ESP SSANGYONG KORANDO 2013 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 985 of 1336

0000-00

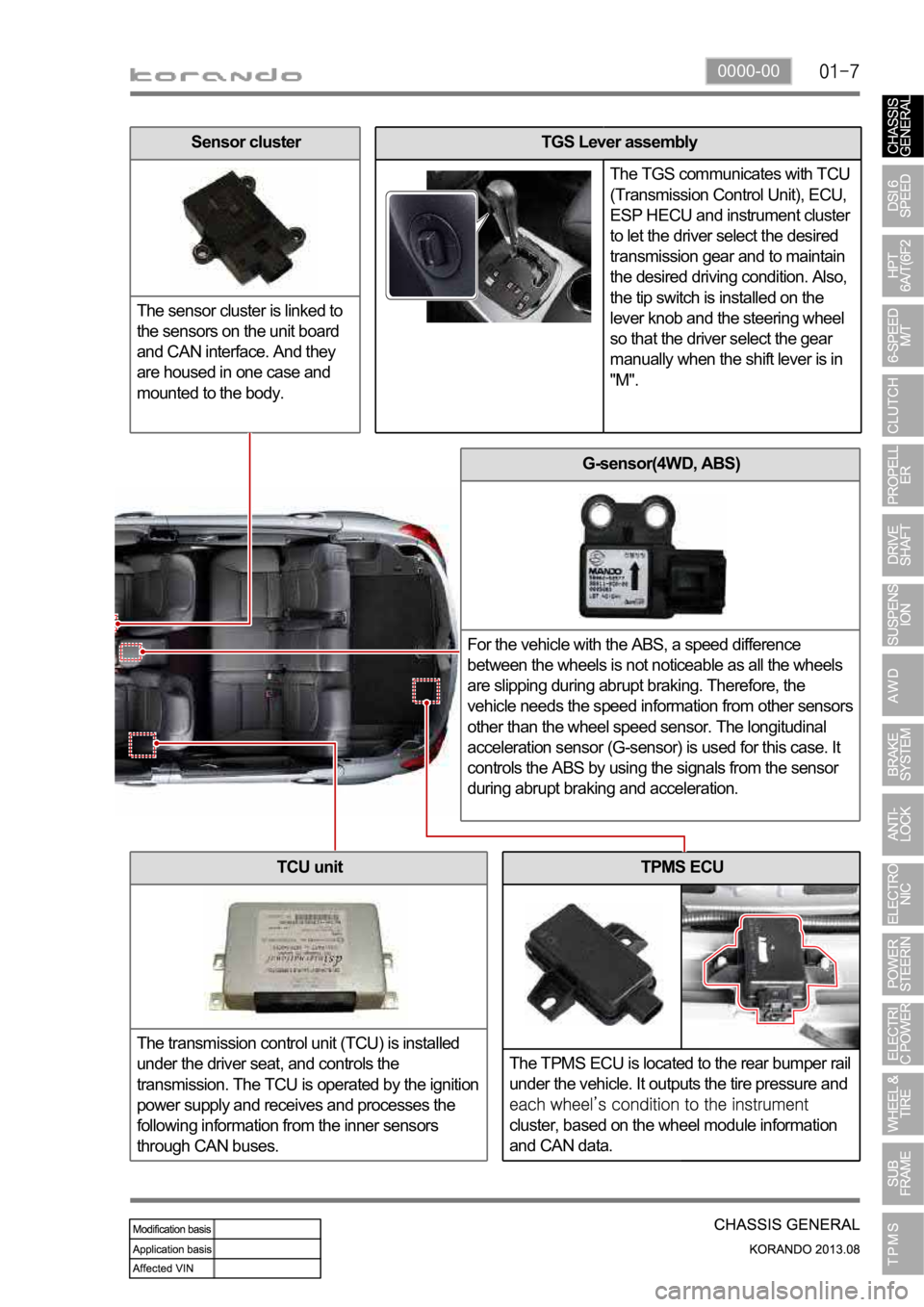

TPMS ECU

The TPMS ECU is located to the rear bumper rail

under the vehicle. It outputs the tire pressure and

cluster, based on the wheel module information

and CAN data.

G-sensor(4WD, ABS)

For the vehicle with the ABS, a speed difference

between the wheels is not noticeable as all the wheels

are slipping during abrupt braking. Therefore, the

vehicle needs the speed information from other sensors

other than the wheel speed sensor. The longitudinal

acceleration sensor (G-sensor) is used for this case. It

controls the ABS by using the signals from the sensor

during abrupt braking and acceleration.

