clutch SSANGYONG MUSSO 1998 Workshop Owners Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1093 of 1463

5A-116 AUTOMATIC TRANSMISSION

18. Install the gasket on the pump cover.

19. Install the cover plate, solenoid 7 with the retainer and the

solenoid wiring retainer to the pump cover, ensuring that

the periphery of the cover plate is flush with the periphery

of the pump cover. Refer to figure 8.34.

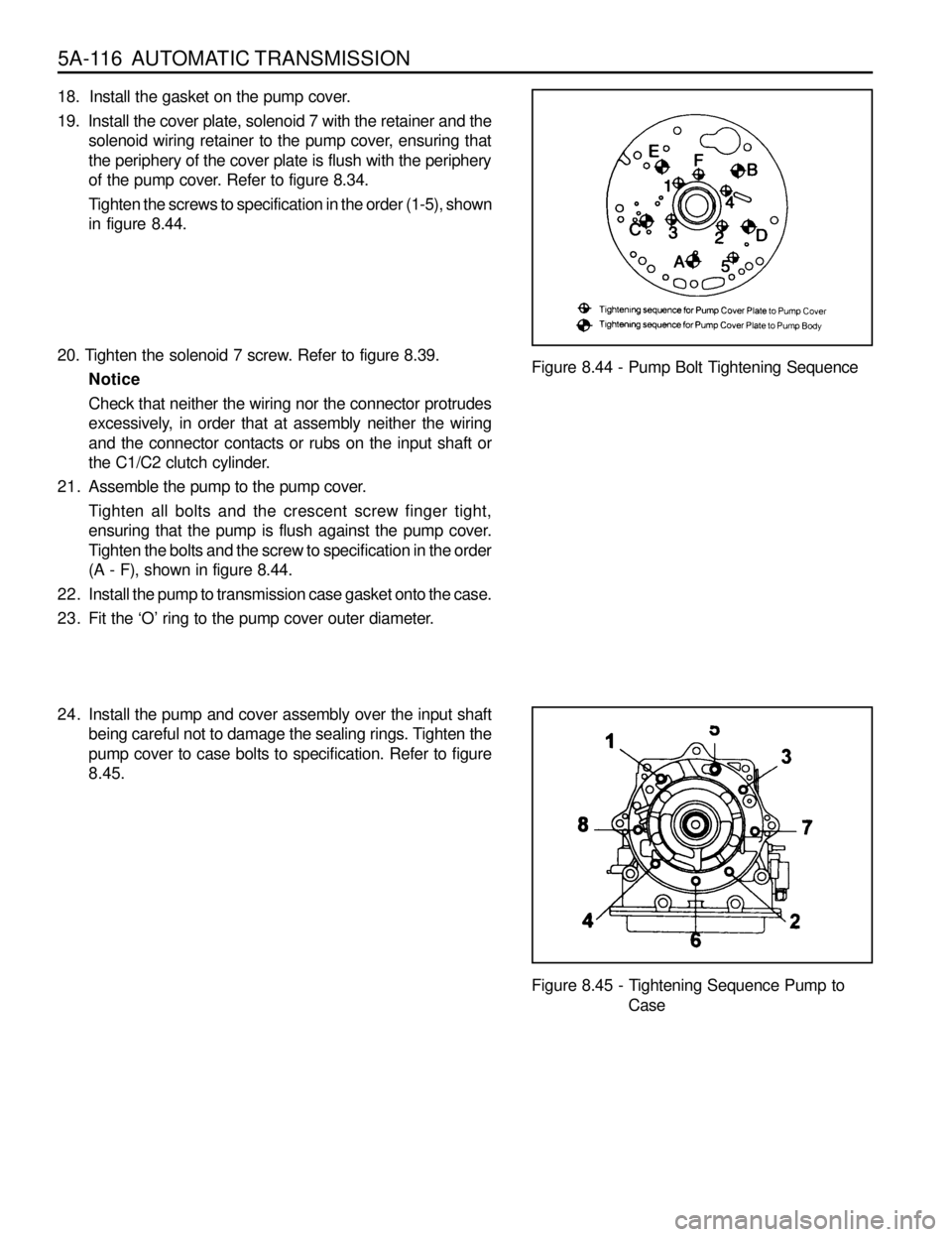

Tighten the screws to specification in the order (1-5), shown

in figure 8.44.

