fuel pressure SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 185 of 1336

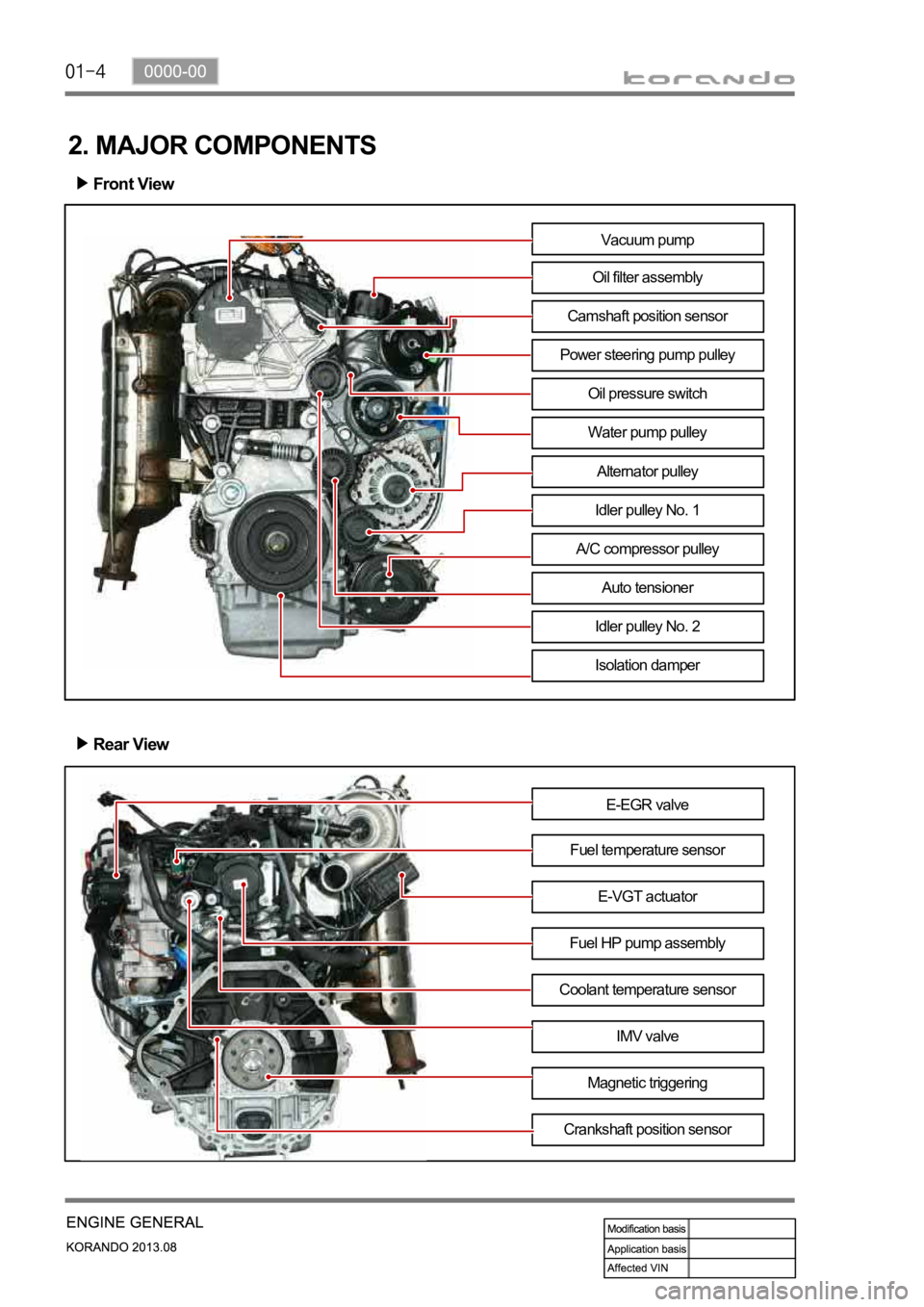

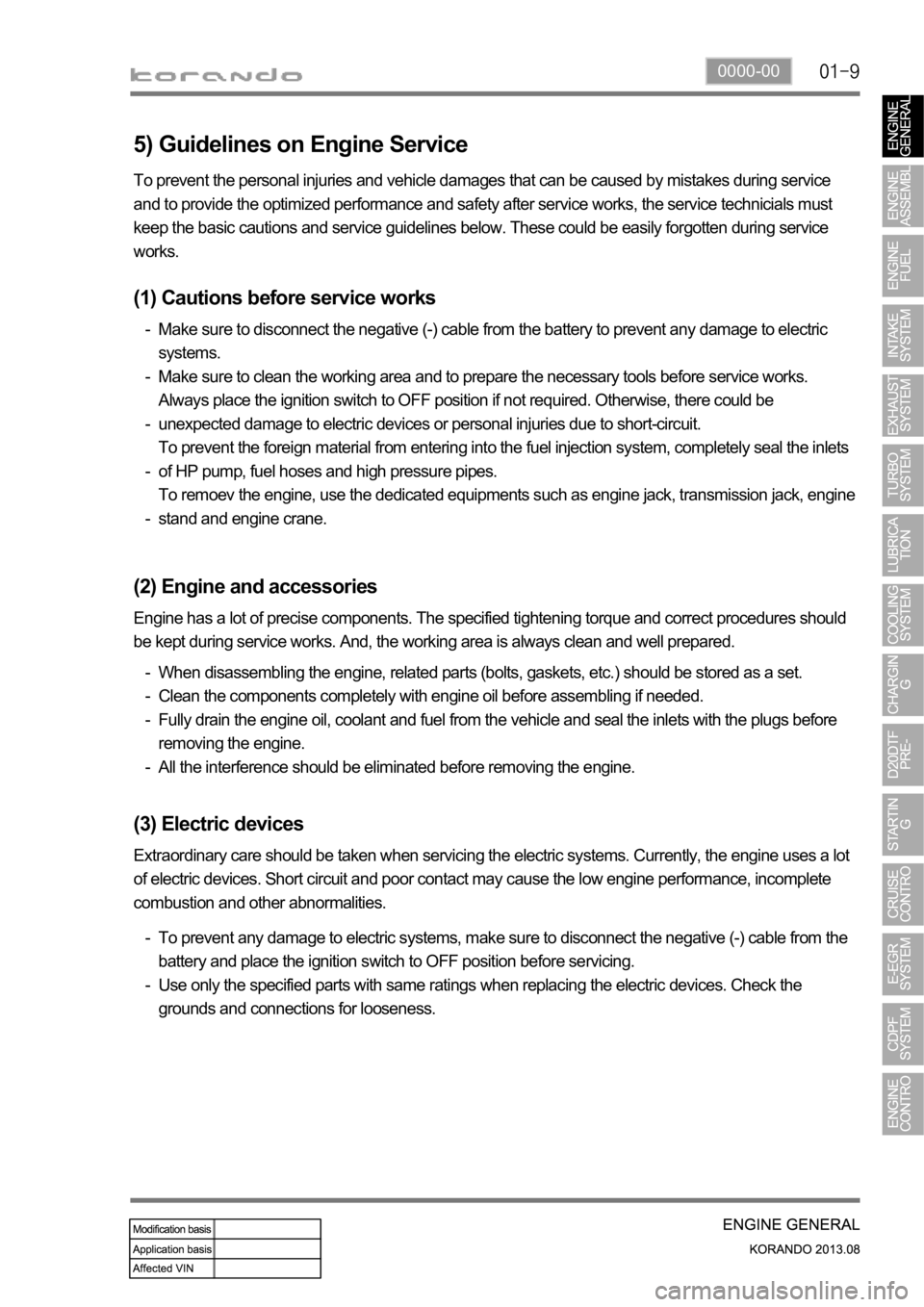

2. MAJOR COMPONENTS

Front View

Rear View

E-EGR valve

Fuel temperature sensor

Fuel HP pump assemblyE-VGT actuator

Coolant temperature sensor

IMV valve

Magnetic triggering

Crankshaft position sensor

Vacuum pump

Oil filter assembly

Camshaft position sensor

Power steering pump pulley

Water pump pulley

Alternator pulley

Idler pulley No. 1

A/C compressor pulley

Auto tensioner

Idler pulley No. 2

Isolation damper

Oil pressure switch

Page 190 of 1336

0000-00

5) Guidelines on Engine Service

(1) Cautions before service works

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

Make sure to clean the working area and to prepare the necessary tools before service works.

Always place the ignition switch to OFF position if not required. Otherwise, there could be

unexpected damage to electric devices or personal injuries due to short-circuit.

To prevent the foreign material from entering into the fuel injection system, completely seal the inlets

of HP pump, fuel hoses and high pressure pipes.

To remoev the engine, use the dedicated equipments such as engine jack, transmission jack, engine

stand and engine crane. -

-

-

-

-

(2) Engine and accessories

When disassembling the engine, related parts (bolts, gaskets, etc.) should be stored as a set.

Clean the components completely with engine oil before assembling if needed.

Fully drain the engine oil, coolant and fuel from the vehicle and seal the inlets with the plugs before

removing the engine.

All the interference should be eliminated before removing the engine. -

-

-

-

(3) Electric devices

To prevent any damage to electric systems, make sure to disconnect the negative (-) cable from the

battery and place the ignition switch to OFF position before servicing.

Use only the specified parts with same ratings when replacing the electric devices. Check the

grounds and connections for looseness. -

- To prevent the personal injuries and vehicle damages that can be caused by mistakes during service

and to provide the optimized performance and safety after service works, the service technicials must

keep the basic cautions and service guidelines below. These could be easily forgotten during service

works.

Engine has a lot of precise components. The specified tightening torque and correct procedures should

be kept during service works. And, the working area is always clean and well prepared.

Extraordinary care should be taken when servicing the electric systems. Currently, the engine uses a lot

of electric devices. Short circuit and poor contact may cause the low engine performance, incomplete

combustion and other abnormalities.

