SSANGYONG KORANDO 2013 Service Manual

KORANDO 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57503/w960_57503-0.png

SSANGYONG KORANDO 2013 Service Manual

Page 185 of 1336

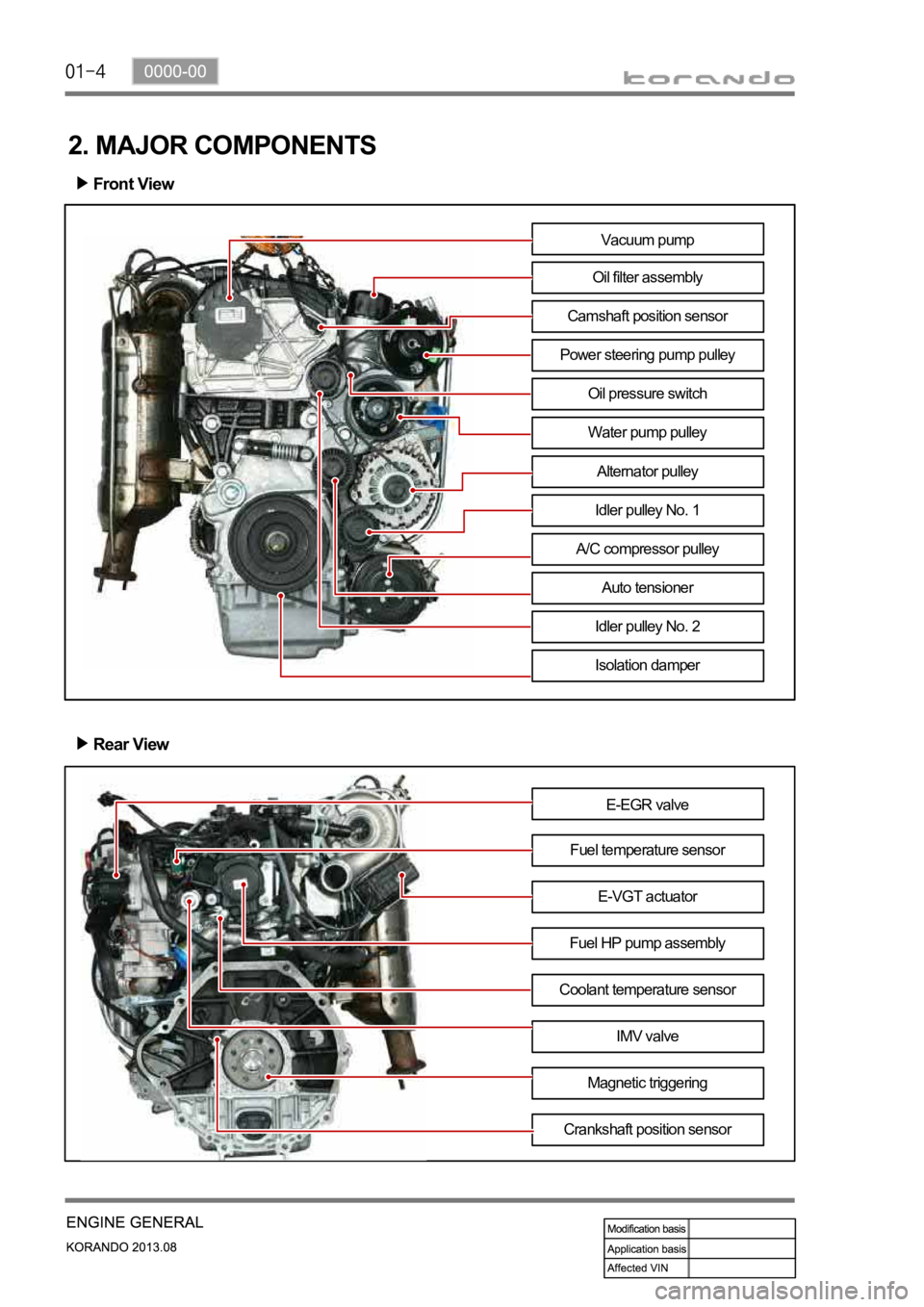

2. MAJOR COMPONENTS

Front View

Rear View

E-EGR valve

Fuel temperature sensor

Fuel HP pump assemblyE-VGT actuator

Coolant temperature sensor

IMV valve

Magnetic triggering

Crankshaft position sensor

Vacuum pump

Oil filter assembly

Camshaft position sensor

Power steering pump pulley

Water pump pulley

Alternator pulley

Idler pulley No. 1

A/C compressor pulley

Auto tensioner

Idler pulley No. 2

Isolation damper

Oil pressure switch

Page 200 of 1336

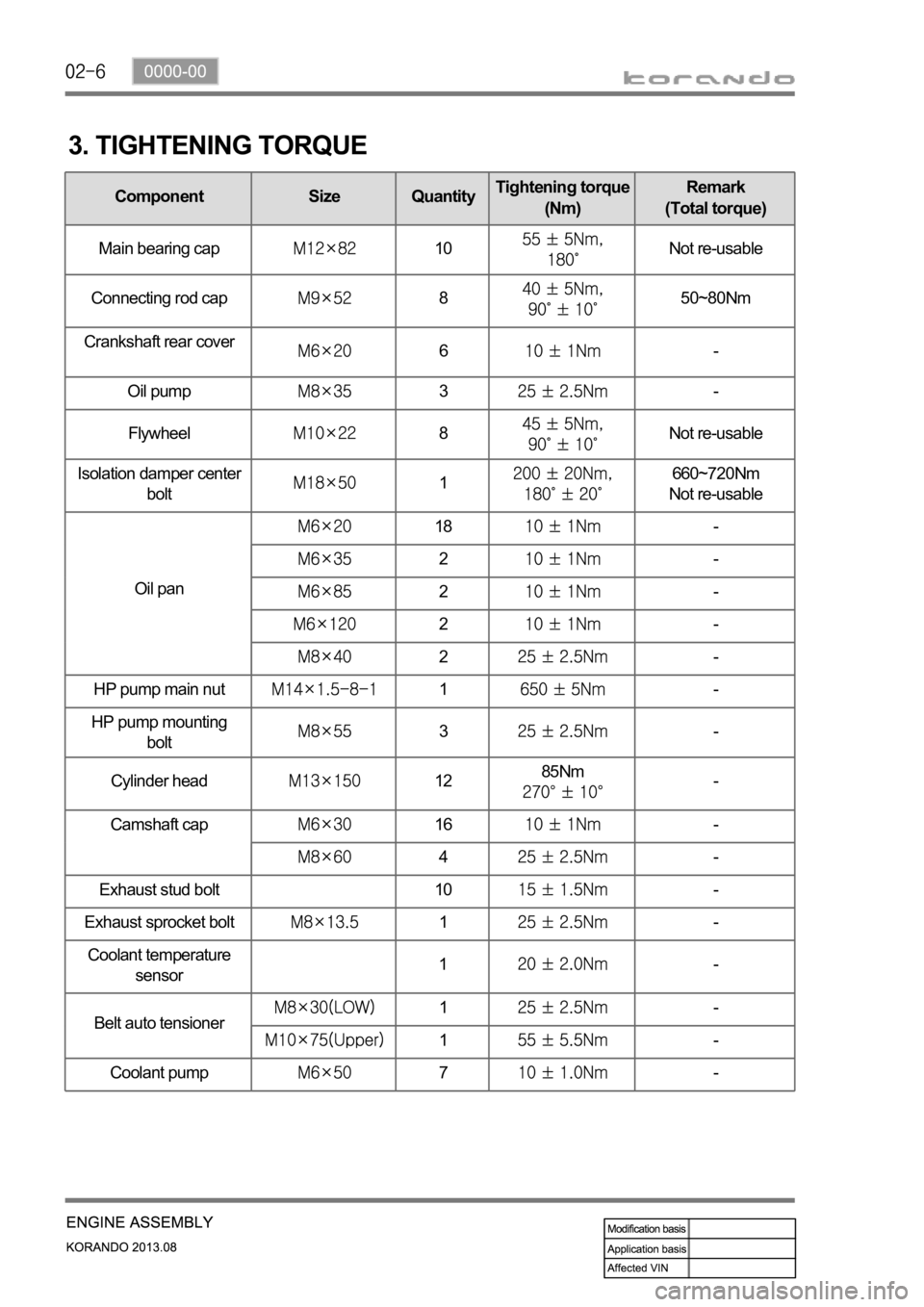

3. TIGHTENING TORQUE

Component Size QuantityTightening torque

(Nm)Remark

(Total torque)

