engine oil SSANGYONG KORANDO 2013 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 427 of 1336

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 428 of 1336

0000-00

5) Guidelines on Engine Service

(1) Cautions before service works

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

Make sure to clean the working area and to prepare the necessary tools before service works.

Always place the ignition switch to OFF position if not required. Otherwise, there could be unexpected

damage to electric devices or personal injuries due to short-circuit.

To prevent the foreign material from entering into the fuel injection system, completely seal the inlets o

f

HP pump, fuel hoses and high pressure pipes.

To remoev the engine, use the dedicated equipments such as engine jack, transmission jack, engine

stand and engine crane. -

-

-

-

-

(2) Engine and accessories

When disassembling the engine, related parts (bolts, gaskets, etc.) should be stored as a set.

Clean the components completely with engine oil before assembling if needed.

Fully drain the engine oil, coolant and fuel from the vehicle and seal the inlets with the plugs before

removing the engine.

All the interference should be eliminated before removing the engine. -

-

-

- To prevent the personal injuries and vehicle damages that can be caused by mistakes during service

and to provide the optimized performance and safety after service works, the service technicials must

keep the basic cautions and service guidelines below. These could be easily forgotten during service

works.

Engine has a lot of precise components. The specified tightening torque and correct procedures should

be kept during service works. And, the working area is always clean and well prepared.

To prevent any damage to electric systems, make sure to disconnect the negative (-) cable from the

battery and place the ignition switch to OFF position before servicing.

Use only the specified parts with same ratings when replacing the electric devices. Check the

grounds and connections for looseness. -

-

(3) Electric devices

Extraordinary care should be taken when servicing the electric systems. Currently, the engine uses a lot

of electric devices. Short circuit and poor contact may cause the low engine performance, incomplete

combustion and other abnormalities.

When working with the fuel or oil systems in enclosed area, always keep the working area well-

ventilated and never allow anybody to smoke.

Gaskets and seals on the fuel and oil systems should be replaced with new ones. All bolts and nuts

should be tightened as specified.

