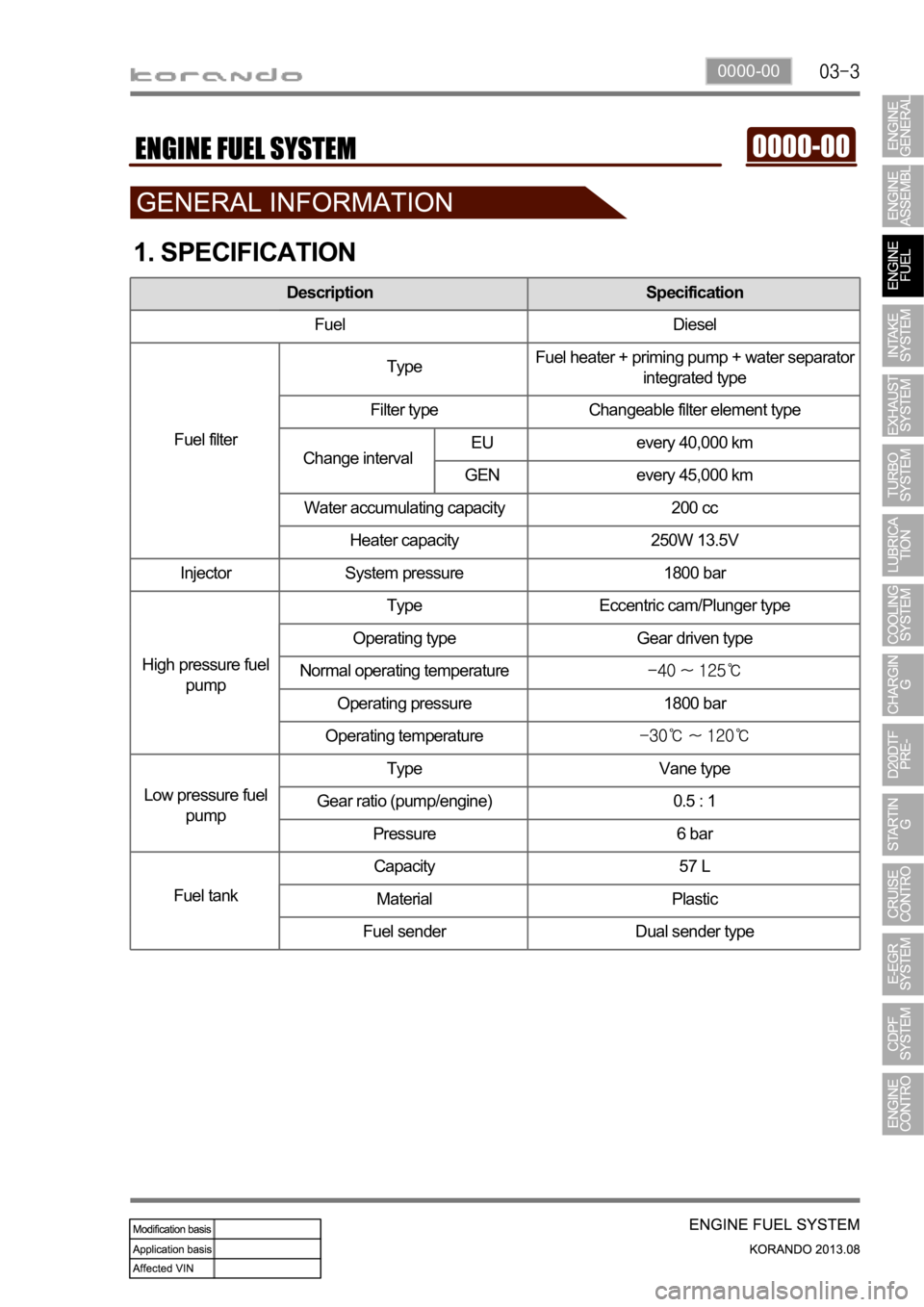

1. SPECIFICATION

Description Specification

Fuel Diesel

Fuel filterTypeFuel heater + priming pump + water separator

integrated type

Filter type Changeable filter element type

every 40,000 km

every 45,000 km

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature

Operating pressure 1800 bar

Operating temperature

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tankCapacity 57 L

Material Plastic

Fuel sender Dual sender type

Change intervalEU

GEN

Page 247 of 1336

0000-00

(2) Di engine and its expected problems and remedies can be caused by

water in fuel

System supplement against paraffin separation

In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and then

can stick on the fuel filter blocking fuel flow and causing difficult starting finally. Oil companies supply

summer fuel and winter fuel by differentiating mixing ratio of kerosene and other elements by region and

season. However, above phenomenon can be happened if stations have poor facilities or sell improper

fuel for the season. In case of DI engine, purity of fuel is very important factor to keep internal

preciseness of HP pump and injector.