Main bearing cap

10Not re-usable

Connecting rod cap

850~80Nm

Crankshaft rear cover

6-

Oil pump

3-

Flywheel

8Not re-usable

Isolation damper center

bolt

1660~720Nm

Not re-usable

Oil pan

18-

2-

2-

2-

2-

HP pump main nut

1-

HP pump mounting

bolt

3-

Cylinder head

1285Nm-

Camshaft cap

16-

4-

Exhaust stud bolt 10

-

Exhaust sprocket bolt

1-

Coolant temperature

sensor1-

Belt auto tensioner

1-

1-

Coolant pump

7-

Page 208 of 1336

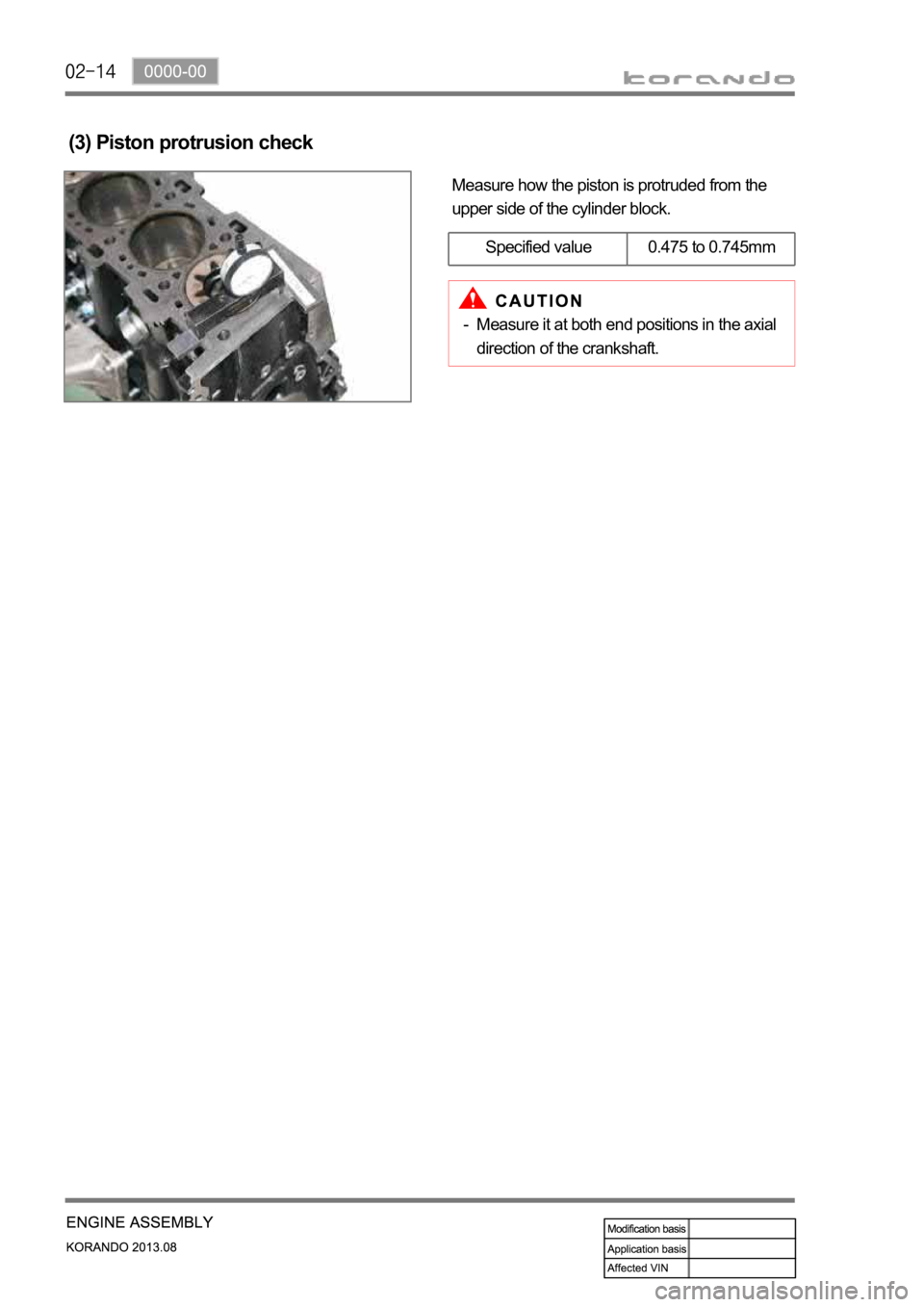

Measure how the piston is protruded from the

upper side of the cylinder block.

(3) Piston protrusion check

Specified value 0.475 to 0.745mm

Measure it at both end positions in the axial

direction of the crankshaft. -

Page 212 of 1336

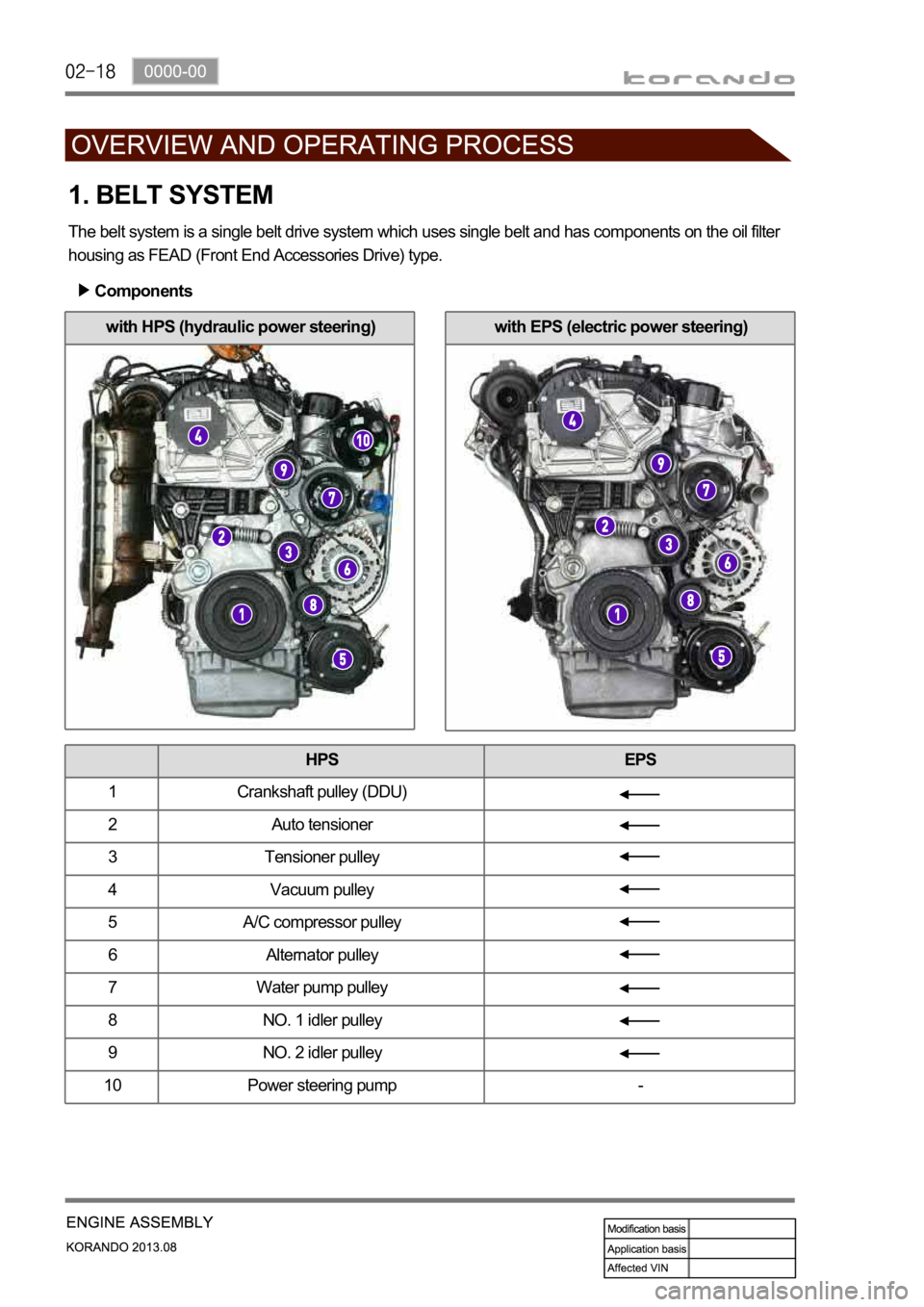

with EPS (electric power steering)with HPS (hydraulic power steering)

