SSANGYONG KORANDO 2013 Service Manual

KORANDO 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57503/w960_57503-0.png

SSANGYONG KORANDO 2013 Service Manual

Trending: warning light, change key battery, relay, gear box, park assist, glass key, brake fluid

Page 1161 of 1336

4170-00

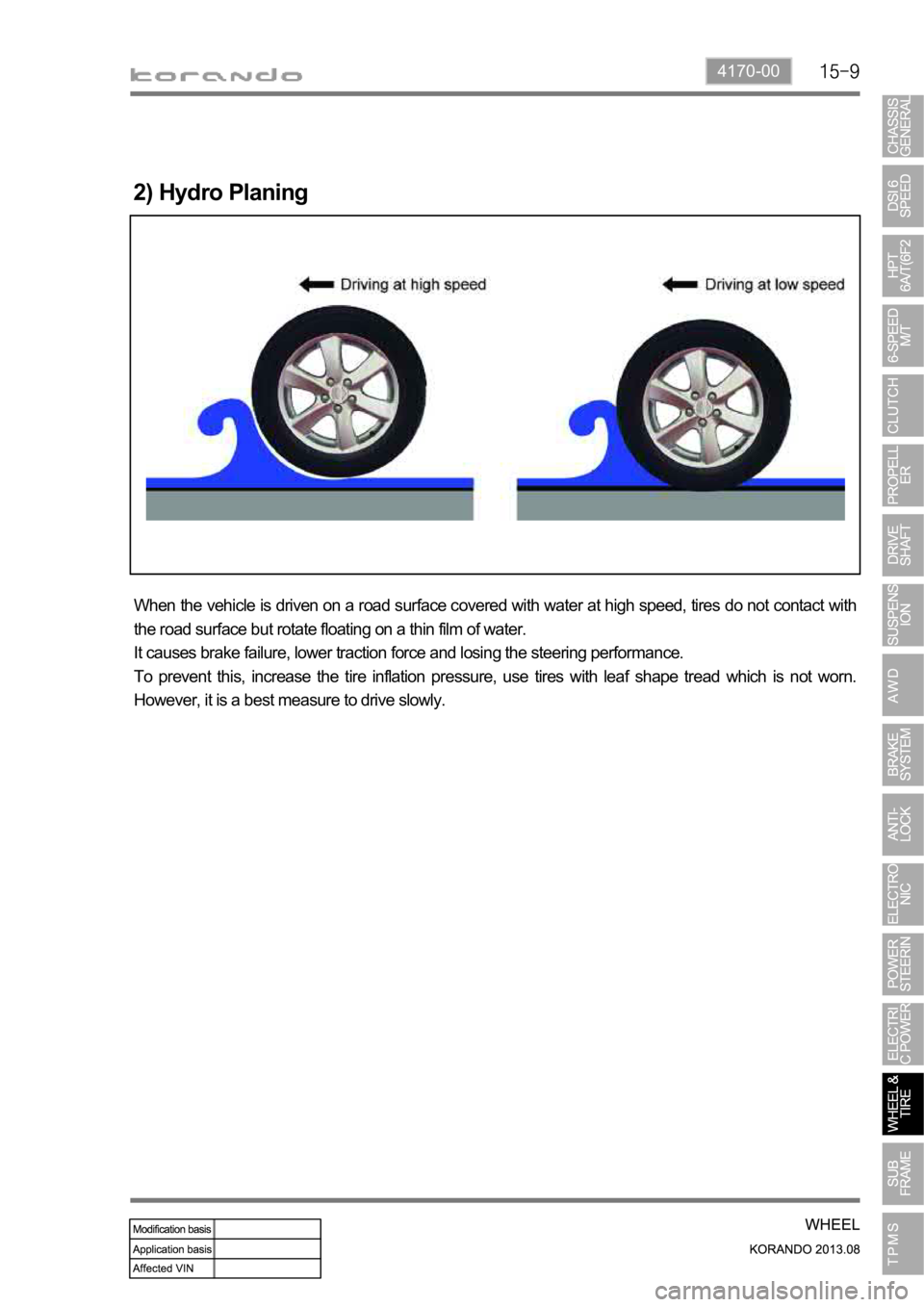

When the vehicle is driven on a road surface covered with water at high speed, tires do not contact with

the road surface but rotate floating on a thin film of water.

It causes brake failure, lower traction force and losing the steering performance.

