lamp SSANGYONG KORANDO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 313 of 1336

0000-00

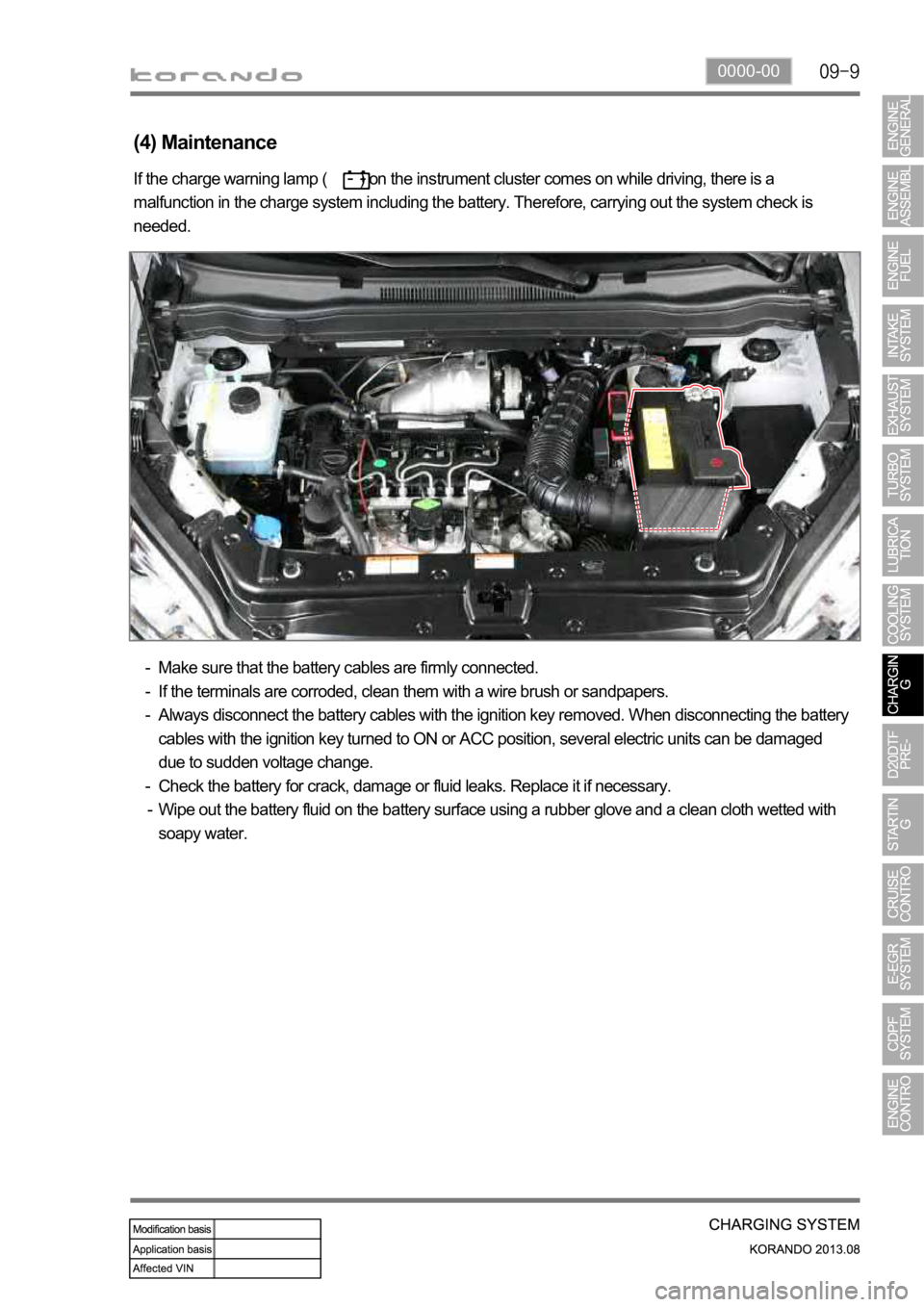

(4) Maintenance

Make sure that the battery cables are firmly connected.