Make sure to check the connections for leak after installation. -

-

-

(4) Fuel and lubrication system

Page 438 of 1336

1116-01

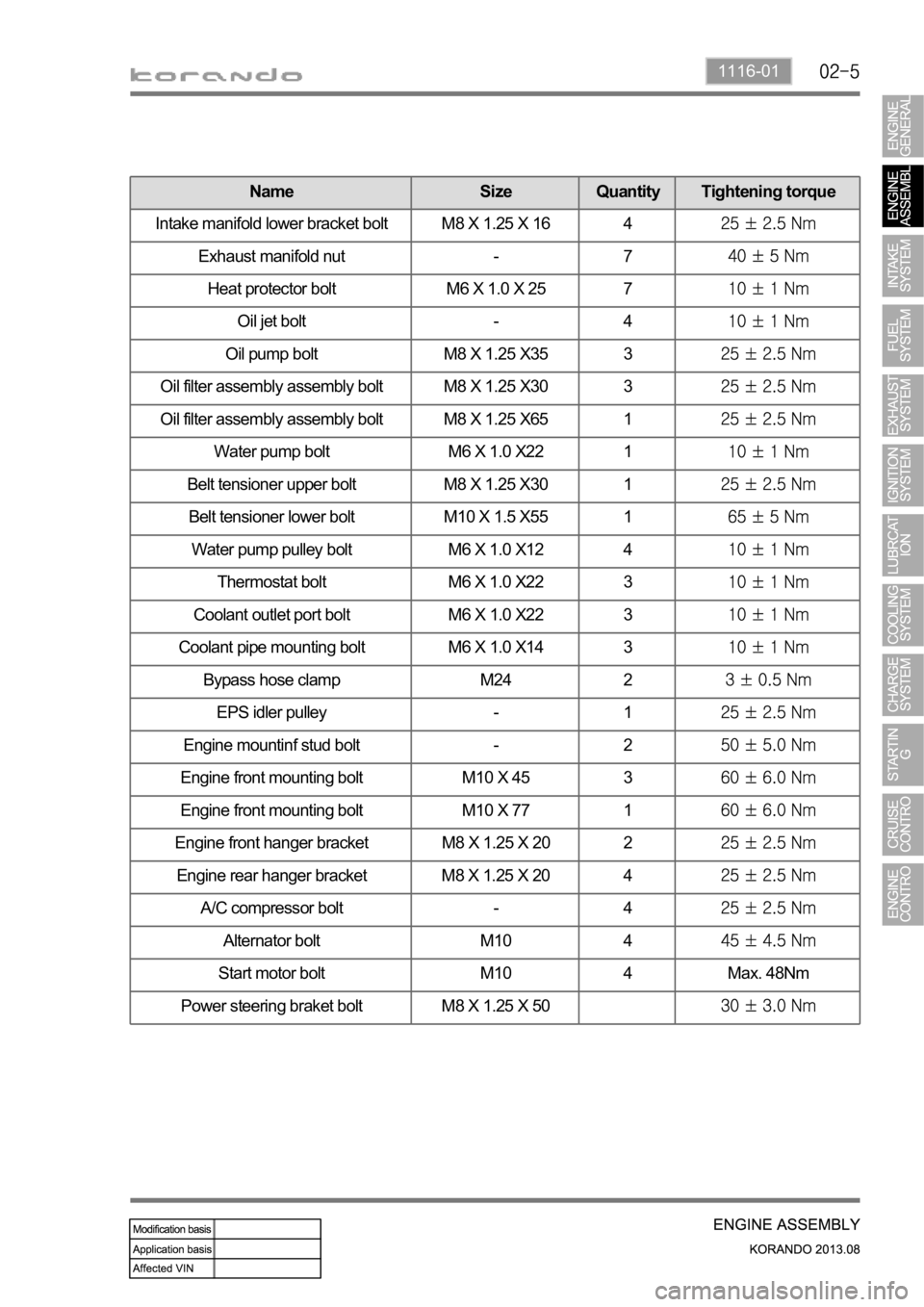

Name Size Quantity Tightening torque

Intake manifold lower bracket bolt M8 X 1.25 X 16 4

Exhaust manifold nut - 7

Heat protector bolt M6 X 1.0 X 25 7

Oil jet bolt - 4

Oil pump bolt M8 X 1.25 X35 3

Oil filter assembly assembly bolt M8 X 1.25 X30 3

Oil filter assembly assembly bolt M8 X 1.25 X65 1

Water pump bolt M6 X 1.0 X22 1

Belt tensioner upper bolt M8 X 1.25 X30 1

Belt tensioner lower bolt M10 X 1.5 X55 1

Water pump pulley bolt M6 X 1.0 X12 4

Thermostat bolt M6 X 1.0 X22 3

Coolant outlet port bolt M6 X 1.0 X22 3

Coolant pipe mounting bolt M6 X 1.0 X14 3

Bypass hose clamp M24 2

EPS idler pulley - 1

Engine mountinf stud bolt - 2

Engine front mounting bolt M10 X 45 3

Engine front mounting bolt M10 X 77 1

Engine front hanger bracket M8 X 1.25 X 20 2

Engine rear hanger bracket M8 X 1.25 X 20 4

A/C compressor bolt - 4

Alternator bolt M10 4

Start motor bolt M10 4 Max. 48Nm

Power steering braket bolt M8 X 1.25 X 50

Page 439 of 1336

3. GUIDELINES ON ENGINE SERVICE

G20DF engine is for FF (Front Engine Front Drive) type vehicle. Therefore, there are some deferent

maintenance and repair works compared to the engine for FR (Front Engine Rear Drive) type vehicle.

For safe and correct works, you must observe the working procedures and instructions in this manual.

And, use the designated tools as follow:

: Power train mounting stand / Engine hanger / Engine stand / Heavy duty engine jack.

Cautions before service works

G20DF engine is FF (Front Engine Front Drive) type engine, and the engine and transmission are

integrated in a same module. Remember that there are many differences compared to

conventional engine in FR (Front Engine Rear Drive) type SUV vehicle.

To remove the engine, use the dedicated equipments such as engine jack, transmission jack,

engine stand and engine crane (1 ton).

To prevent the engine from abruptly starting during service in engine compartment, never allow

anybody to stay in the vehicle.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

Make sure to clean the working area and to prepare the necessary tools before service works.