Accordingly, more dense mesh than conventional fuel filter is used. To prevent fuel filter internal clogging

due to paraffin separation, SYMC is using fuel line that high pressure and temperature fuel injected by

injector returns through fuel filter to have an effect of built-in heater (see fuel system).

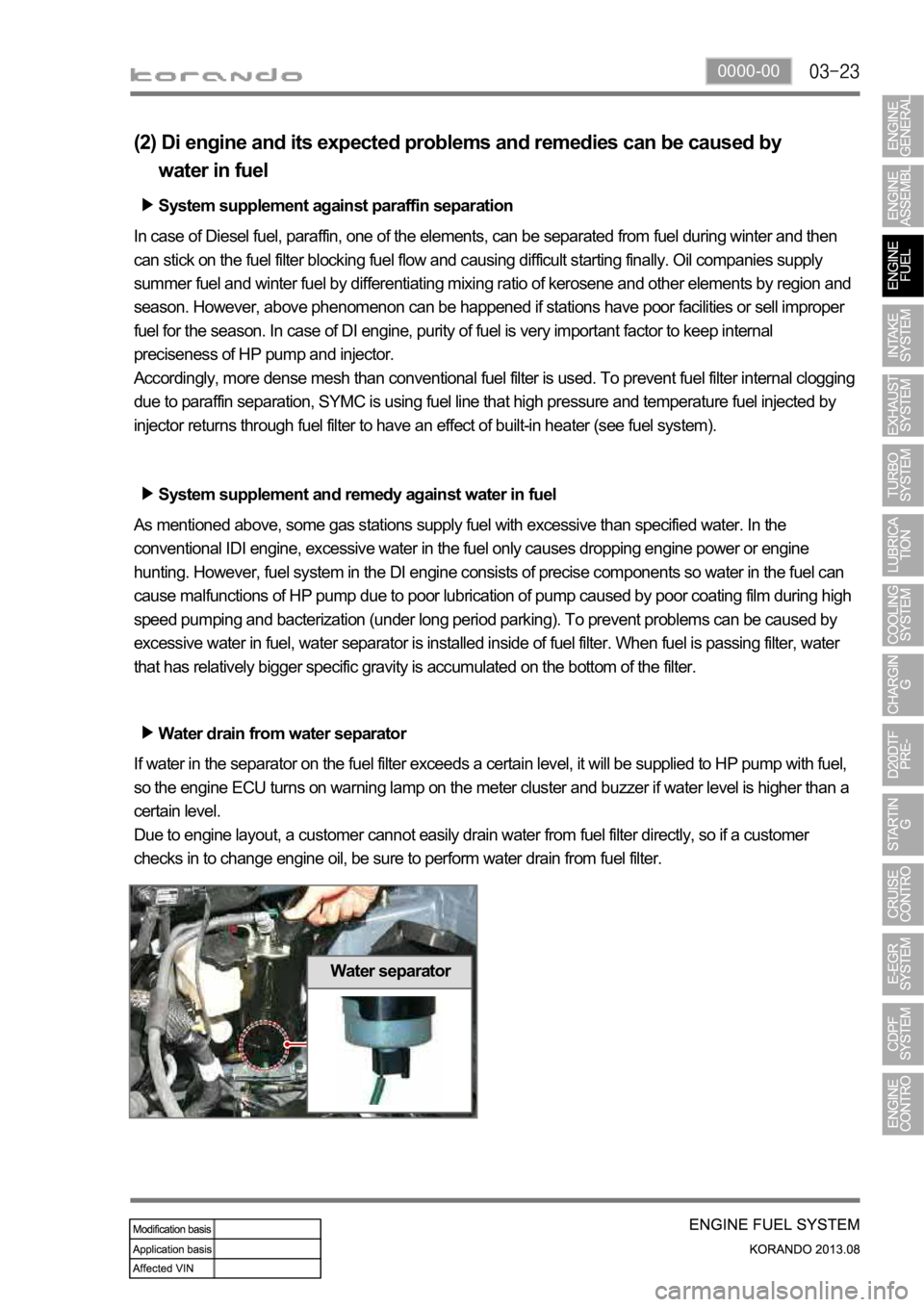

System supplement and remedy against water in fuel

As mentioned above, some gas stations supply fuel with excessive than specified water. In the

