ESP SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 1142 of 1336

0000-00

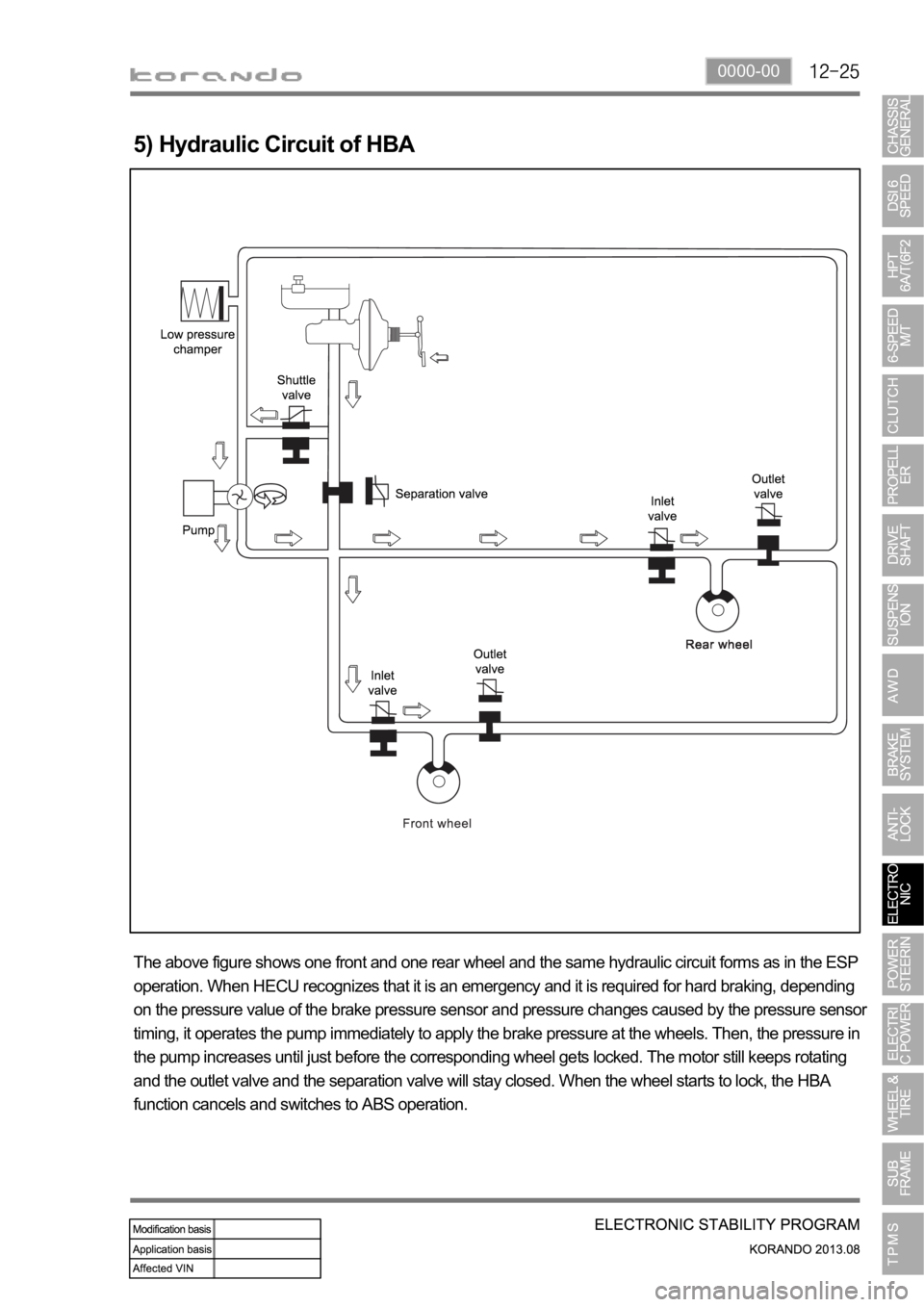

5) Hydraulic Circuit of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as in the ESP

operation. When HECU recognizes that it is an emergency and it is required for hard braking, depending

on the pressure value of the brake pressure sensor and pressure changes caused by the pressure sensor

timing, it operates the pump immediately to apply the brake pressure at the wheels. Then, the pressure in

the pump increases until just before the corresponding wheel gets locked. The motor still keeps rotating

and the outlet valve and the separation valve will stay closed. When the wheel starts to lock, the HBA

function cancels and switches to ABS operation.