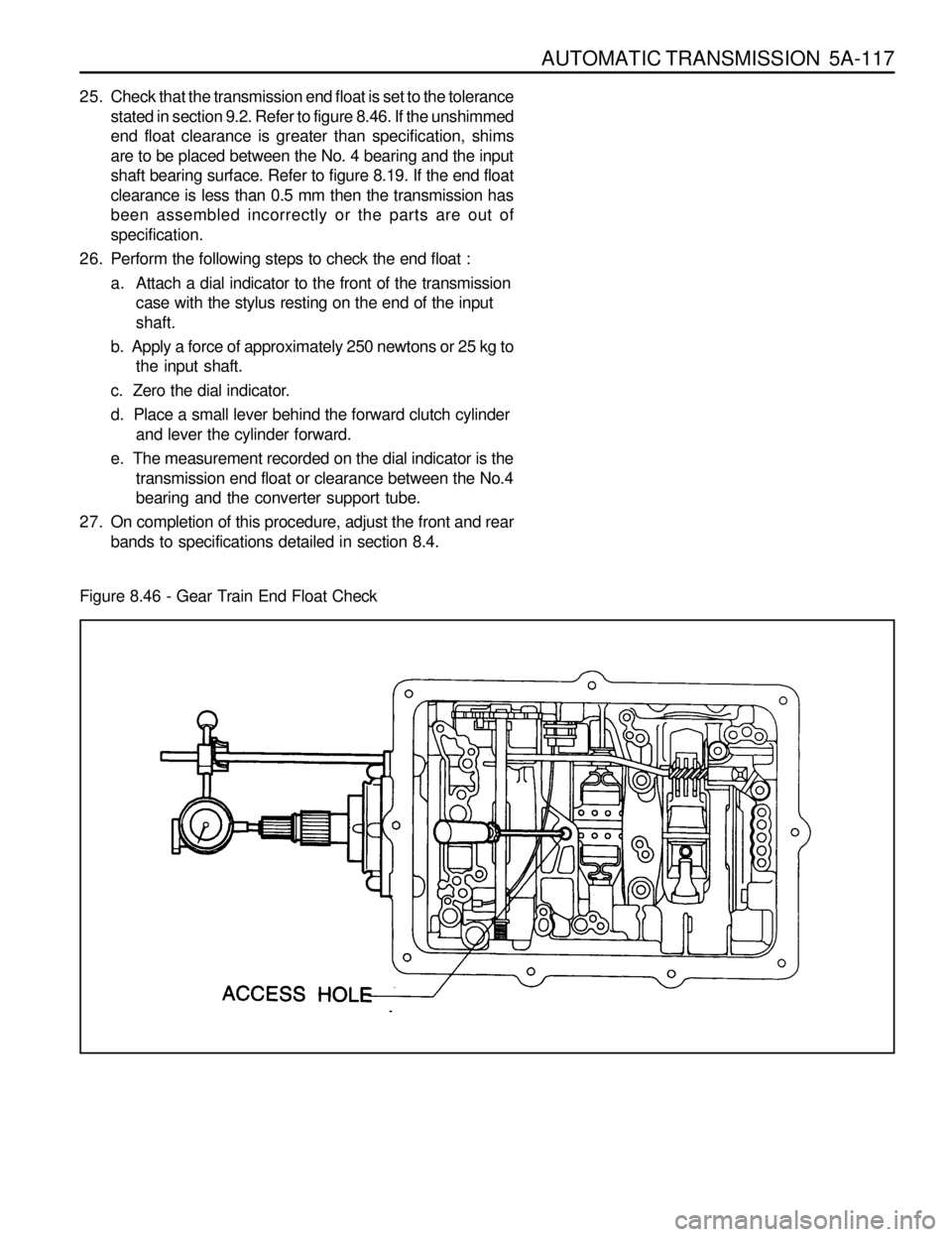

24. Install the pump and cover assembly over the input shaft

being careful not to damage the sealing rings. Tighten the

pump cover to case bolts to specification. Refer to figure

8.45. 20. Tighten the solenoid 7 screw. Refer to figure 8.39.