conventional IDI engine, excessive water in the fuel only causes dropping engine power or engine

hunting. However, fuel system in the DI engine consists of precise components so water in the fuel can

cause malfunctions of HP pump due to poor lubrication of pump caused by poor coating film during high

speed pumping and bacterization (under long period parking). To prevent problems can be caused by

excessive water in fuel, water separator is installed inside of fuel filter. When fuel is passing filter, water

that has relatively bigger specific gravity is accumulated on the bottom of the filter.

Water drain from water separator

If water in the separator on the fuel filter exceeds a certain level, it will be supplied to HP pump with fuel,

so the engine ECU turns on warning lamp on the meter cluster and buzzer if water level is higher than a

certain level.

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a customer

checks in to change engine oil, be sure to perform water drain from fuel filter.

Water separator

Page 252 of 1336

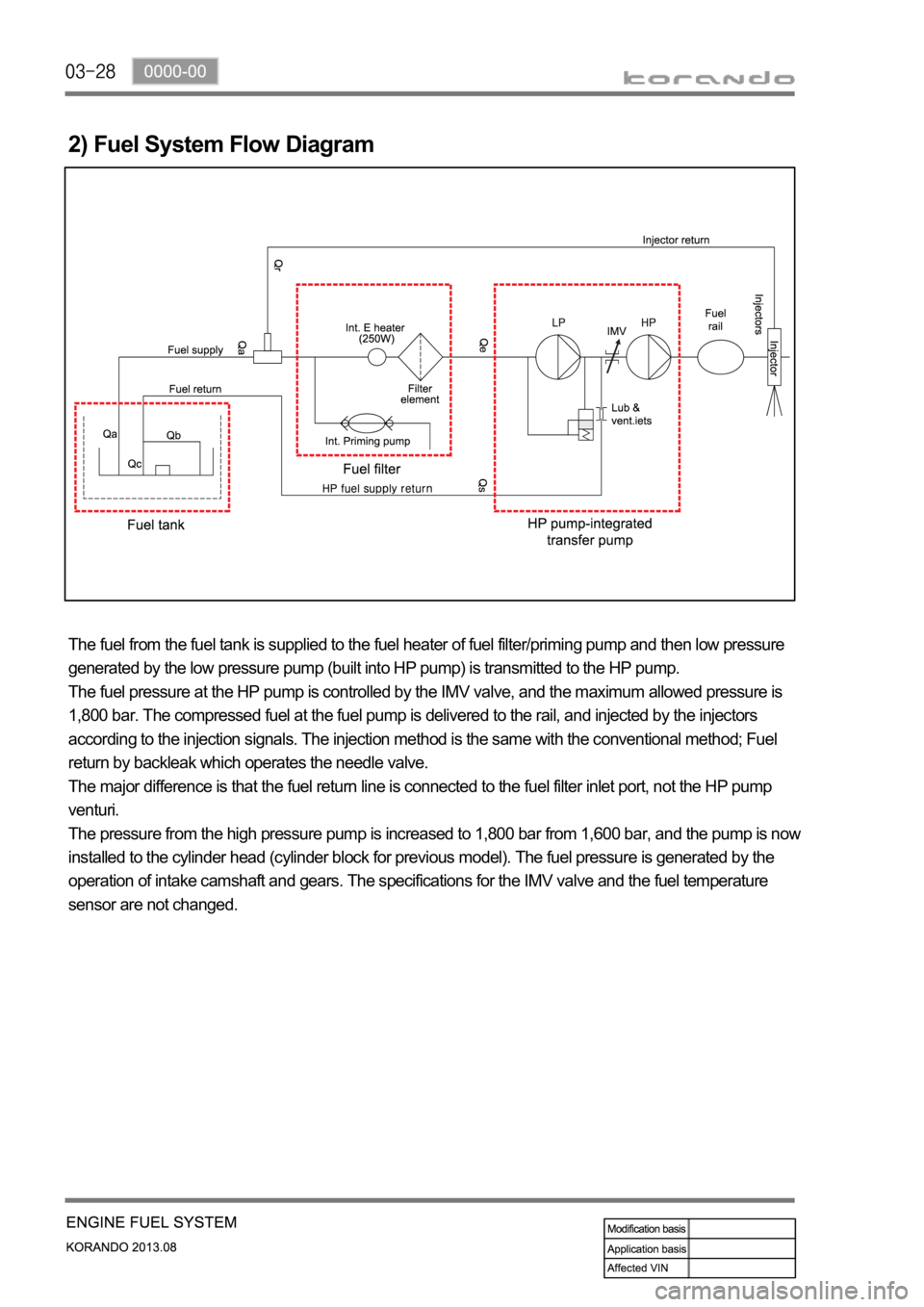

2) Fuel System Flow Diagram

The fuel from the fuel tank is supplied to the fuel heater of fuel filter/priming pump and then low pressure

generated by the low pressure pump (built into HP pump) is transmitted to the HP pump.

The fuel pressure at the HP pump is controlled by the IMV valve, and the maximum allowed pressure is

1,800 bar. The compressed fuel at the fuel pump is delivered to the rail, and injected by the injectors

according to the injection signals. The injection method is the same with the conventional method; Fuel

return by backleak which operates the needle valve.

The major difference is that the fuel return line is connected to the fuel filter inlet port, not the HP pump

venturi.

The pressure from the high pressure pump is increased to 1,800 bar from 1,600 bar, and the pump is now

installed to the cylinder head (cylinder block for previous model). The fuel pressure is generated by the

operation of intake camshaft and gears. The specifications for the IMV valve and the fuel temperature

sensor are not changed.

