steering SSANGYONG KORANDO 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 997 of 1336

0000-00

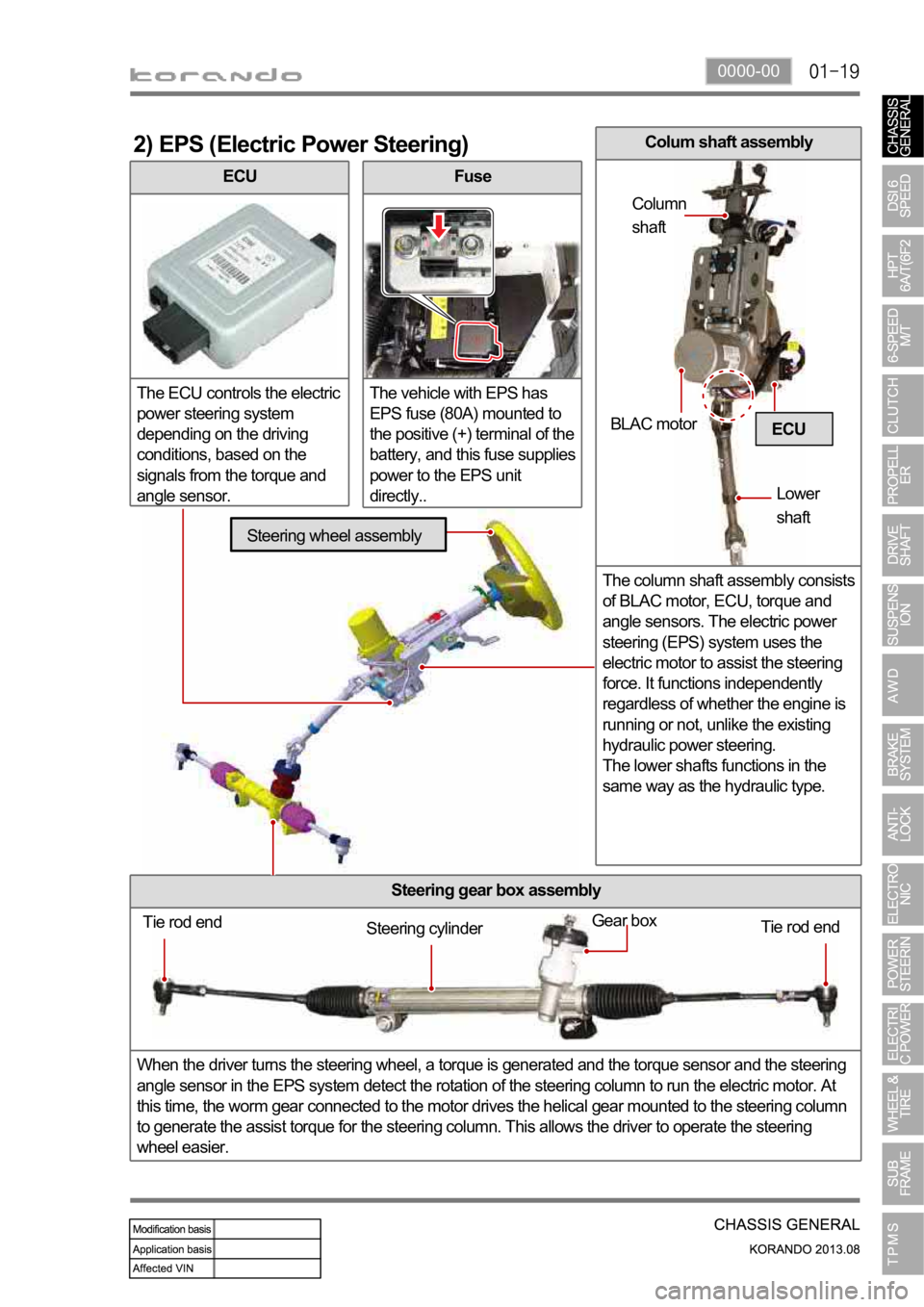

ECU

The ECU controls the electric

power steering system

depending on the driving

conditions, based on the

signals from the torque and

angle sensor.

2) EPS (Electric Power Steering)

Fuse

The vehicle with EPS has

EPS fuse (80A) mounted to

the positive (+) terminal of the

battery, and this fuse supplies

power to the EPS unit

directly..

Steering gear box assembly

When the driver turns the steering wheel, a torque is generated and the torque sensor and the steering

angle sensor in the EPS system detect the rotation of the steering column to run the electric motor. At

this time, the worm gear connected to the motor drives the helical gear mounted to the steering column

to generate the assist torque for the steering column. This allows the driver to operate the steering

wheel easier.

ECU

Tie rod end

Tie rod end Gear boxSteering cylinder

Steering wheel assembly

BLAC motor

Lower

shaft Column

shaft

Colum shaft assembly

The column shaft assembly consists

of BLAC motor, ECU, torque and

angle sensors. The electric power

steering (EPS) system uses the

electric motor to assist the steering

force. It functions independently

regardless of whether the engine is

running or not, unlike the existing

hydraulic power steering.

The lower shafts functions in the

same way as the hydraulic type.

