SSANGYONG KORANDO 2013 Service Manual

KORANDO 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57503/w960_57503-0.png

SSANGYONG KORANDO 2013 Service Manual

Trending: dashboard, service schedule, power steering, clock, water pump, lane assist, parking brake

Page 491 of 1336

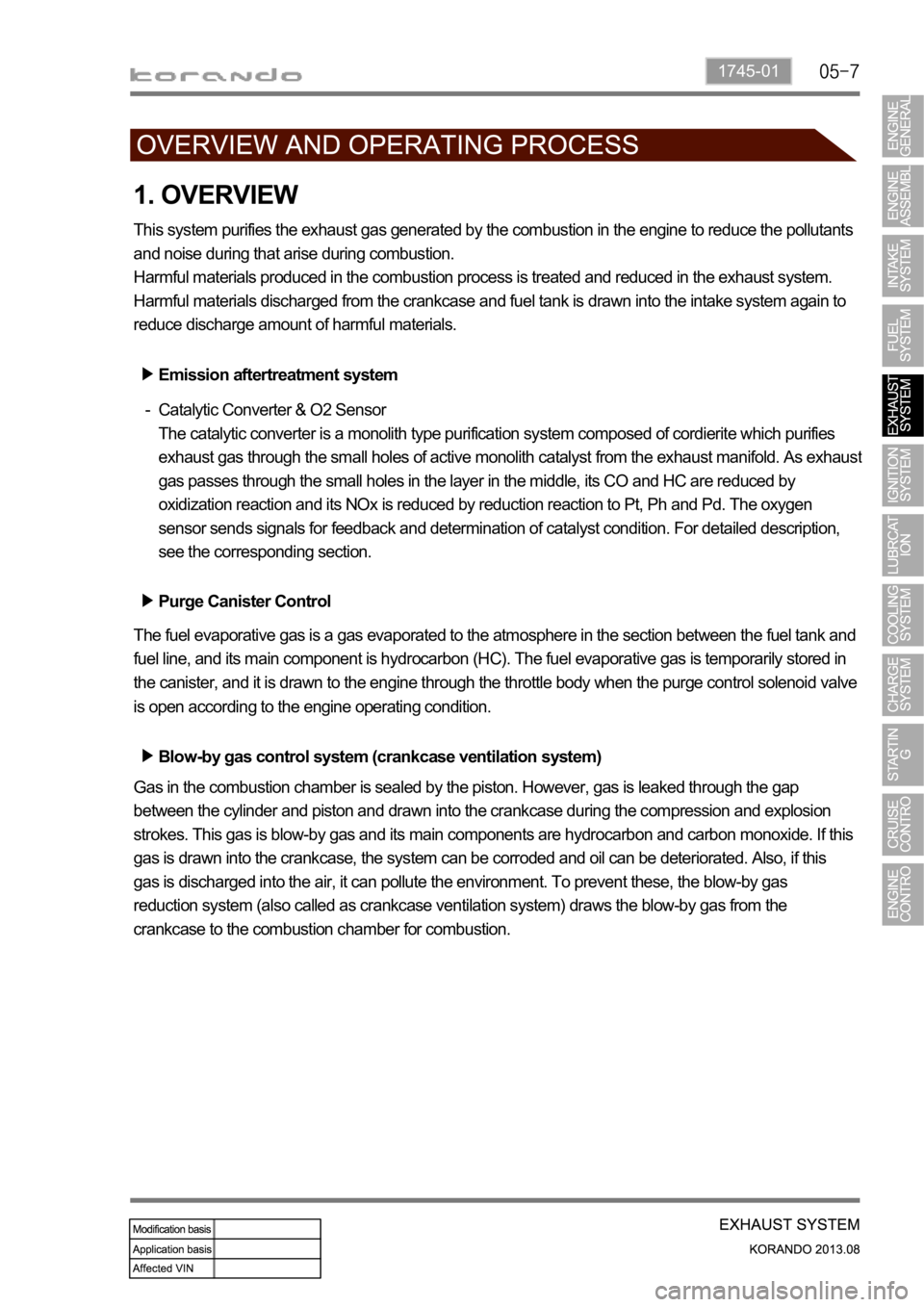

1745-01

WCC Compl

Exhaust FRT Pipe Assy

UCC Compl

Muffler Complete ?RR

Exhaust FRT Heat Protector

CTR Muffler Heat Protector

RR Muffler Heat Protector

Clamp

Gasket 1.