TCU unit

The transmission control unit (TCU) is installed

under the driver seat, and controls the

transmission. The TCU is operated by the ignition

power supply and receives and processes the

following information from the inner sensors

through CAN buses.

TGS Lever assembly

The TGS communicates with TCU

(Transmission Control Unit), ECU,

ESP HECU and instrument cluster

to let the driver select the desired

transmission gear and to maintain

the desired driving condition. Also,

the tip switch is installed on the

lever knob and the steering wheel

so that the driver select the gear

manually when the shift lever is in

"M".Sensor cluster

The sensor cluster is linked to

the sensors on the unit board

and CAN interface. And they

are housed in one case and

mounted to the body.

Page 986 of 1336

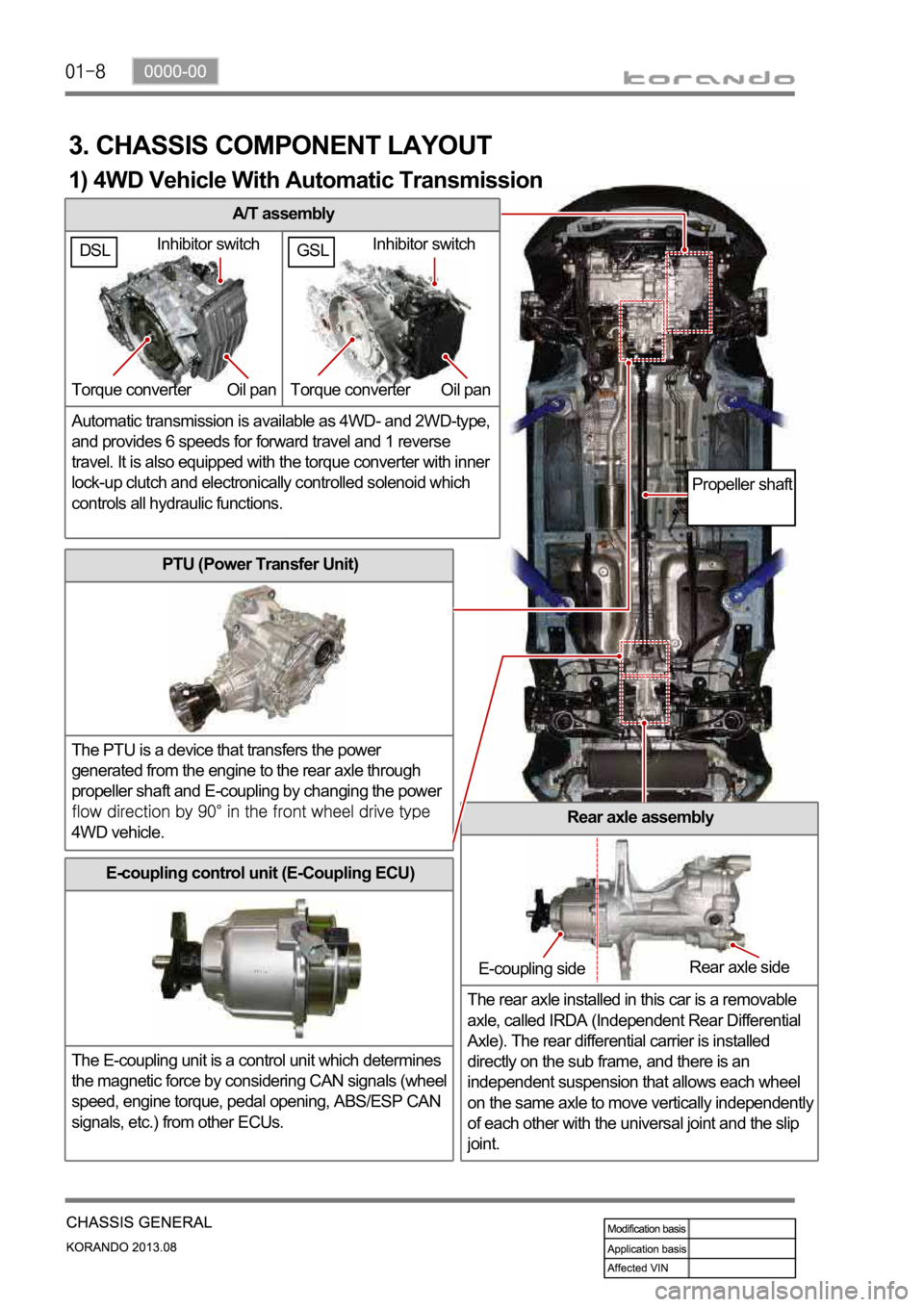

A/T assembly

Automatic transmission is available as 4WD- and 2WD-type,

and provides 6 speeds for forward travel and 1 reverse

travel. It is also equipped with the torque converter with inner

lock-up clutch and electronically controlled solenoid which

controls all hydraulic functions.

