ESP SSANGYONG KORANDO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 395 of 1336

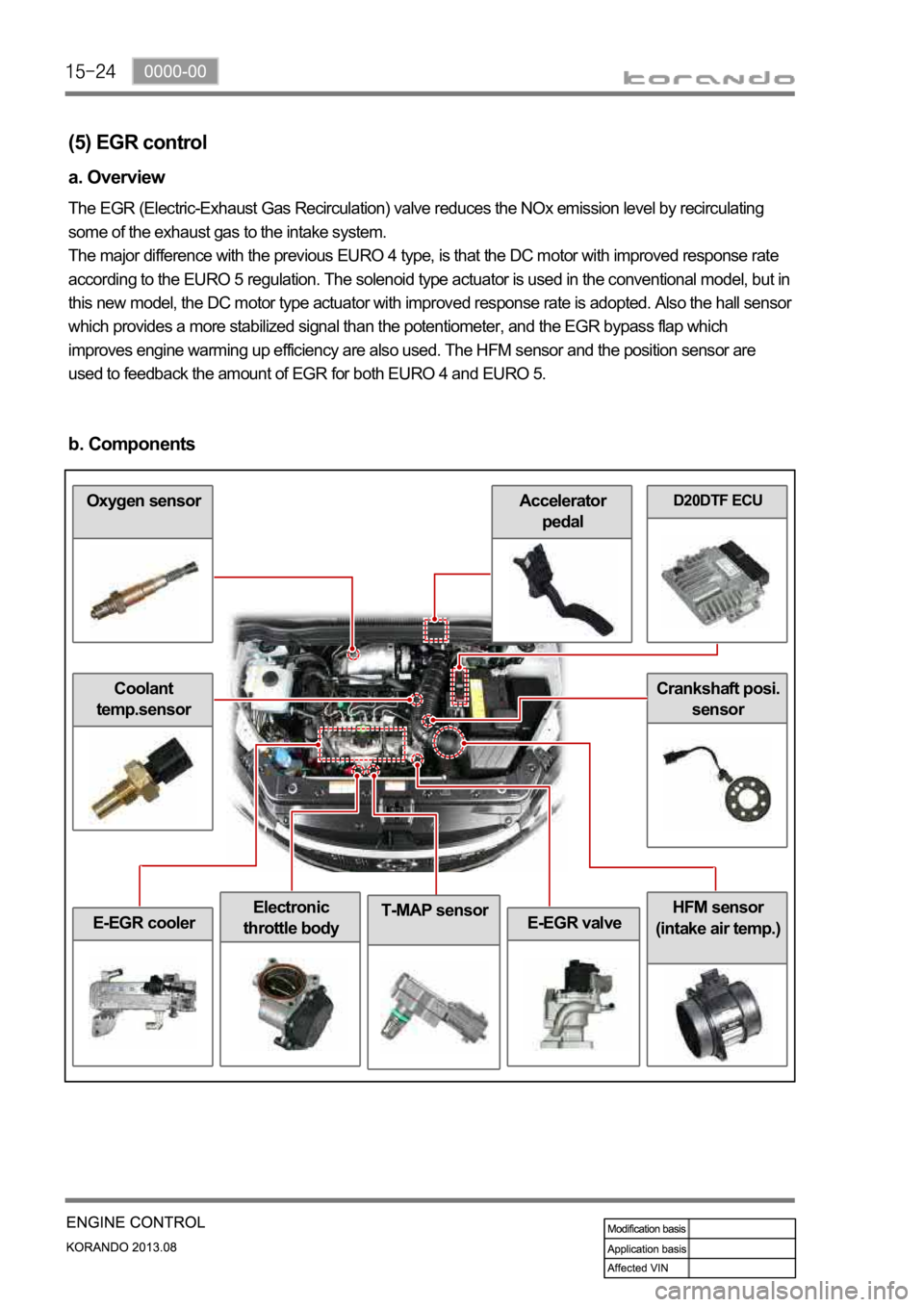

T-MAP sensor

D20DTF ECUOxygen sensor

Electronic

throttle bodyHFM sensor

(intake air temp.)