Page 1000 of 1336

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 1004 of 1336

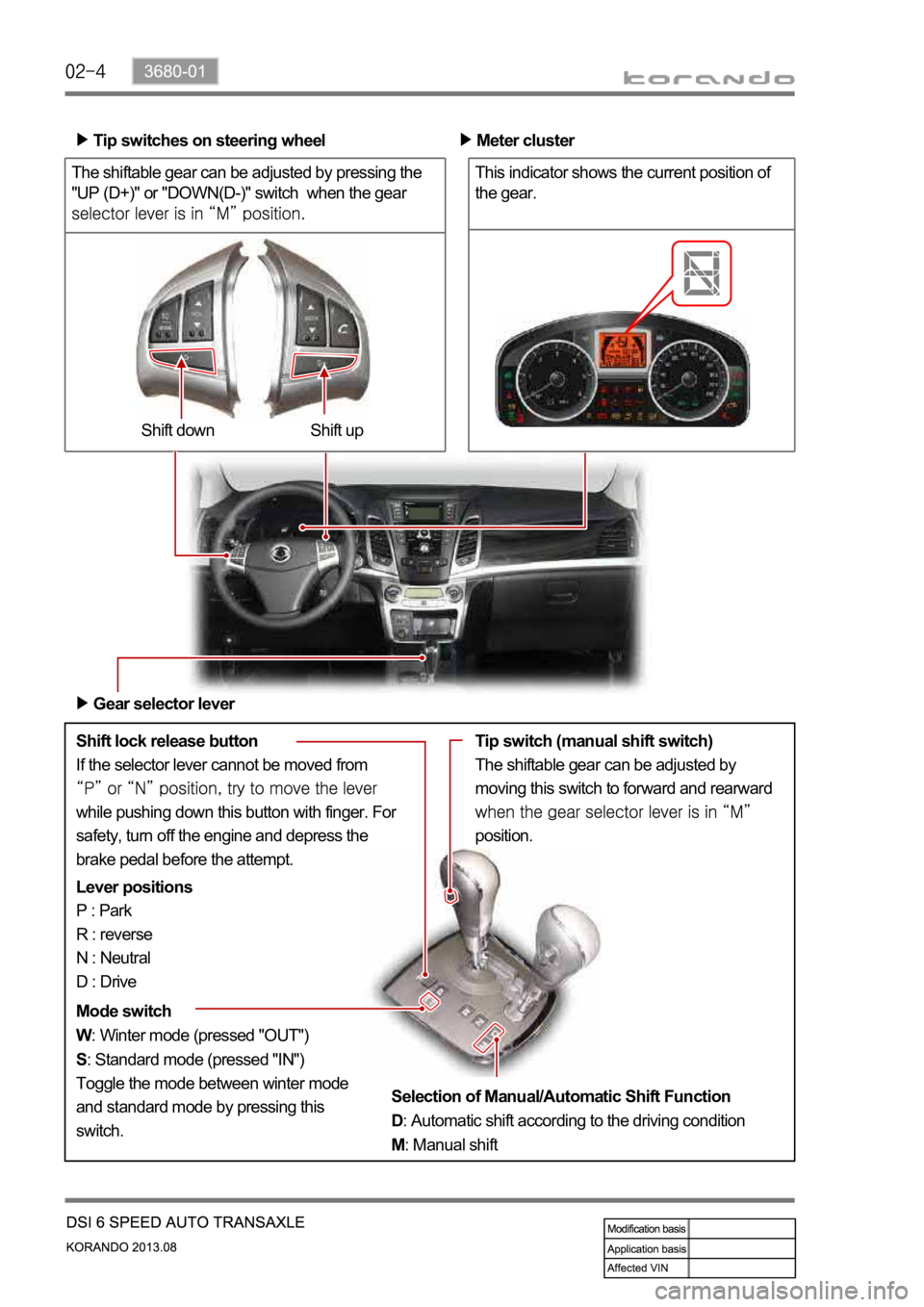

The shiftable gear can be adjusted by pressing the

"UP (D+)" or "DOWN(D-)" switch when the gear

Shift lock release button

If the selector lever cannot be moved from

while pushing down this button with finger. For

safety, turn off the engine and depress the

brake pedal before the attempt.Shift up Shift down Tip switches on steering wheel

Meter cluster

This indicator shows the current position of

the gear.

Gear selector lever

Lever positions

P : Park

R : reverse

N : Neutral

D : Drive

Mode switch

W: Winter mode (pressed "OUT")

S: Standard mode (pressed "IN")

Toggle the mode between winter mode

and standard mode by pressing this

switch.Tip switch (manual shift switch)

The shiftable gear can be adjusted by

moving this switch to forward and rearward

position.

