torque SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 188 of 1336

0000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners with the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15) Remove the engine and transaxle as a set.

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Page 190 of 1336

0000-00

5) Guidelines on Engine Service

(1) Cautions before service works

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

Make sure to clean the working area and to prepare the necessary tools before service works.

Always place the ignition switch to OFF position if not required. Otherwise, there could be

unexpected damage to electric devices or personal injuries due to short-circuit.

To prevent the foreign material from entering into the fuel injection system, completely seal the inlets

of HP pump, fuel hoses and high pressure pipes.

To remoev the engine, use the dedicated equipments such as engine jack, transmission jack, engine

stand and engine crane. -

-

-

-

-

(2) Engine and accessories

When disassembling the engine, related parts (bolts, gaskets, etc.) should be stored as a set.

Clean the components completely with engine oil before assembling if needed.

Fully drain the engine oil, coolant and fuel from the vehicle and seal the inlets with the plugs before

removing the engine.

All the interference should be eliminated before removing the engine. -

-

-

-

(3) Electric devices

To prevent any damage to electric systems, make sure to disconnect the negative (-) cable from the

battery and place the ignition switch to OFF position before servicing.

Use only the specified parts with same ratings when replacing the electric devices. Check the

grounds and connections for looseness. -

- To prevent the personal injuries and vehicle damages that can be caused by mistakes during service

and to provide the optimized performance and safety after service works, the service technicials must

keep the basic cautions and service guidelines below. These could be easily forgotten during service

works.

Engine has a lot of precise components. The specified tightening torque and correct procedures should

be kept during service works. And, the working area is always clean and well prepared.

Extraordinary care should be taken when servicing the electric systems. Currently, the engine uses a lot

of electric devices. Short circuit and poor contact may cause the low engine performance, incomplete

combustion and other abnormalities.