Page 1143 of 1336

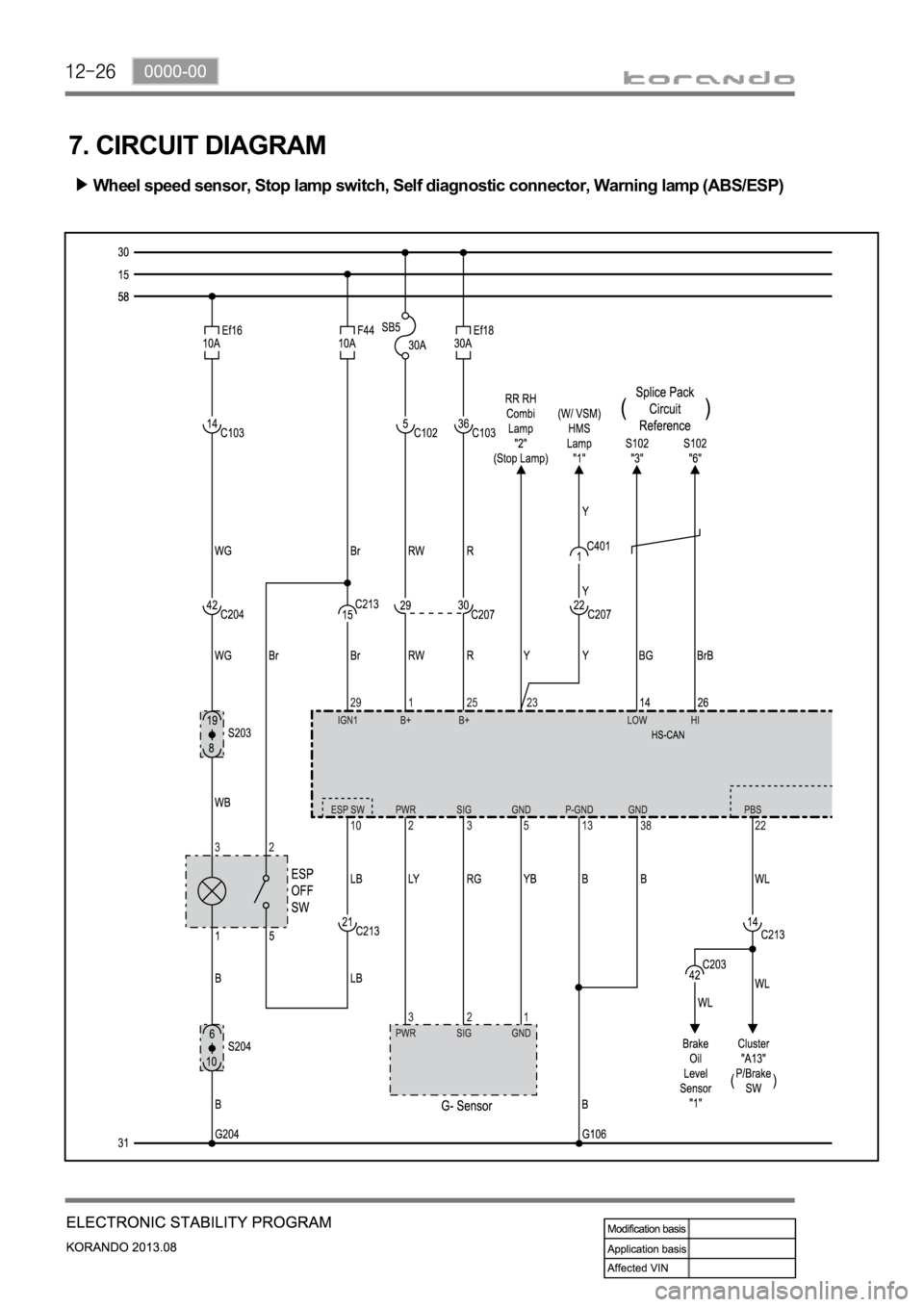

7. CIRCUIT DIAGRAM

Wheel speed sensor, Stop lamp switch, Self diagnostic connector, Warning lamp (ABS/ESP)