3. CHASSIS COMPONENT LAYOUT

PTU (Power Transfer Unit)

The PTU is a device that transfers the power

generated from the engine to the rear axle through

propeller shaft and E-coupling by changing the power

4WD vehicle.Rear axle assembly

The rear axle installed in this car is a removable

axle, called IRDA (Independent Rear Differential

Axle). The rear differential carrier is installed

directly on the sub frame, and there is an

independent suspension that allows each wheel

on the same axle to move vertically independentl

y

of each other with the universal joint and the slip

joint.

E-coupling control unit (E-Coupling ECU)

The E-coupling unit is a control unit which determines

the magnetic force by considering CAN signals (wheel

speed, engine torque, pedal opening, ABS/ESP CAN

signals, etc.) from other ECUs.

Inhibitor switch

Torque converter Oil pan

E-coupling sideRear axle side

Propeller shaft

1) 4WD Vehicle With Automatic Transmission

GSLDSLInhibitor switch

Torque converter Oil pan

Page 994 of 1336

A. Indicators on instrument cluster

C. HECU assembly

The HECU assemblies for ABS and ESP have

similar appearance but they have different inner

structure and connector connections from each

other. D. Front brake assembly

The disc brake for 4WD vehicle is the same with

the one for 2WD vehicle.

7. BRAKE SYSTEM AND ESP SYSTEM LAYOUT

B. Master cylinder assembly

Description for master cylinder in this chapter is

based on ABS/ESP equipped vehicle. For CBS,

there is an extra pressure valve mounted to the

master cylinder.