Page 193 of 1336

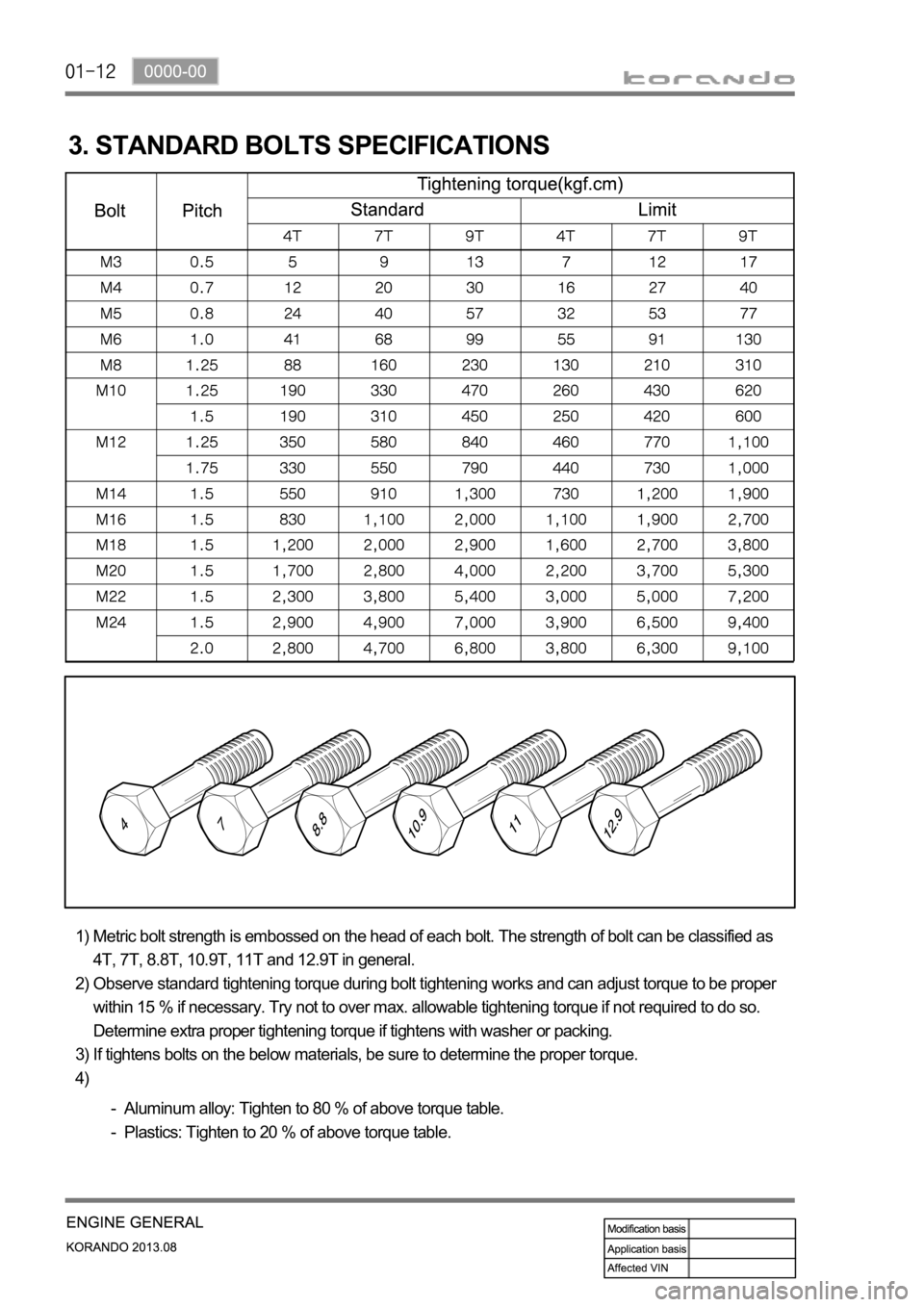

3. STANDARD BOLTS SPECIFICATIONS

Metric bolt strength is embossed on the head of each bolt. The strength of bolt can be classified as

4T, 7T, 8.8T, 10.9T, 11T and 12.9T in general.

Observe standard tightening torque during bolt tightening works and can adjust torque to be proper

within 15 % if necessary. Try not to over max. allowable tightening torque if not required to do so.

Determine extra proper tightening torque if tightens with washer or packing.

If tightens bolts on the below materials, be sure to determine the proper torque. 1)

2)

3)

4)

Aluminum alloy: Tighten to 80 % of above torque table.