To prevent this, increase the tire inflation pressure, use tires with leaf shape tread which is not worn.

However, it is a best measure to drive slowly.

2) Hydro Planing

Page 1162 of 1336

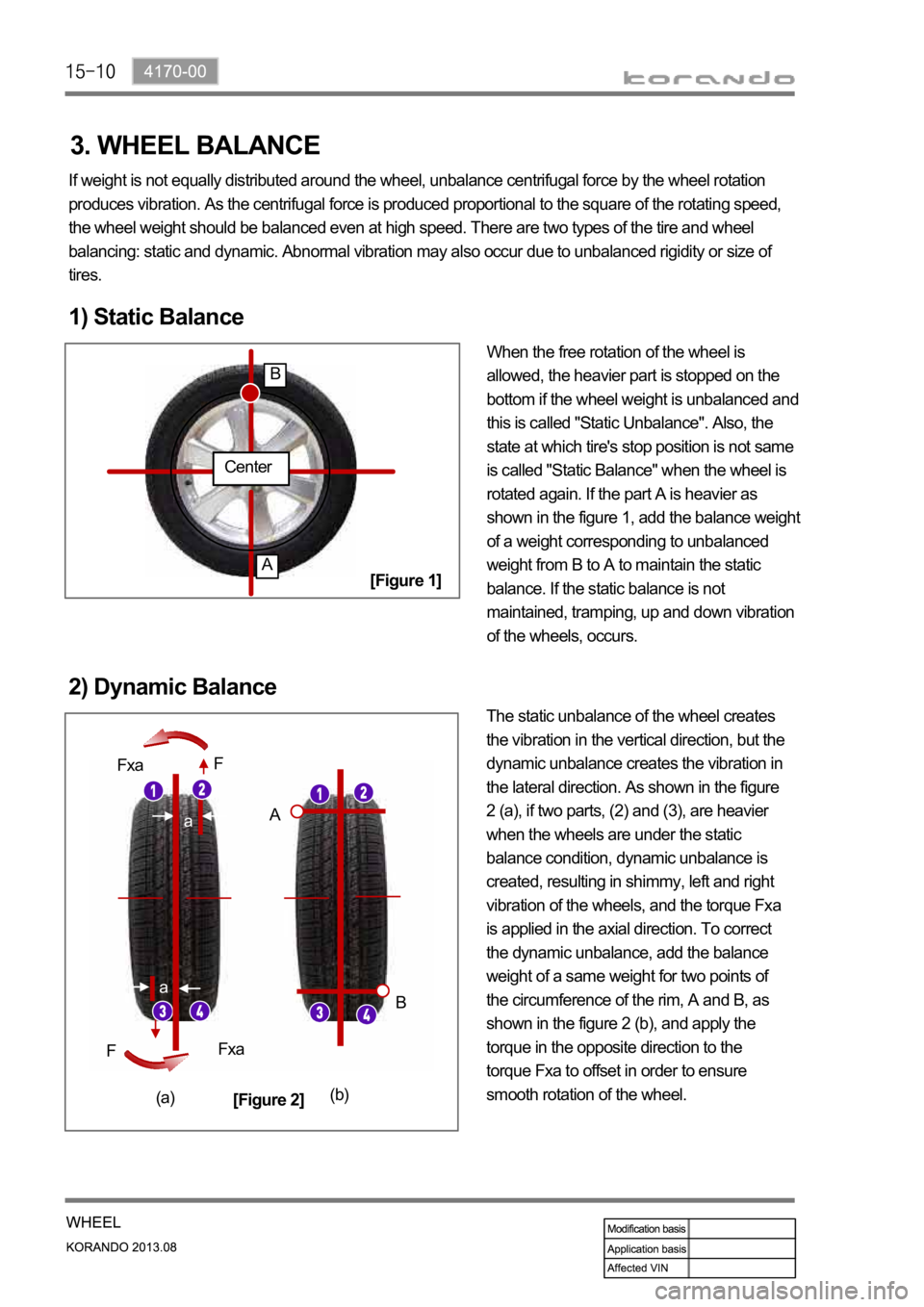

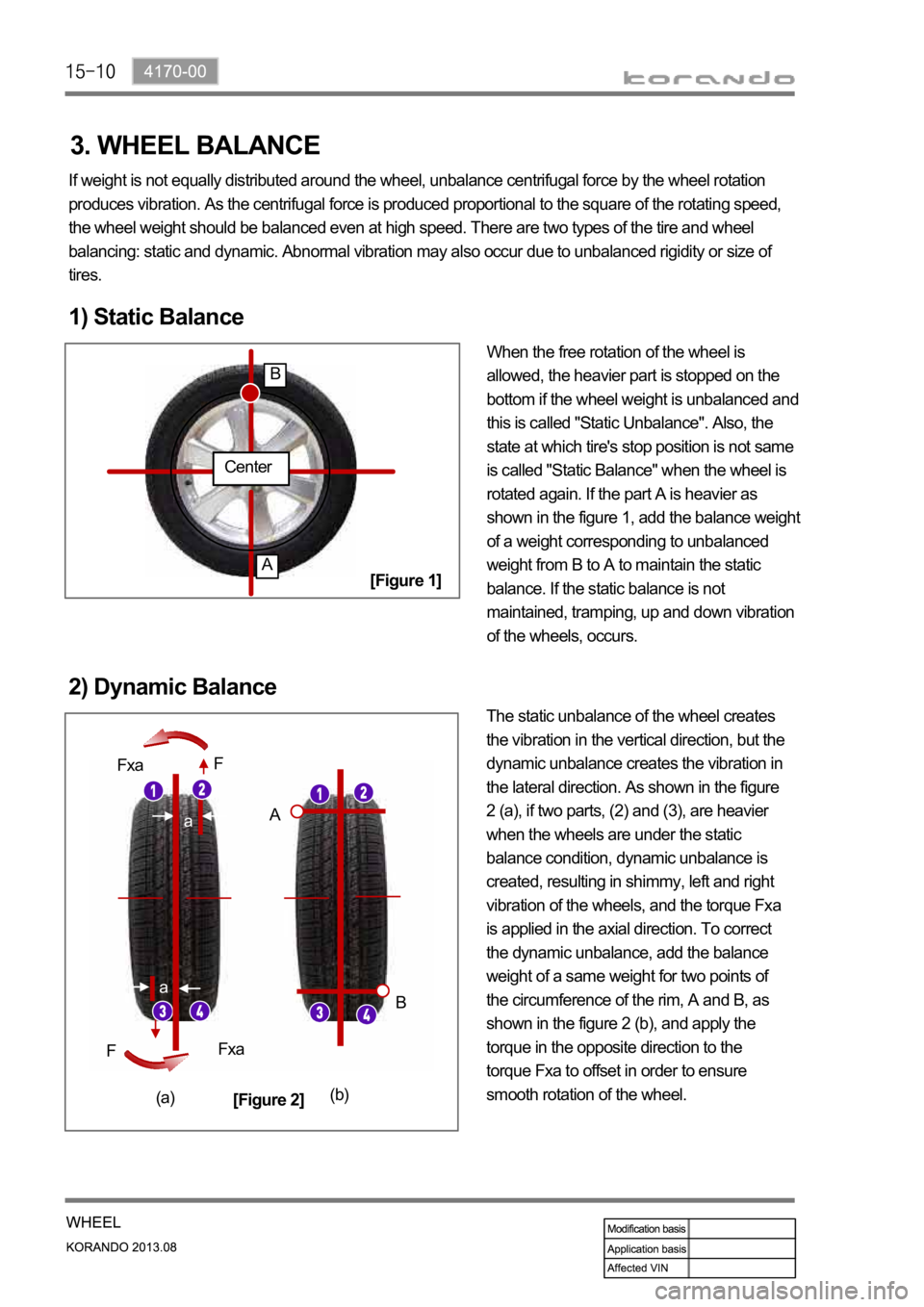

If weight is not equally distributed around the wheel, unbalance centrifugal force by the wheel rotation

produces vibration. As the centrifugal force is produced proportional to the square of the rotating speed,

the wheel weight should be balanced even at high speed. There are two types of the tire and wheel

balancing: static and dynamic. Abnormal vibration may also occur due to unbalanced rigidity or size of

tires.

1) Static Balance

When the free rotation of the wheel is

allowed, the heavier part is stopped on the

bottom if the wheel weight is unbalanced and

this is called "Static Unbalance". Also, the

state at which tire's stop position is not same

is called "Static Balance" when the wheel is

rotated again. If the part A is heavier as

shown in the figure 1, add the balance weight

of a weight corresponding to unbalanced

weight from B to A to maintain the static

balance. If the static balance is not

maintained, tramping, up and down vibration

of the wheels, occurs.