Notice

Check that neither the wiring nor the connector protrudes

excessively, in order that at assembly neither the wiring

and the connector contacts or rubs on the input shaft or

the C1/C2 clutch cylinder.

21. Assemble the pump to the pump cover.

Tighten all bolts and the crescent screw finger tight,

ensuring that the pump is flush against the pump cover.

Tighten the bolts and the screw to specification in the order

(A - F), shown in figure 8.44.

22. Install the pump to transmission case gasket onto the case.

23. Fit the ‘O’ ring to the pump cover outer diameter.Figure 8.44 - Pump Bolt Tightening Sequence

Figure 8.45 - Tightening Sequence Pump to

Case

Page 1094 of 1463

AUTOMATIC TRANSMISSION 5A-117

25. Check that the transmission end float is set to the tolerance

stated in section 9.2. Refer to figure 8.46. If the unshimmed

end float clearance is greater than specification, shims

are to be placed between the No. 4 bearing and the input

shaft bearing surface. Refer to figure 8.19. If the end float

clearance is less than 0.5 mm then the transmission has

been assembled incorrectly or the parts are out of

specification.

26. Perform the following steps to check the end float :

a. Attach a dial indicator to the front of the transmission

case with the stylus resting on the end of the input

shaft.

b. Apply a force of approximately 250 newtons or 25 kg to

the input shaft.

c. Zero the dial indicator.

d. Place a small lever behind the forward clutch cylinder

and lever the cylinder forward.

e. The measurement recorded on the dial indicator is the

transmission end float or clearance between the No.4

bearing and the converter support tube.

27. On completion of this procedure, adjust the front and rear

bands to specifications detailed in section 8.4.