Coolant

temp.sensor

E-EGR valve

Crankshaft posi.

sensor

Accelerator

pedal

E-EGR cooler

(5) EGR control

a. Overview

The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating

some of the exhaust gas to the intake system.

The major difference with the previous EURO 4 type, is that the DC motor with improved response rate

according to the EURO 5 regulation. The solenoid type actuator is used in the conventional model, but in

this new model, the DC motor type actuator with improved response rate is adopted. Also the hall senso

r

which provides a more stabilized signal than the potentiometer, and the EGR bypass flap which

improves engine warming up efficiency are also used. The HFM sensor and the position sensor are

used to feedback the amount of EGR for both EURO 4 and EURO 5.

b. Components

Page 419 of 1336

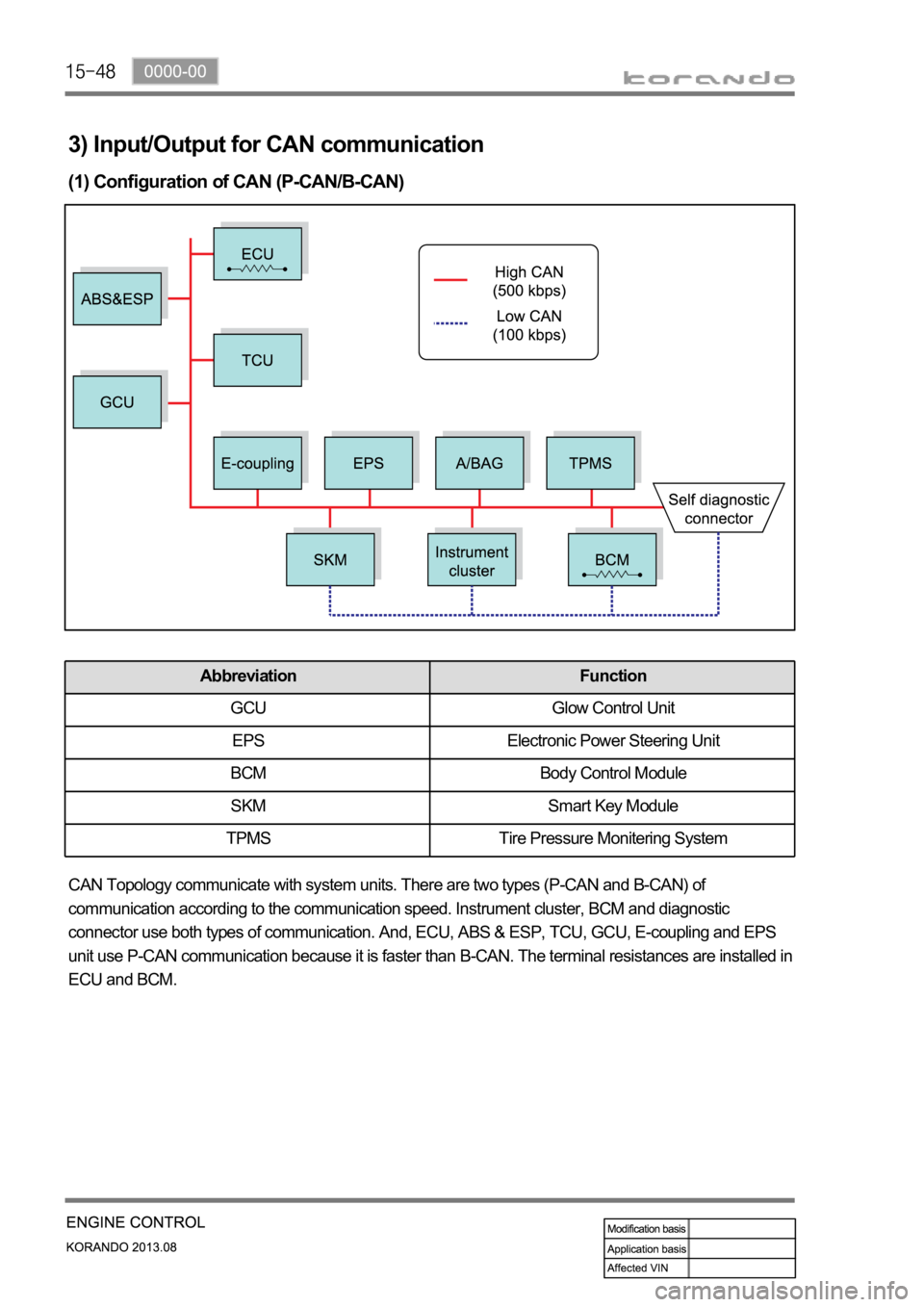

3) Input/Output for CAN communication

(1) Configuration of CAN (P-CAN/B-CAN)

CAN Topology communicate with system units. There are two types (P-CAN and B-CAN) of

communication according to the communication speed. Instrument cluster, BCM and diagnostic

connector use both types of communication. And, ECU, ABS & ESP, TCU, GCU, E-coupling and EPS

unit use P-CAN communication because it is faster than B-CAN. The terminal resistances are installed in

ECU and BCM.