2) Dynamic Balance

The static unbalance of the wheel creates

the vibration in the vertical direction, but the

dynamic unbalance creates the vibration in

the lateral direction. As shown in the figure

2 (a), if two parts, (2) and (3), are heavier

when the wheels are under the static

balance condition, dynamic unbalance is

created, resulting in shimmy, left and right

vibration of the wheels, and the torque Fxa

is applied in the axial direction. To correct

the dynamic unbalance, add the balance

weight of a same weight for two points of

the circumference of the rim, A and B, as

shown in the figure 2 (b), and apply the

torque in the opposite direction to the

torque Fxa to offset in order to ensure

smooth rotation of the wheel.

Center

A

B

a

a

Fxa

Fxa F

F

A

B

(a)(b)

[Figure 1]

[Figure 2]

3. WHEEL BALANCE

Page 1163 of 1336

4012-00

Unit Construction

Front sub

frame

Rear sub

frame

(4WD)

Rear sub

frame

(2WD)

1. SPECIFICATION

Body mounting:

4-points bush

Transaxle mounting:

2-points bush

Weight: 22.37 kg 1.

2.

3.

Body mounting:

4-points bush

Axle mounting:

4-points bush

Weight: 16.61 kg 1.

2.

3.

Body mounting:

40 points direct

mounting

Spring link:

Direct mounting

without bracket on

rear cross member

Weight: 12.74 kg 1.

2.

3.