If the terminals are corroded, clean them with a wire brush or sandpapers.

Always disconnect the battery cables with the ignition key removed. When disconnecting the battery

cables with the ignition key turned to ON or ACC position, several electric units can be damaged

due to sudden voltage change.

Check the battery for crack, damage or fluid leaks. Replace it if necessary.

Wipe out the battery fluid on the battery surface using a rubber glove and a clean cloth wetted with

soapy water. -

-

-

-

-

If the charge warning lamp ( ) on the instrument cluster comes on while driving, there is a

malfunction in the charge system including the battery. Therefore, carrying out the system check is

needed.

Page 360 of 1336

2. CAUTIONS

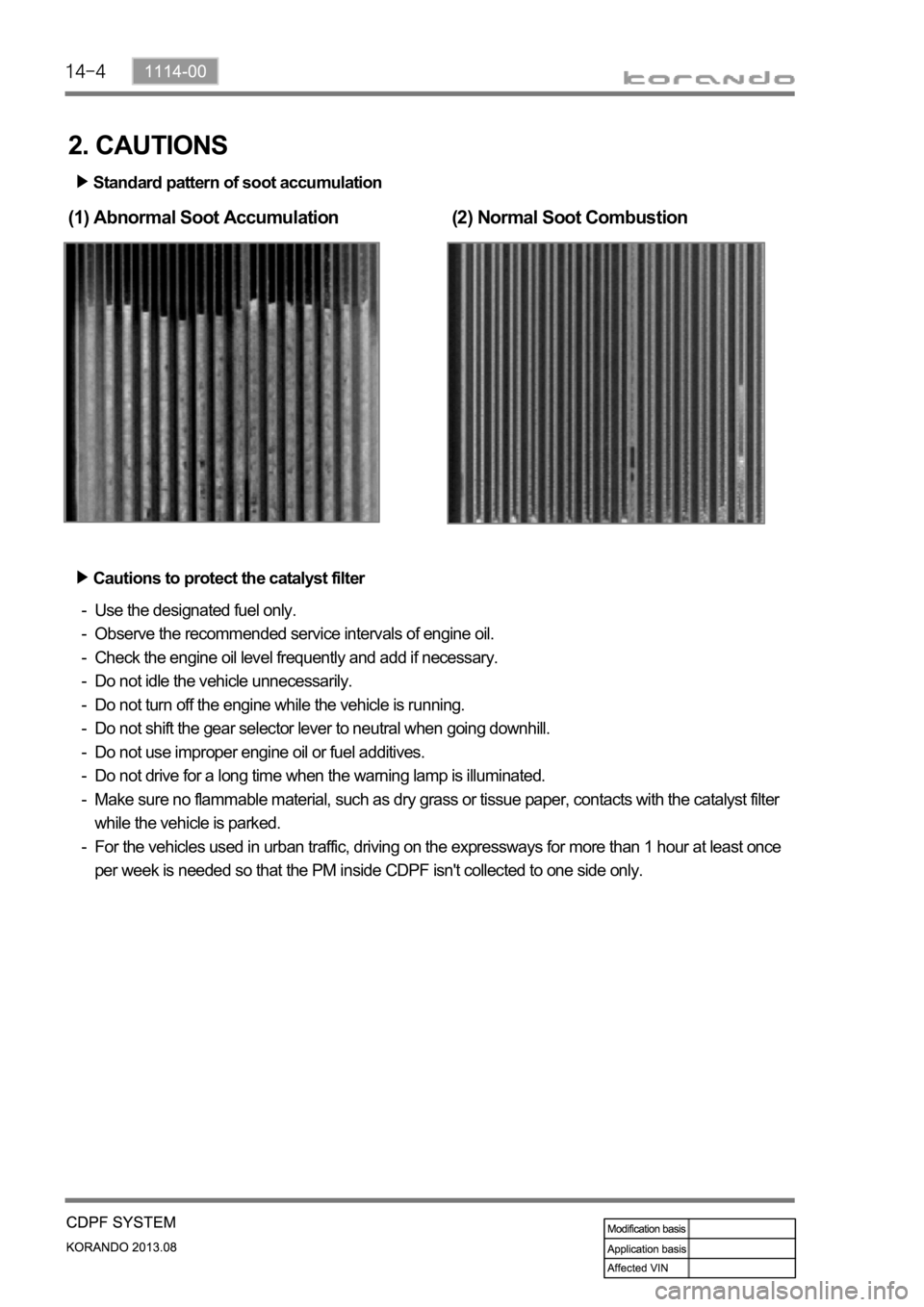

Standard pattern of soot accumulation

(1) Abnormal Soot Accumulation(2) Normal Soot Combustion

Cautions to protect the catalyst filter

Use the designated fuel only.

Observe the recommended service intervals of engine oil.

Check the engine oil level frequently and add if necessary.

Do not idle the vehicle unnecessarily.

Do not turn off the engine while the vehicle is running.

Do not shift the gear selector lever to neutral when going downhill.

Do not use improper engine oil or fuel additives.

Do not drive for a long time when the warning lamp is illuminated.

Make sure no flammable material, such as dry grass or tissue paper, contacts with the catalyst filter

while the vehicle is parked.

For the vehicles used in urban traffic, driving on the expressways for more than 1 hour at least once

per week is needed so that the PM inside CDPF isn't collected to one side only. -