1. BELT SYSTEM

The belt system is a single belt drive system which uses single belt and has components on the oil filter

housing as FEAD (Front End Accessories Drive) type.

Components

HPS EPS

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pulley

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 NO. 1 idler pulley

9 NO. 2 idler pulley

10 Power steering pump -

Page 219 of 1336

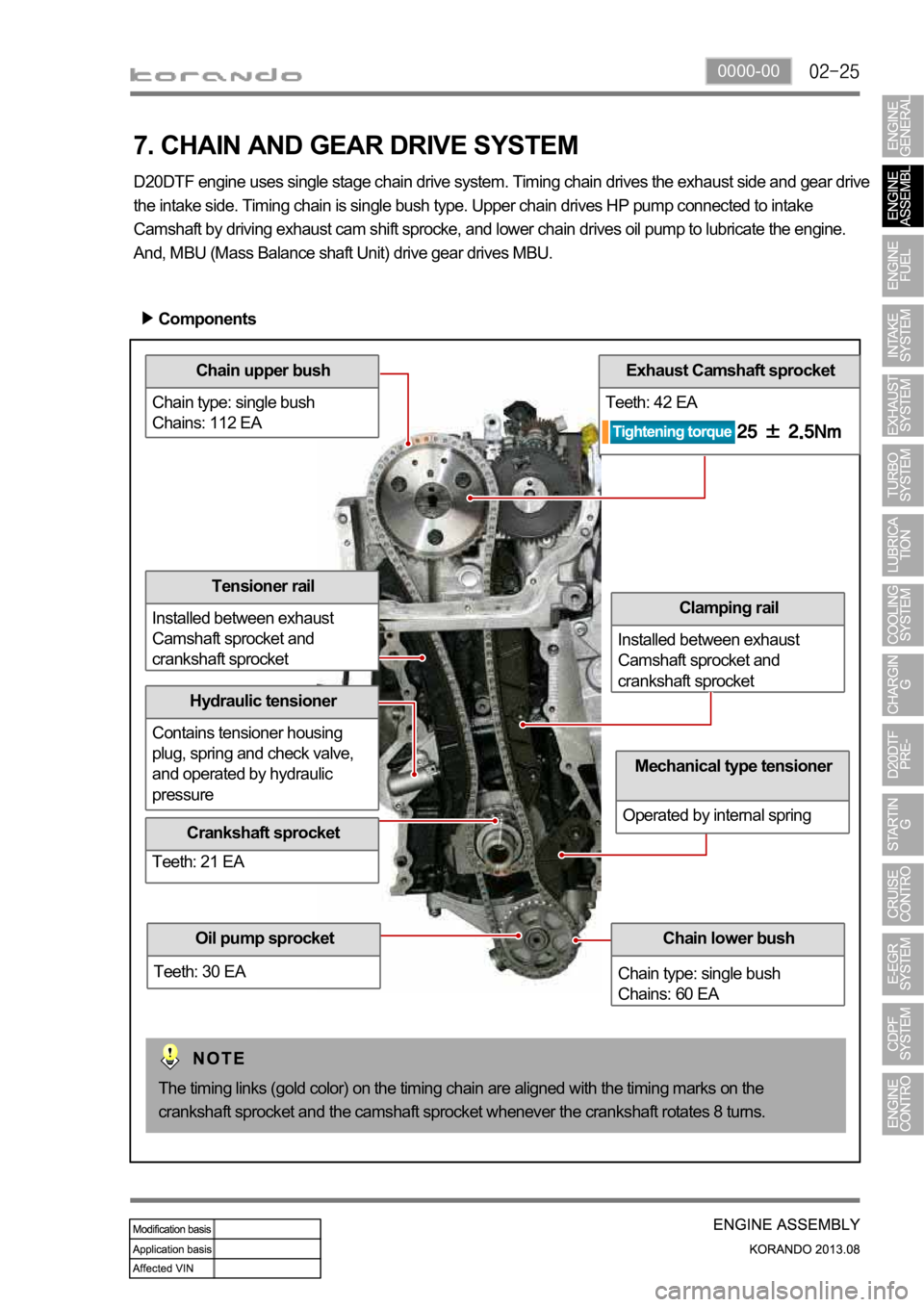

0000-00

Chain upper bush

Chain type: single bush

Chains: 112 EA

Hydraulic tensioner

Contains tensioner housing

plug, spring and check valve,

and operated by hydraulic

pressure

Exhaust Camshaft sprocket

Teeth: 42 EA

Clamping rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