Abbreviation Function

GCU Glow Control Unit

EPS Electronic Power Steering Unit

BCM Body Control Module

SKM Smart Key Module

TPMS Tire Pressure Monitering System

Page 426 of 1336

0000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

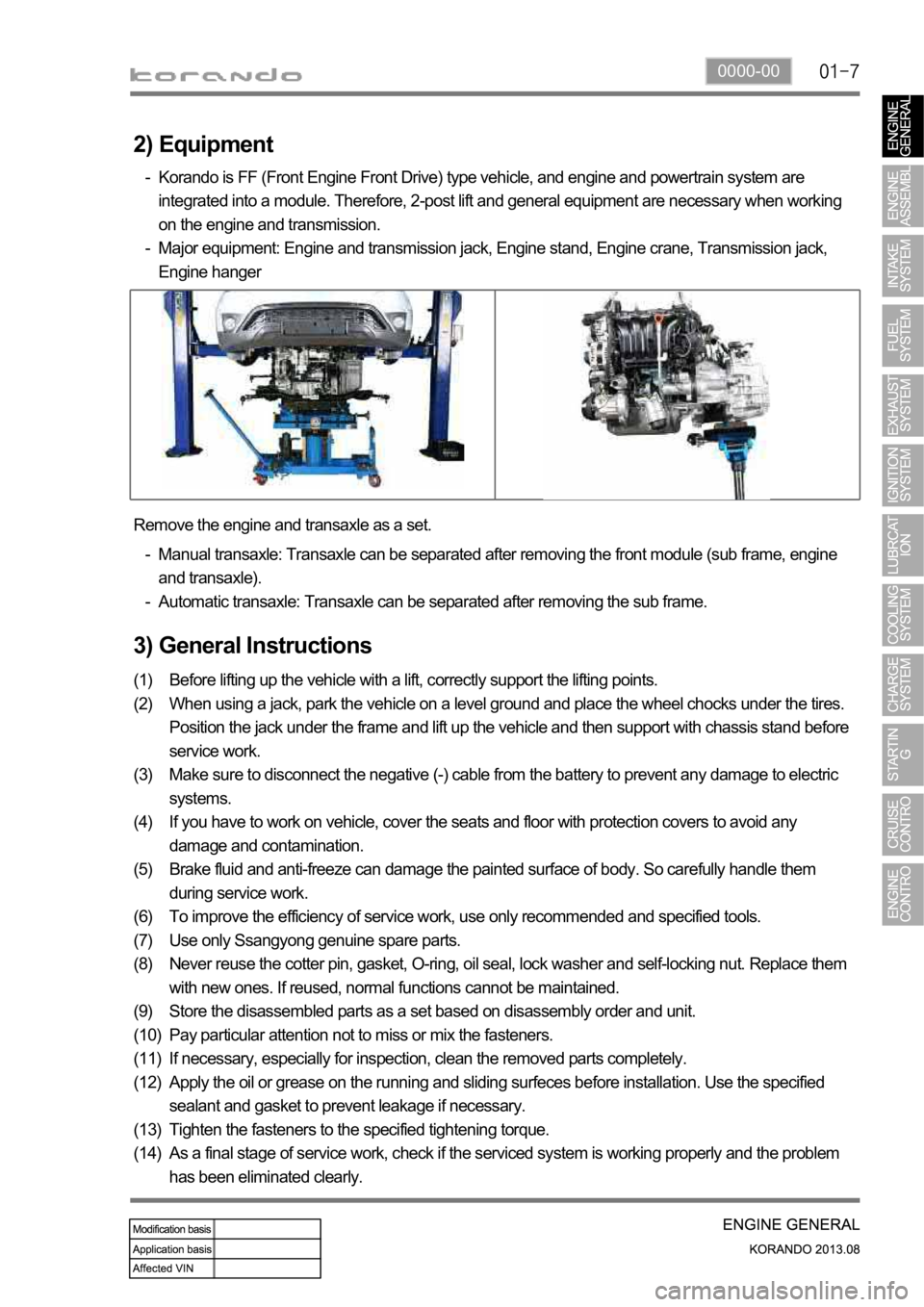

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Page 433 of 1336

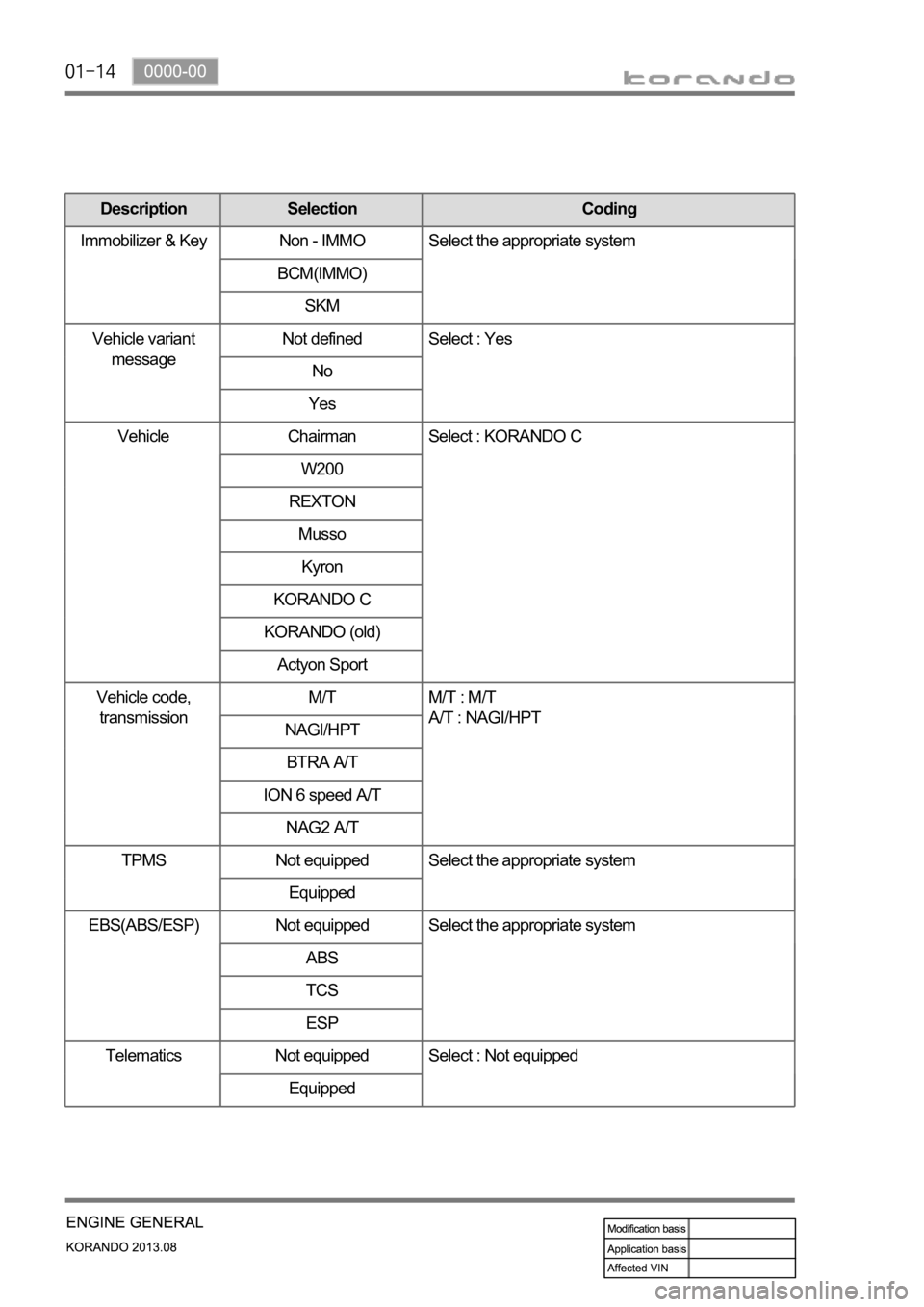

Description Selection Coding

Immobilizer & Key Non - IMMO Select the appropriate system

BCM(IMMO)

SKM

Vehicle variant

messageNot defined Select : Yes

No

Yes

Vehicle Chairman Select : KORANDO C

W200

REXTON

Musso

Kyron

KORANDO C

KORANDO (old)

Actyon Sport

Vehicle code,

transmissionM/T M/T : M/T

A/T : NAGI/HPT

NAGI/HPT

BTRA A/T

ION 6 speed A/T

NAG2 A/T

TPMS Not equipped Select the appropriate system

Equipped

EBS(ABS/ESP) Not equipped Select the appropriate system

ABS

TCS

ESP