Figure 8.46 - Gear Train End Float Check

Page 1098 of 1463

AUTOMATIC TRANSMISSION 5A-121

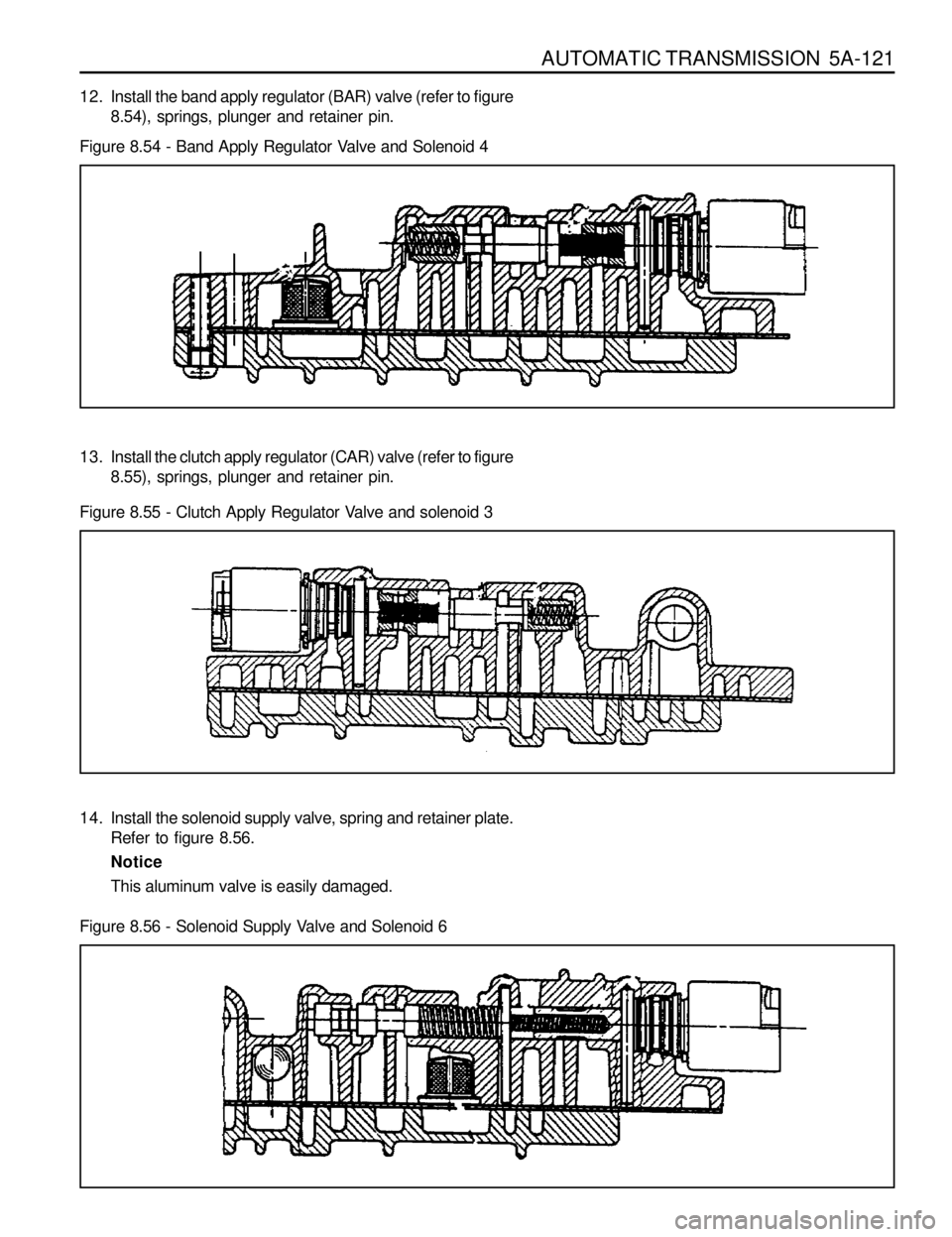

12. Install the band apply regulator (BAR) valve (refer to figure

8.54), springs, plunger and retainer pin.

Figure 8.54 - Band Apply Regulator Valve and Solenoid 4

13. Install the clutch apply regulator (CAR) valve (refer to figure

8.55), springs, plunger and retainer pin.

Figure 8.55 - Clutch Apply Regulator Valve and solenoid 3

14. Install the solenoid supply valve, spring and retainer plate.

Refer to figure 8.56.

Notice

This aluminum valve is easily damaged.

Figure 8.56 - Solenoid Supply Valve and Solenoid 6

Page 1112 of 1463

MANUAL TRANSMISSION 5B-5

Check

Clutch not releasing.

Improper or low transmission oil.

Shift or shift rail binding.

Binding of sliding synchronizers or gears.

If reverse only, faulty backup switch.

Worn or damaged flywheel pilot bushing.Check

Control lever assembly broken or damaged.

Damaged offset lever, shift fork, selector place or

selector arm.

DIAGNOSIS

WILL NOT SHIFT(CONTROL LEVER MOVES)

Action

Replace control lever and housing assembly.

Remove extension, adapter or case cover.

Check or replace damaged parts.

HARD SHIFT OR CONTROL LEVER WILL NOT MOVE INTO GEAR

Action

Adjust or replace clutch.

Add or replace with specified oil.

Remove extension, adapter or case cover.

Check or replace damaged parts.

Remove extension, adapter or case cover.

Check synchronizers and gears and replace

damaged parts.

Check or replace backup switch.

Replace pilot bushing.

GEARS CRASH WHEN SHIFTING

Check

Engine idle speed too high.

Damaged or faulty clutch.

Pilot bearing between input shaft and output shaft binding.

Damaged synchronizer.

Bell housing misaligned.

Damaged gear(s).

Worn or damaged flywheel pilot bushing.Action

Adjust idle speed to specified speed.

Adjust or replace clutch.

Replace or check roller bearings.