Page 1162 of 1336

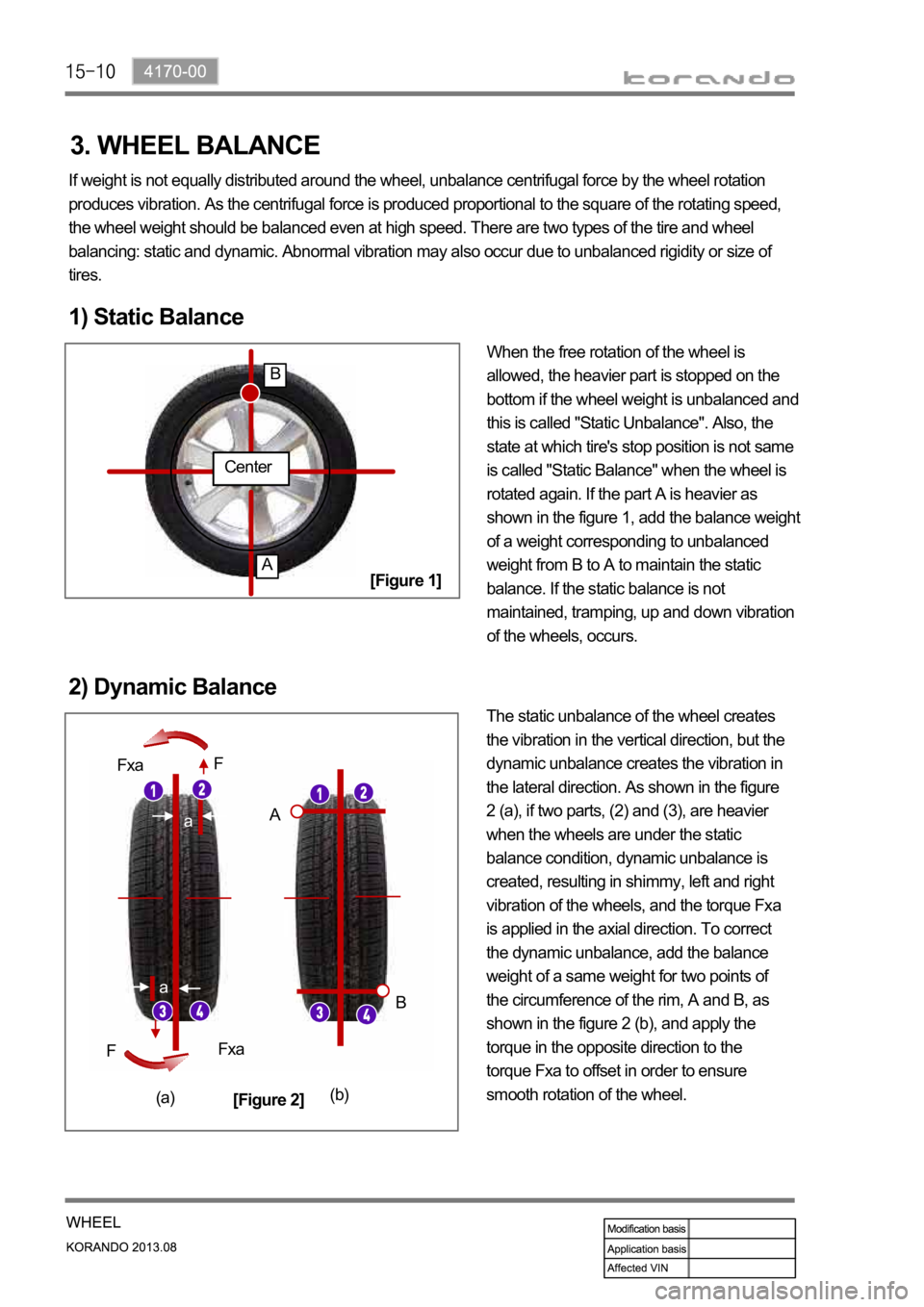

If weight is not equally distributed around the wheel, unbalance centrifugal force by the wheel rotation

produces vibration. As the centrifugal force is produced proportional to the square of the rotating speed,

the wheel weight should be balanced even at high speed. There are two types of the tire and wheel

balancing: static and dynamic. Abnormal vibration may also occur due to unbalanced rigidity or size of

tires.