BRKT-ENG MTG RRBRKT-ENG MTG FRT

Page 1164 of 1336

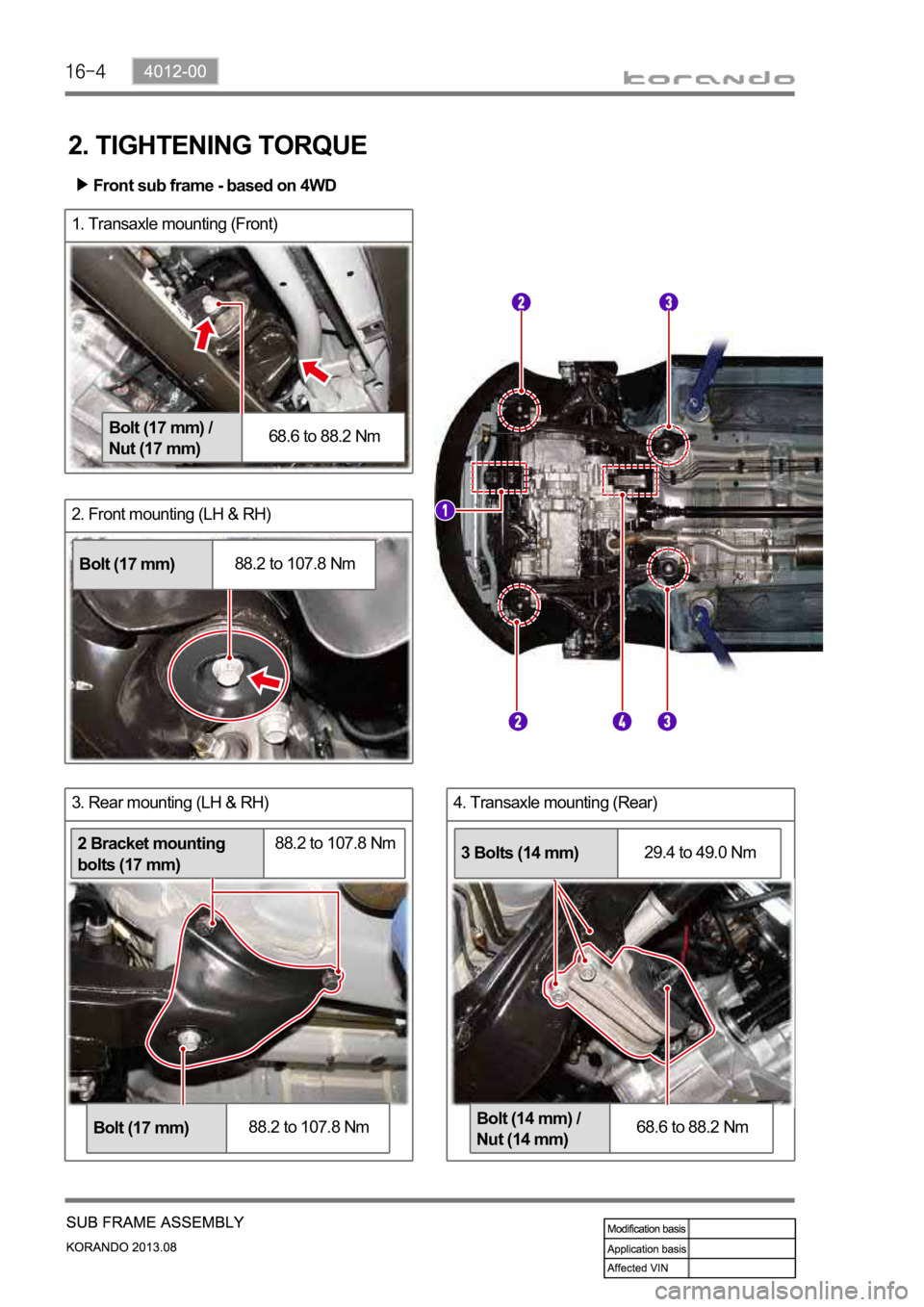

4. Transaxle mounting (Rear)3. Rear mounting (LH & RH)

2. Front mounting (LH & RH)

1. Transaxle mounting (Front)

2. TIGHTENING TORQUE

Bolt (17 mm) /

Nut (17 mm)68.6 to 88.2 Nm

Bolt (17 mm)88.2 to 107.8 Nm

Bolt (17 mm)88.2 to 107.8 Nm

2 Bracket mounting

bolts (17 mm)88.2 to 107.8 Nm

Bolt (14 mm) /

Nut (14 mm)68.6 to 88.2 Nm

3 Bolts (14 mm)29.4 to 49.0 Nm

Front sub frame - based on 4WD

Page 1165 of 1336

4012-00

8. Other connections for rear sub frame (LH &

RH)7. Rear axle mounting

5. Front mounting (LH & RH)

Bolt (17 mm)88.2 to 107.8 Nm

6. Rear mounting (LH & RH)

Bolt (17 mm)88.2 to 107.8 Nm

Rear mounting

bolt (14 mm)68.6 to 88.2 Nm

Upper arm bolt

(17 mm) / Nut (19

mm)98.0 to 117.6 Nm

Lower arm nut/Bolt

(19 mm)98.0 to 117.6 Nm

Rear sub frame - based on 4WD

Rear mounting

bolt (17 mm)107.8 to 127.4 Nm

Page 1166 of 1336

Installation Sectional diagram

1. Front

2. Rear

Mounting bracket Mounting bolt

3. Transaxle mounting (Front)

For manual transaxle For automatic transaxle

(diesel)

4. Transaxle mounting (Rear)

1) Sectional Diagram and Bolts for Front Sub Frame

Mounting nut

29.4 to 39.2 Nm

Bolt9.4 to 39.2 Nm

Page 1167 of 1336

4012-00

2) Sectional Diagram and Bolts for Rear Sub Frame

Installation Sectional structure

1. Front

4WD 2WD

2. Rear

4WD 2WD

3. Rear axle - Front

(4WD)

4. Rear axle - rear

(4WD)