Check or replace synchronizer parts.

Align bell housing and bore.

Check or replace gear(s).

Replace pilot bushing.

Page 1115 of 1463

5B-8 MANUAL TRANSMISSION

1 Shift Hop-out

2 Shift Gear Crash

3 Shift Block-out

4 Hard Shift

5 Noise in Reverse Gear

6 Noise in 5th Gear

7 Noise in 4th Gear

8 Noise in 3rd Gear

9 Noise in 2nd Gear

10 Noise in 1st Gear

11 Noise in All Speeds

12 Leak at Transmission Rear Part

13 Leak at Transmission Center Part

14 Leak at Transmission Front

DIAGNOSIS TABLE

Condition

Possible Faulty Part

Transmission Case

Extension Housing

Shift Cover / Shift Shift

Shift Control Lever

Input Bearing Retainer

Input Gear Set

3rd Speed Gear Set

2nd Speed Gear Set

Reverse Speed Gear Set

1st Speed Gear Set

5th Speed Gear Set

Clutch Housing and Release Derive

Crankshaft Pilot Bushing and Release Bearing

Input Bearing

Main Shaft Input Bearing

Main Shaft Thrust Bearing

3rd Speed Gear Bearing

2nd Speed Gear Bearing

1st Speed Gear Bearing

Reverse Idler Gear Bushing

Counter Shaft Front Bearing

Counter Shaft Rear Bearing

Counter Shaft Thrust Bearing

5th Speed Drive Gear Bearing

Slip Yoke Bushing

Slip Yoke Seal

Speedometer Drive / Driven Gears

Speedometer Driven Gear Housing