Selection of Manual/Automatic Shift Function

D: Automatic shift according to the driving condition

M: Manual shift

Page 1031 of 1336

3660-01

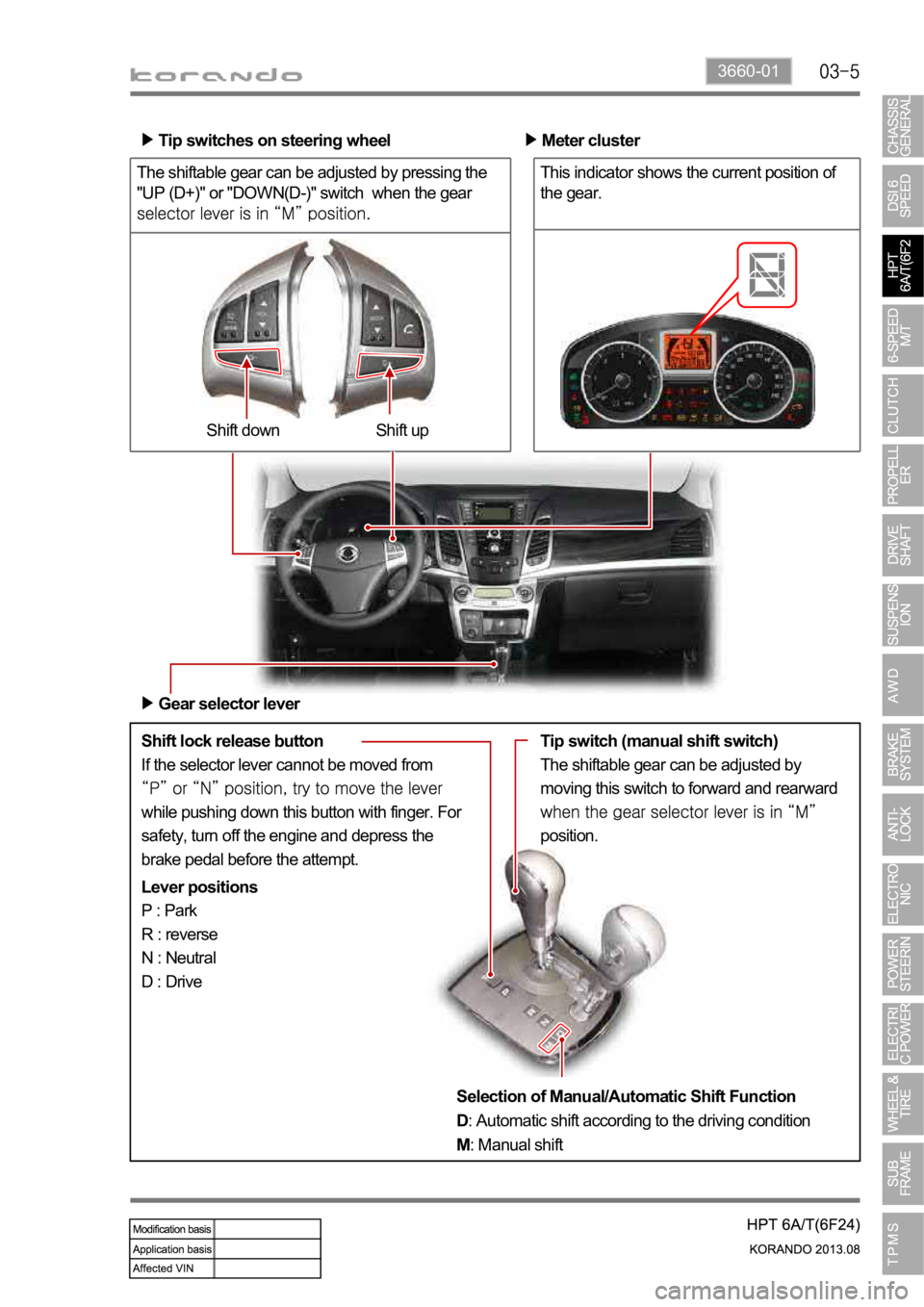

The shiftable gear can be adjusted by pressing the

"UP (D+)" or "DOWN(D-)" switch when the gear

Shift lock release button

If the selector lever cannot be moved from

while pushing down this button with finger. For

safety, turn off the engine and depress the

brake pedal before the attempt.Shift up Shift down Tip switches on steering wheel

Meter cluster

This indicator shows the current position of

the gear.

Gear selector lever

Lever positions

P : Park

R : reverse

N : Neutral

D : DriveTip switch (manual shift switch)

The shiftable gear can be adjusted by

moving this switch to forward and rearward

position.