-

-

-

-

-

-

-

-

-

Page 361 of 1336

1114-00

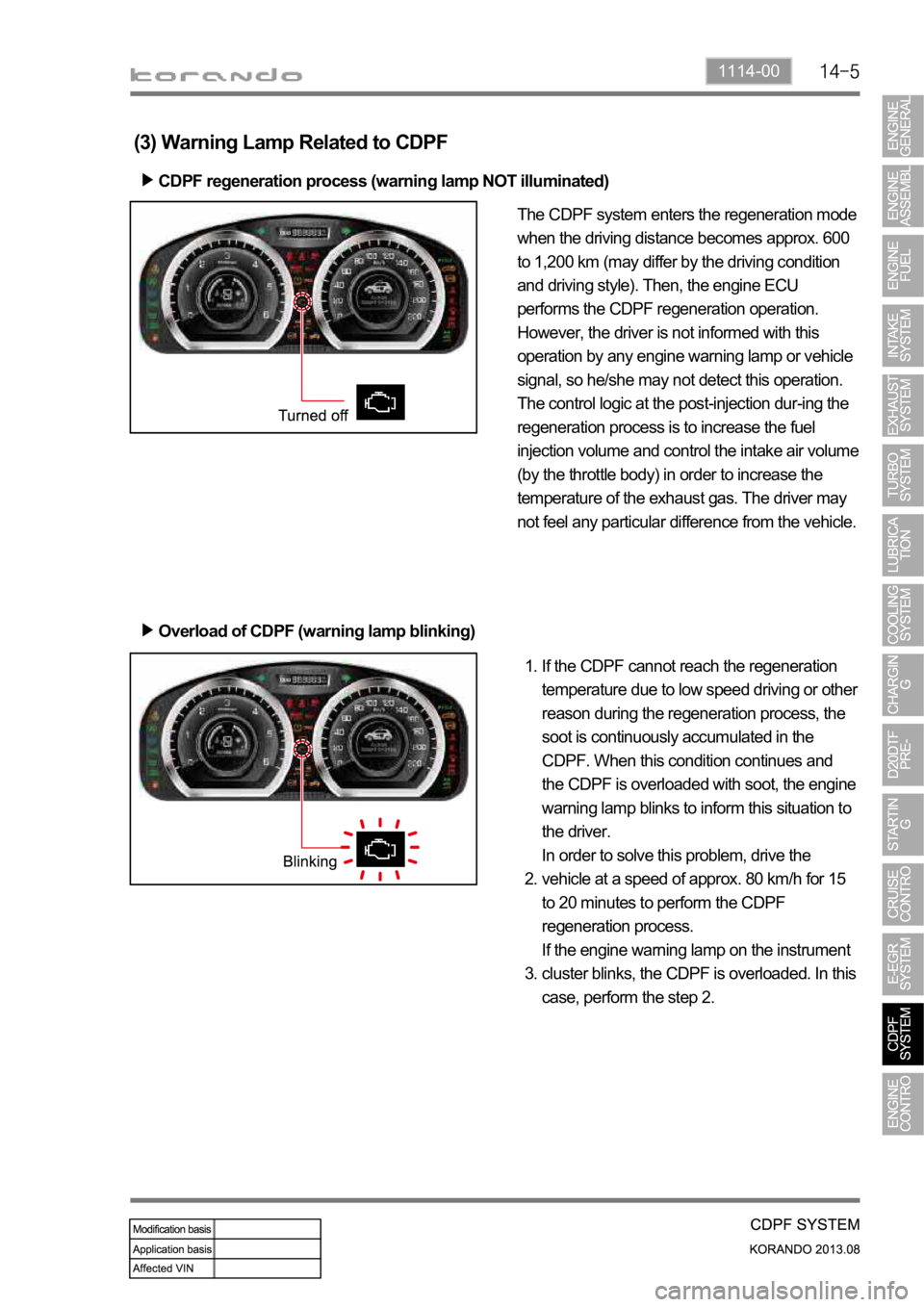

(3) Warning Lamp Related to CDPF

CDPF regeneration process (warning lamp NOT illuminated)

Overload of CDPF (warning lamp blinking)

The CDPF system enters the regeneration mode

when the driving distance becomes approx. 600

to 1,200 km (may differ by the driving condition

and driving style). Then, the engine ECU

performs the CDPF regeneration operation.

However, the driver is not informed with this

operation by any engine warning lamp or vehicle

signal, so he/she may not detect this operation.

The control logic at the post-injection dur-ing the

regeneration process is to increase the fuel

injection volume and control the intake air volume

(by the throttle body) in order to increase the

temperature of the exhaust gas. The driver may

not feel any particular difference from the vehicle.

If the CDPF cannot reach the regeneration

temperature due to low speed driving or other

reason during the regeneration process, the

soot is continuously accumulated in the

CDPF. When this condition continues and

the CDPF is overloaded with soot, the engine

warning lamp blinks to inform this situation to

the driver.

In order to solve this problem, drive the

vehicle at a speed of approx. 80 km/h for 15

to 20 minutes to perform the CDPF

regeneration process.

If the engine warning lamp on the instrument

cluster blinks, the CDPF is overloaded. In this

case, perform the step 2. 1.

2.

3.

Page 362 of 1336

Excessive overload of CDPF (warning lamp illuminated)

If the vehicle is driven at a speed of 5 to 10

km/h for an extended period of time, the soot

accumulated in the CDPF cannot be burned

as the CDPF cannot reach the regeneration

temperature. Then, an excessive amount of

soot can be accumulated in the CDPF.

This case is much worse than the simple over-

load of the CDPF. To inform this to the driver,

the engine warning lamp comes on and the

engine power is decreased to protect the

system.

To solve this problem, blow soot between the

engine and exhaust system several times and

erase the related DTC. Then, check if the

same DTC is regenerated again. If so, check

the DTC related to the differential pressure

sensor. 1.

2.

3.