1) Static Balance

When the free rotation of the wheel is

allowed, the heavier part is stopped on the

bottom if the wheel weight is unbalanced and

this is called "Static Unbalance". Also, the

state at which tire's stop position is not same

is called "Static Balance" when the wheel is

rotated again. If the part A is heavier as

shown in the figure 1, add the balance weight

of a weight corresponding to unbalanced

weight from B to A to maintain the static

balance. If the static balance is not

maintained, tramping, up and down vibration

of the wheels, occurs.

2) Dynamic Balance

The static unbalance of the wheel creates

the vibration in the vertical direction, but the

dynamic unbalance creates the vibration in

the lateral direction. As shown in the figure

2 (a), if two parts, (2) and (3), are heavier

when the wheels are under the static

balance condition, dynamic unbalance is

created, resulting in shimmy, left and right

vibration of the wheels, and the torque Fxa

is applied in the axial direction. To correct

the dynamic unbalance, add the balance

weight of a same weight for two points of

the circumference of the rim, A and B, as

shown in the figure 2 (b), and apply the

torque in the opposite direction to the

torque Fxa to offset in order to ensure

smooth rotation of the wheel.

Center

A

B

a

a

Fxa

Fxa F

F

A

B

(a)(b)

[Figure 1]

[Figure 2]

3. WHEEL BALANCE

Page 1183 of 1336

1) DOT LCD Display Related to TPMS

Status DOT LCD display Condition & illumination method

Correct tire pressureThe specified tire pressure is based on a

cold tire with the vehicle unloaded (no

Excessive tire pressureCorresponding status lamp blinks with

reverse shading at interval of 0.4 seconds if

tire pressure is 50 psi or higher

Low tire pressureWhen tire pressure is less than 13~20% of

specified value for a period of time,

corresponding status lamp blinks with

reverse shading for 70 seconds at interval o

f

0.4 seconds

Lower than minimum tire

pressureCorresponding status lamp comes on if tire

pressure is 24 psi or less

Sudden tire pressure lossCorresponding status lamp blinks with

shading reverse at interval of 0.4 seconds if

tire pressure changes more than 3 psi per 1

minute at speed of 0 km/h or above.