Selection of Manual/Automatic Shift Function

D: Automatic shift according to the driving condition

M: Manual shift

Page 1076 of 1336

4110-01

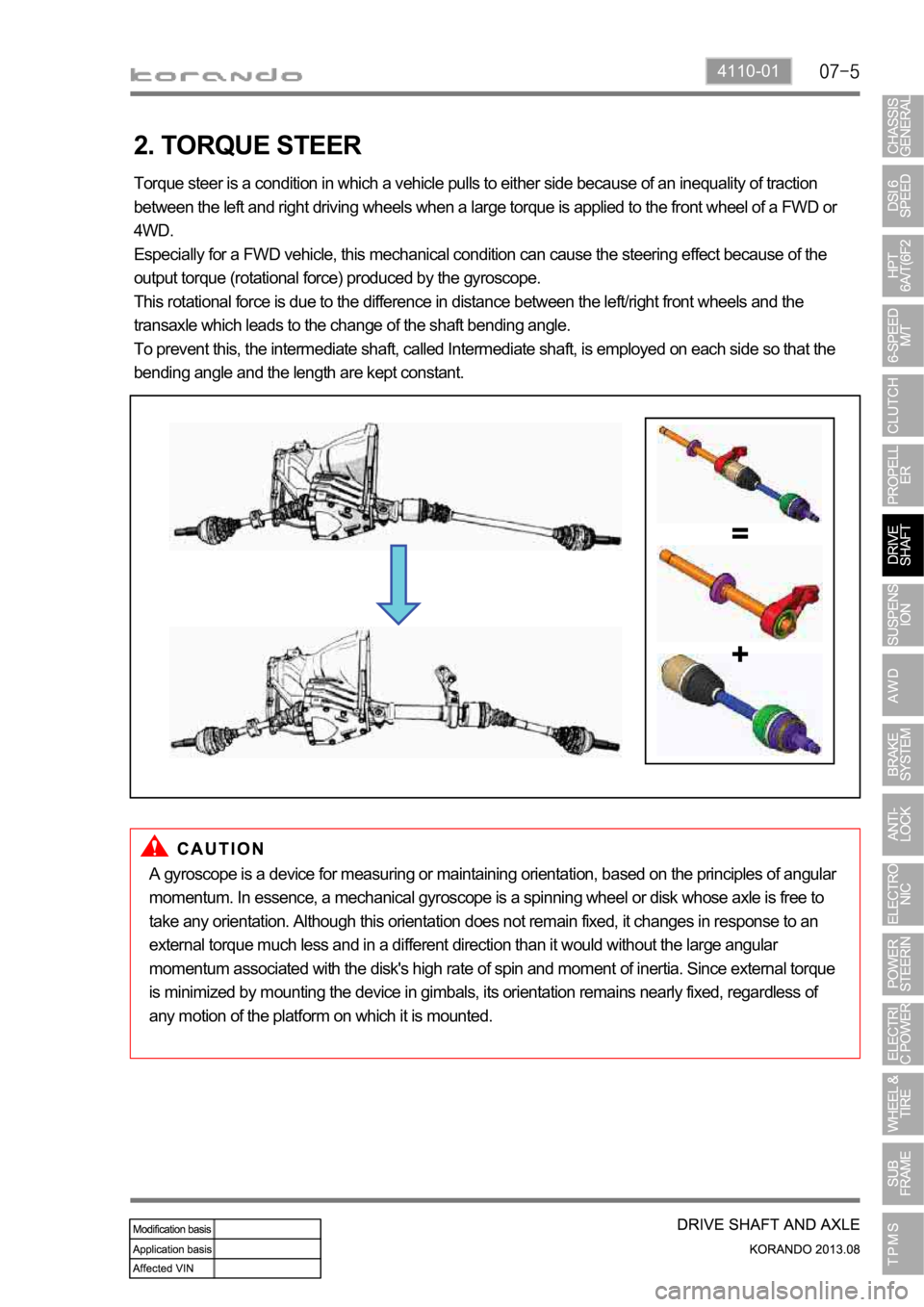

2. TORQUE STEER

Torque steer is a condition in which a vehicle pulls to either side because of an inequality of traction

between the left and right driving wheels when a large torque is applied to the front wheel of a FWD or

4WD.

Especially for a FWD vehicle, this mechanical condition can cause the steering effect because of the

output torque (rotational force) produced by the gyroscope.

This rotational force is due to the difference in distance between the left/right front wheels and the

transaxle which leads to the change of the shaft bending angle.

To prevent this, the intermediate shaft, called Intermediate shaft, is employed on each side so that the

bending angle and the length are kept constant.

A gyroscope is a device for measuring or maintaining orientation, based on the principles of angular

momentum. In essence, a mechanical gyroscope is a spinning wheel or disk whose axle is free to

take any orientation. Although this orientation does not remain fixed, it changes in response to an

external torque much less and in a different direction than it would without the large angular

momentum associated with the disk's high rate of spin and moment of inertia. Since external torque

is minimized by mounting the device in gimbals, its orientation remains nearly fixed, regardless of

any motion of the platform on which it is mounted.