Page 427 of 1336

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 438 of 1336

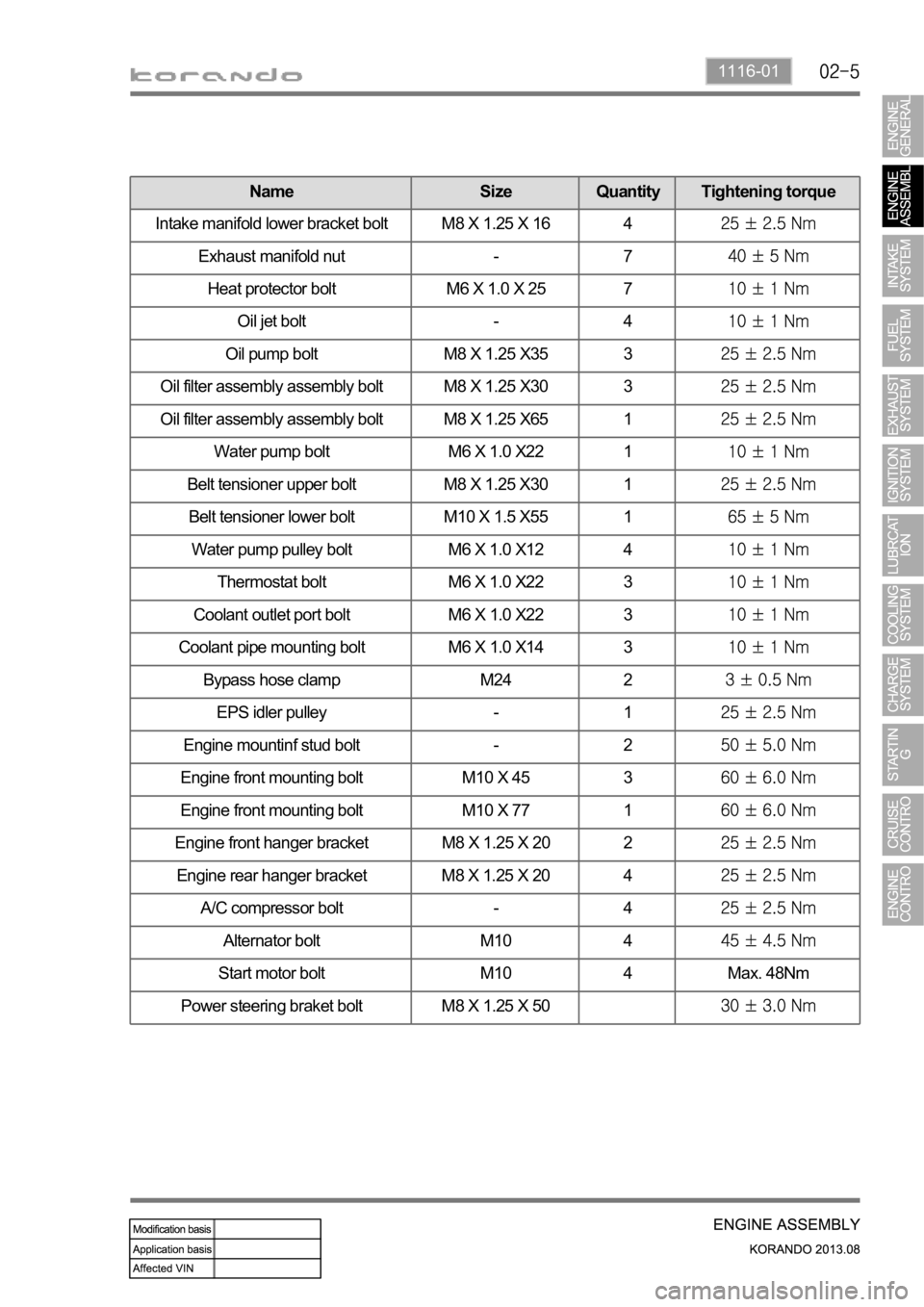

1116-01

Name Size Quantity Tightening torque

Intake manifold lower bracket bolt M8 X 1.25 X 16 4

Exhaust manifold nut - 7

Heat protector bolt M6 X 1.0 X 25 7

Oil jet bolt - 4

Oil pump bolt M8 X 1.25 X35 3

Oil filter assembly assembly bolt M8 X 1.25 X30 3

Oil filter assembly assembly bolt M8 X 1.25 X65 1

Water pump bolt M6 X 1.0 X22 1

Belt tensioner upper bolt M8 X 1.25 X30 1

Belt tensioner lower bolt M10 X 1.5 X55 1

Water pump pulley bolt M6 X 1.0 X12 4

Thermostat bolt M6 X 1.0 X22 3

Coolant outlet port bolt M6 X 1.0 X22 3

Coolant pipe mounting bolt M6 X 1.0 X14 3

Bypass hose clamp M24 2

EPS idler pulley - 1

Engine mountinf stud bolt - 2

Engine front mounting bolt M10 X 45 3

Engine front mounting bolt M10 X 77 1

Engine front hanger bracket M8 X 1.25 X 20 2

Engine rear hanger bracket M8 X 1.25 X 20 4

A/C compressor bolt - 4

Alternator bolt M10 4

Start motor bolt M10 4 Max. 48Nm

Power steering braket bolt M8 X 1.25 X 50

Page 454 of 1336

1311-01

The drive chain is single chain drive system with simple design and variable performance, and it utilizes

the hydraulic tensioner to reduce the wave impact generated by the chain. The silent chain provides the

silence during the operation. To improve NVH, the shoulder bolt has been introduced. Overview

Layout and Components

Hydraulic tensioner

Consists of tensioner housing

plug, spring, check valve, and

operated by hydraulic

pressure and spring in

tensioner

Timing chain

Chain type: Silent chain type

Links: 146 ea

Tensioner rail