Imbalance between left and

right tire pressureCorresponding status lamps blink

alternately at interval of 1.0 second if tire

pressure differs by more than 4 psi in the left

and right tires while driving for more than 10

minutes

Impossible to determine tire

pressurePressure of the tire displayed as "--" when

not possible to determine tire pressure

correctly

* At initial start, the tire pressure can be

displayed after 10 minutes of driving at

speed of 20 km/h or higher

Supervision type

Page 1196 of 1336

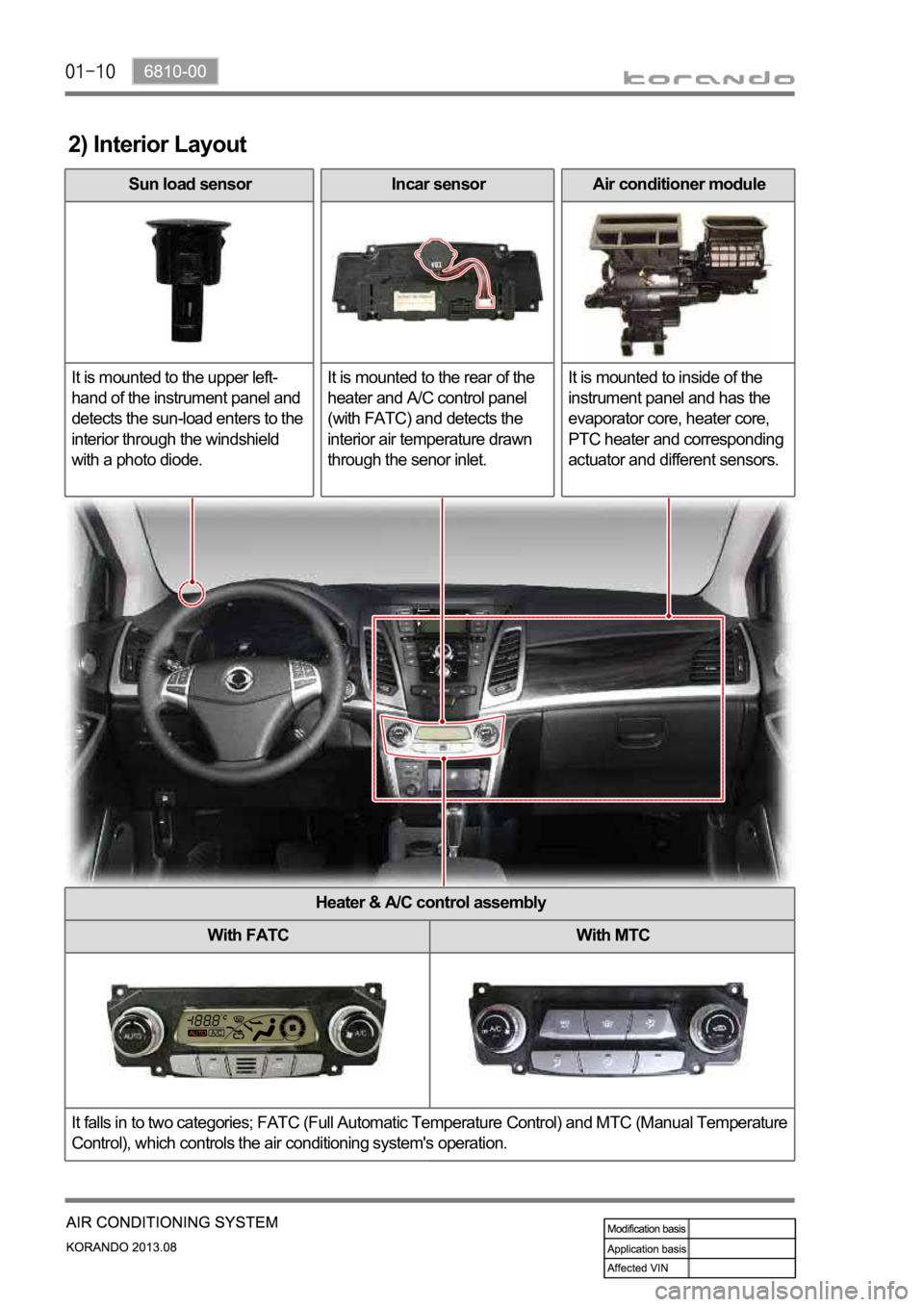

2) Interior Layout

Sun load sensor

It is mounted to the upper left-

hand of the instrument panel and

detects the sun-load enters to the

interior through the windshield

with a photo diode. Incar sensor

It is mounted to the rear of the

heater and A/C control panel

(with FATC) and detects the

interior air temperature drawn

through the senor inlet.Air conditioner module

It is mounted to inside of the

instrument panel and has the

evaporator core, heater core,

PTC heater and corresponding

actuator and different sensors.

Heater & A/C control assembly

With FATC With MTC

It falls in to two categories; FATC (Full Automatic Temperature Control) and MTC (Manual Temperature

Control), which controls the air conditioning system's operation.

Page 1229 of 1336

3. CAUTIONS FOR AIR BAG SYSTEM

Cautions for air bag maintenance

Whenever installing or removing the devices related to the air bag system, disconnect the negative

battery cable and wait for at least 30 seconds.

Do not connect a tester probe to the inflator to measure the resistance of the component of the air

bag system. The detonator of the inflator may explode due to a sudden extra power supplied by the

tester.

Note that the used components related to the air bag system, especially the air bag unit, should be

packed in an air tight container and prevent it from any impact or damage.

When there is any deployed air bag (including curtain air bag and seat belt pretensioner), the entire

system including the air bag unit should be replaced. The deployed air bag unit should not be reused

since it has status data when it is deployed, and the data cannot be cleared with a diagnostic device.

The air bag and seat belt pretensioner systems contain explosive charges, so handle carefully when

disposing or replacing them. 1.

2.

3.

4.

5.