Page 1083 of 1336

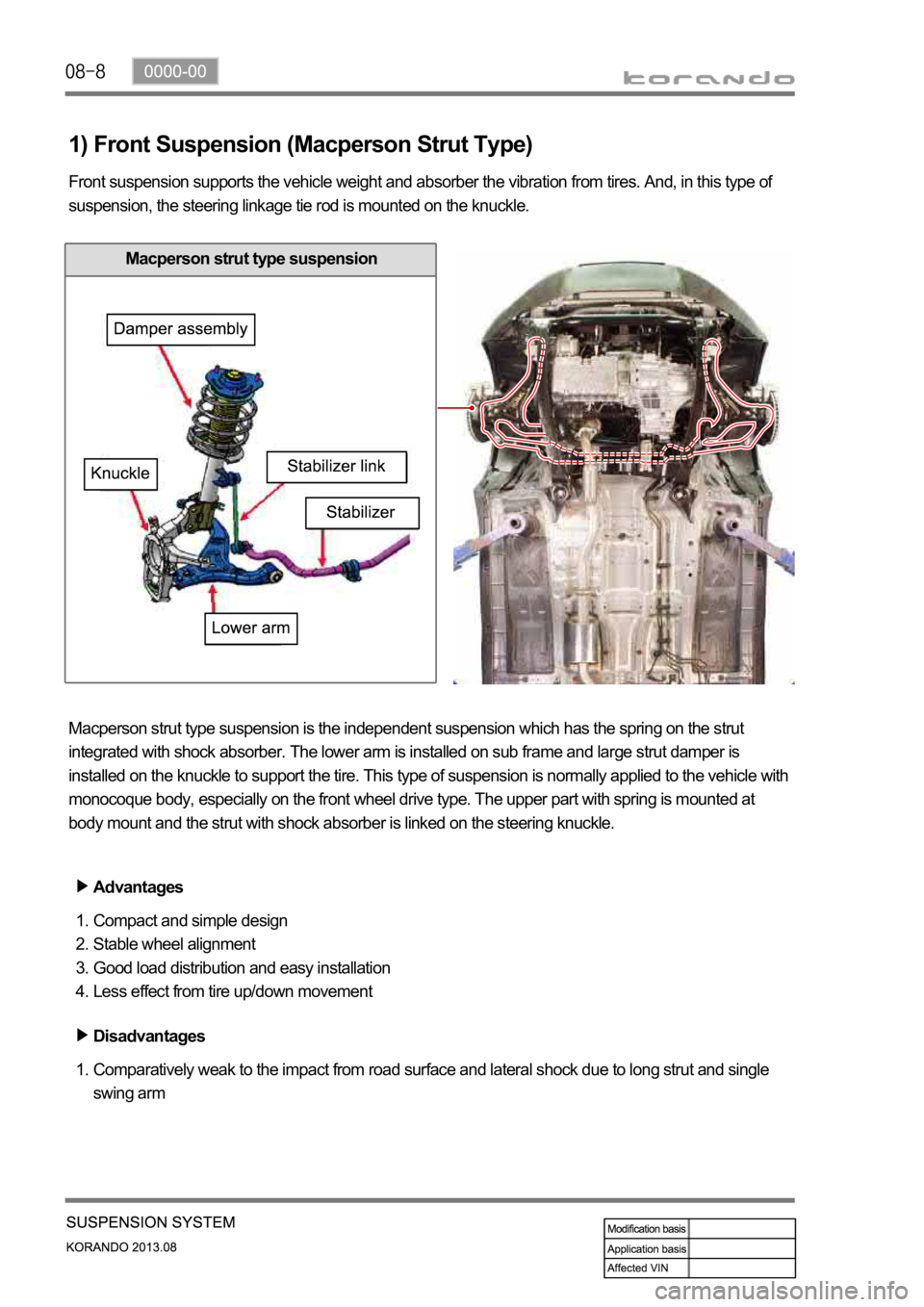

1) Front Suspension (Macperson Strut Type)

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this type of

suspension, the steering linkage tie rod is mounted on the knuckle.

Macperson strut type suspension is the independent suspension which has the spring on the strut

integrated with shock absorber. The lower arm is installed on sub frame and large strut damper is

installed on the knuckle to support the tire. This type of suspension is normally applied to the vehicle with

monocoque body, especially on the front wheel drive type. The upper part with spring is mounted at

body mount and the strut with shock absorber is linked on the steering knuckle.

Advantages

Compact and simple design

Stable wheel alignment

Good load distribution and easy installation

Less effect from tire up/down movement 1.

2.

3.

4.

Disadvantages

Comparatively weak to the impact from road surface and lateral shock due to long strut and single

swing arm 1.