Plastics: Tighten to 20 % of above torque table. -

-

Page 200 of 1336

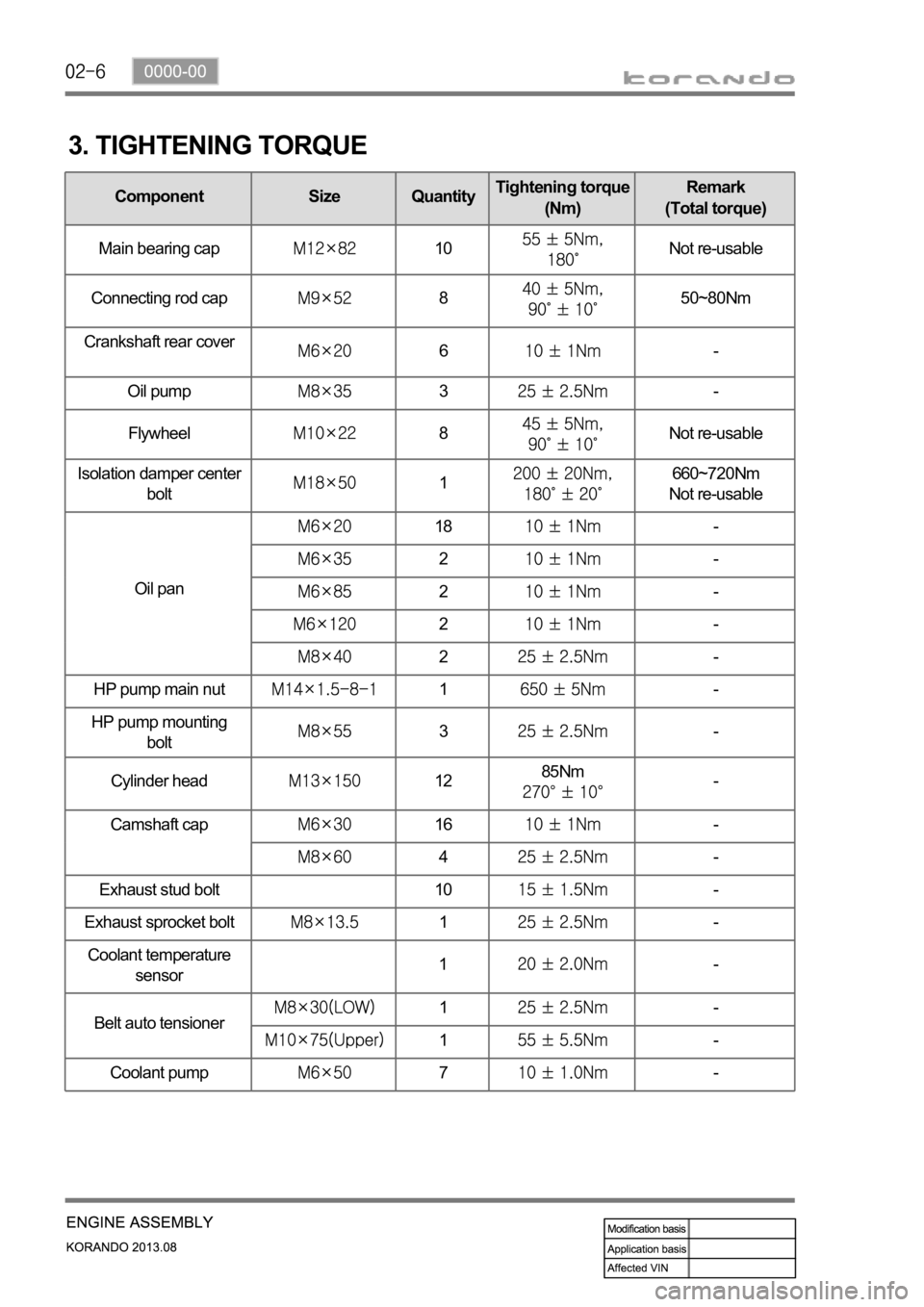

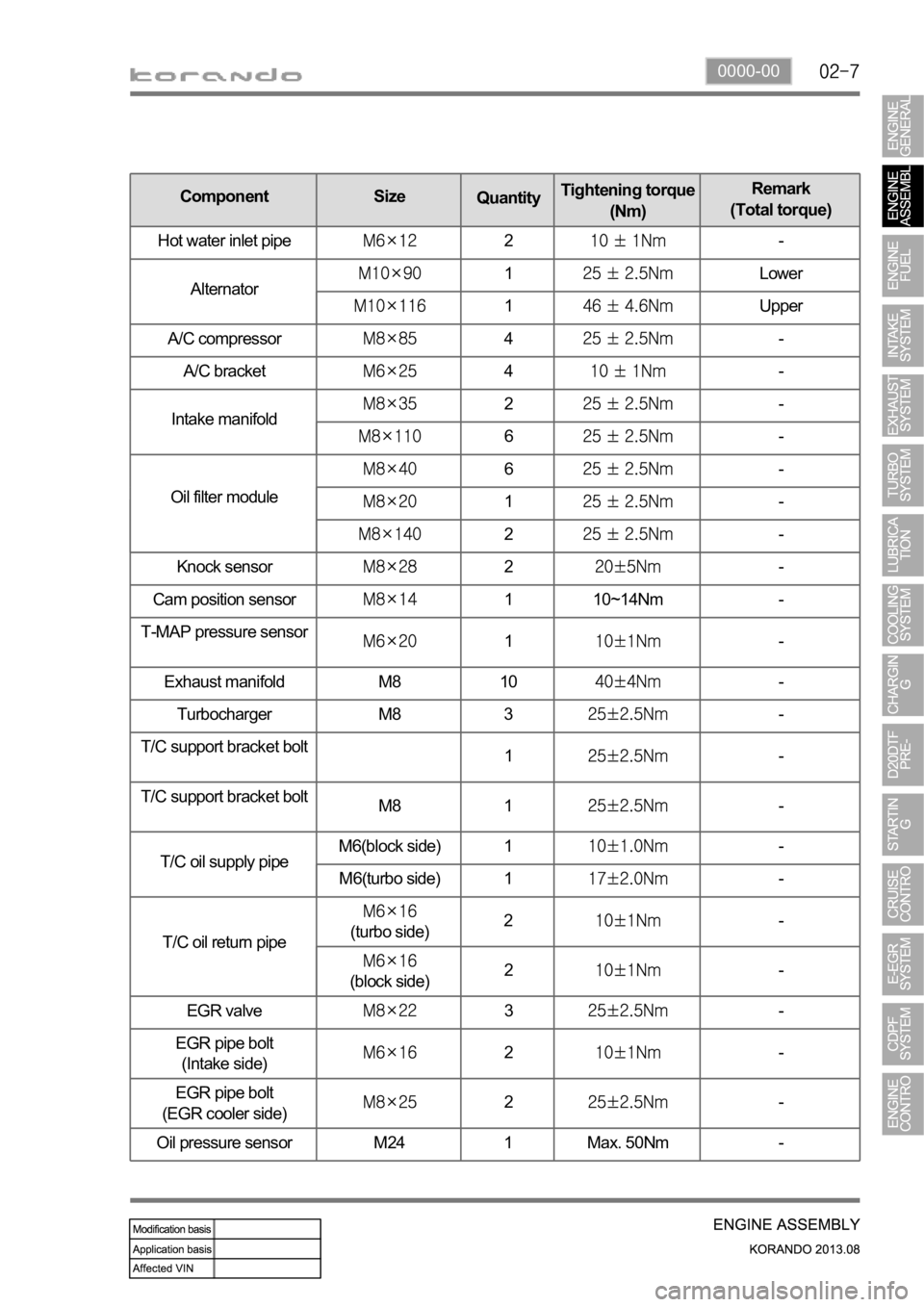

3. TIGHTENING TORQUE

Component Size QuantityTightening torque

(Nm)Remark

(Total torque)