CaliperDisc

Parking brake

warning light

ABS warning lamp

ESP indicator

Page 999 of 1336

0000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

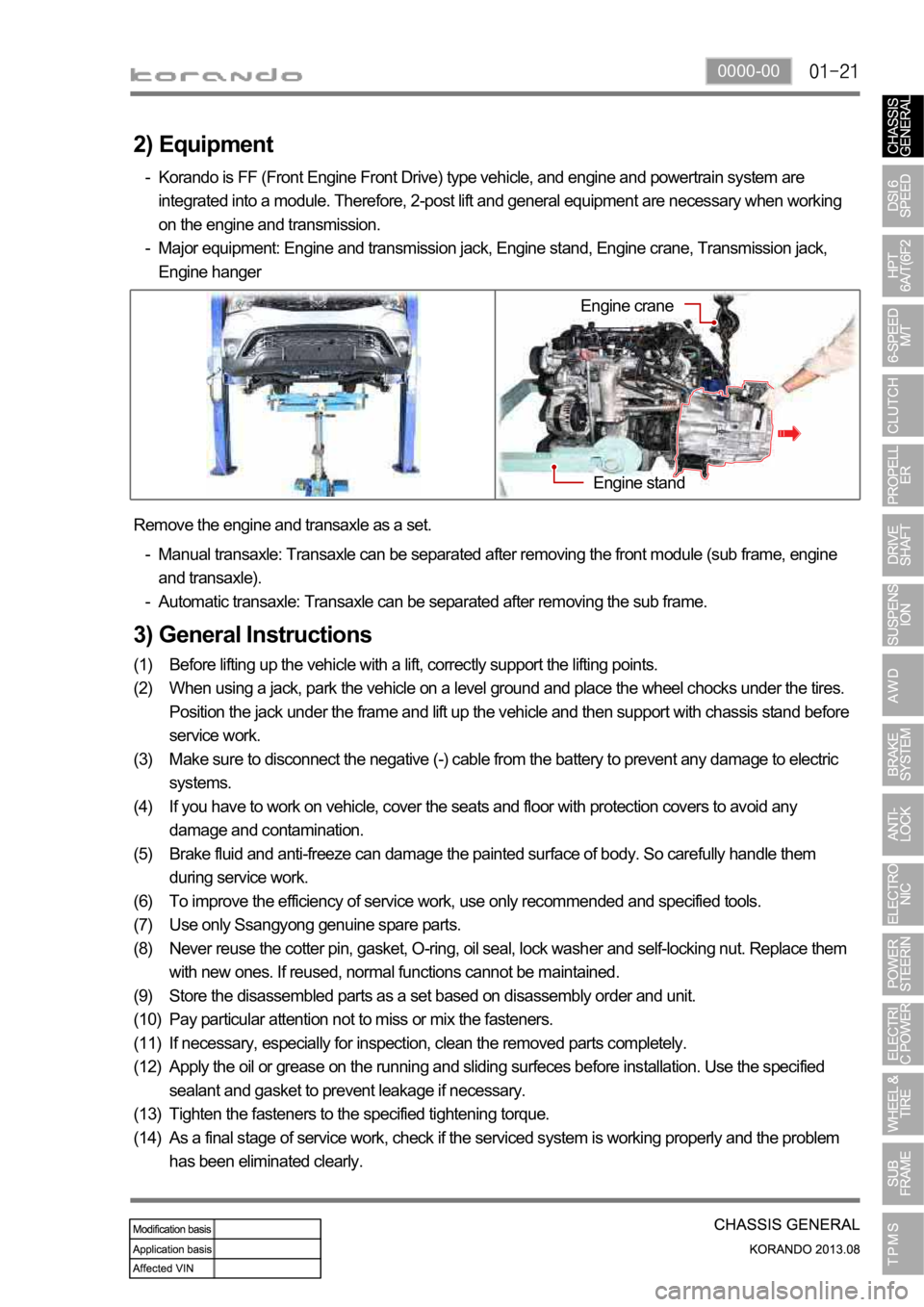

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane

Page 1076 of 1336

4110-01

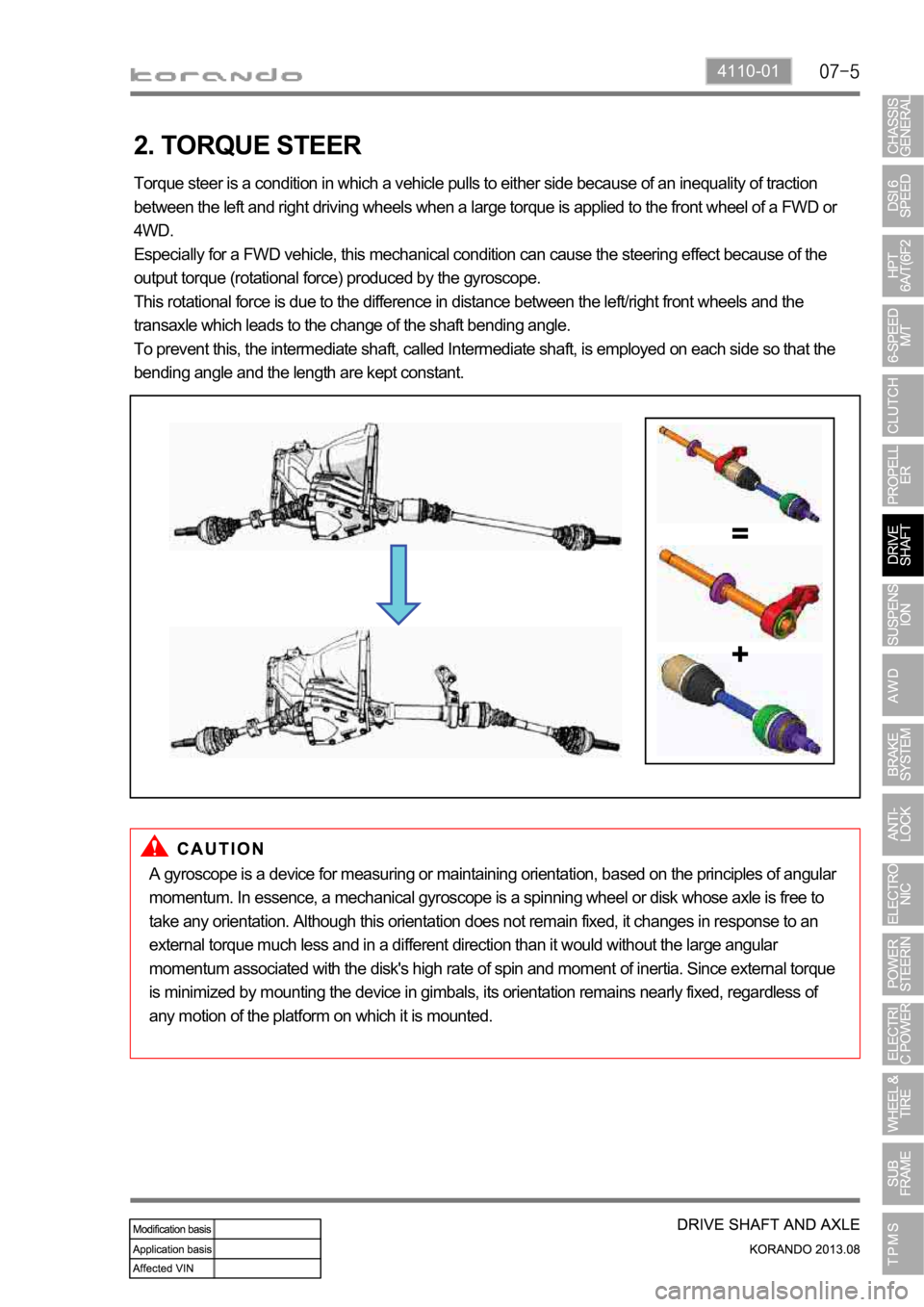

2. TORQUE STEER

Torque steer is a condition in which a vehicle pulls to either side because of an inequality of traction

between the left and right driving wheels when a large torque is applied to the front wheel of a FWD or

4WD.

Especially for a FWD vehicle, this mechanical condition can cause the steering effect because of the

output torque (rotational force) produced by the gyroscope.

This rotational force is due to the difference in distance between the left/right front wheels and the

transaxle which leads to the change of the shaft bending angle.

To prevent this, the intermediate shaft, called Intermediate shaft, is employed on each side so that the

bending angle and the length are kept constant.

A gyroscope is a device for measuring or maintaining orientation, based on the principles of angular

momentum. In essence, a mechanical gyroscope is a spinning wheel or disk whose axle is free to

take any orientation. Although this orientation does not remain fixed, it changes in response to an

external torque much less and in a different direction than it would without the large angular

momentum associated with the disk's high rate of spin and moment of inertia. Since external torque

is minimized by mounting the device in gimbals, its orientation remains nearly fixed, regardless of

any motion of the platform on which it is mounted.