Input Shaft Seal

1 - 2 Synchronizer Assembly

3 - 4 Synchronizer Assembly

5th Synchronizer Assembly

Ring Oil Seal

T/C Front Facel

l

ll

l

l

l l

l

l

l

l l

l

l

l

l

l

l

l

l

l

ll

l

ll

l

l

ll

l

l

l

ll

l

l

l

ll

l

ll

l

ll

l

ll

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Page 1121 of 1463

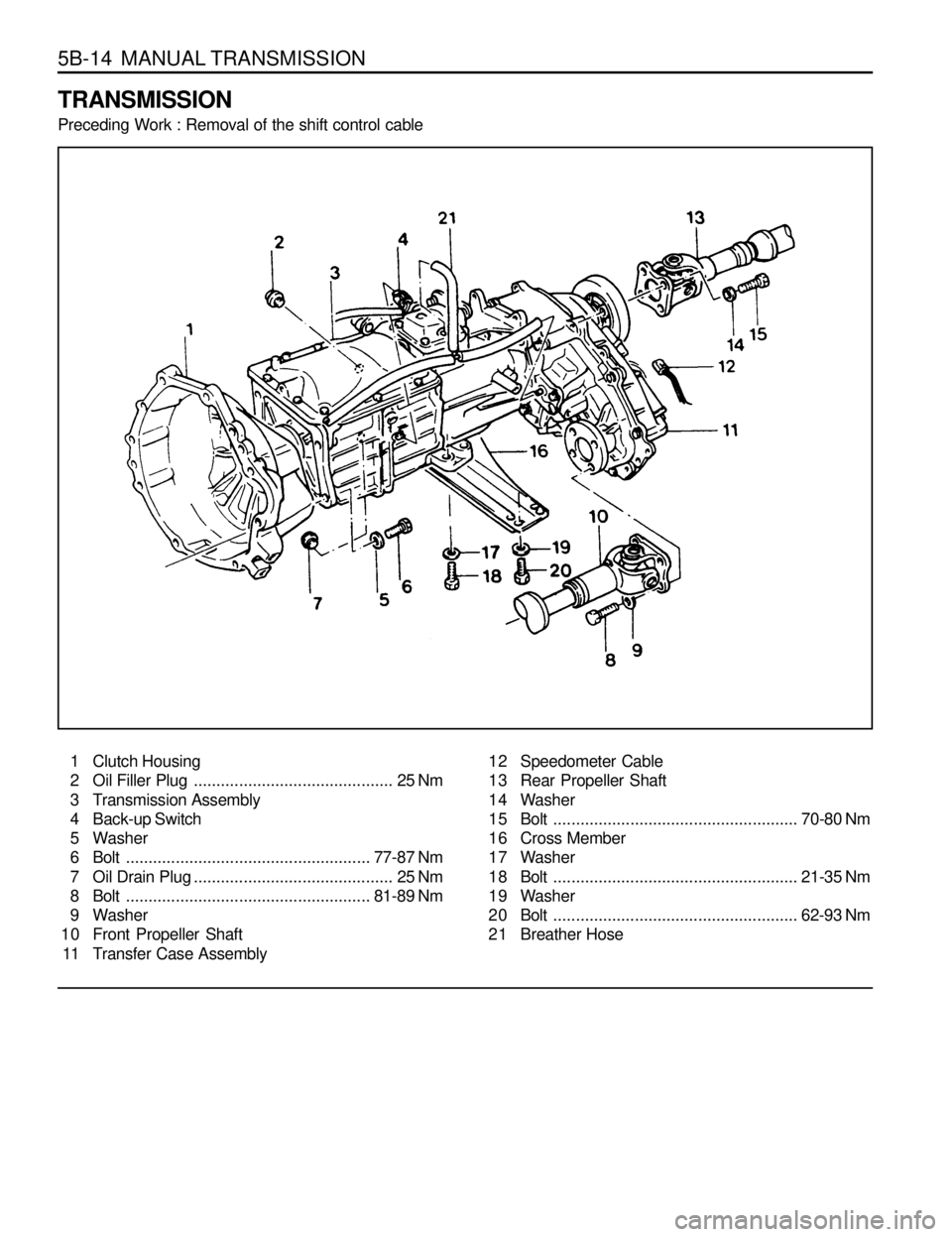

5B-14 MANUAL TRANSMISSION

TRANSMISSION

Preceding Work : Removal of the shift control cable

1 Clutch Housing

2 Oil Filler Plug............................................ 25 Nm

3 Transmission Assembly

4 Back-up Switch

5 Washer

6 Bolt......................................................77-87 Nm

7 Oil Drain Plug............................................ 25 Nm

8 Bolt......................................................81-89 Nm

9 Washer

10 Front Propeller Shaft

11 Transfer Case Assembly12 Speedometer Cable

13 Rear Propeller Shaft

14 Washer

1 5 Bolt......................................................70-80 Nm

16 Cross Member

17 Washer

1 8 Bolt......................................................21-35 Nm

19 Washer

2 0 Bolt......................................................62-93 Nm

21 Breather Hose

Page 1149 of 1463