Installed between exjaust

camshaft sprocket and

crankshaft sprocket

Crankshaft sprocket

Teeth: 21 ea

Oil pump sprocket

Teeth: 28 ea

Exhaust camshaft

sprocket

Teeth:42 eaIntake camshaft

sprocket

CVVT

Teeth: 42 ea

OCV

Controls the hydraulic circuit

to control the intake cam

sprocket variably

Clamping rail

Installed between intake

camshaft sprocket and

crankshaft sprocket

Mechanical tensioner

Operated by spring in

tensioner

Oil pump chain

Chain type: Silent chain type

Links: 58 ea

Page 459 of 1336

Clamping rail

Installed between intake

camshaft sprocket and

crankshaft sprocket

5) Chain Rails

The chain rails are used for optimizing the movement of chain drive system. And they also prevent the

chain from contacting each other when the chain is loose, and reduces the chain wear. The chain rail is

normally made of PA (Polyamide nylon), and PA66 and PA46 are used for the chain rails in G20DF

engine. For the tensioner rail, PA46 is used to provide high anti-wear function and high strength since

the load to the rail is huge. Ther is an open area for shoulder bolt hole in the clamping rail. The chain

rails are installed by shoulder bolts.

Tensioner rail

Installed between

exhaust camshaft

sprocket and crankshaft

sprocket

Page 474 of 1336

0000-00

Air Cleaner Assy

Element Assy

Air Cleaner MTG NO.2

Insulator Collar

Spring Clamp

Resonance Duct

Resonance O-Ring

Air Cleaner MTG NO.1

Air Cleaner MTG Bolt 1.

3.

5.

6.

7.

8.

9.

10.

11.Snorkel Assy

Water Portector

Resonator Assy

RR Fascia MTG Screw Rivet

Bolt

Nut

Screw

Air Cleaner to Engine Hose Assy 12.

13.

14.

17.

18.

19.

20.

21.