Page 299 of 1336

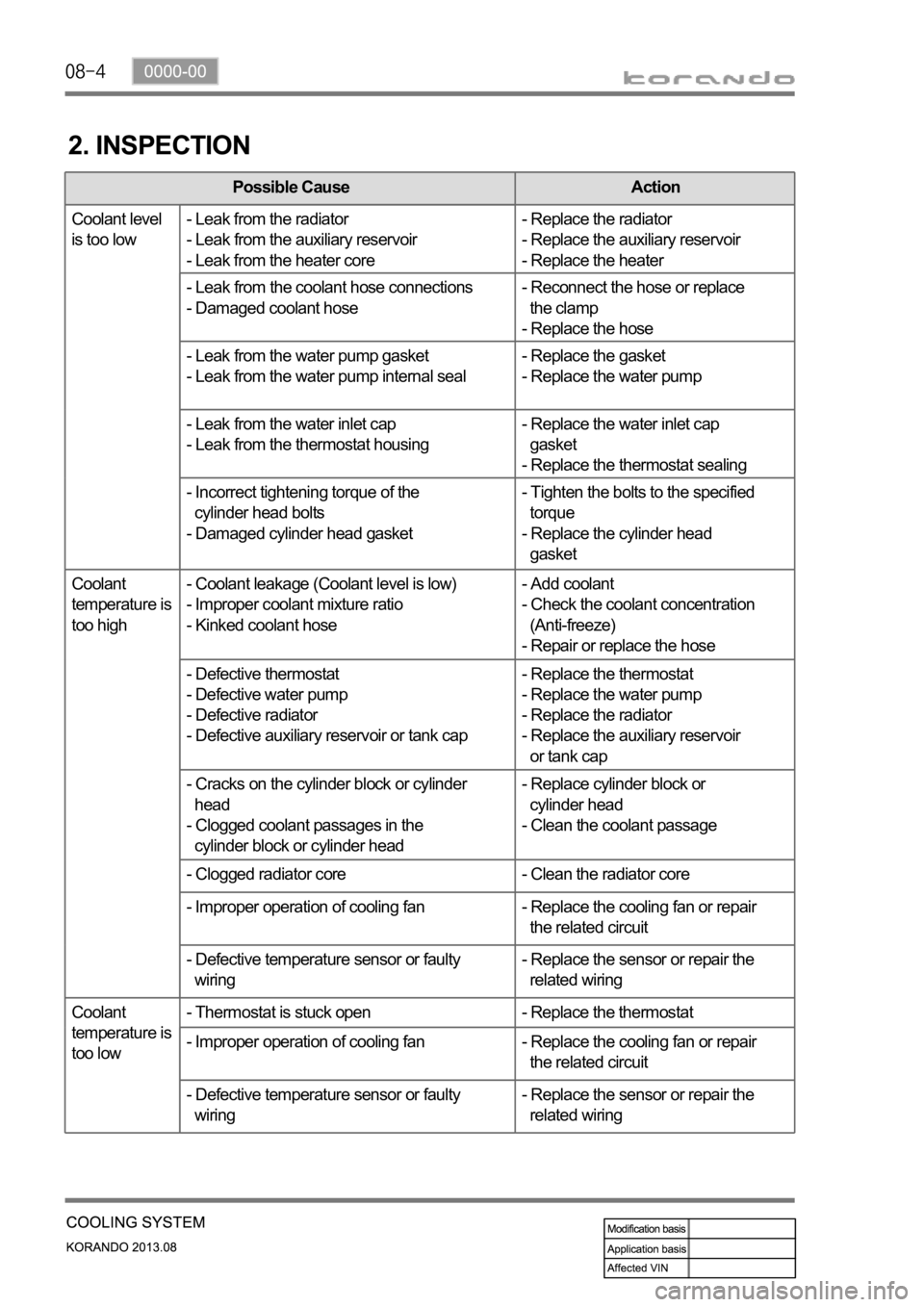

2. INSPECTION

Possible Cause Action

Coolant level

is too low- Leak from the radiator

- Leak from the auxiliary reservoir

- Leak from the heater core- Replace the radiator

- Replace the auxiliary reservoir

- Replace the heater

- Leak from the coolant hose connections

- Damaged coolant hose- Reconnect the hose or replace

the clamp

- Replace the hose

- Leak from the water pump gasket

- Leak from the water pump internal seal- Replace the gasket

- Replace the water pump

- Leak from the water inlet cap

- Leak from the thermostat housing- Replace the water inlet cap

gasket

- Replace the thermostat sealing

- Incorrect tightening torque of the

cylinder head bolts

- Damaged cylinder head gasket- Tighten the bolts to the specified

torque

- Replace the cylinder head

gasket

Coolant

temperature is

too high- Coolant leakage (Coolant level is low)

- Improper coolant mixture ratio

- Kinked coolant hose- Add coolant

- Check the coolant concentration

(Anti-freeze)