5B-42 MANUAL TRANSMISSION

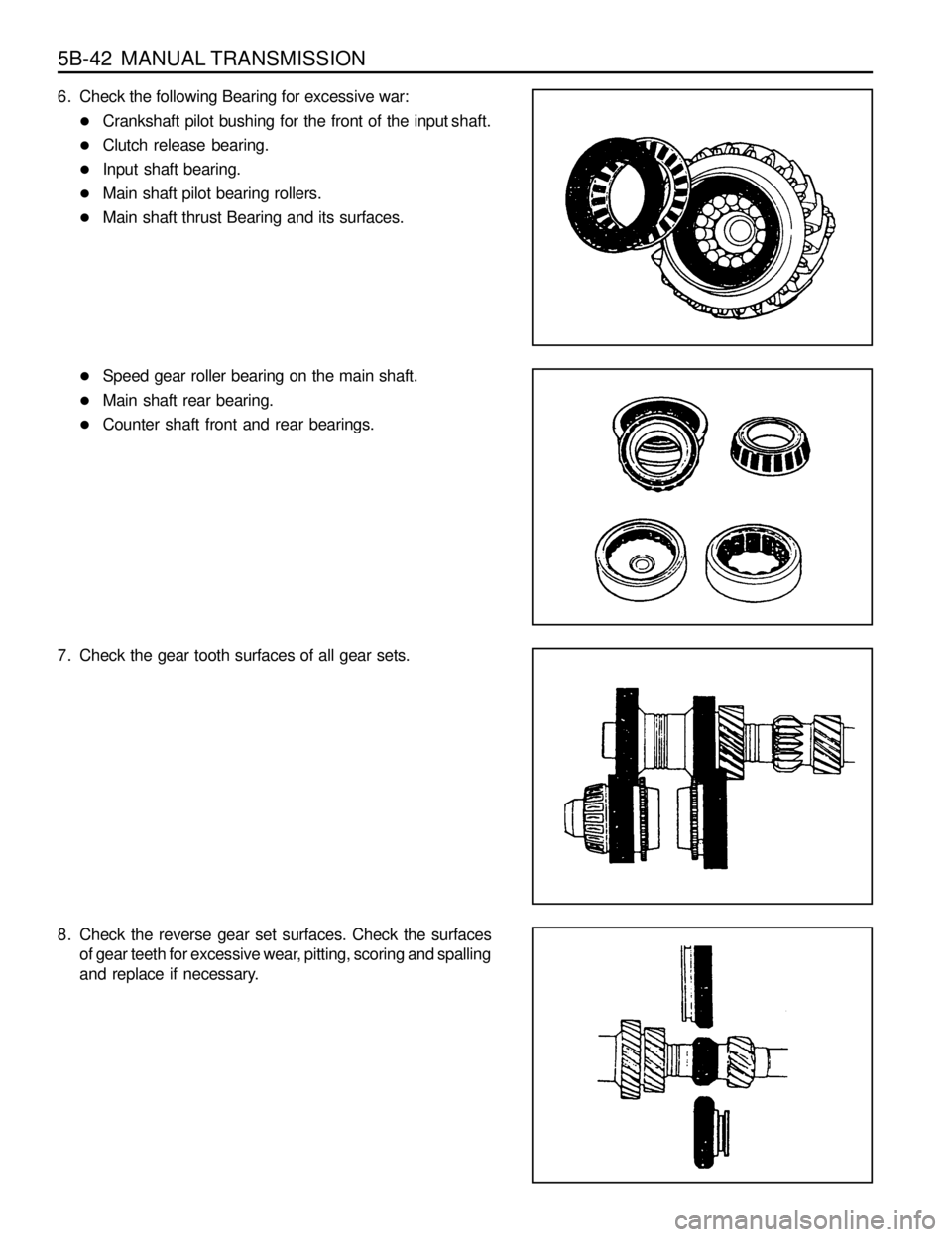

6. Check the following Bearing for excessive war:

lCrankshaft pilot bushing for the front of the inputshaft.

lClutch release bearing.

lInput shaft bearing.

lMain shaft pilot bearing rollers.

lMain shaft thrust Bearing and its surfaces.

lSpeed gear roller bearing on the main shaft.

lMain shaft rear bearing.

lCounter shaft front and rear bearings.

7. Check the gear tooth surfaces of all gear sets.

8. Check the reverse gear set surfaces. Check the surfaces

of gear teeth for excessive wear, pitting, scoring and spalling

and replace if necessary.

Page 1150 of 1463

MANUAL TRANSMISSION 5B-43

9. Take apart the three synchronizer assemblies and check :

lThe 1-2 synchronizer.

lThe 5th blocking ring.

10. Check the fit between the hub and sleeve of each

synchronizer

lExcessively tight or loose hub-to-sleeve fit.

lWear of the cone clutch surfaces of brass blocking

rings and gears.

11. Measure the clearance between the blocking ring and the

speed gear

lNew 1-2 blocking ring : 0.87-1.4mm

lNew 3-4 blocking ring : 0.88-1.5mm

Notice

Excessive wear of the blocking ring or the speed gear cone

surface will cause shift block-out gear clash.