Macperson strut type suspension

Page 1089 of 1336

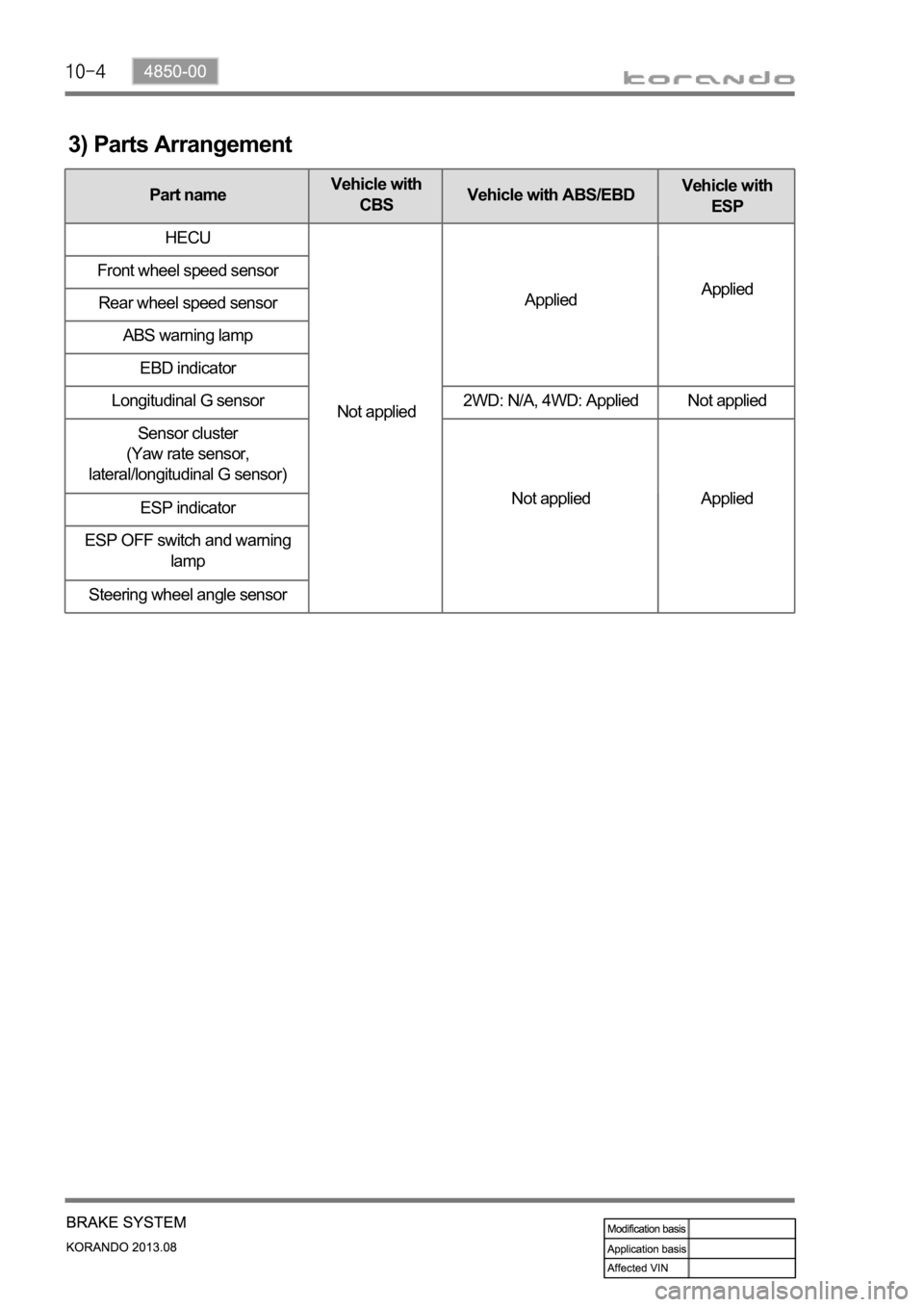

3) Parts Arrangement

Part nameVehicle with

CBSVehicle with ABS/EBDVehicle with

ESP

HECU

Not appliedAppliedApplied Front wheel speed sensor

Rear wheel speed sensor

ABS warning lamp

EBD indicator

Longitudinal G sensor 2WD: N/A, 4WD: Applied Not applied

Sensor cluster

(Yaw rate sensor,

lateral/longitudinal G sensor)

Not applied Applied

ESP indicator

ESP OFF switch and warning

lamp

Steering wheel angle sensor

Page 1101 of 1336

4890-00

1. SYSTEM OVERVIEW

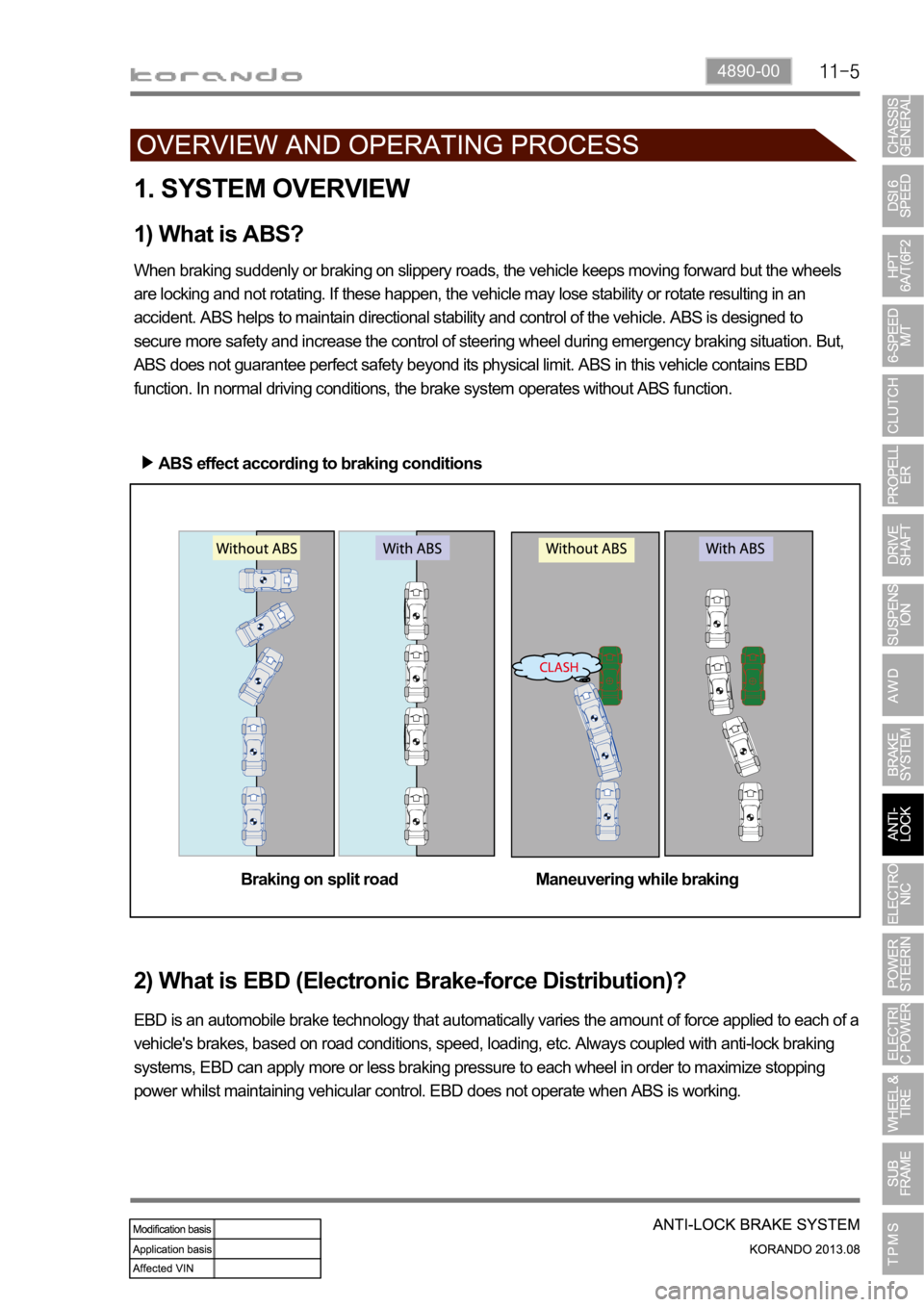

1) What is ABS?