2.

3.

4.

5.

6.

7.

8.

9.Hanger

Hanger

Hanger

Nut

Nut

Bolt

Gasket Ring

Nut

CTR Muffler Complete 10.

11.

12.

13.

14.

15.

16.

19.

20.

Page 492 of 1336

3. CAUTIONS

Do not park the vehicle on flammable materials, such as grass, leaves and carpet.

Do not touch the catalyst or the exhaust gas ignition system when the engine is running.

If a misfire occurs in the combustion chamber or the emission of pollutant exceeds the specified level,

the catalyst can be damaged.

When servicing or replacing components of the exhaust system, makes sure that the components

are positioned at regular intervals from all other parts of the under body.

Be careful not to damage the exhaust system when lifting the vehicle from its side.

All components and body parts of the engine exhaust system should be inspected for crack, damage,

air hole, part loss and incorrect mounting location. Also check for any deformation which can result in

exhaust gas drawn into the vehicle.

Make sure that the exhaust pipe is cooled down sufficiently before working on it because it is still hot

right after the engine is stopped.

Wear protective gloves when removing the exhaust pipe. -

-

-

-

-

-

-

-

Page 493 of 1336

1745-01

1. OVERVIEW

This system purifies the exhaust gas generated by the combustion in the engine to reduce the pollutants

and noise during that arise during combustion.

Harmful materials produced in the combustion process is treated and reduced in the exhaust system.

Harmful materials discharged from the crankcase and fuel tank is drawn into the intake system again to

reduce discharge amount of harmful materials.

Emission aftertreatment system

Catalytic Converter & O2 Sensor

The catalytic converter is a monolith type purification system composed of cordierite which purifies

exhaust gas through the small holes of active monolith catalyst from the exhaust manifold. As exhaus

t

gas passes through the small holes in the layer in the middle, its CO and HC are reduced by

oxidization reaction and its NOx is reduced by reduction reaction to Pt, Ph and Pd. The oxygen

sensor sends signals for feedback and determination of catalyst condition. For detailed description,

see the corresponding section. -

The fuel evaporative gas is a gas evaporated to the atmosphere in the section between the fuel tank and

fuel line, and its main component is hydrocarbon (HC). The fuel evaporative gas is temporarily stored in

the canister, and it is drawn to the engine through the throttle body when the purge control solenoid valve

is open according to the engine operating condition.

Gas in the combustion chamber is sealed by the piston. However, gas is leaked through the gap

between the cylinder and piston and drawn into the crankcase during the compression and explosion

strokes. This gas is blow-by gas and its main components are hydrocarbon and carbon monoxide. If this

gas is drawn into the crankcase, the system can be corroded and oil can be deteriorated. Also, if this

gas is discharged into the air, it can pollute the environment. To prevent these, the blow-by gas

reduction system (also called as crankcase ventilation system) draws the blow-by gas from the

crankcase to the combustion chamber for combustion.

Purge Canister Control

Blow-by gas control system (crankcase ventilation system)

Page 494 of 1336

PCV valve

2. COMPONENTS

Engine ECUWCCEngine CHECK lamp

Blow-by hoseExhaust manifold

Page 495 of 1336

2414-00

Rear oxygen sensor

Exhaust No.2Exhaust No.1Exhaust No.3

(main muffler)