Always place the ignition switch to OFF position if not required. Otherwise, there could be

unexpected damage to electric devices or personal injuries due to short-circuit..

To prevent the foreign material from entering into the fuel injection system, completely seal the

inlets of HP pump, fuel hoses and high pressure pipes.

Do not remove the engine while supporting the oil pan with a jack. -

-

-

-

-

-

-

Lifting up the vehicle

Before lifting up the vehicle with a lift, correctly support the lifting points.

To prevent the vehicle from rolling down, put the chocks under the tires (when using a 4-post lift).

Make sure to support the correct lifting points (when using a 2-post lift). -

-

-

Page 440 of 1336

1116-01

Engine and accessories

Engine has a lot of precise components. The specified tightening torque and correct procedures should

be kept during service works. And, the working area is always clean and well prepared.

When disassembling the engine, related parts (bolts, gaskets, etc.) should be stored as a set.

Carefully read the disassembly and reassembly procedures in this manual before starting the

works.

Clean the components completely with engine oil before assembling if needed.

Fully drain the engine oil, coolant and fuel from the vehicle and seal the inlets with the plugs before

removing the engine.

All the interference should be eliminated before removing the engine. -

-

-

-

Tightening the fastener

When reassembling the parts to G20DF, use the angle tightening as a final step.

1. Clean the mating surfaces before tightening.

2. Place the marks with paint to tighten by angle if the angle wrench is not available. Exhaust system

Wear the protective gloves before removing the exhaust pipe.

The exhaust pipe is very hot immediately after stopping th engine. Check if the exhaust pipe is fully

cooled down before servicing the exhaust system. -

-

Cooling system

Scalding hot coolant and steam could be blown out under pressure, which could cause serious

injury. Never remove the coolant reservoir cap when the engine and the radiator are hot. -

The position and direction of the componets is based on the rear view.

Do not tighten the fasteners with excessive force. Especially, the threads of cylinder block could be

damaged.

The self screw bolt makes the thread itself when tightening it. Do not apply excessive force.

Do not reuse the bolt that has been tightened with angle tightening method.

Page 441 of 1336

Fuel and engine oil system

The engine oil and fuel damages the painted surfaces and rubber material of the vehicle.

Disconnect the negative cable from the battery before servicing the fuel system, and prepare the

service plug grip.

When working with the fuel or oil systems in enclosed area, always keep the working area well-

ventilated and never allow anybody to smoke.

Do not allow the gasoline to contact to rubber or leather parts.

Carefully separate the pipe between high pressure fuel pump and fuel injector so that any fuel can

be spilled out.

Fully release the pressure from the fuel system before removing any parts of fuel system.

To release the fuel pressure in high pressure line, let the engine fully cool down.

Gaskets and seals on the fuel and oil systems should be replaced with new ones. All bolts and nuts

should be tightened as specified.

Prolonged exposure to the engine oil make cause a skin cancer or an irritation.

Used engine cotains the hazardous material that may cause the skin cancer. Do not allow the used

engine to make contact with your skin.

Make sure to wear the protection gloves and goggle when handling the engine oil. If contact

happens, rinse affected areas immediately with plenty of water. Do not wash it with gasoline or

solvent. If irritation persists, consult a doctor.

Improperly disposed engine oil can pollute the environment. Dispose the used engine oil and oil

filter in accordance with local environmental regulations.

Make sure to check the connections for leak after installation. -

-

-

-

-

-

-

-

-

-

-

-

Electric devices

To prevent any damage to electric systems, make sure to disconnect the negative (-) cable from the

battery and place the ignition switch to OFF position before servicing.

Use only the specified parts with same ratings when replacing the electric devices. Check the

grounds and connections for looseness. -

- Extraordinary care should be taken when servicing the electric systems. Currently, the engine uses a lot

of electric devices. Short circuit and poor contact may cause the low engine performance, incomplete

combustion and other abnormalities.