Telematics Not equipped Select : Not equipped

Equipped

Page 440 of 1336

1116-01

Engine and accessories

Engine has a lot of precise components. The specified tightening torque and correct procedures should

be kept during service works. And, the working area is always clean and well prepared.

When disassembling the engine, related parts (bolts, gaskets, etc.) should be stored as a set.

Carefully read the disassembly and reassembly procedures in this manual before starting the

works.

Clean the components completely with engine oil before assembling if needed.

Fully drain the engine oil, coolant and fuel from the vehicle and seal the inlets with the plugs before

removing the engine.

All the interference should be eliminated before removing the engine. -

-

-

-

Tightening the fastener

When reassembling the parts to G20DF, use the angle tightening as a final step.

1. Clean the mating surfaces before tightening.

2. Place the marks with paint to tighten by angle if the angle wrench is not available. Exhaust system

Wear the protective gloves before removing the exhaust pipe.

The exhaust pipe is very hot immediately after stopping th engine. Check if the exhaust pipe is fully

cooled down before servicing the exhaust system. -

-

Cooling system

Scalding hot coolant and steam could be blown out under pressure, which could cause serious

injury. Never remove the coolant reservoir cap when the engine and the radiator are hot. -

The position and direction of the componets is based on the rear view.

Do not tighten the fasteners with excessive force. Especially, the threads of cylinder block could be

damaged.

The self screw bolt makes the thread itself when tightening it. Do not apply excessive force.

Do not reuse the bolt that has been tightened with angle tightening method.