Main bearing cap

10Not re-usable

Connecting rod cap

850~80Nm

Crankshaft rear cover

6-

Oil pump

3-

Flywheel

8Not re-usable

Isolation damper center

bolt

1660~720Nm

Not re-usable

Oil pan

18-

2-

2-

2-

2-

HP pump main nut

1-

HP pump mounting

bolt

3-

Cylinder head

1285Nm-

Camshaft cap

16-

4-

Exhaust stud bolt 10

-

Exhaust sprocket bolt

1-

Coolant temperature

sensor1-

Belt auto tensioner

1-

1-

Coolant pump

7-

Page 201 of 1336

0000-00

Knock sensor2-

Cam position sensor

1 10~14Nm -

T-MAP pressure sensor

1-

Exhaust manifold M8 10

-

Turbocharger M8 3

-

T/C support bracket bolt

1

-

T/C support bracket bolt

M8 1

-

T/C oil supply pipeM6(block side) 1

-

M6(turbo side) 1

-

T/C oil return pipe

(turbo side)2-

(block side)2-

EGR valve

3-

EGR pipe bolt

(Intake side)

2-

EGR pipe bolt

(EGR cooler side)

2-

Oil pressure sensor M24 1 Max. 50Nm -

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Hot water inlet pipe

2-

Alternator

1Lower

1Upper

A/C compressor

4-

A/C bracket

4-

Intake manifold

2-

6-

Oil filter module

6-

1-

2-

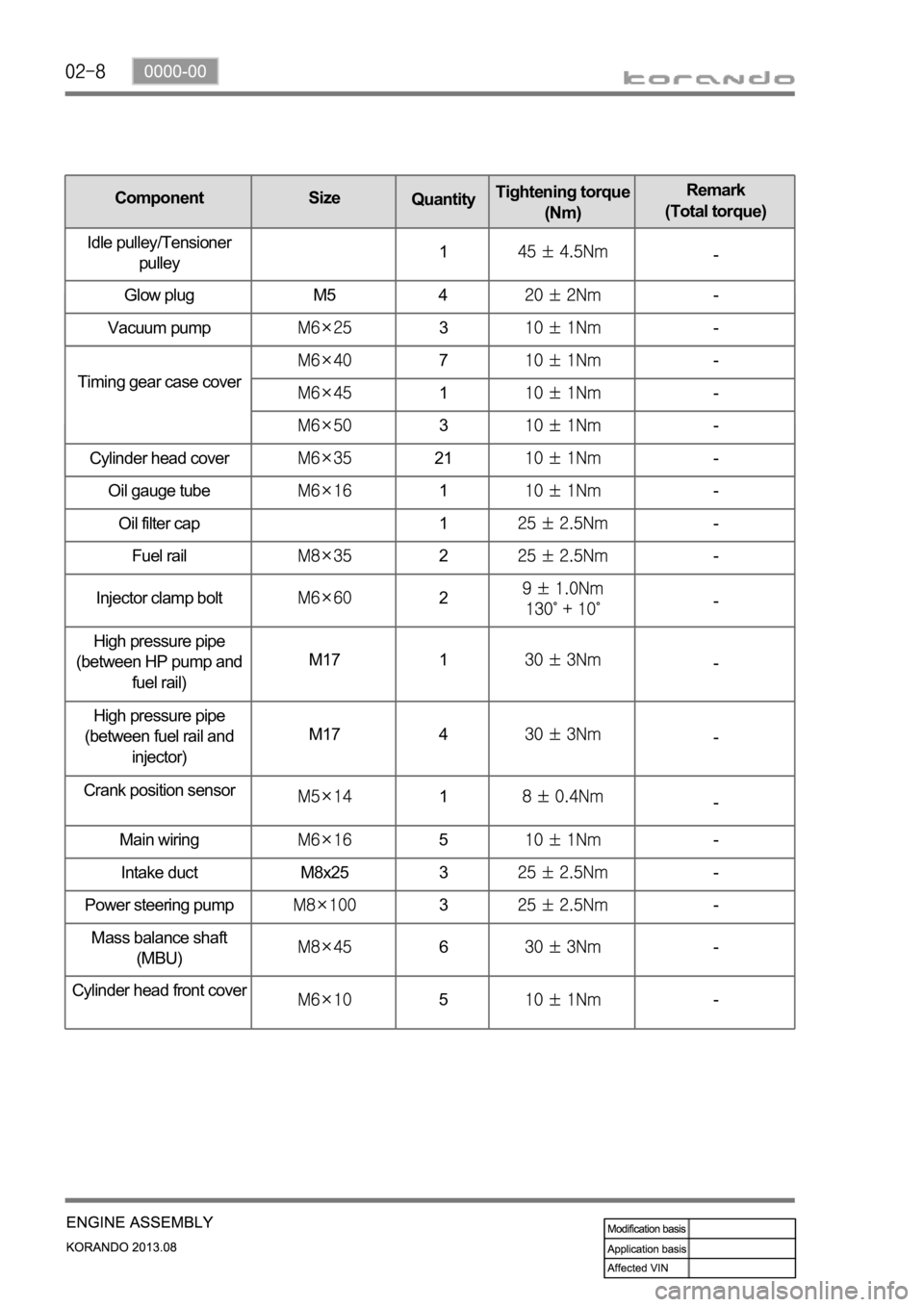

Page 202 of 1336

Oil gauge tube1-

Oil filter cap 1

-

Fuel rail

2-

Injector clamp bolt

2-

High pressure pipe

(between HP pump and

fuel rail)M17 1

-

High pressure pipe

(between fuel rail and

injector)M17 4

-

Crank position sensor

1-

Main wiring

5-

Intake duct M8x25 3

-

Power steering pump

3-

Mass balance shaft

(MBU)