Page 202 of 1336

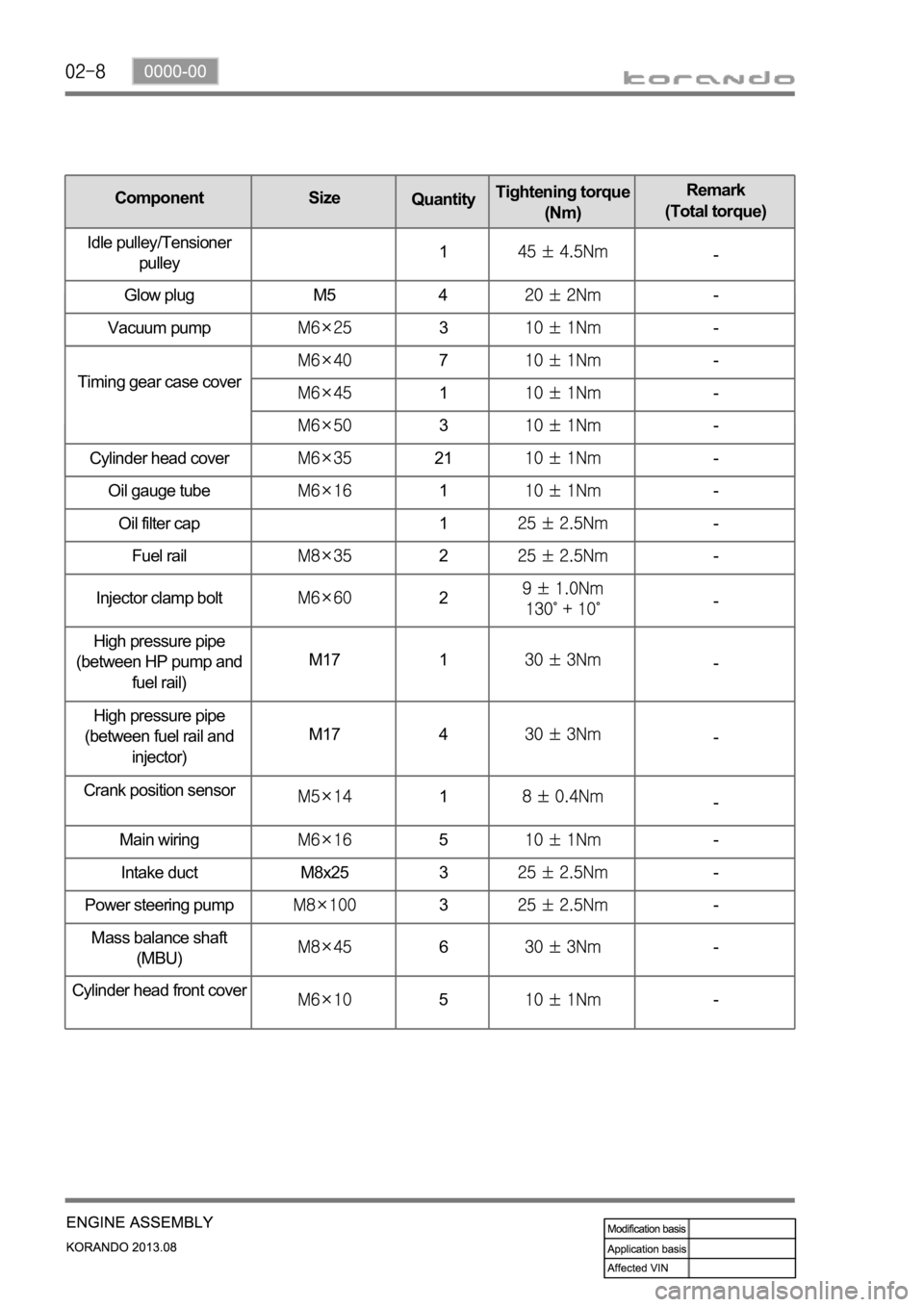

Oil gauge tube1-

Oil filter cap 1

-

Fuel rail

2-

Injector clamp bolt

2-

High pressure pipe

(between HP pump and

fuel rail)M17 1

-

High pressure pipe

(between fuel rail and

injector)M17 4

-

Crank position sensor

1-

Main wiring

5-

Intake duct M8x25 3

-

Power steering pump

3-

Mass balance shaft

(MBU)

6-

Cylinder head front cove

r5-

Timing gear case cover

7-

1-

3-

Cylinder head cover

21-

Component Size

QuantityTightening torque

(Nm)Remark

(Total torque)