Page 453 of 1336

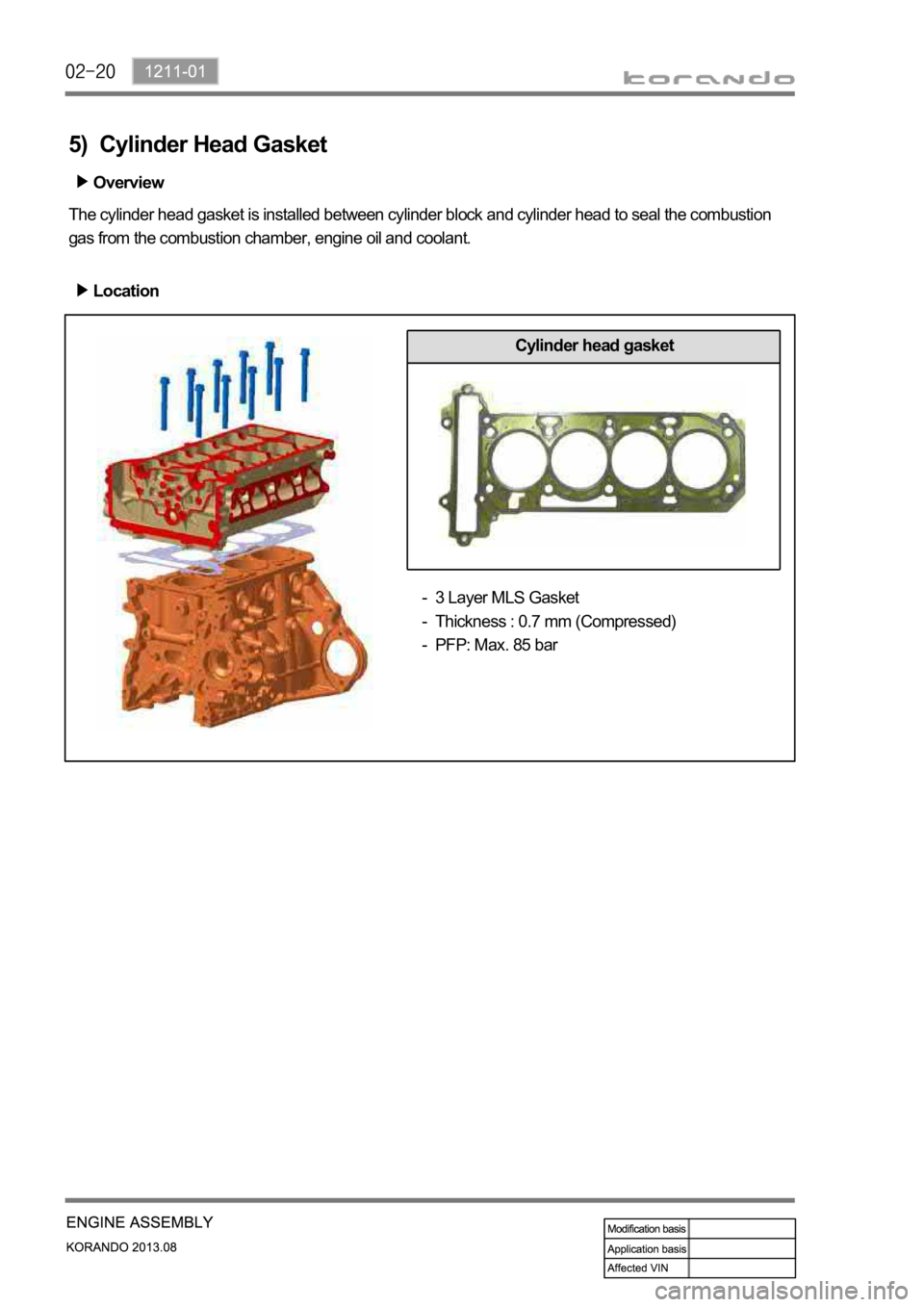

5) Cylinder Head Gasket

The cylinder head gasket is installed between cylinder block and cylinder head to seal the combustion

gas from the combustion chamber, engine oil and coolant.Overview

Location

Cylinder head gasket

3 Layer MLS Gasket

Thickness : 0.7 mm (Compressed)