Page 1083 of 1336

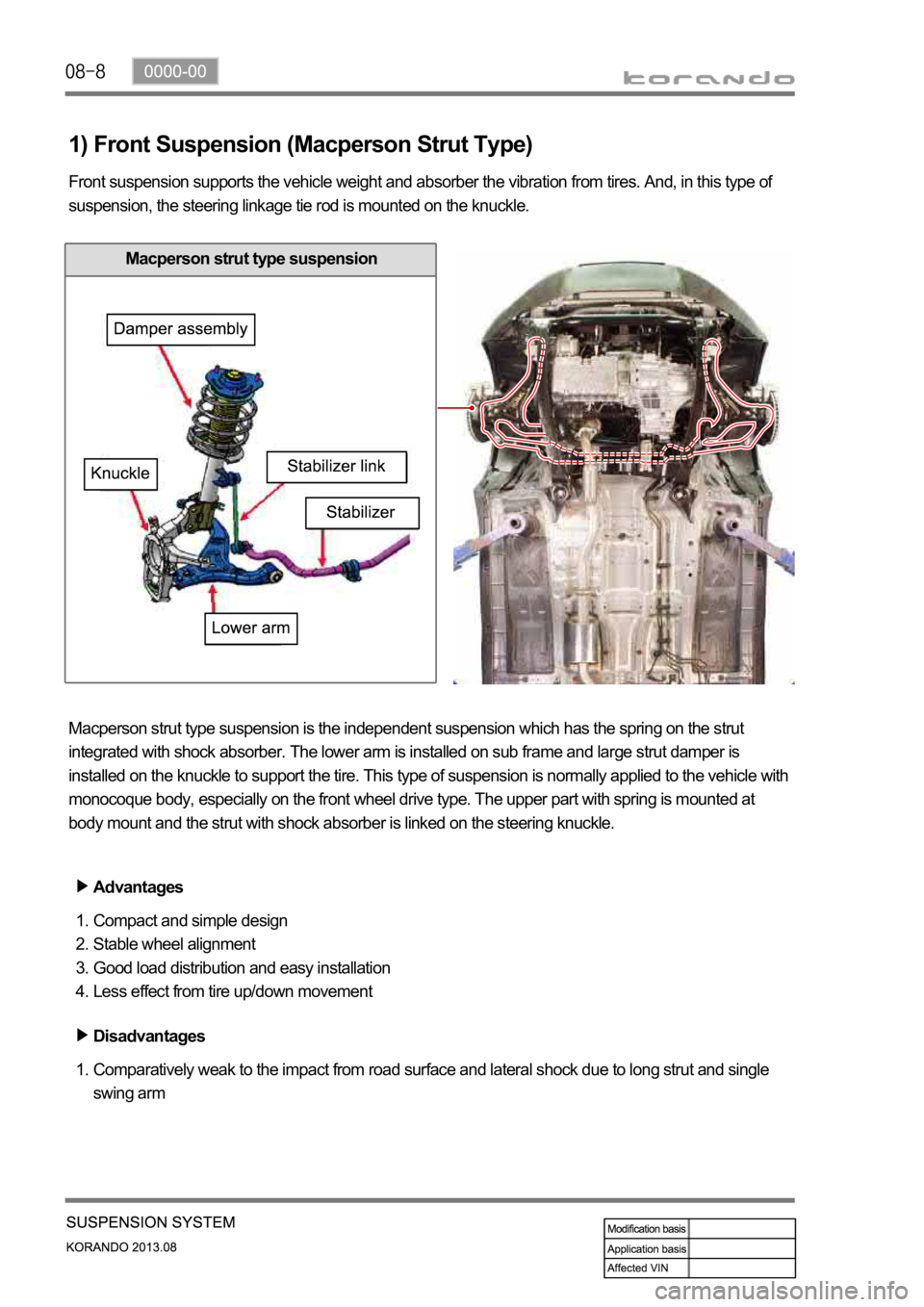

1) Front Suspension (Macperson Strut Type)

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this type of

suspension, the steering linkage tie rod is mounted on the knuckle.

Macperson strut type suspension is the independent suspension which has the spring on the strut

integrated with shock absorber. The lower arm is installed on sub frame and large strut damper is

installed on the knuckle to support the tire. This type of suspension is normally applied to the vehicle with

monocoque body, especially on the front wheel drive type. The upper part with spring is mounted at

body mount and the strut with shock absorber is linked on the steering knuckle.

Advantages

Compact and simple design

Stable wheel alignment

Good load distribution and easy installation

Less effect from tire up/down movement 1.

2.

3.

4.

Disadvantages

Comparatively weak to the impact from road surface and lateral shock due to long strut and single

swing arm 1.