6-

Cylinder head front cove

r5-

Timing gear case cover

7-

1-

3-

Cylinder head cover

21-

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Idle pulley/Tensioner

pulley1

-

Glow plug M5 4

-

Vacuum pump

3-

Page 210 of 1336

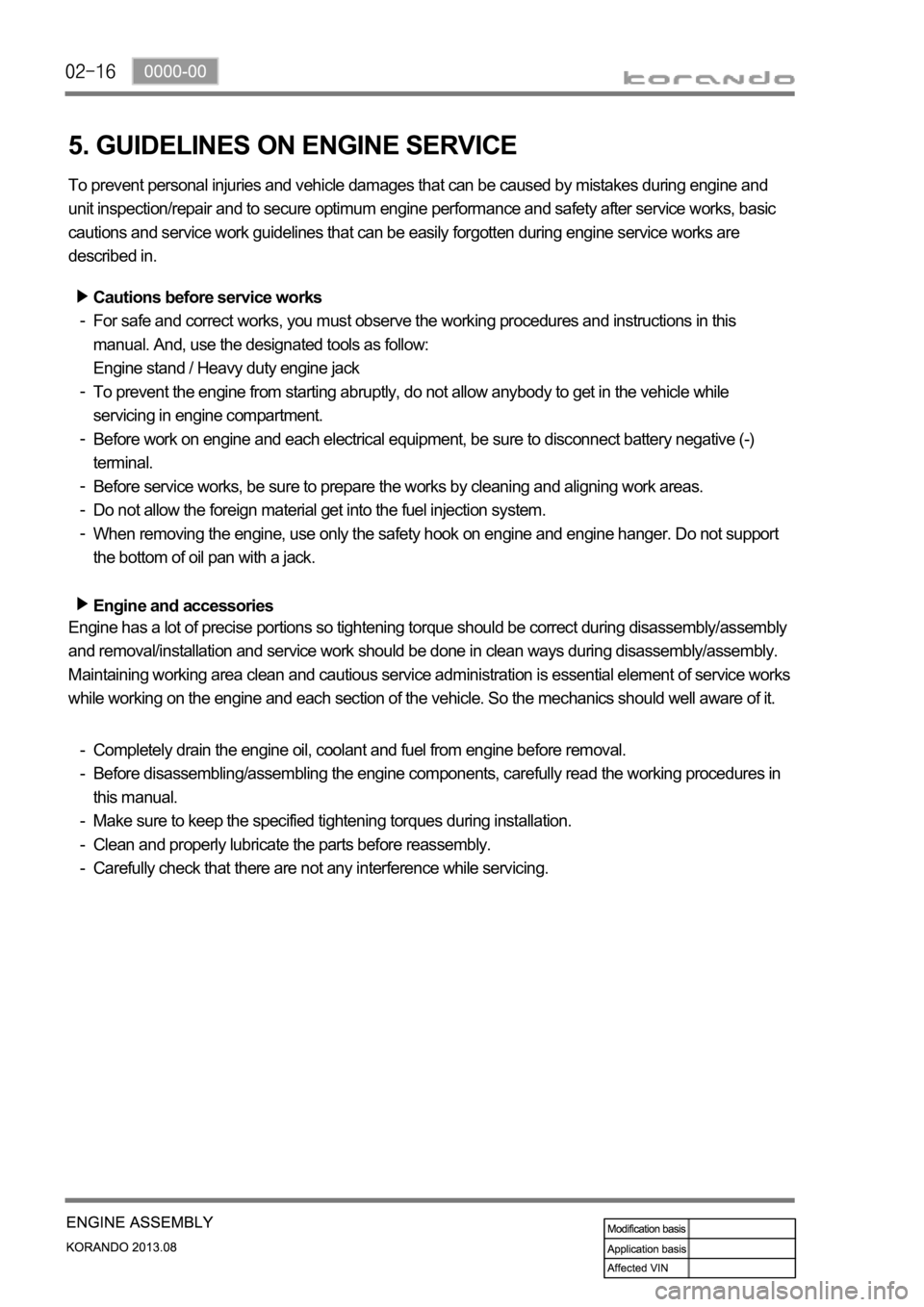

5. GUIDELINES ON ENGINE SERVICE

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and

unit inspection/repair and to secure optimum engine performance and safety after service works, basic

cautions and service work guidelines that can be easily forgotten during engine service works are

described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not support

the bottom of oil pan with a jack.