- Repair or replace the hose

- Defective thermostat

- Defective water pump

- Defective radiator

- Defective auxiliary reservoir or tank cap- Replace the thermostat

- Replace the water pump

- Replace the radiator

- Replace the auxiliary reservoir

or tank cap

- Cracks on the cylinder block or cylinder

head

- Clogged coolant passages in the

cylinder block or cylinder head- Replace cylinder block or

cylinder head

- Clean the coolant passage

- Clogged radiator core - Clean the radiator core

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or faulty

wiring- Replace the sensor or repair the

related wiring

Coolant

temperature is

too low- Thermostat is stuck open - Replace the thermostat

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or faulty

wiring- Replace the sensor or repair the

related wiring

Page 322 of 1336

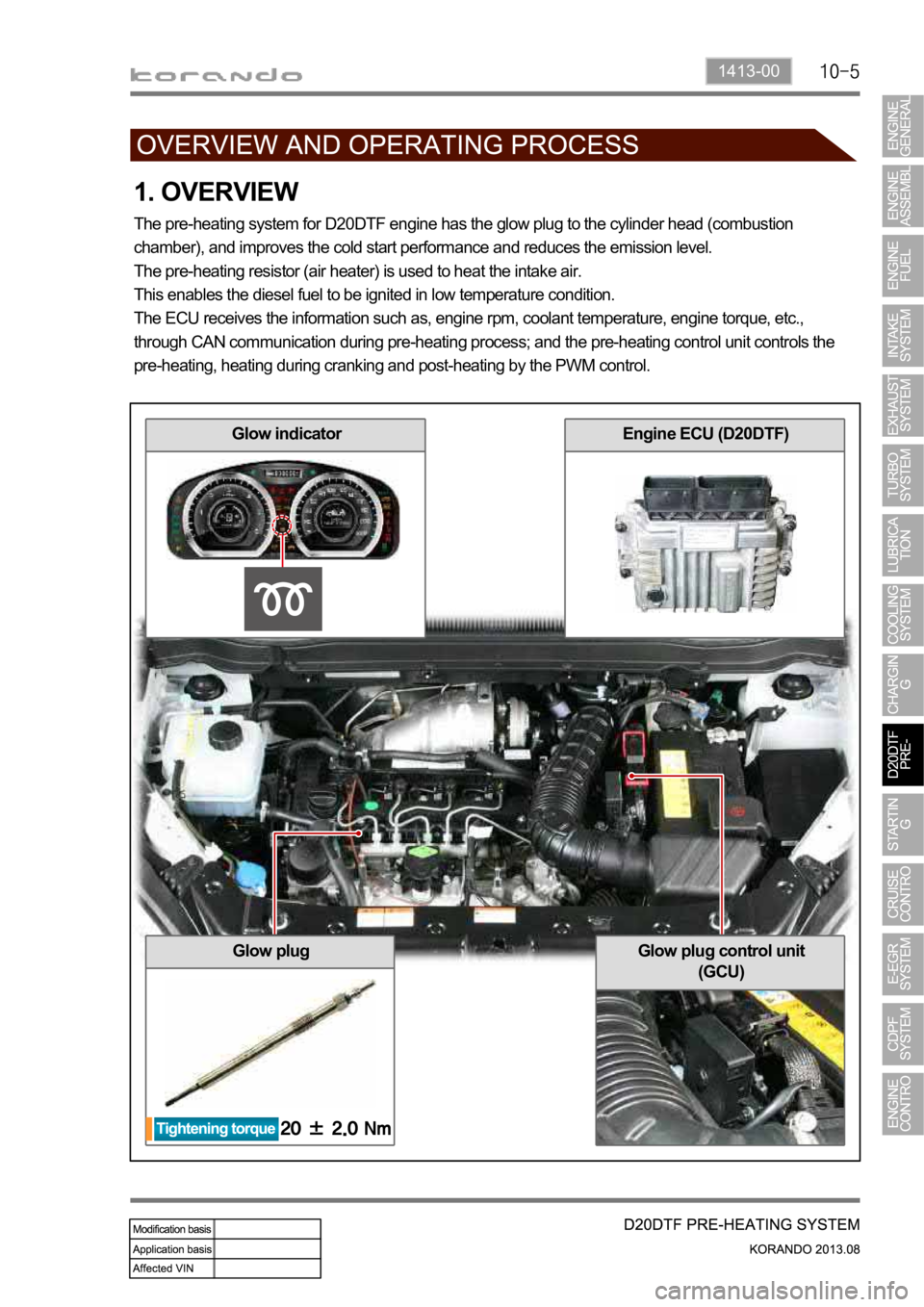

1413-00

1. OVERVIEW

The pre-heating system for D20DTF engine has the glow plug to the cylinder head (combustion

chamber), and improves the cold start performance and reduces the emission level.

The pre-heating resistor (air heater) is used to heat the intake air.

This enables the diesel fuel to be ignited in low temperature condition.

The ECU receives the information such as, engine rpm, coolant temperature, engine torque, etc.,

through CAN communication during pre-heating process; and the pre-heating control unit controls the

pre-heating, heating during cranking and post-heating by the PWM control.

Glow plugGlow plug control unit

(GCU)

Glow indicatorEngine ECU (D20DTF)