Page 481 of 1336

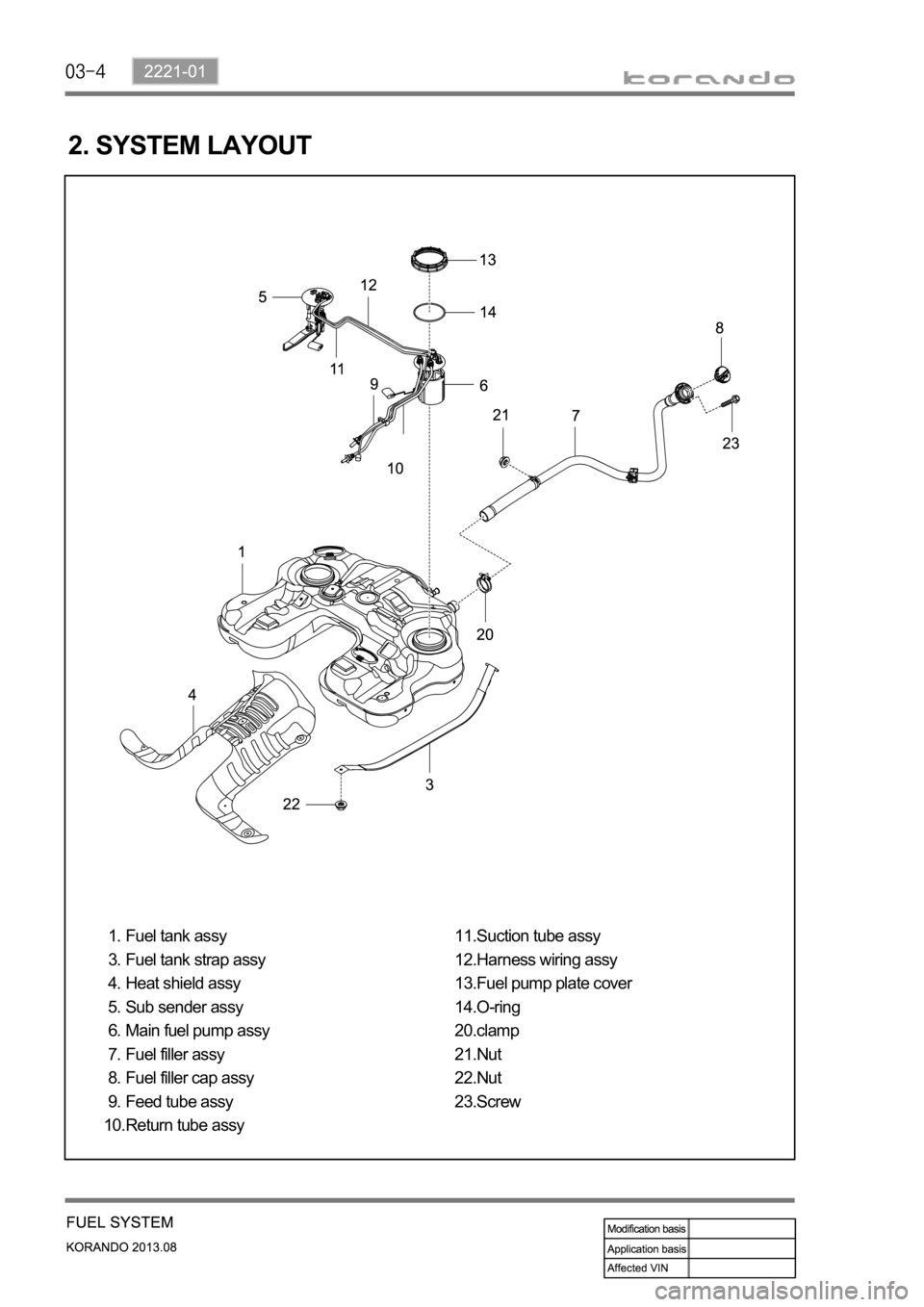

2. SYSTEM LAYOUT

Fuel tank assy

Fuel tank strap assy

Heat shield assy

Sub sender assy

Main fuel pump assy

Fuel filler assy

Fuel filler cap assy

Feed tube assy

Return tube assy 1.

3.

4.

5.

6.

7.

8.

9.

10.Suction tube assy

Harness wiring assy

Fuel pump plate cover

O-ring

clamp

Nut

Nut

Screw 11.

12.

13.

14.

20.

21.

22.

23.