Page 442 of 1336

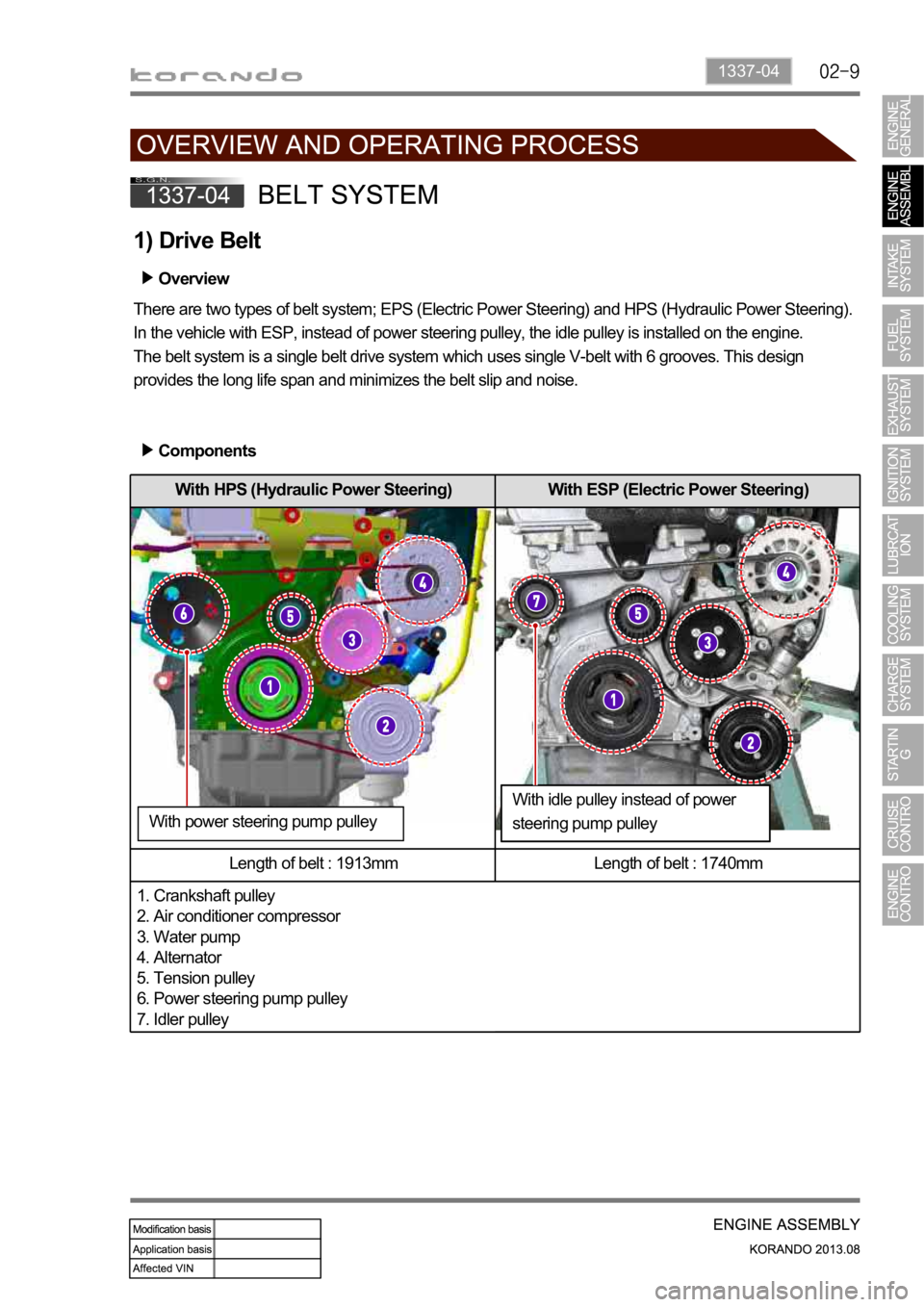

1337-04

With HPS (Hydraulic Power Steering) With ESP (Electric Power Steering)

Length of belt : 1913mm Length of belt : 1740mm

1. Crankshaft pulley

2. Air conditioner compressor

3. Water pump

4. Alternator

5. Tension pulley

6. Power steering pump pulley

7. Idler pulley

1) Drive Belt

Overview

There are two types of belt system; EPS (Electric Power Steering) and HPS (Hydraulic Power Steering).