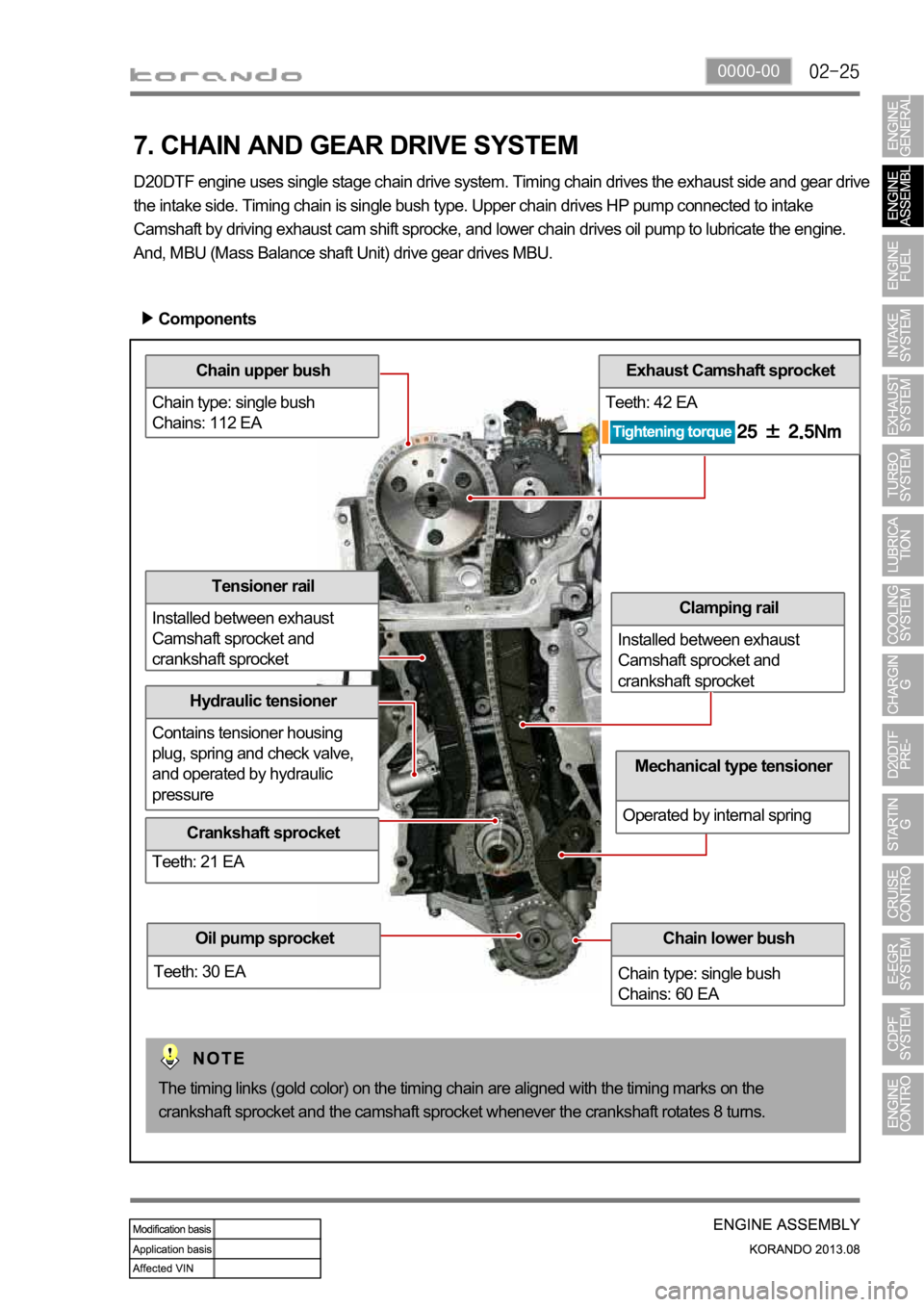

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTF engine uses single stage chain drive system. Timing chain drives the exhaust side and gear drive

the intake side. Timing chain is single bush type. Upper chain drives HP pump connected to intake

Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil pump to lubricate the engine.

And, MBU (Mass Balance shaft Unit) drive gear drives MBU.

Components

Chain lower bush

Chain type: single bush

Chains: 60 EA

Mechanical type tensioner

Operated by internal spring

The timing links (gold color) on the timing chain are aligned with the timing marks on the

crankshaft sprocket and the camshaft sprocket whenever the crankshaft rotates 8 turns.