Page 1168 of 1336

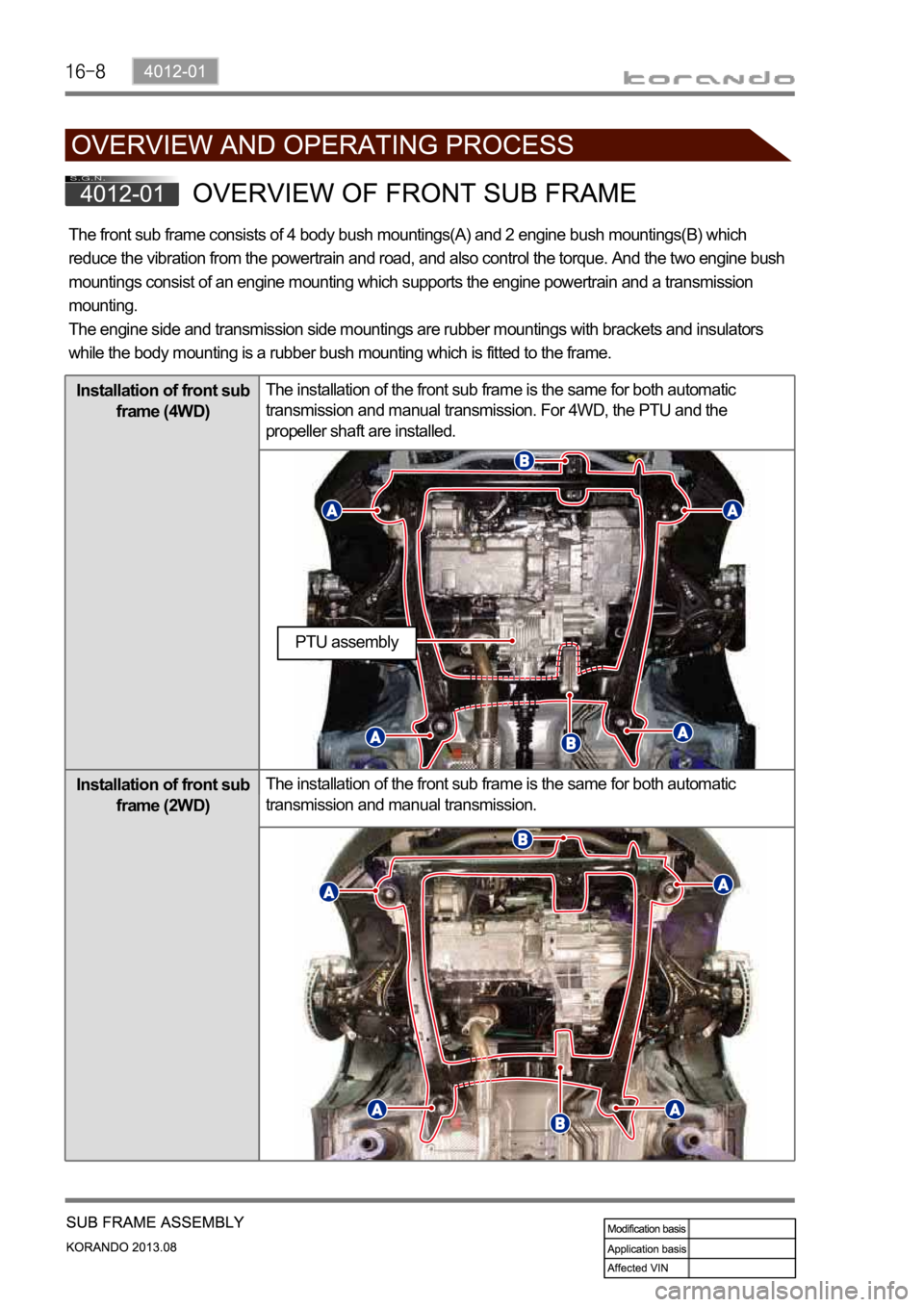

The front sub frame consists of 4 body bush mountings(A) and 2 engine bush mountings(B) which

reduce the vibration from the powertrain and road, and also control the torque. And the two engine bush

mountings consist of an engine mounting which supports the engine powertrain and a transmission

mounting.

The engine side and transmission side mountings are rubber mountings with brackets and insulators

while the body mounting is a rubber bush mounting which is fitted to the frame.

Installation of front sub

frame (4WD)The installation of the front sub frame is the same for both automatic

transmission and manual transmission. For 4WD, the PTU and the

propeller shaft are installed.

Installation of front sub

frame (2WD)The installation of the front sub frame is the same for both automatic

transmission and manual transmission.

PTU assembly

Page 1169 of 1336

4015-01

Installation of rear sub

frame (4WD)The installation of the rear sub frame is the same for both automatic

transmission and manual transmission. For 4WD, the E-coupling, propeller

shaft and rear axle are installed.

Installation of rear sub

frame (2WD) The installation of the rear sub frame is the same for both automatic

transmission and manual transmission.

The rear sub frame system consists of body bush mountings and direct mountings which reduce the

vibration transmitted from the powertrain and road to the vehicle body.

For 4WD, it consists of 4 body mountings (bush mountings) and 2 axle mountings (bush mountings) and

for 2WD, it consists of 4 body mountings (direct mountings).