Idle pulley/Tensioner

pulley1

-

Glow plug M5 4

-

Vacuum pump

3-

Page 227 of 1336

0000-00

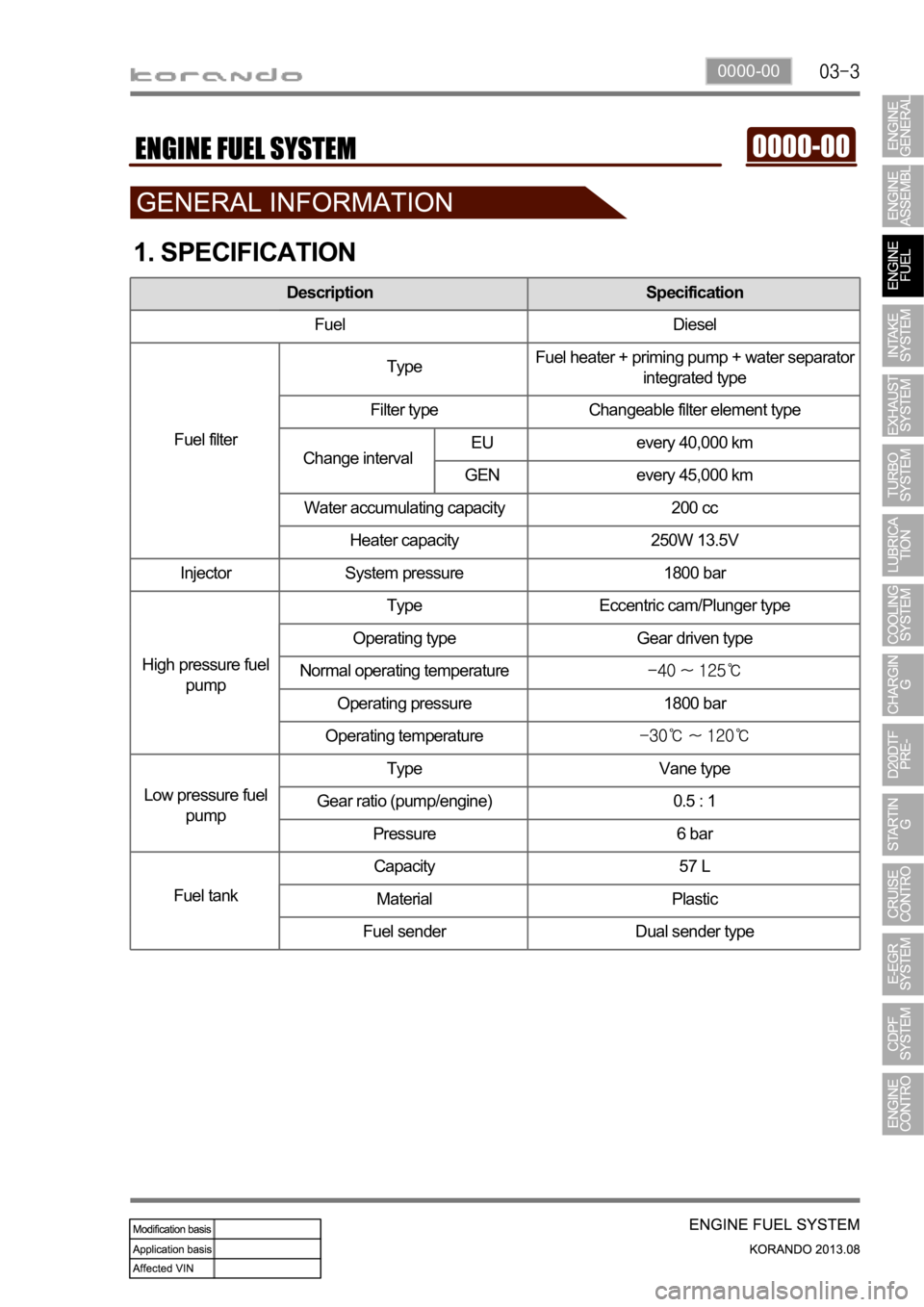

1. SPECIFICATION

Description Specification

Fuel Diesel

Fuel filterTypeFuel heater + priming pump + water separator

integrated type

Filter type Changeable filter element type

every 40,000 km

every 45,000 km

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature

Operating pressure 1800 bar

Operating temperature

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tankCapacity 57 L

Material Plastic

Fuel sender Dual sender type

Change intervalEU

GEN

Page 229 of 1336

0000-00

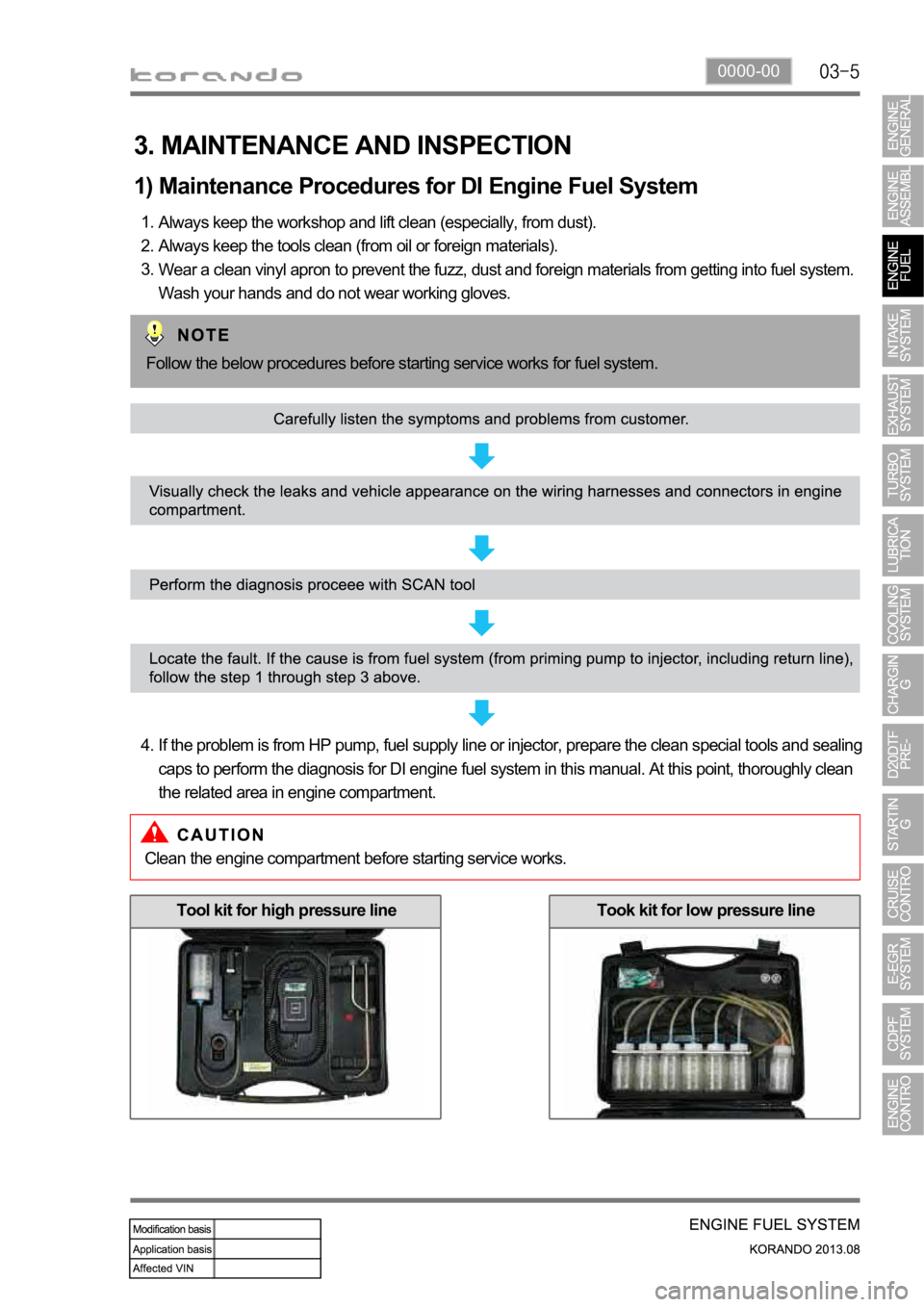

3. MAINTENANCE AND INSPECTION

1) Maintenance Procedures for DI Engine Fuel System

Always keep the workshop and lift clean (especially, from dust).