UCCFront oxygen sensor

Page 496 of 1336

3. WORK FLOW IN EXHAUST SYSTEM

Page 497 of 1336

1745-01

4. INPUT/OUTPUT DEVICES

Page 498 of 1336

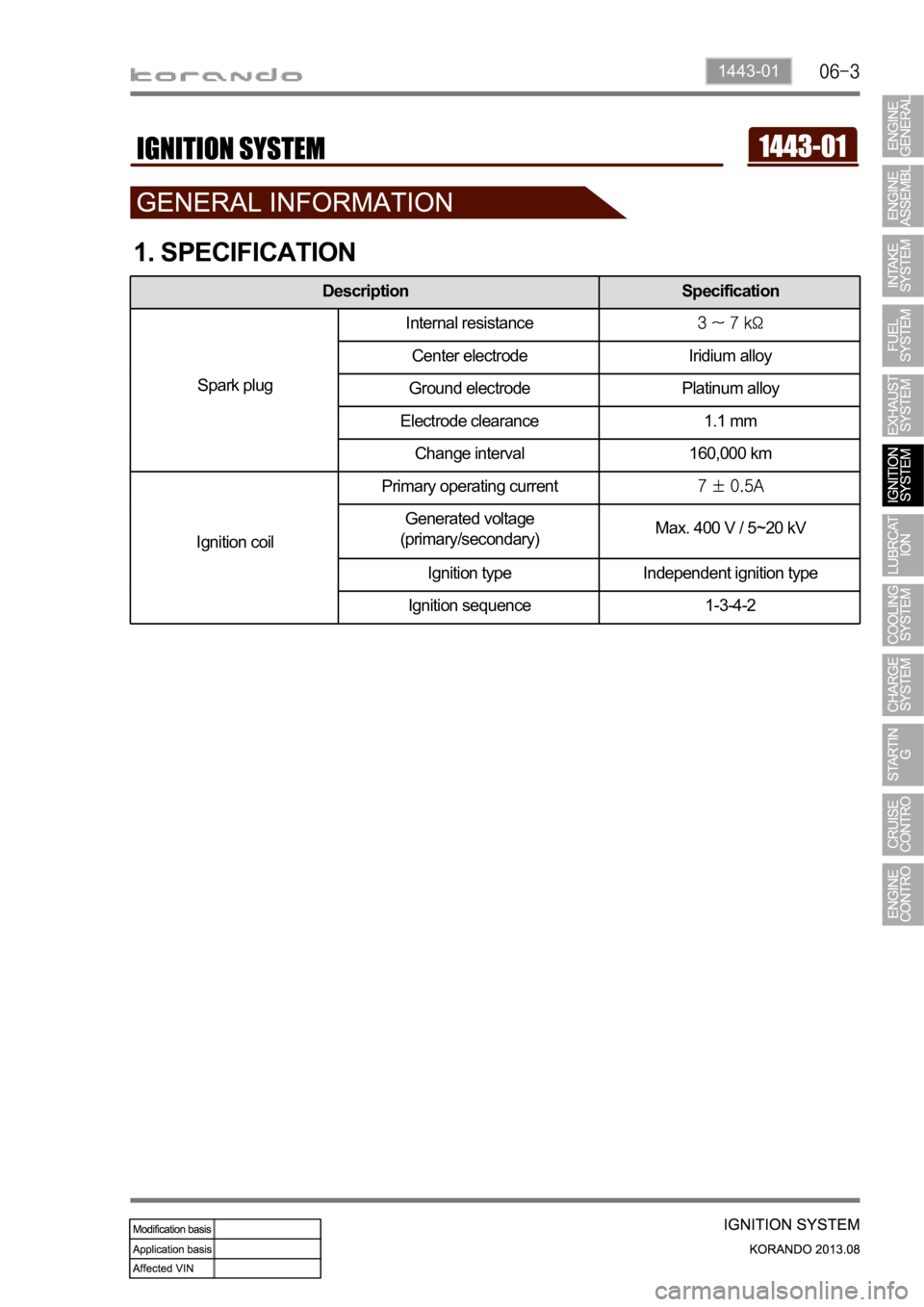

1443-01

1. SPECIFICATION

Description Specification

Spark plugInternal resistance

Center electrode Iridium alloy

Ground electrode Platinum alloy

Electrode clearance 1.1 mm

Change interval 160,000 km

Ignition coilPrimary operating current

Generated voltage

(primary/secondary)Max. 400 V / 5~20 kV

Ignition type Independent ignition type

Ignition sequence 1-3-4-2

Page 499 of 1336

2. LAYOUT

Ignition Coil

Bolt

Spark Plug 1.

2.

3.

Page 500 of 1336

1443-01

1. OVERVIEW

The ignition system is to supply high voltage generated from the ignition coil to the spark plug. The

G20DF engine is equipped with the independent type direct ignition system that the ignition coil is

installed in each cylinder.

The basic ignition timing in each cylinder is determined by the signals from camshaft position sensor and

crankshaft position sensor.

This ignition system controls the electronic ignition timing received from the engine ECU. To control the

ignition timing precisely, the ECU use the information below:

Engine load

Coolant temperature

Intake air temperature

Engine rpm

Camshaft position sensor (CPS)

Crankshaft position sensor (CKS) -

-

-

-

-

-

If the signal from the camshaft position sensor is not delivered to the engine ECU, the ignition coil and

fuel system cannot be operated.

Trending: maintenance schedule, power steering fluid, tire pressure, brake fluid, air condition, radiator, immobilizer