PFP: Max. 85 bar -

-

-

Page 455 of 1336

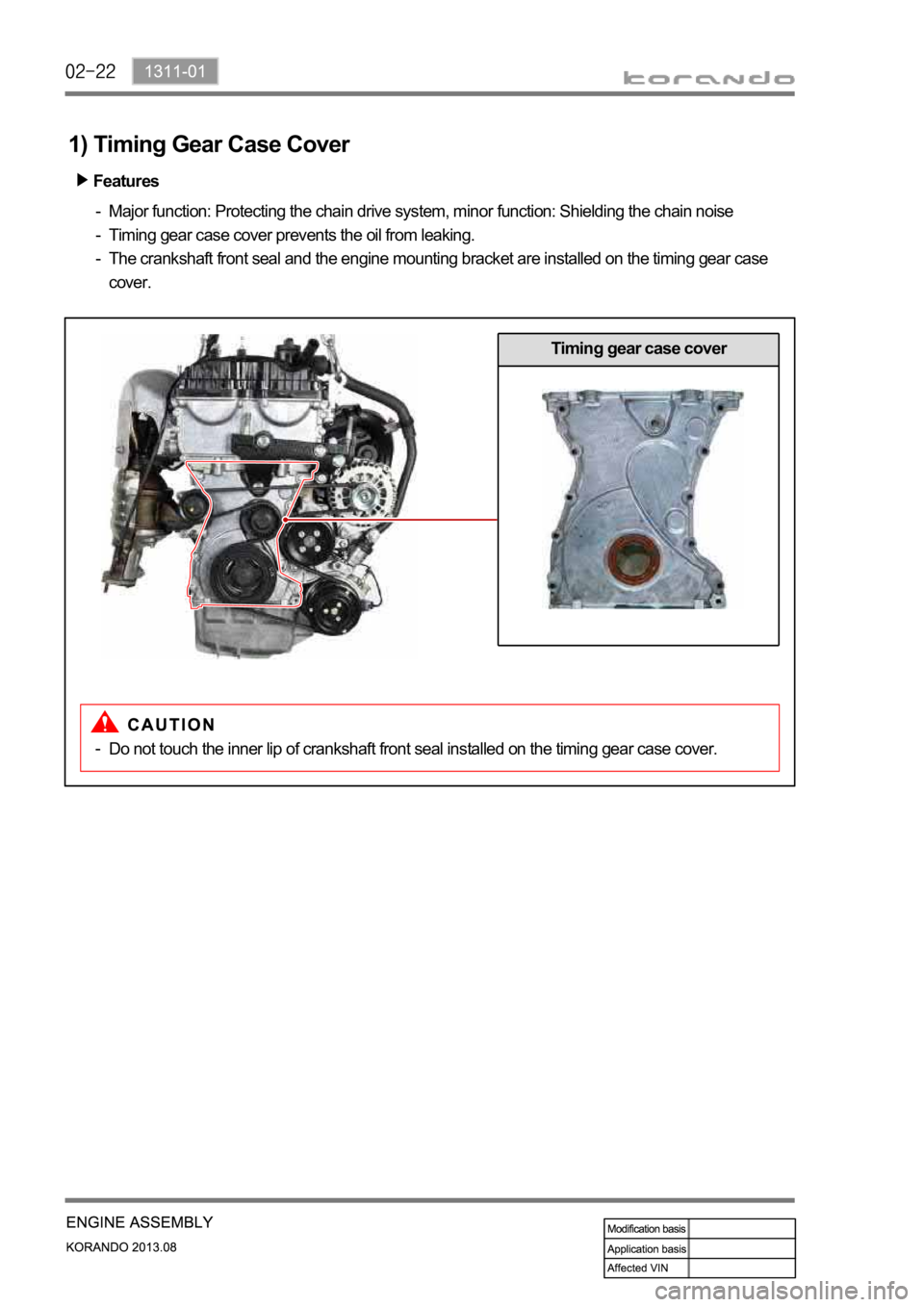

1) Timing Gear Case Cover

Features

Major function: Protecting the chain drive system, minor function: Shielding the chain noise

Timing gear case cover prevents the oil from leaking.