Cautions for air bag maintenance

Do not modify, change or apply impact on any air bag component. The air bag may be deployed

abruptly, causing serious injuries.

Children and infants should ride in a rear seat. Seating in the passenger seat with carrying a

child or infant is strictly prohibited. An infant or a child could be severely injured by the air bag

deployment.

A child restraint system must not be installed on the front seat. An infant or a child could be severely

injured by the air bag deployment when it is fitted to the passenger seat.

Do not place any objects on the air bag inflation location. You may get injured by those objects during

deployment.

Never put your arms around the front seat from behind, lean on the front seatback, or put your arms

out of the window. You can severely injured when the side air bag deploys.

Never lean on the door since it becomes very dangerous when the side air bag deploys.

The side air bag deploys when there is a severe side collision.

Do not slam the front door to close it. The side air bag may deploy unexpectedly.

When an occupant fastens the seat belt in an unstable or inclined posture, the air bag system cannot

protect the occupant properly. Moreover, the occupant can be injured by the air bag.

Do not move your seat too close to the steering wheel or dashboard. Being too close to the

steering wheel or instrument panel during the air bag deployment could cause serious injury,

including death

Hold only the outer rim of the steering so that the air bag can inflate without any hindrance.

Do not incline toward the steering wheel. Never allow the passenger to put hands or feet on the dash

board. The air bag cannot work properly Do not hold and operate the steering wheel by crossing your

arms You could get seriously injured when the air bag deploys. 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Page 1235 of 1336

3. AIR BAG SYSTEM OPERATING PROCESS

1) Air Bag System Input/Output

The air bag unit (SDM) performs the internal/external diagnosis on the air bag system for about 6

seconds after IGN ON. The air bag unit is ready to deploy air bag after this diagnosis, and when a

certain level of collision occurs, it determines the deployment of the air bag using the signals from the

impact sensors, deploys the corresponding air bag, and stores the collision data and EDR data. The

body control module (BCM) activates the auto door unlock function and various lamps including hazard

warning lamp and room lamps, when the crash signal from the SDM is received to notify others of

emergency situation and let the occupant escape easily.

Major functions

Detects frontal and side collision (Rear-end collision only with EDR trigger)

Activates the front air bag, side air bag, curtain air bag and belt pretensioners

Indicates system readiness and faults to the driver by means of a fault warning lamp

Facilitates servicing capability via a serial diagnostic communication interfaces

Records crash data and DTCs

Keeps power for deployment of air bag even when the power to the air bag unit is cut off due to the