Always keep the tools clean (from oil or foreign materials).

Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel system.

Wash your hands and do not wear working gloves. 1.

2.

3.

Follow the below procedures before starting service works for fuel system.

If the problem is from HP pump, fuel supply line or injector, prepare the clean special tools and sealing

caps to perform the diagnosis for DI engine fuel system in this manual. At this point, thoroughly clean

the related area in engine compartment. 4.

Clean the engine compartment before starting service works.

Tool kit for high pressure lineTook kit for low pressure line

Page 232 of 1336

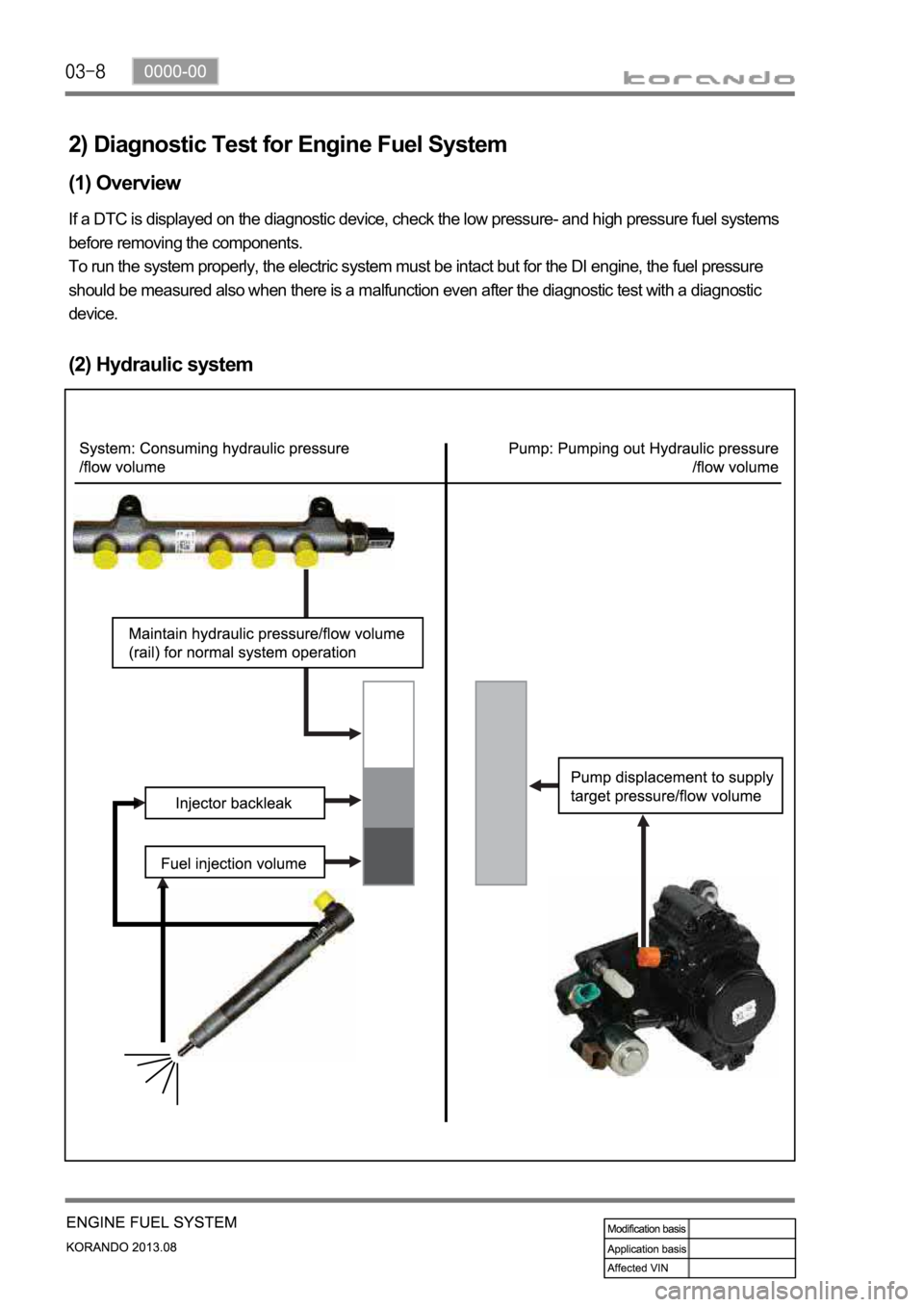

2) Diagnostic Test for Engine Fuel System

(1) Overview

If a DTC is displayed on the diagnostic device, check the low pressure- and high pressure fuel systems

before removing the components.

To run the system properly, the electric system must be intact but for the DI engine, the fuel pressure

should be measured also when there is a malfunction even after the diagnostic test with a diagnostic

device.