Page 1170 of 1336

4190-00

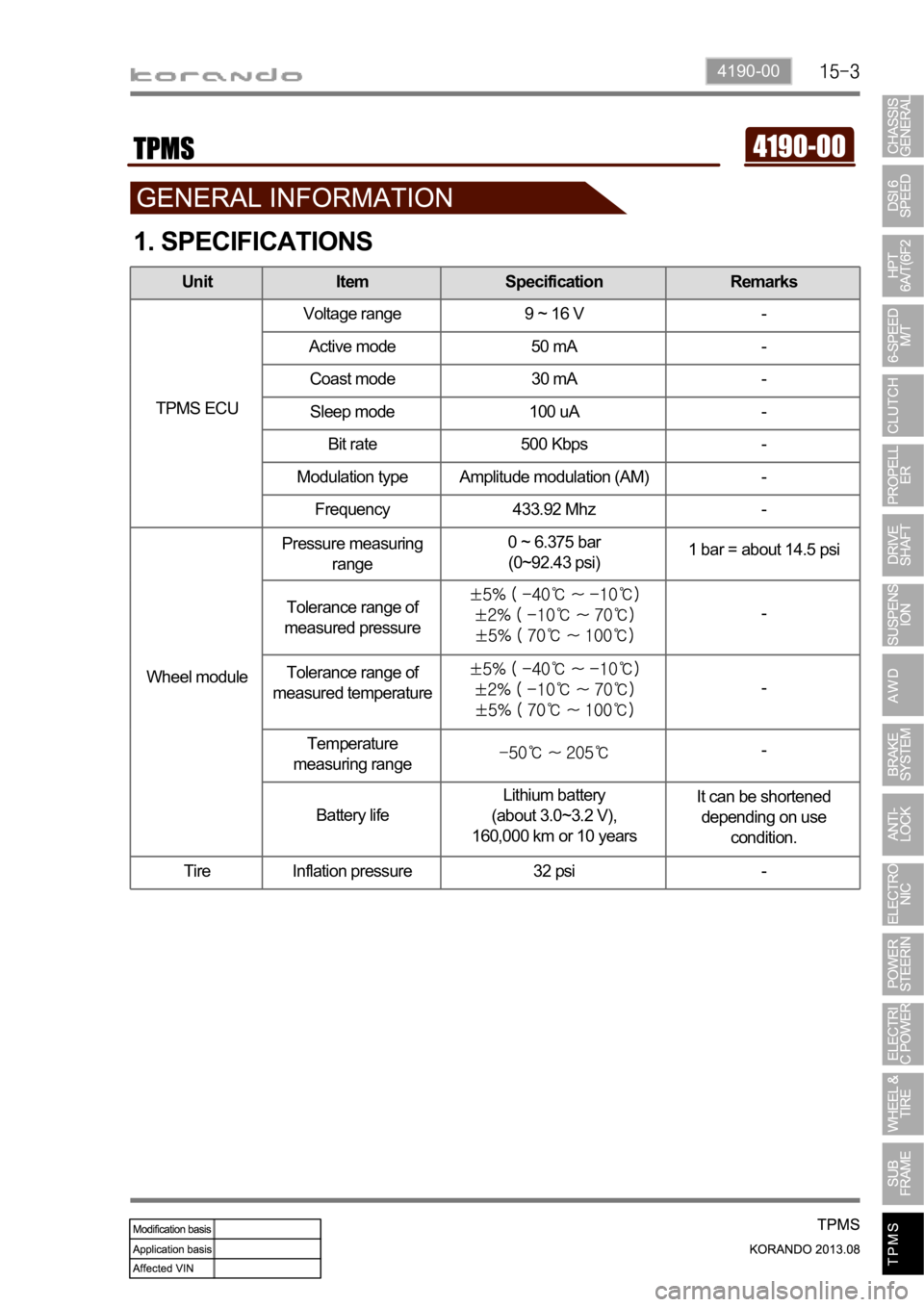

1. SPECIFICATIONS

Unit Item Specification Remarks

TPMS ECUVoltage range 9 ~ 16 V -

Active mode 50 mA -

Coast mode 30 mA -

Sleep mode 100 uA -

Bit rate 500 Kbps -

Modulation type Amplitude modulation (AM) -

Frequency 433.92 Mhz -

Wheel modulePressure measuring

range0 ~ 6.375 bar

(0~92.43 psi)1 bar = about 14.5 psi

Tolerance range of

measured pressure

-

Tolerance range of

measured temperature

-

Temperature

measuring range

-

Battery lifeLithium battery

(about 3.0~3.2 V),

160,000 km or 10 yearsIt can be shortened

depending on use

condition.

Tire Inflation pressure 32 psi -

Trending: height adjustment, diagram, child restraint, spare tire, remove seats, fuse box location, oil dipstick