In the vehicle with ESP, instead of power steering pulley, the idle pulley is installed on the engine.

The belt system is a single belt drive system which uses single V-belt with 6 grooves. This design

provides the long life span and minimizes the belt slip and noise.

Components

With idle pulley instead of power

steering pump pulley With power steering pump pulley

Page 462 of 1336

1130-13

3) Features of DMF

Reduced vibration noise from the powertrain by blocking the torsional vibrations

Enhanced vehicle silence and riding comforts: reduced engine torque fluctuation

Reduced shifting shocks

Smooth acceleration and deceleration -

-

-

-

4) Advantages of DMF

Improved torque response by using 2-stage type spring: Strengthens the torque response in all

ranges (low, medium, and high speed) by applying respective spring constant at each

range.

Stable revolution of the primary and secondary wheel by using planetary gear: Works as auxiliary

damper against spring changes

Less heat generation due to no direct friction against spring surface: Plastic material is covered on the

spring outer surface

Increased durability by using plastic bushing (extends the lifetime of grease) -

-

-

-

Page 493 of 1336

1745-01

1. OVERVIEW

This system purifies the exhaust gas generated by the combustion in the engine to reduce the pollutants

and noise during that arise during combustion.

Harmful materials produced in the combustion process is treated and reduced in the exhaust system.

Harmful materials discharged from the crankcase and fuel tank is drawn into the intake system again to

reduce discharge amount of harmful materials.

Emission aftertreatment system

Catalytic Converter & O2 Sensor

The catalytic converter is a monolith type purification system composed of cordierite which purifies

exhaust gas through the small holes of active monolith catalyst from the exhaust manifold. As exhaus

t

gas passes through the small holes in the layer in the middle, its CO and HC are reduced by

oxidization reaction and its NOx is reduced by reduction reaction to Pt, Ph and Pd. The oxygen

sensor sends signals for feedback and determination of catalyst condition. For detailed description,

see the corresponding section. -

The fuel evaporative gas is a gas evaporated to the atmosphere in the section between the fuel tank and

fuel line, and its main component is hydrocarbon (HC). The fuel evaporative gas is temporarily stored in

the canister, and it is drawn to the engine through the throttle body when the purge control solenoid valve

is open according to the engine operating condition.

Gas in the combustion chamber is sealed by the piston. However, gas is leaked through the gap

between the cylinder and piston and drawn into the crankcase during the compression and explosion

strokes. This gas is blow-by gas and its main components are hydrocarbon and carbon monoxide. If this

gas is drawn into the crankcase, the system can be corroded and oil can be deteriorated. Also, if this

gas is discharged into the air, it can pollute the environment. To prevent these, the blow-by gas

reduction system (also called as crankcase ventilation system) draws the blow-by gas from the

crankcase to the combustion chamber for combustion.

Purge Canister Control

Blow-by gas control system (crankcase ventilation system)

Page 535 of 1336

Battery

It converts the chemical energy to the

electrical energy and supplies power to the

corresponding electric units when starting the

engine.

1. OVERVIEW

The charge system is designed to supply electrical energy to the vehicle while driving, and supplies a

constant direct current voltage by converting mechanical rotational movement to electrical energy. The

voltage regulator on the back of the alternator controls the generated voltage in all rotating ranges and

adjusts the system voltage according to the electric load and ambient temperature change.

Body ground

B+ wiringAlternator

The alternator charges the battery and

supplies power to each electric unit by

converting the mechanical energy to the

electrical energy.