When braking suddenly or braking on slippery roads, the vehicle keeps moving forward but the wheels

are locking and not rotating. If these happen, the vehicle may lose stability or rotate resulting in an

accident. ABS helps to maintain directional stability and control of the vehicle. ABS is designed to

secure more safety and increase the control of steering wheel during emergency braking situation. But,

ABS does not guarantee perfect safety beyond its physical limit. ABS in this vehicle contains EBD

function. In normal driving conditions, the brake system operates without ABS function.

2) What is EBD (Electronic Brake-force Distribution)?

EBD is an automobile brake technology that automatically varies the amount of force applied to each of a

vehicle's brakes, based on road conditions, speed, loading, etc. Always coupled with anti-lock braking

systems, EBD can apply more or less braking pressure to each wheel in order to maximize stopping

power whilst maintaining vehicular control. EBD does not operate when ABS is working. ABS effect according to braking conditions

Braking on split road Maneuvering while braking

Page 1102 of 1336

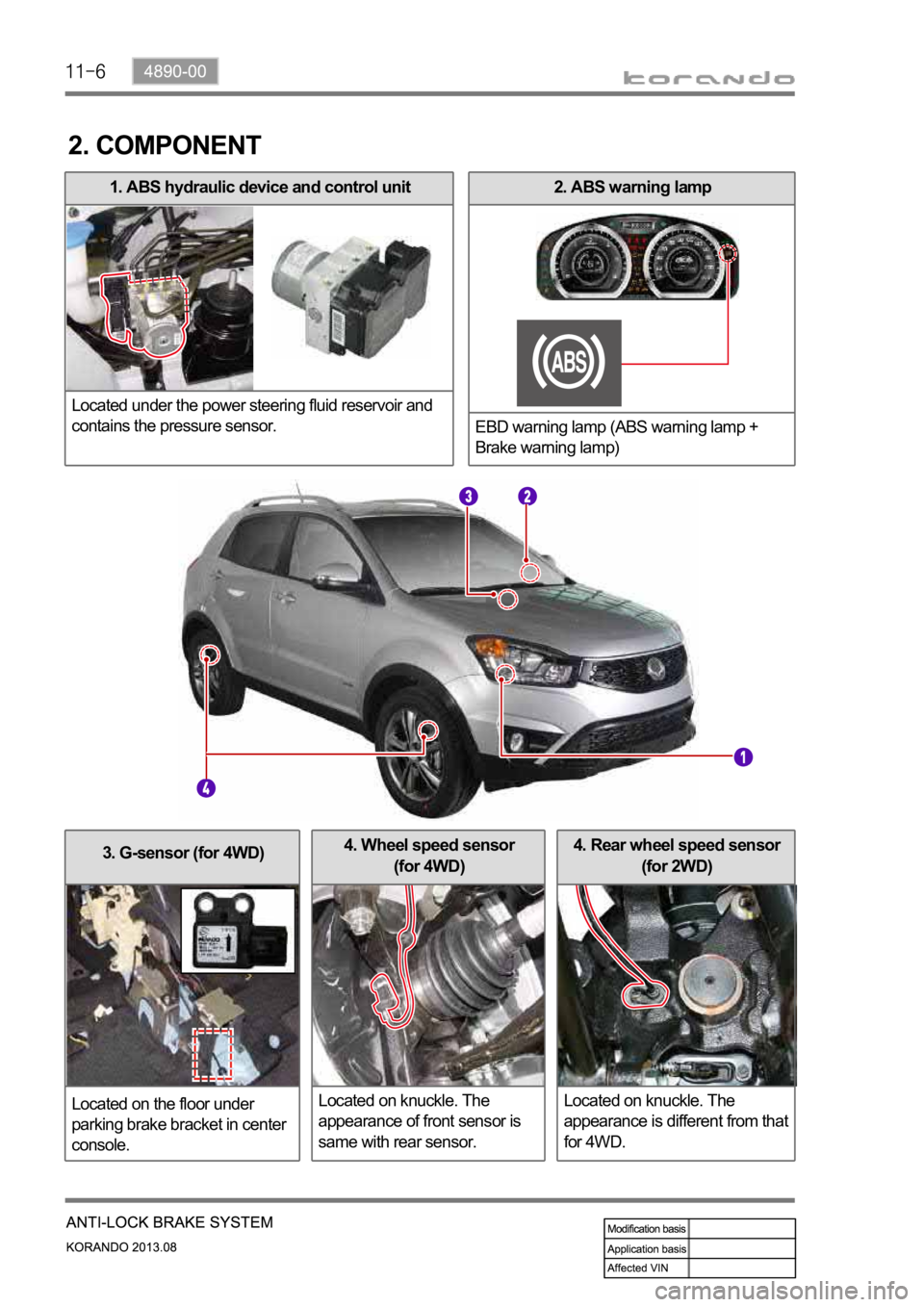

3. G-sensor (for 4WD)

Located on the floor under

parking brake bracket in center

console.4. Rear wheel speed sensor

(for 2WD)

Located on knuckle. The

appearance is different from that

for 4WD.4. Wheel speed sensor

(for 4WD)

Located on knuckle. The

appearance of front sensor is

same with rear sensor.