Engine and accessories

-

-

-

-

-

-

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working procedures in

this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there are not any interference while servicing. -

-

-

-

- Engine has a lot of precise portions so tightening torque should be correct during disassembly/assembly

and removal/installation and service work should be done in clean ways during disassembly/assembly.

Maintaining working area clean and cautious service administration is essential element of service works

while working on the engine and each section of the vehicle. So the mechanics should well aware of it.

Page 214 of 1336

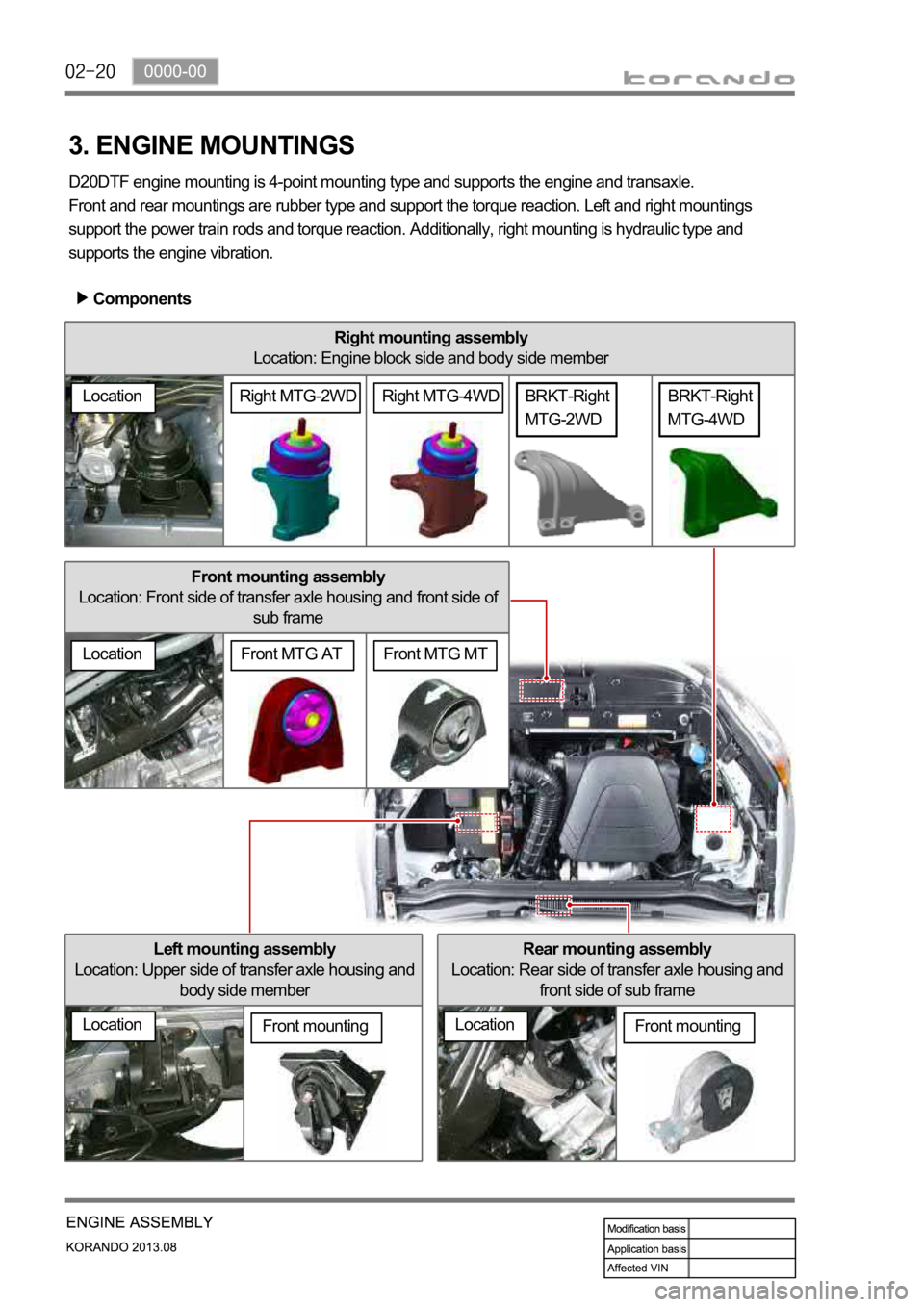

Front mounting assembly

Location: Front side of transfer axle housing and front side of

sub frame

Right mounting assembly

Location: Engine block side and body side member

Rear mounting assembly

Location: Rear side of transfer axle housing and

front side of sub frame

3. ENGINE MOUNTINGS

D20DTF engine mounting is 4-point mounting type and supports the engine and transaxle.

Front and rear mountings are rubber type and support the torque reaction. Left and right mountings

support the power train rods and torque reaction. Additionally, right mounting is hydraulic type and

supports the engine vibration.