Oil pump sprocket

Teeth: 30 EA

Tensioner rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

Crankshaft sprocket

Teeth: 21 EA

Page 222 of 1336

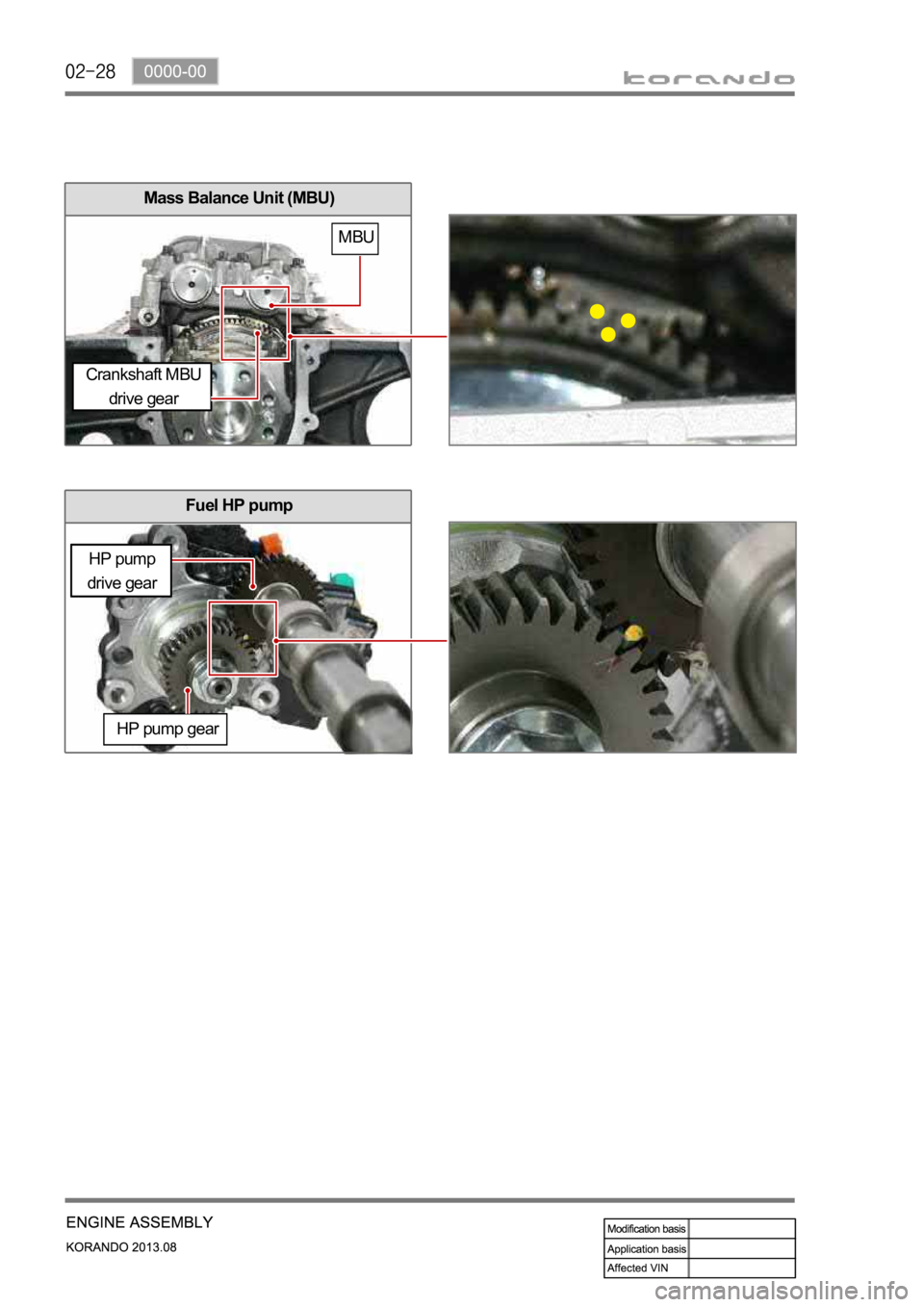

Mass Balance Unit (MBU)