Page 379 of 1336

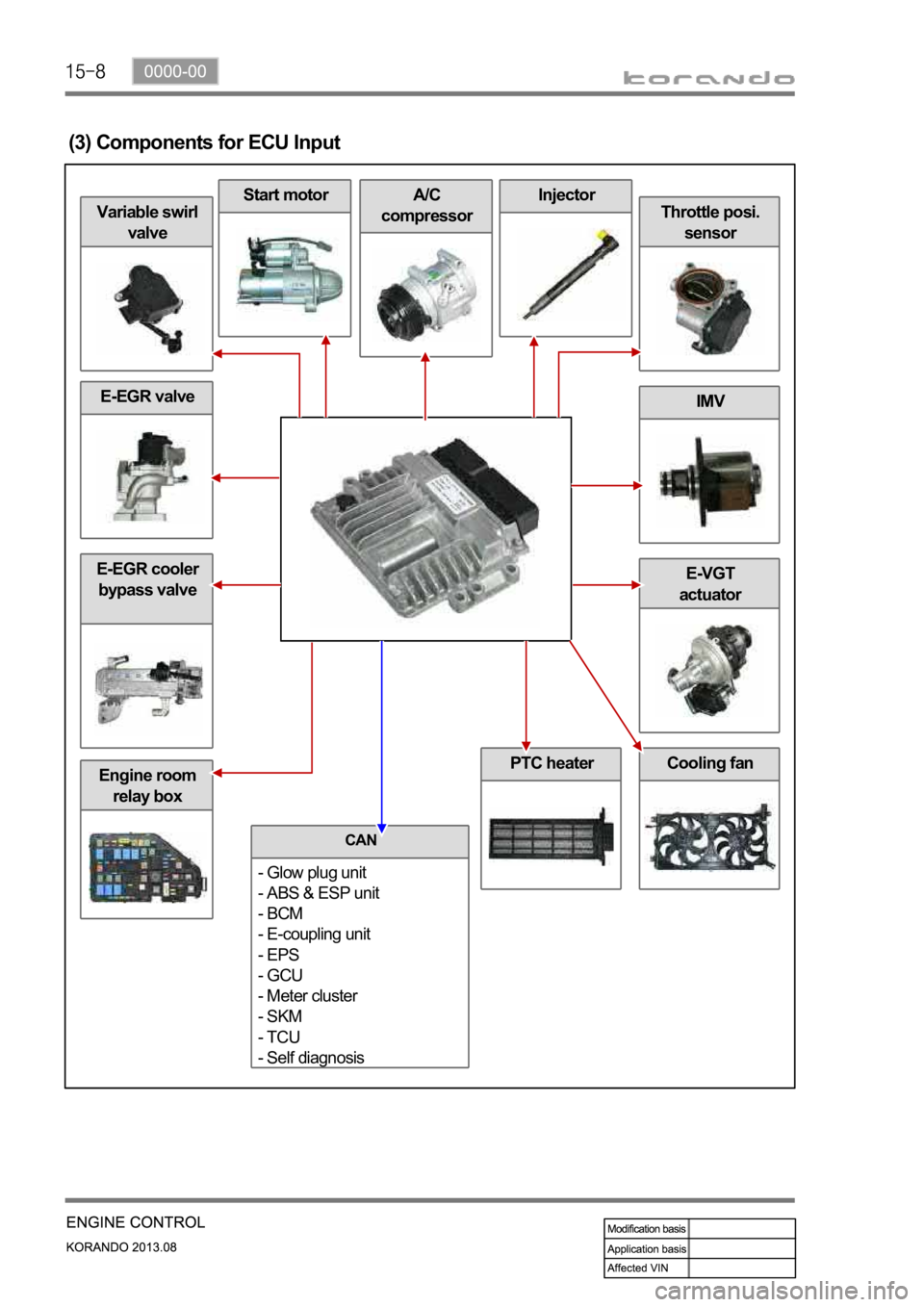

Engine room

relay box

E-EGR valve

Cooling fan

E-EGR cooler

bypass valveE-VGT

actuator

IMV

Throttle posi.