Macperson strut type suspension

Page 1087 of 1336

0000-00

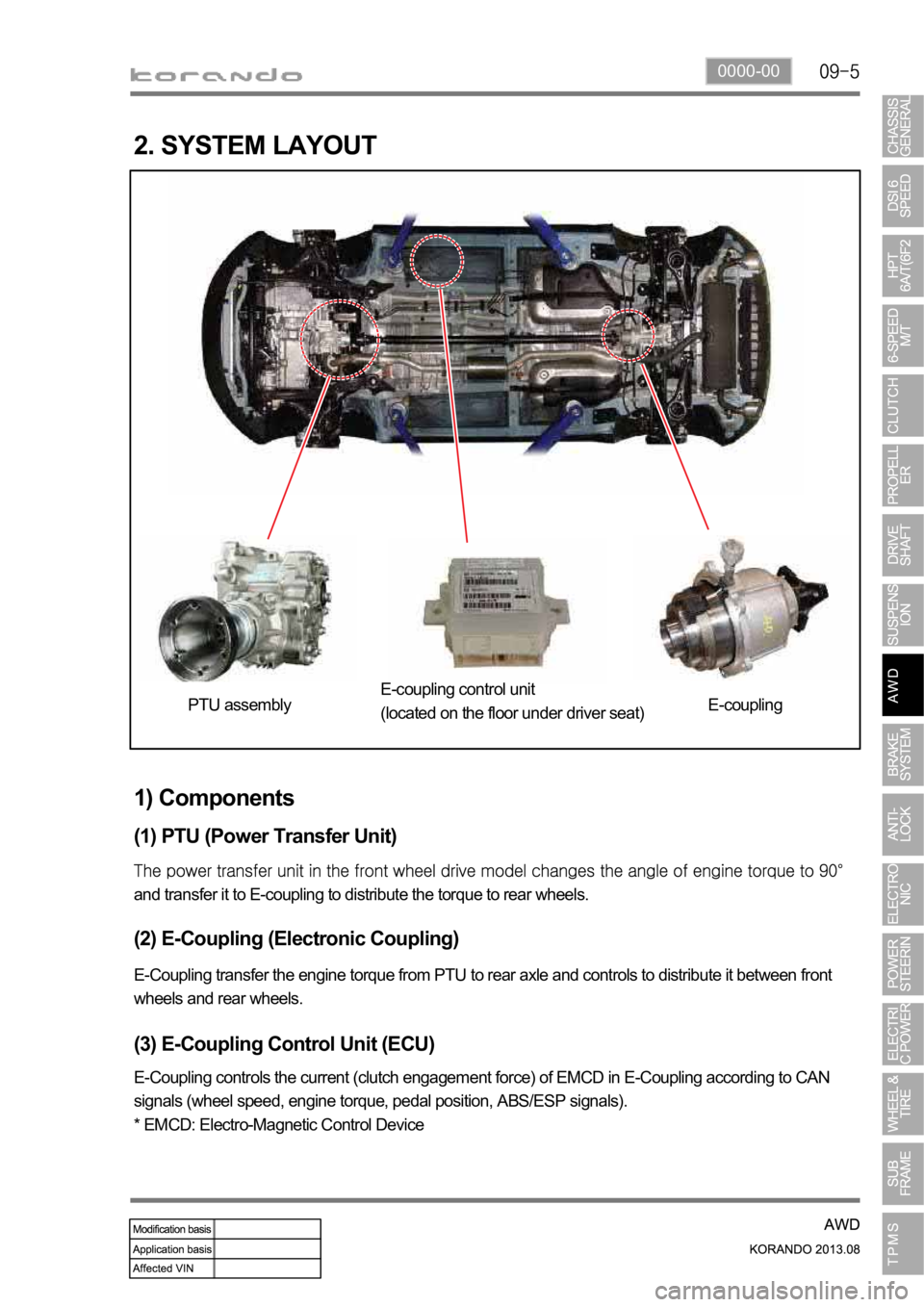

2. SYSTEM LAYOUT

1) Components

(1) PTU (Power Transfer Unit)

and transfer it to E-coupling to distribute the torque to rear wheels.

(2) E-Coupling (Electronic Coupling)

E-Coupling transfer the engine torque from PTU to rear axle and controls to distribute it between front

wheels and rear wheels.

(3) E-Coupling Control Unit (ECU)

E-Coupling controls the current (clutch engagement force) of EMCD in E-Coupling according to CAN

signals (wheel speed, engine torque, pedal position, ABS/ESP signals).

* EMCD: Electro-Magnetic Control Device PTU assemblyE-coupling control unit

(located on the floor under driver seat)E-coupling

Page 1088 of 1336

4850-00

1. SYSTEM OVERVIEW

1) Terms and Definition

CBS: Conventional Brake System

ABS: Anti-Lock Brake System

EBD: Electronic brake-Force Distribution

ESP: Electronic Stability Program

ABD: Automatic Braking Differential

ASR: Acceleration Slip Regulation

AYC: Active Yaw Control (Understeer and Oversteer Control)