(2) Hydraulic system

Page 234 of 1336

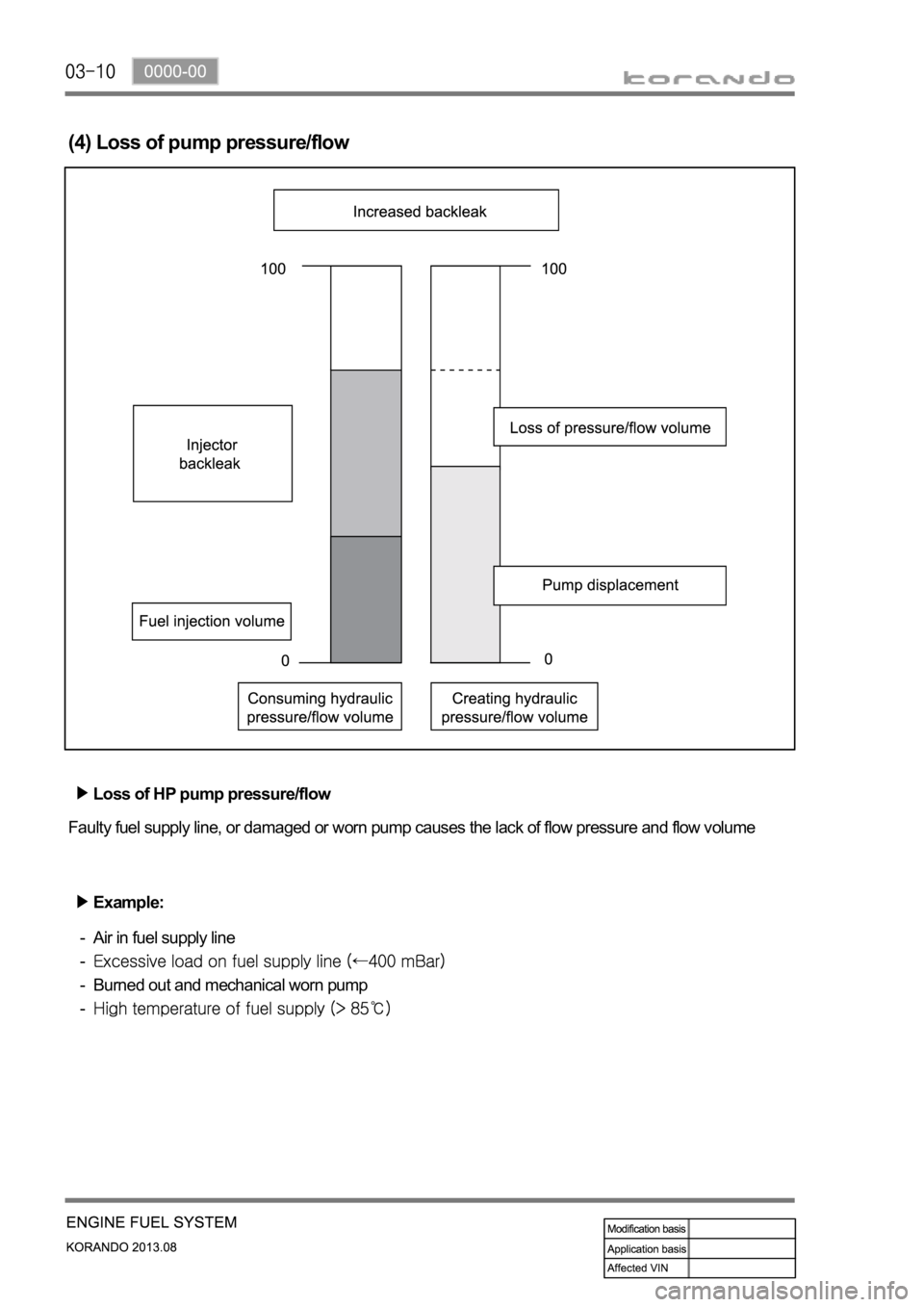

(4) Loss of pump pressure/flow

Loss of HP pump pressure/flow

Faulty fuel supply line, or damaged or worn pump causes the lack of flow pressure and flow volume

Example:

Air in fuel supply line

Burned out and mechanical worn pump

-

-

-

-

Page 235 of 1336

0000-00

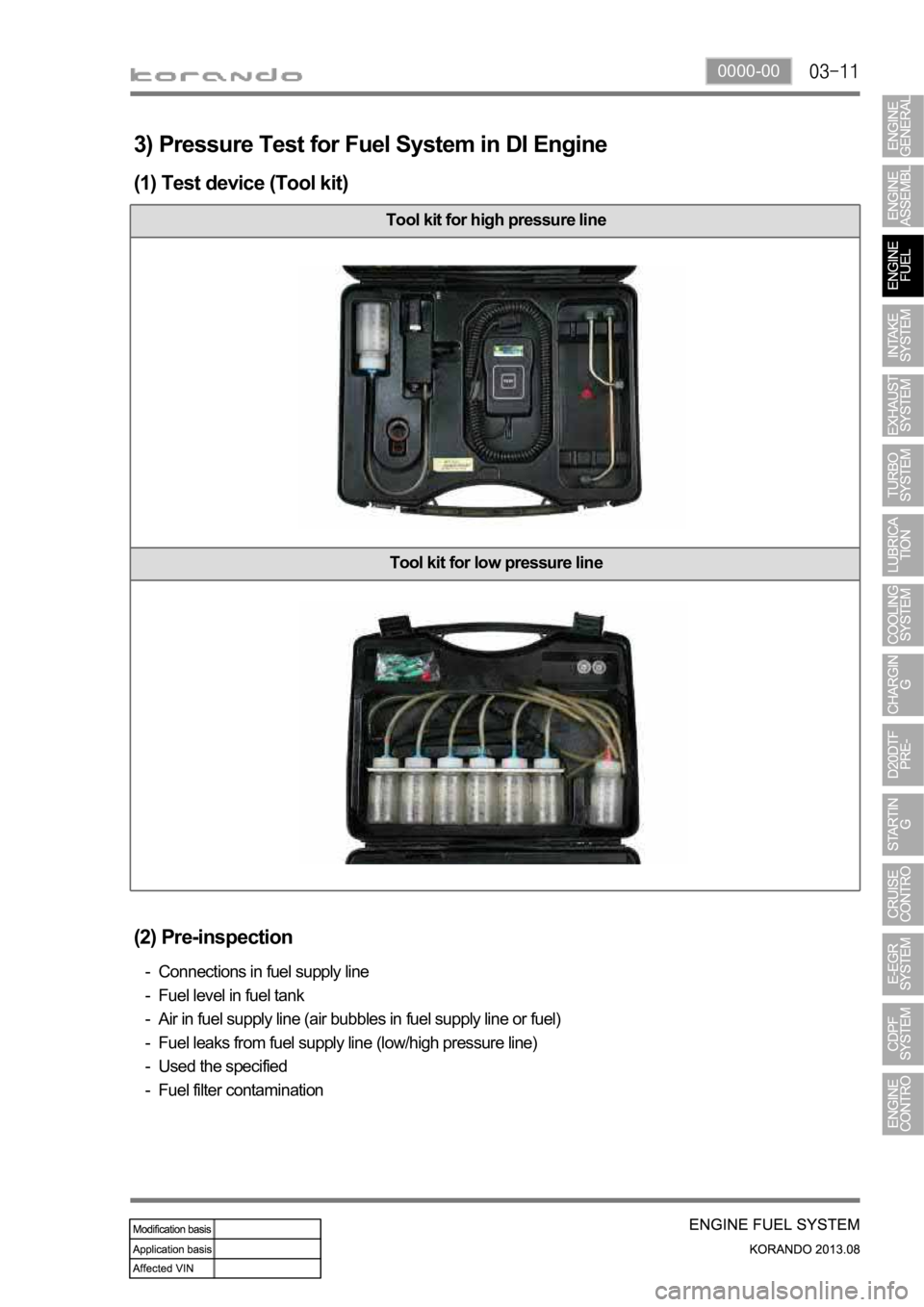

3) Pressure Test for Fuel System in DI Engine

(1) Test device (Tool kit)

Tool kit for high pressure line

Tool kit for low pressure line

(2) Pre-inspection

Connections in fuel supply line

Fuel level in fuel tank

Air in fuel supply line (air bubbles in fuel supply line or fuel)

Fuel leaks from fuel supply line (low/high pressure line)