sensor

InjectorA/C

compressorStart motor

Variable swirl

valve

(3) Components for ECU Input

PTC heater

CAN

- Glow plug unit

- ABS & ESP unit

- BCM

- E-coupling unit

- EPS

- GCU

- Meter cluster

- SKM

- TCU

- Self diagnosis

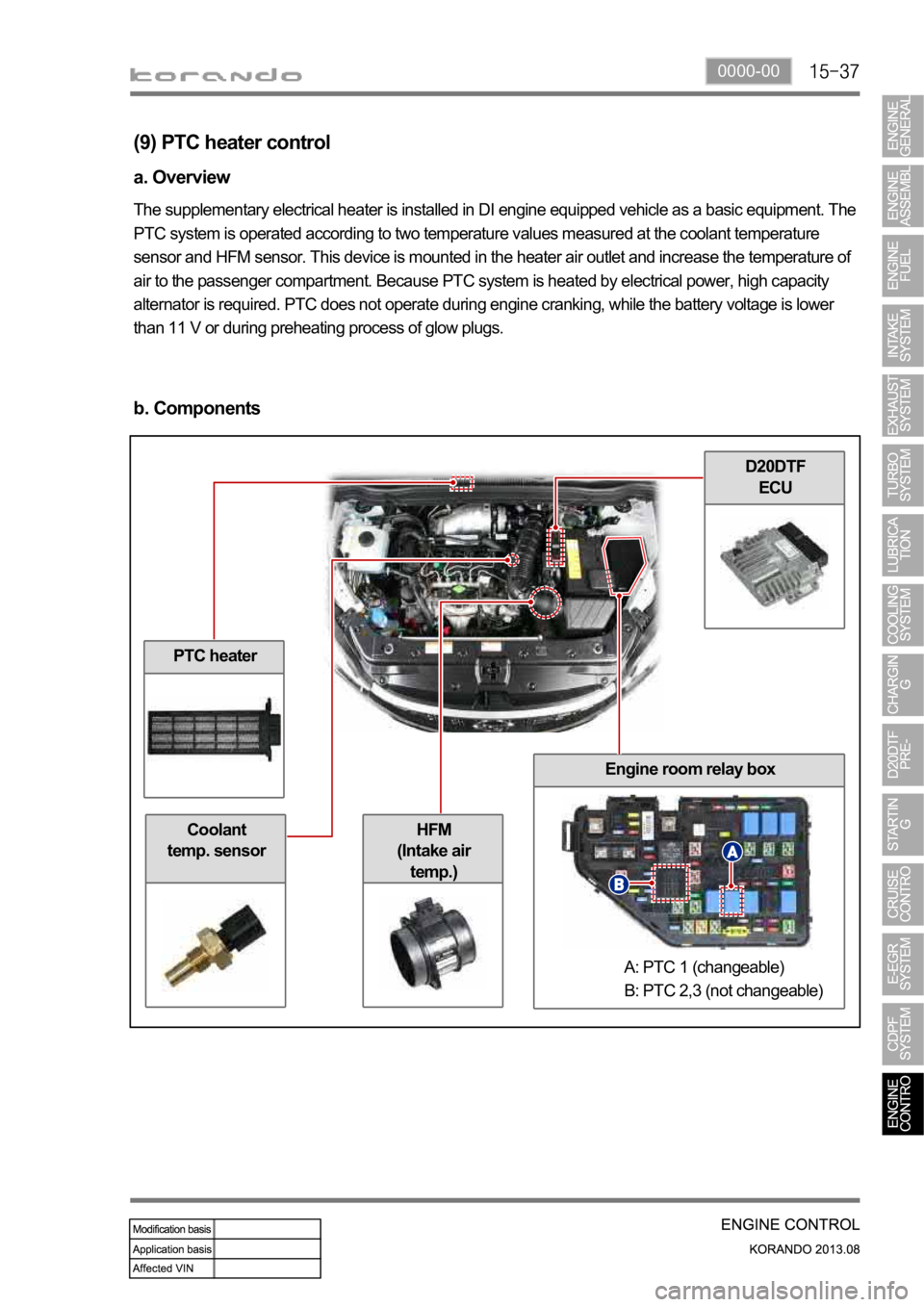

Page 408 of 1336

0000-00

PTC heater

Coolant

temp. sensor

D20DTF

ECU

Engine room relay box

HFM

(Intake air

temp.)

(9) PTC heater control

a. Overview

The supplementary electrical heater is installed in DI engine equipped vehicle as a basic equipment. The

PTC system is operated according to two temperature values measured at the coolant temperature

sensor and HFM sensor. This device is mounted in the heater air outlet and increase the temperature of

air to the passenger compartment. Because PTC system is heated by electrical power, high capacity

alternator is required. PTC does not operate during engine cranking, while the battery voltage is lower

than 11 V or during preheating process of glow plugs.

b. Components

A: PTC 1 (changeable)

B: PTC 2,3 (not changeable)

Page 409 of 1336

c. Operation process

The ceramic PTC has a feature that the resistance goes up very high at a certain temperature. There

are three circuits in PTC heater. Only one circuit is connected when PTC1 relay is ON, and two circuits

are connected when PTC2 relay is ON.

Page 410 of 1336

0000-00

d. Control conditions

Operation Operating condition PTC Heater

HI

(PTC2)

PTC HI ON

LO

(PTC1)

PTC LO ON

Stop- A/C blower switch OFF

- Defective ambient air temperature sensor

(including open or short circuit)

- Engine cranking

- Low battery voltage (below 11V)

- During pre-glow process (glow indicator ON)

Operation diagram for PTC heater LO (step 2)