The crankshaft front seal and the engine mounting bracket are installed on the timing gear case

cover. -

-

-

Timing gear case cover

Do not touch the inner lip of crankshaft front seal installed on the timing gear case cover. -

Page 456 of 1336

1311-01

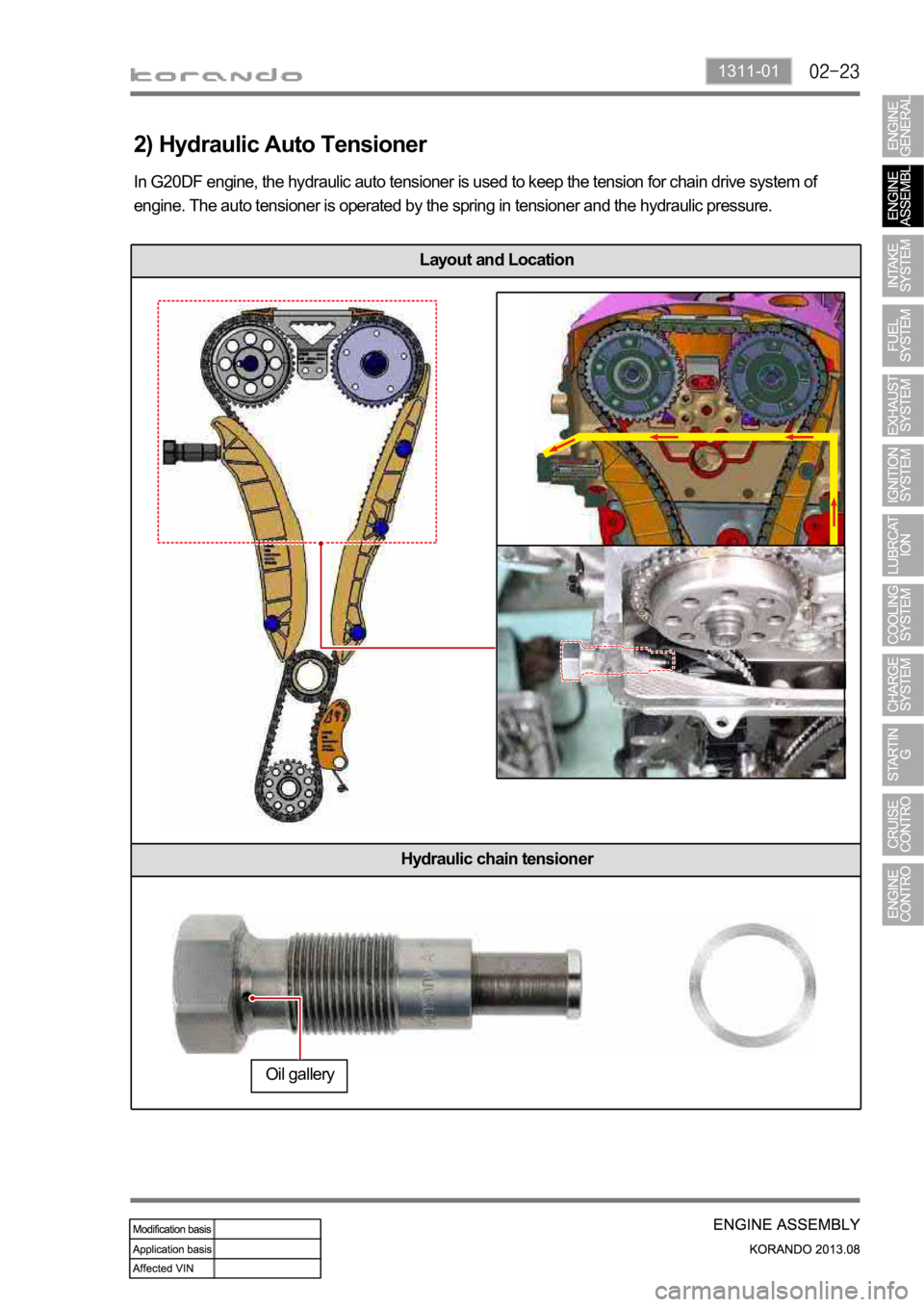

Layout and Location

Hydraulic chain tensioner

In G20DF engine, the hydraulic auto tensioner is used to keep the tension for chain drive system of

engine. The auto tensioner is operated by the spring in tensioner and the hydraulic pressure.