collision

Event data recorder (EDR) -

-

-

-

-

-

-

Page 1240 of 1336

8810-00

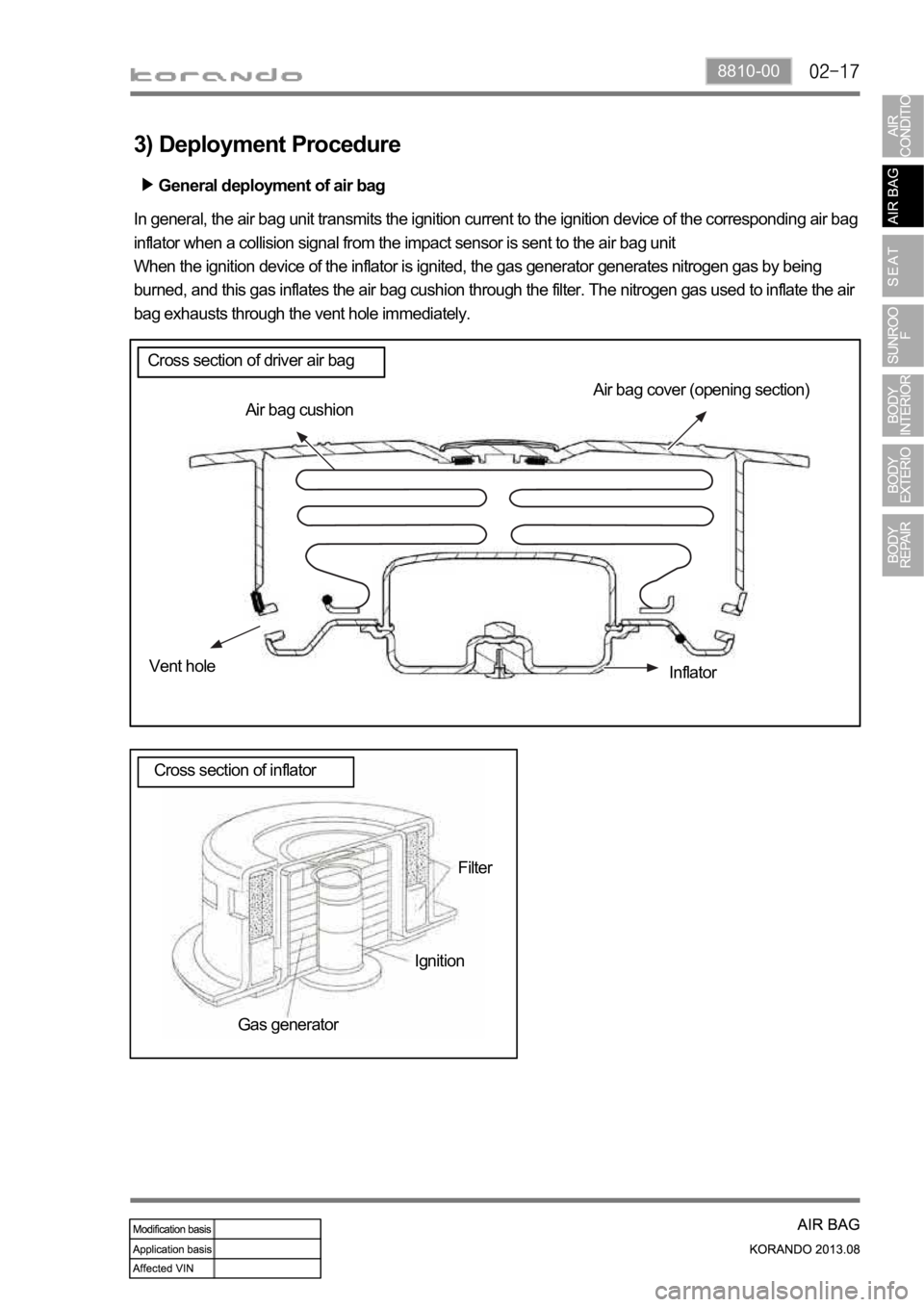

General deployment of air bag

3) Deployment Procedure

Air bag cover (opening section)

Air bag cushion

Vent hole

Inflator

Filter

Ignition

Gas generator In general, the air bag unit transmits the ignition current to the ignition device of the corresponding air bag

inflator when a collision signal from the impact sensor is sent to the air bag unit

When the ignition device of the inflator is ignited, the gas generator generates nitrogen gas by being

burned, and this gas inflates the air bag cushion through the filter. The nitrogen gas used to inflate the air

bag exhausts through the vent hole immediately.

Cross section of driver air bag

Cross section of inflator

Page 1276 of 1336

7410-00

5) Front Seat Heated Wire and Ventilation Operation

Operating conditions

Engine running

If the engine starts to crank during the seat heated wire and ventilation signal output, the seat heated

wire will not be operated until the cranking stops. -

-

Operation description

After the ignition is turned on, the temperature of the seat can be adjusted in 3 levels (Level 2

pressed, the temperature level goes down by one level. Pressing the switch a third time will turn off

the operation. -

Operating process

When the front seat heated wire and ventilation switch is pressed, the front seat heated wire and

ventilation unit supplies the power to the corresponding seat for heated wire and ventilation operation

through the switch. -

The heated wire and ventilation functions cannot be operated at the same time.