Components

Left mounting assembly

Location: Upper side of transfer axle housing and

body side member

LocationFront mounting

Location

BRKT-Right

MTG-4WD

LocationFront mounting

BRKT-Right

MTG-2WD

Front MTG MTFront MTG AT

LocationRight MTG-4WDRight MTG-2WD

Page 225 of 1336

0000-00

10. FLYWHEEL AND DRIVE PLATE

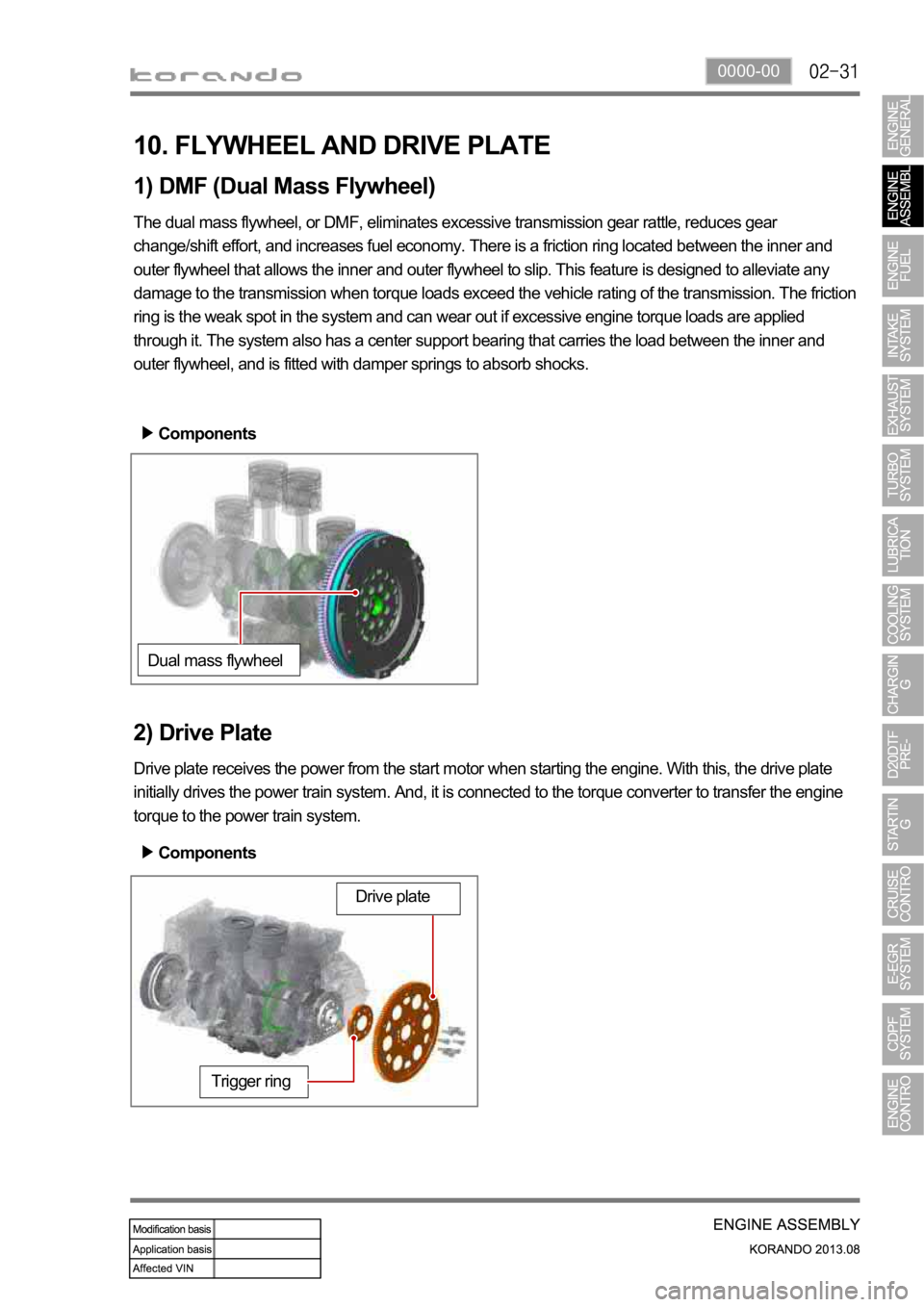

1) DMF (Dual Mass Flywheel)

The dual mass flywheel, or DMF, eliminates excessive transmission gear rattle, reduces gear

change/shift effort, and increases fuel economy. There is a friction ring located between the inner and

outer flywheel that allows the inner and outer flywheel to slip. This feature is designed to alleviate any

damage to the transmission when torque loads exceed the vehicle rating of the transmission. The friction

ring is the weak spot in the system and can wear out if excessive engine torque loads are applied

through it. The system also has a center support bearing that carries the load between the inner and

outer flywheel, and is fitted with damper springs to absorb shocks.