2) Hydraulic Auto Tensioner

Oil gallery

Page 463 of 1336

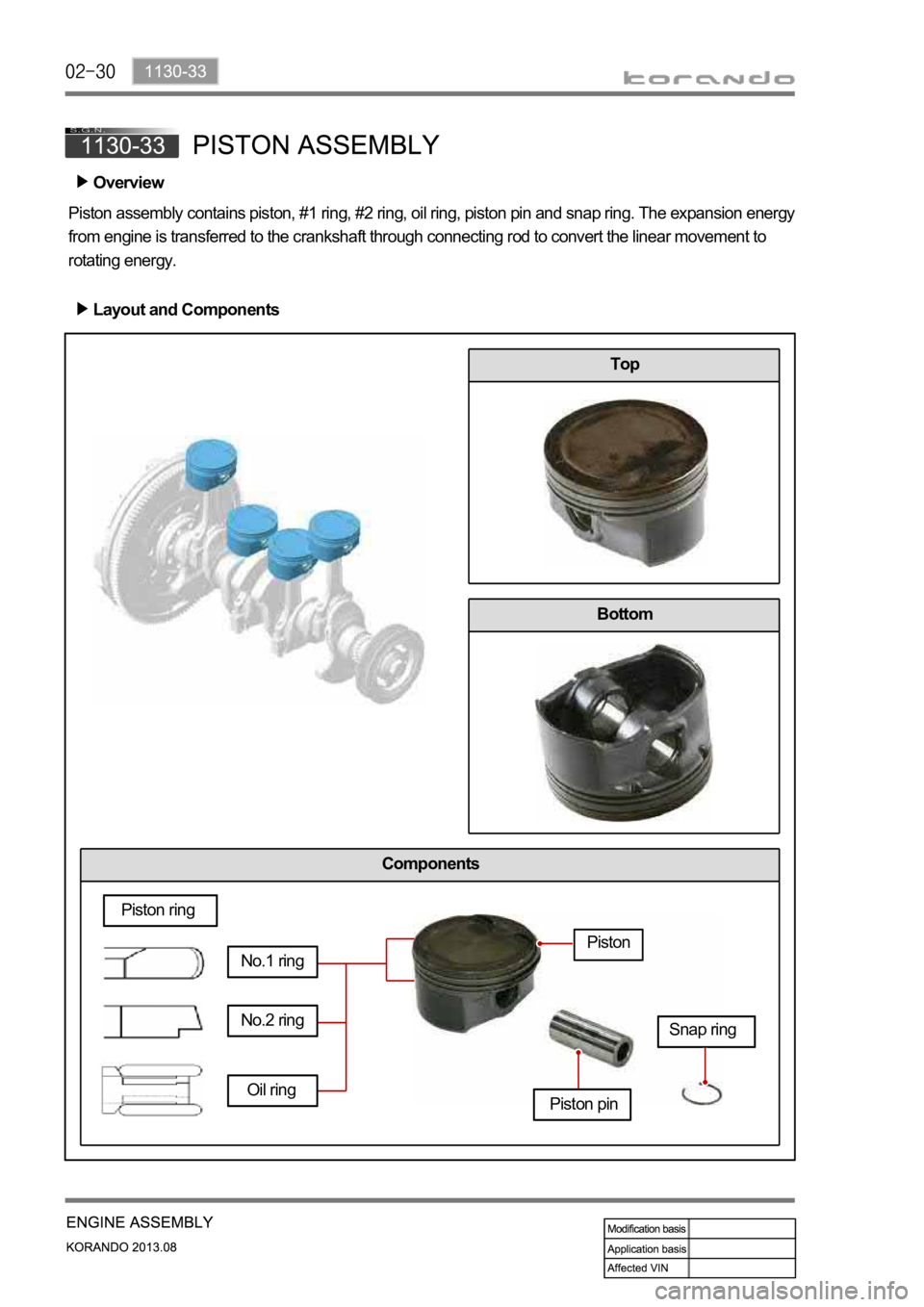

Components

Piston assembly contains piston, #1 ring, #2 ring, oil ring, piston pin and snap ring. The expansion energy

from engine is transferred to the crankshaft through connecting rod to convert the linear movement to

rotating energy.Overview

Layout and Components

Top

Bottom

Oil ring

Piston ring

No.1 ring

Piston pin

No.2 ringSnap ring

Piston