HBA: Hydraulic Brake Assistant

ARP: Active Rollover Protection

HSA: Hill Start Assistant -

-

-

-

-

-

-

-

-

-

2) Functions

FunctionVehicle with CBS

Vehicle with ABS/EBD Vehicle with ESP

ABS

Not appliedApplied

Applied EBD Applied

ABD

Not applied ASR

AYC

HBA

ARP

HSA

Page 1089 of 1336

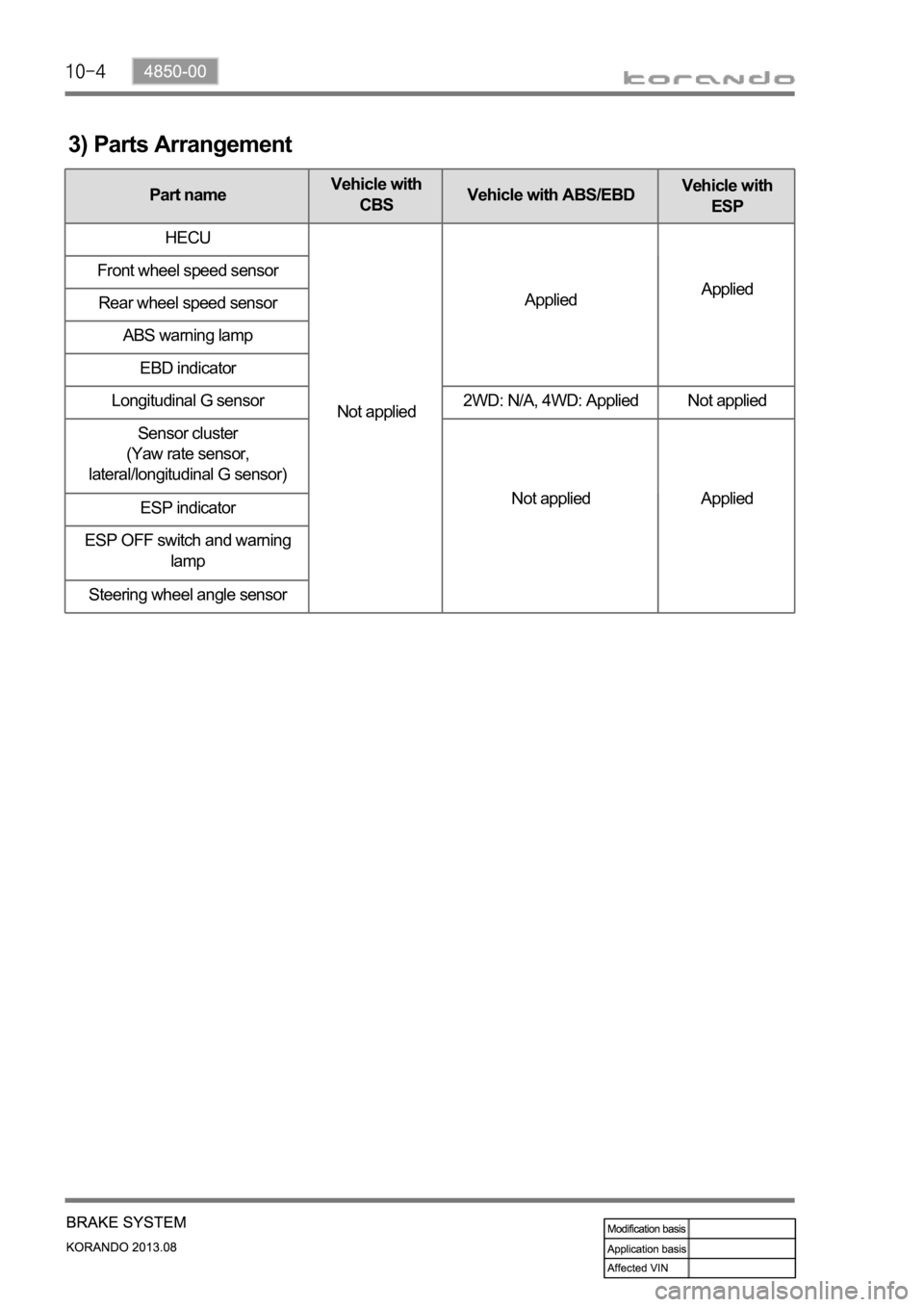

3) Parts Arrangement

Part nameVehicle with

CBSVehicle with ABS/EBDVehicle with

ESP

HECU

Not appliedAppliedApplied Front wheel speed sensor

Rear wheel speed sensor

ABS warning lamp

EBD indicator

Longitudinal G sensor 2WD: N/A, 4WD: Applied Not applied

Sensor cluster

(Yaw rate sensor,

lateral/longitudinal G sensor)

Not applied Applied

ESP indicator

ESP OFF switch and warning

lamp

Steering wheel angle sensor

Page 1090 of 1336

4850-00

A. Meter cluster-ABS, EBD, ESP

indicator/warning lampB. Master cylinder and

boosterC. HECU

F. Front/rear wheel speed sensor

Front/rear-4WD Rear-2WDH. Parking brakeG. Brake pedal

4) Component

ABS warning lamp

ESP indicator

D. Front brake

assembly

E. Rear brake

assembly

Disc

Disc

Parking brake

warning lamp

Caliper

Caliper