2) Drive Plate

Drive plate receives the power from the start motor when starting the engine. With this, the drive plate

initially drives the power train system. And, it is connected to the torque converter to transfer the engine

torque to the power train system.Components

Dual mass flywheel

Trigger ring

Drive plate

Components

Page 230 of 1336

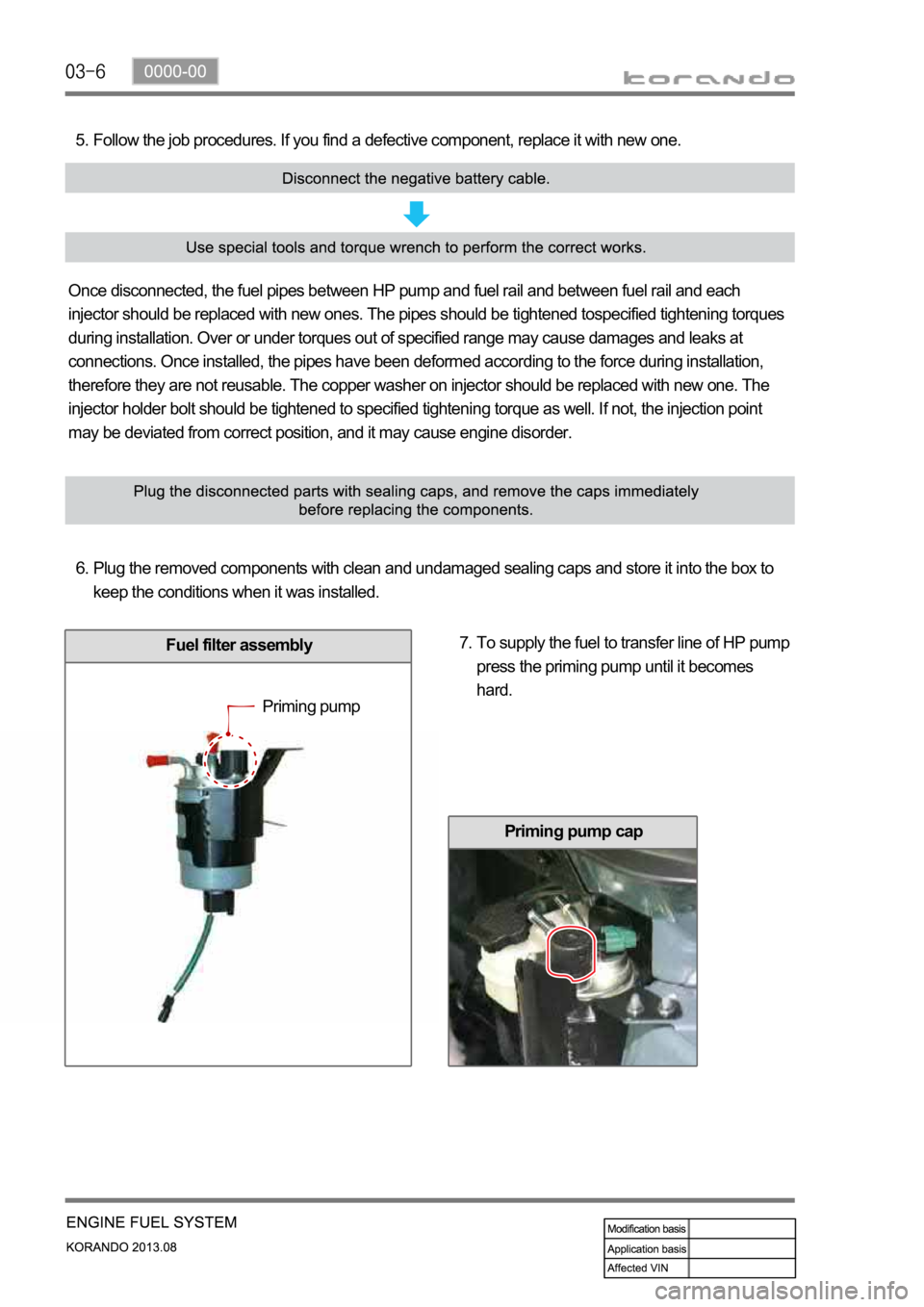

Fuel filter assembly

Follow the job procedures. If you find a defective component, replace it with new one. 5.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each

injector should be replaced with new ones. The pipes should be tightened tospecified tightening torques

during installation. Over or under torques out of specified range may cause damages and leaks at

connections. Once installed, the pipes have been deformed according to the force during installation,

therefore they are not reusable. The copper washer on injector should be replaced with new one. The

injector holder bolt should be tightened to specified tightening torque as well. If not, the injection point

may be deviated from correct position, and it may cause engine disorder.

Plug the removed components with clean and undamaged sealing caps and store it into the box to

keep the conditions when it was installed. 6.

To supply the fuel to transfer line of HP pump

press the priming pump until it becomes

hard. 7.

Priming pump

Priming pump cap