2. ABS warning lamp

EBD warning lamp (ABS warning lamp +

Brake warning lamp)1. ABS hydraulic device and control unit

Located under the power steering fluid reservoir and

contains the pressure sensor.

2. COMPONENT

Page 1120 of 1336

0000-00

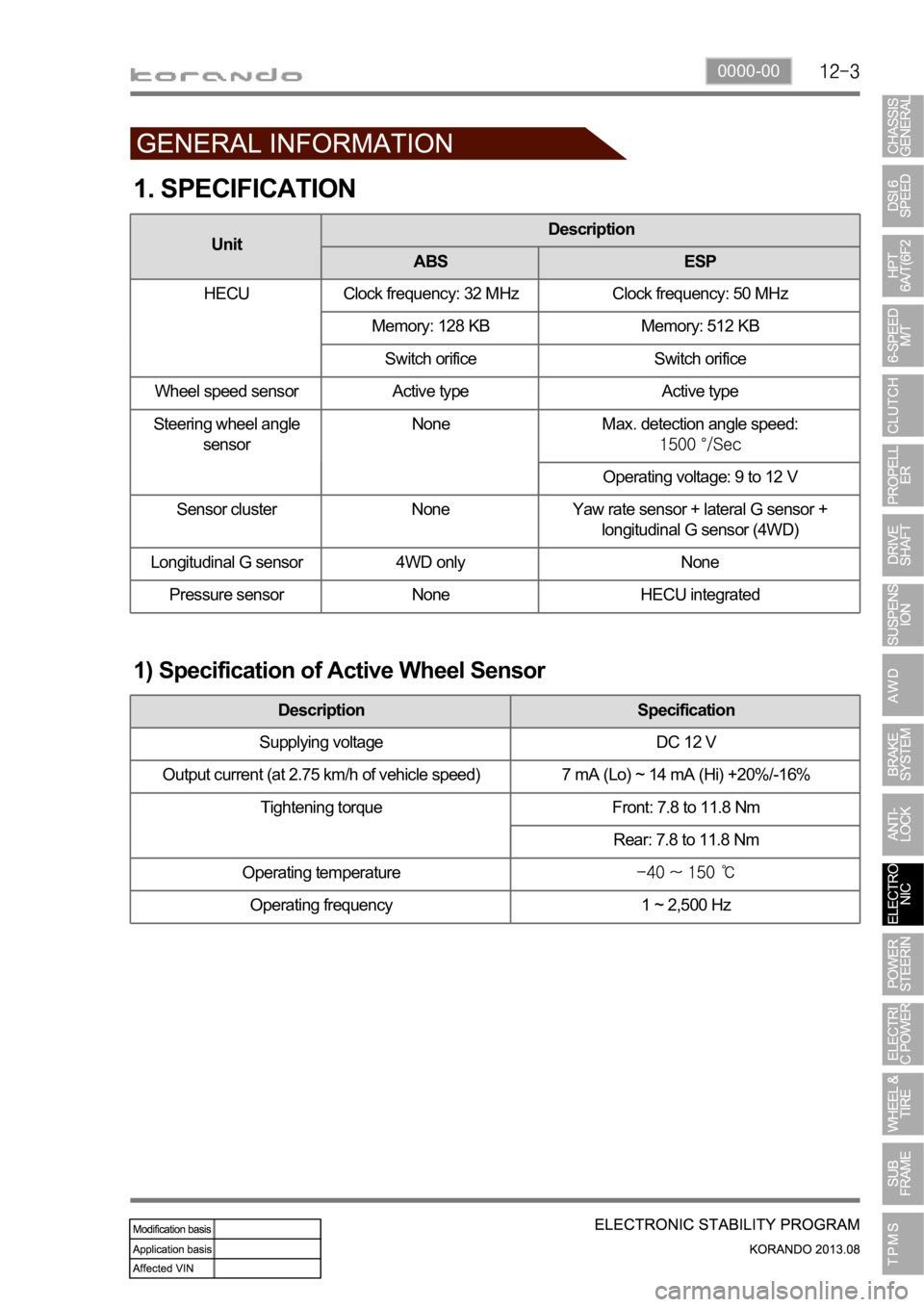

1. SPECIFICATION

1) Specification of Active Wheel Sensor

Description Specification

Supplying voltage DC 12 V

Output current (at 2.75 km/h of vehicle speed) 7 mA (Lo) ~ 14 mA (Hi) +20%/-16%

Tightening torque Front: 7.8 to 11.8 Nm

Rear: 7.8 to 11.8 Nm

Operating temperature

Operating frequency 1 ~ 2,500 Hz

UnitDescription

ABS ESP

HECU Clock frequency: 32 MHz Clock frequency: 50 MHz

Memory: 128 KB Memory: 512 KB

Switch orifice Switch orifice

Wheel speed sensor Active type Active type

Steering wheel angle

sensorNone Max. detection angle speed:

Operating voltage: 9 to 12 V

Sensor cluster None Yaw rate sensor + lateral G sensor +

longitudinal G sensor (4WD)

Longitudinal G sensor 4WD only None

Pressure sensor None HECU integrated