Fuel HP pump

HP pump gear

Crankshaft MBU

drive gear

MBU

HP pump

drive gear

Page 226 of 1336

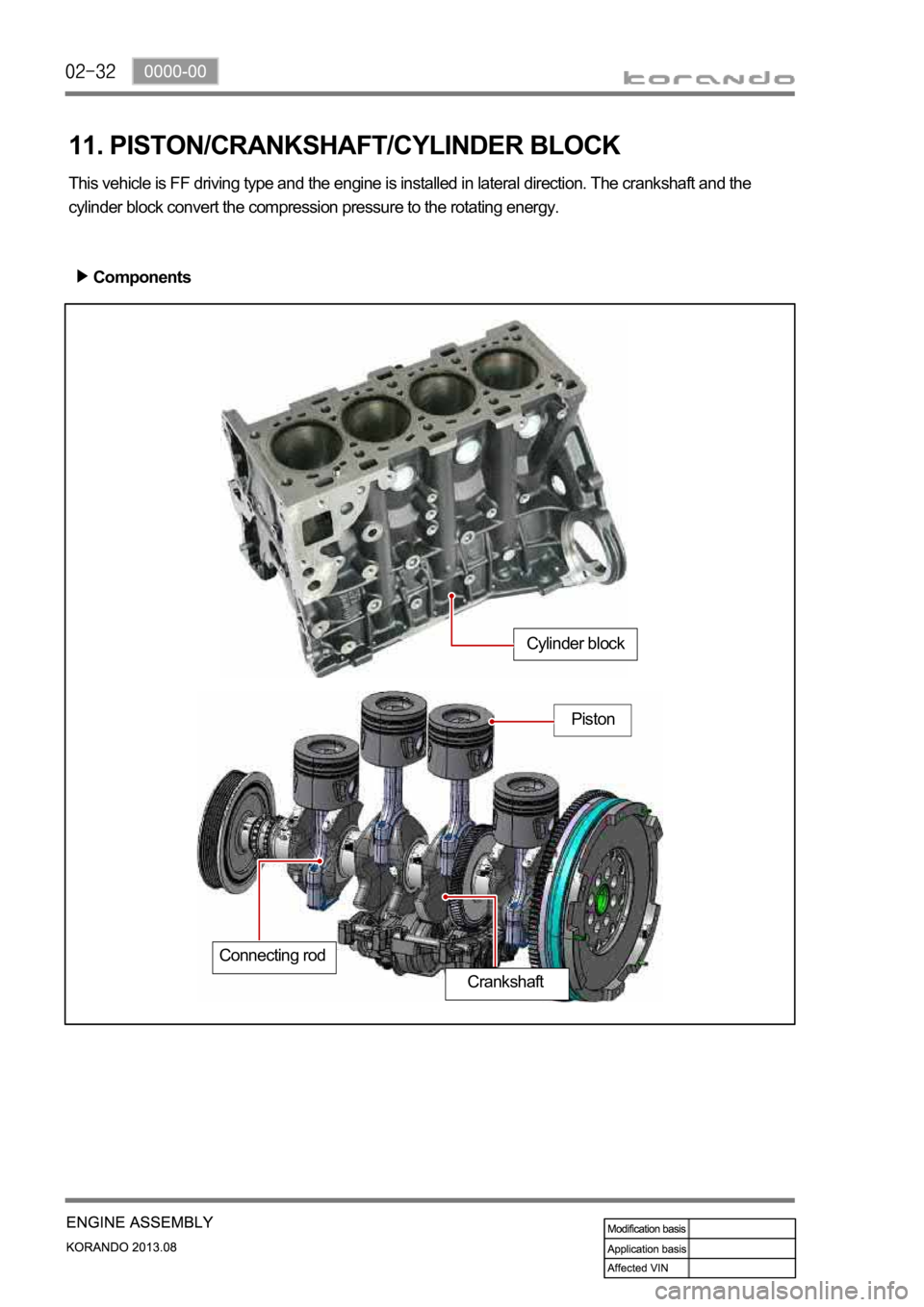

11. PISTON/CRANKSHAFT/CYLINDER BLOCK

This vehicle is FF driving type and the engine is installed in lateral direction. The crankshaft and the

cylinder block convert the compression pressure to the rotating energy.

Components

Cylinder block

Piston

Connecting rod

Crankshaft

Page 251 of 1336

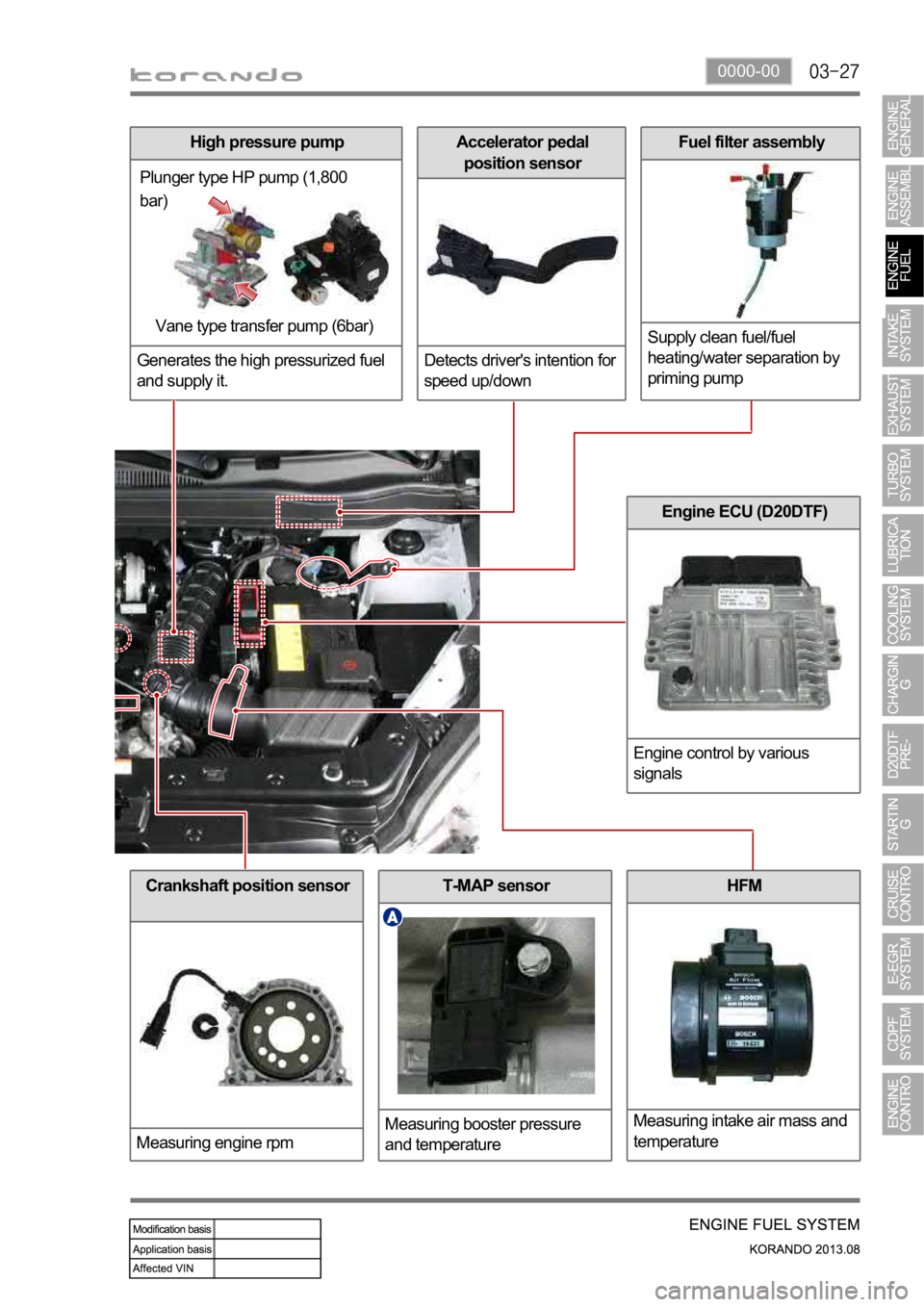

0000-00

Crankshaft position sensor

Measuring engine rpmT-MAP sensor

Measuring booster pressure

and temperatureHFM

Measuring intake air mass and

temperature

Engine ECU (D20DTF)

Engine control by various

signals

High pressure pump

Generates the high pressurized fuel

and supply it.