Used the specified

Fuel filter contamination -

-

-

-

-

-

Page 236 of 1336

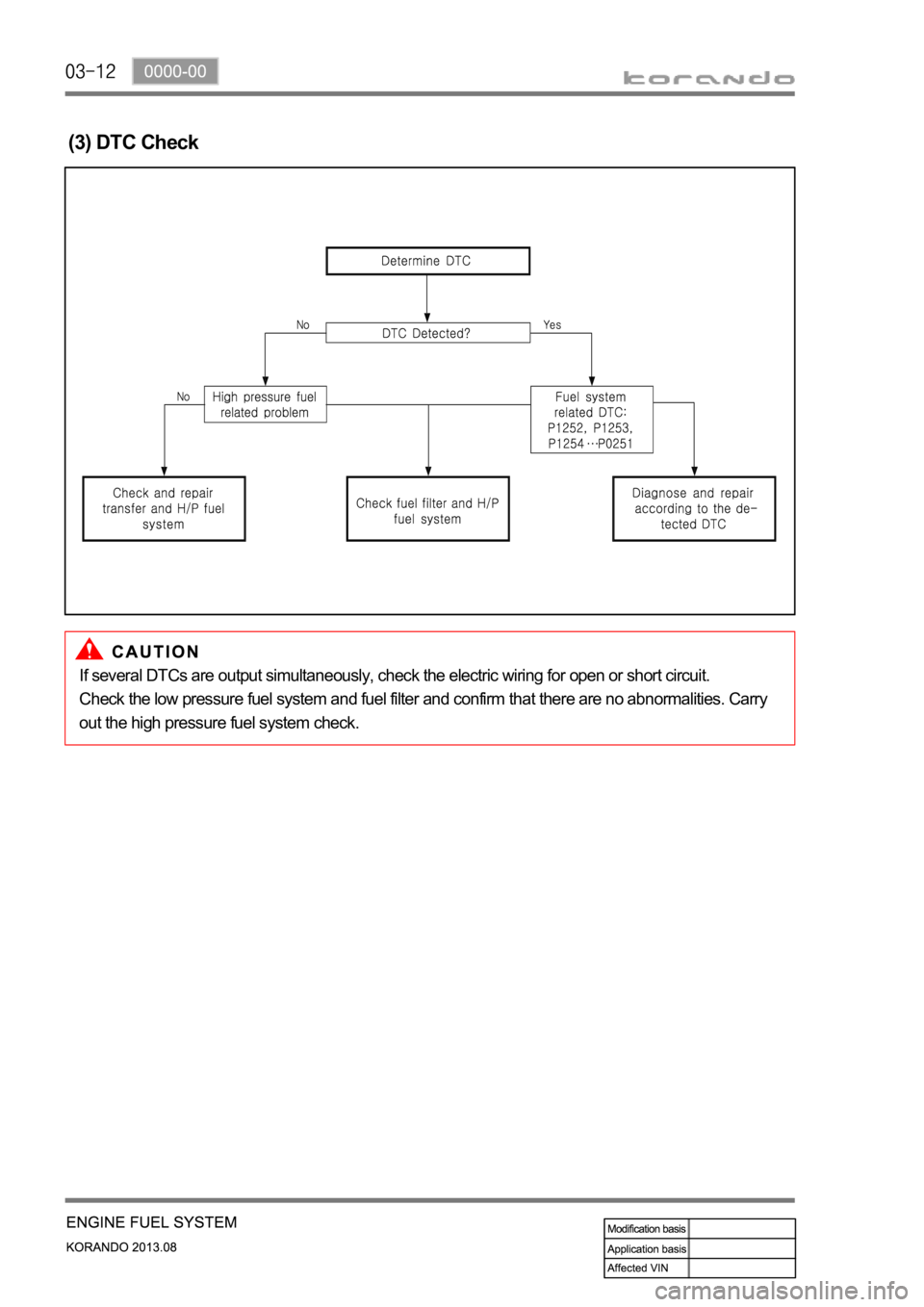

(3) DTC Check

If several DTCs are output simultaneously, check the electric wiring for open or short circuit.

Check the low pressure fuel system and fuel filter and confirm that there are no abnormalities. Carry

out the high pressure fuel system check.

Page 238 of 1336

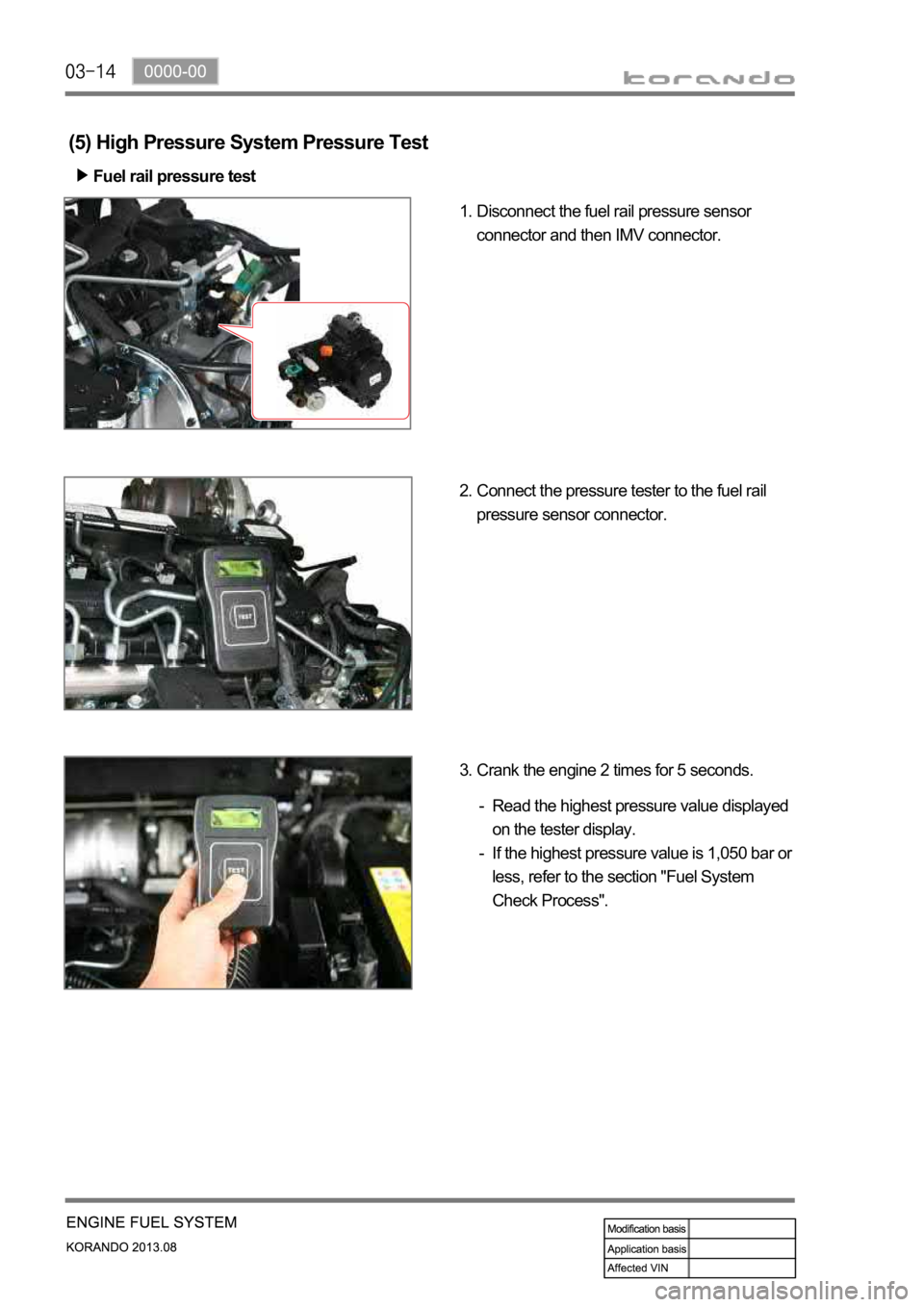

(5) High Pressure System Pressure Test

Fuel rail pressure test

Disconnect the fuel rail pressure sensor

connector and then IMV connector. 1.

Connect the pressure tester to the fuel rail

pressure sensor connector. 2.

Crank the engine 2 times for 5 seconds. 3.

Read the highest pressure value displayed

on the tester display.

If the highest pressure value is 1,050 bar or

less, refer to the section "Fuel System

Check Process". -

-