(1) Heated wire and ventilation functions for front seat (driver seat heated

wire and ventilation - 2 levels, passenger seat heated wire - 2 levels)

Page 1277 of 1336

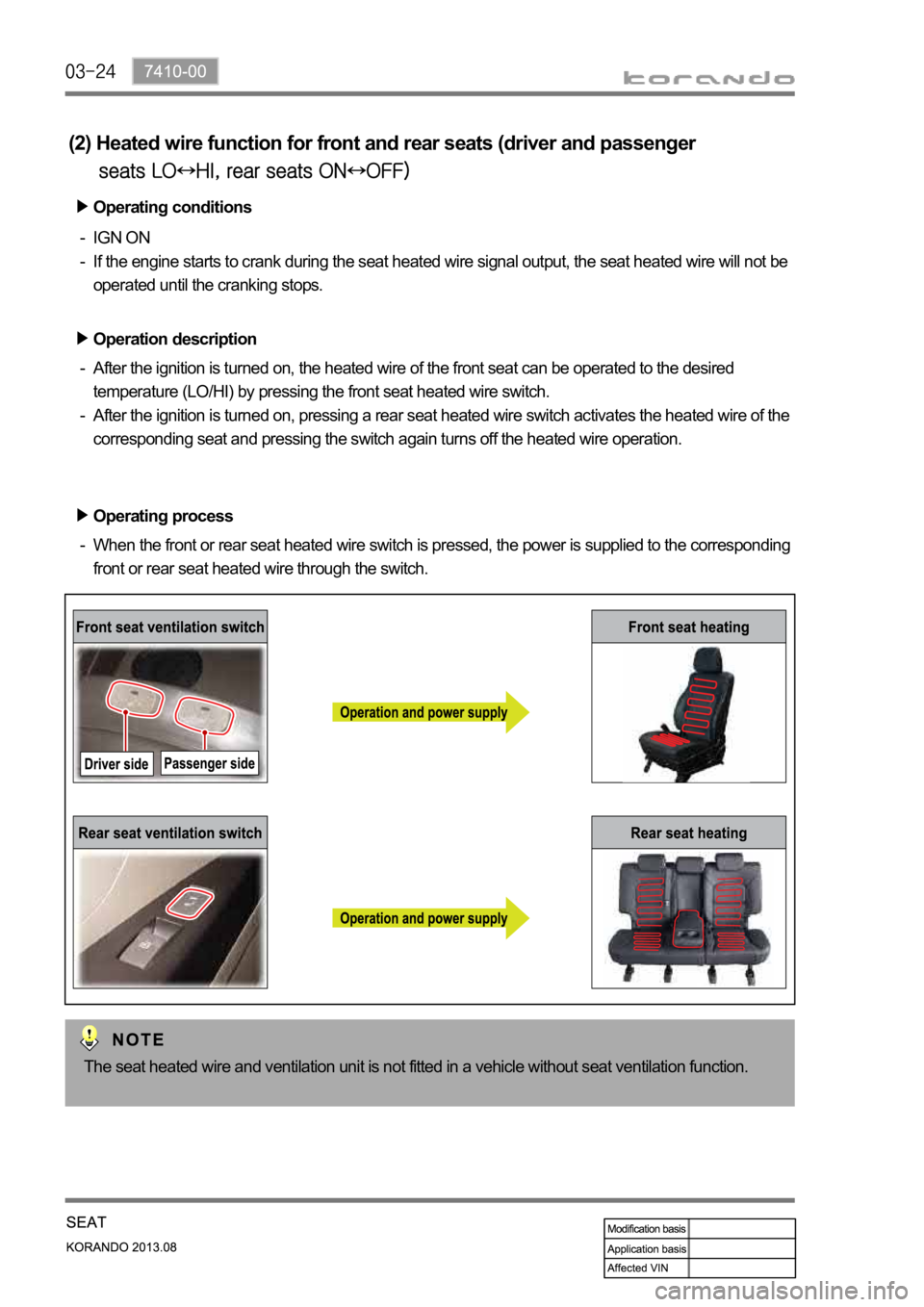

Operating conditions

IGN ON

If the engine starts to crank during the seat heated wire signal output, the seat heated wire will not be

operated until the cranking stops. -

-

Operation description

After the ignition is turned on, the heated wire of the front seat can be operated to the desired

temperature (LO/HI) by pressing the front seat heated wire switch.

After the ignition is turned on, pressing a rear seat heated wire switch activates the heated wire of the

corresponding seat and pressing the switch again turns off the heated wire operation. -

-

Operating process

When the front or rear seat heated wire switch is pressed, the power is supplied to the corresponding

front or rear seat heated wire through the switch. -

The seat heated wire and ventilation unit is not fitted in a vehicle without seat ventilation function.

(2) Heated wire function for front and rear seats (driver and passenger