Plunger type HP pump (1,800

bar)

Vane type transfer pump (6bar)

Accelerator pedal

position sensor

Detects driver's intention for

speed up/downFuel filter assembly

Supply clean fuel/fuel

heating/water separation by

priming pump

Page 254 of 1336

The engine ECU calculates the accelerator pedal based on the input signals from various sensors, and

controls the overall operation of the vehicle.

The ECU receives the signals from various sensor through data line, and performs effective air-fuel ratio

control based on these signals.

The crankshaft speed (position) sensor measures the engine speed, and the camshaft speed (position)

sensor determines the order of injections, and the ECU detects the amount of the accelerator pedal

depressed (driver's will) by receiving the electrical signals from the accelerator pedal sensor.

The mass air flow sensor detects the volume of intake air and sends the value to the ECU.

The major function of the ECU is controlling air-fuel ratio to reduce the emission level (EGR valve control)

by detecting instantaneous air flow change with the signals from the mass air flow sensor.

Also, the ECU uses the signals from the coolant temperature & air temperature sensors, booster pressure

sensor, atmospheric pressure sensor to: a) determine injection starting point and set value for pilot

injection, and b) deal with various operations and variable conditions.

Page 307 of 1336

0000-00

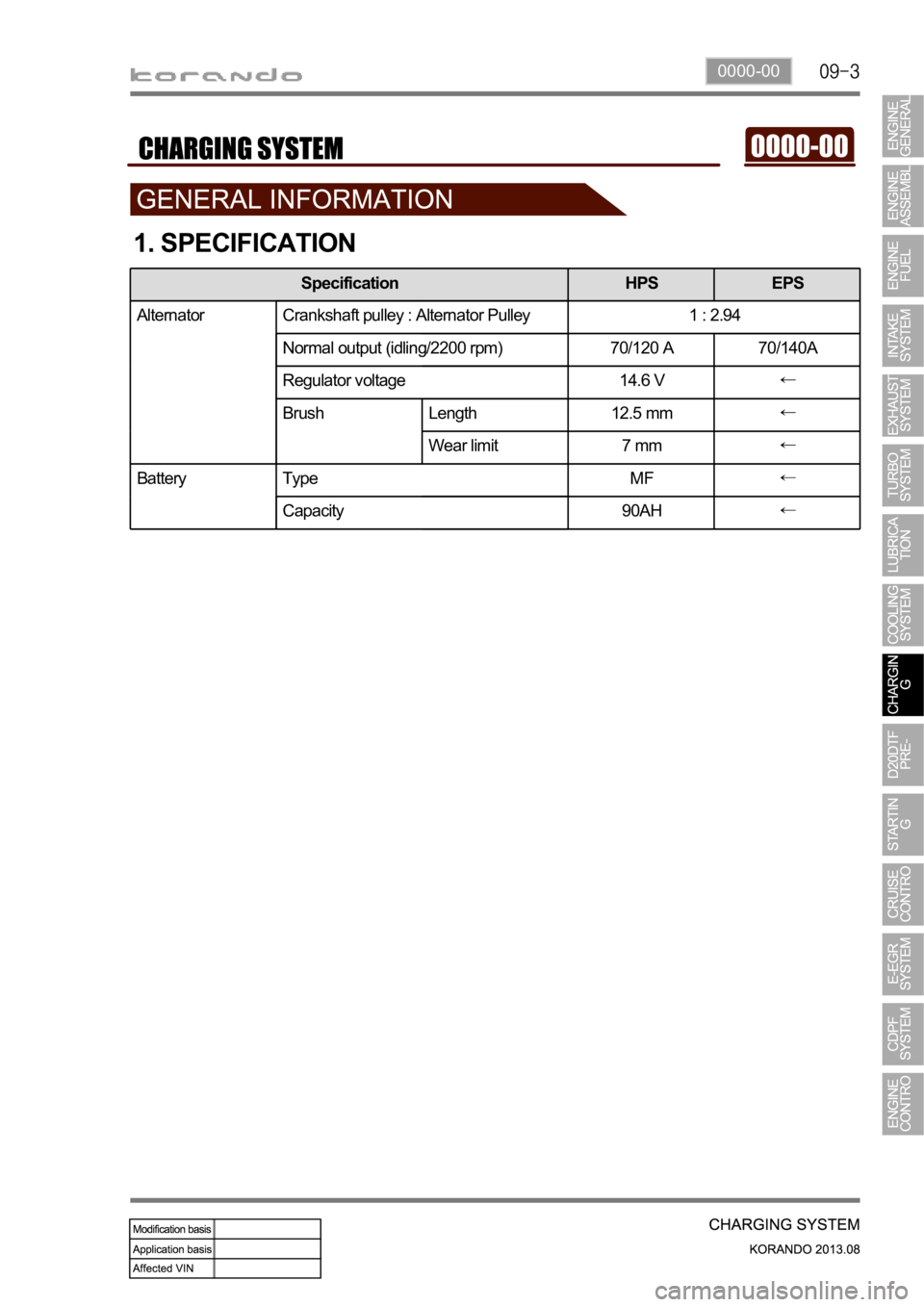

1. SPECIFICATION

Specification HPS EPS

Alternator Crankshaft pulley : Alternator Pulley 1 : 2.94

Normal output (idling/2200 rpm) 70/120 A 70/140A

Regulator voltage 14.6 V

Brush Length 12.5 mm

Wear limit 7 mm

Battery Type MF

Capacity 90AH