Page 546 of 1336

8530-00

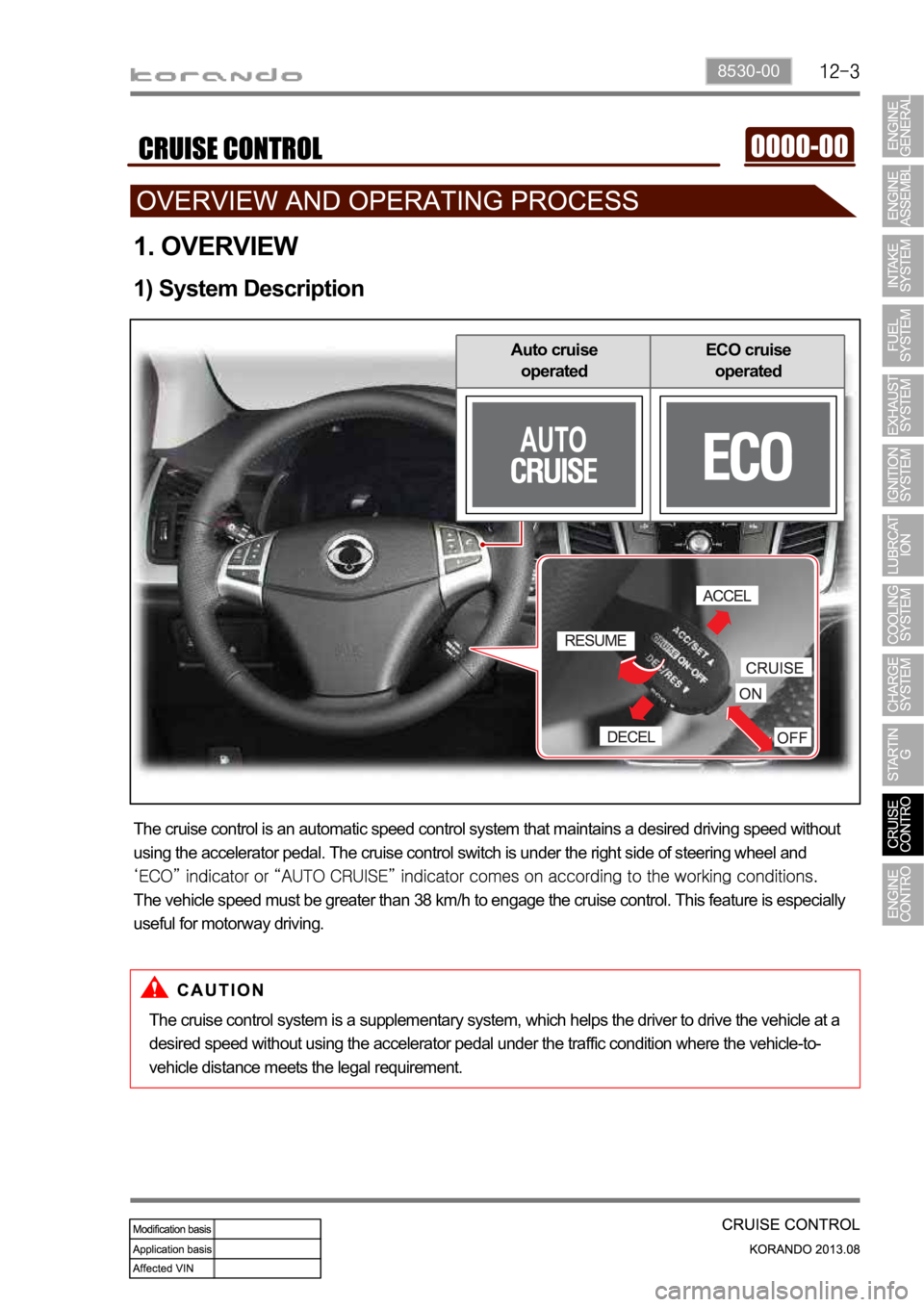

1. OVERVIEW

1) System Description

The cruise control is an automatic speed control system that maintains a desired driving speed without

using the accelerator pedal. The cruise control switch is under the right side of steering wheel and

The vehicle speed must be greater than 38 km/h to engage the cruise control. This feature is especially

useful for motorway driving.

The cruise control system is a supplementary system, which helps the driver to drive the vehicle at a

desired speed without using the accelerator pedal under the traffic condition where the vehicle-to-

vehicle distance meets the legal requirement.

Auto cruise

operatedECO cruise

operated