Page 1151 of 1463

5B-44 MANUAL TRANSMISSION

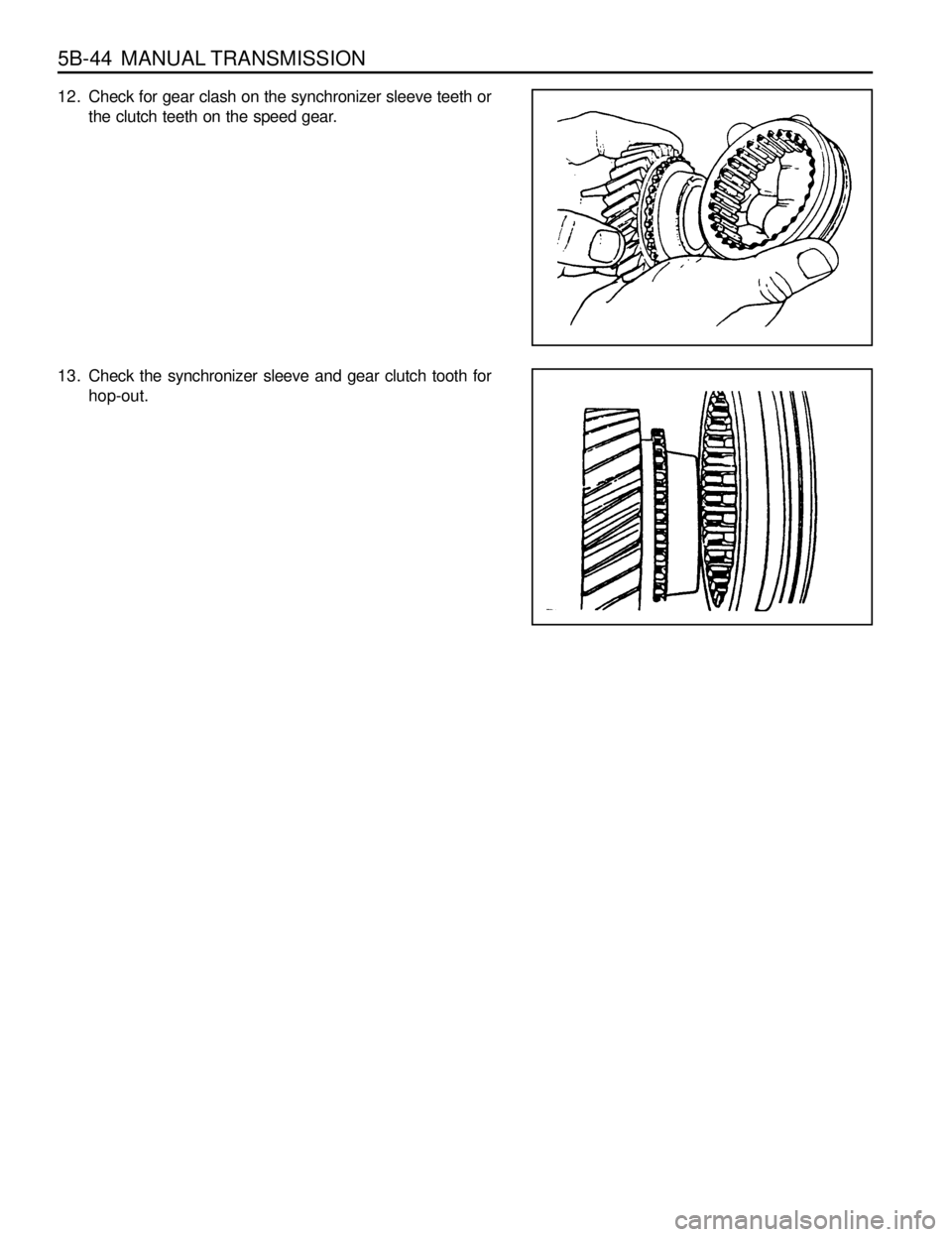

12. Check for gear clash on the synchronizer sleeve teeth or

the clutch teeth on the speed gear.

13. Check the synchronizer sleeve and gear clutch tooth for

hop-out.

Page 1152 of 1463

MANUAL TRANSMISSION 5B-45

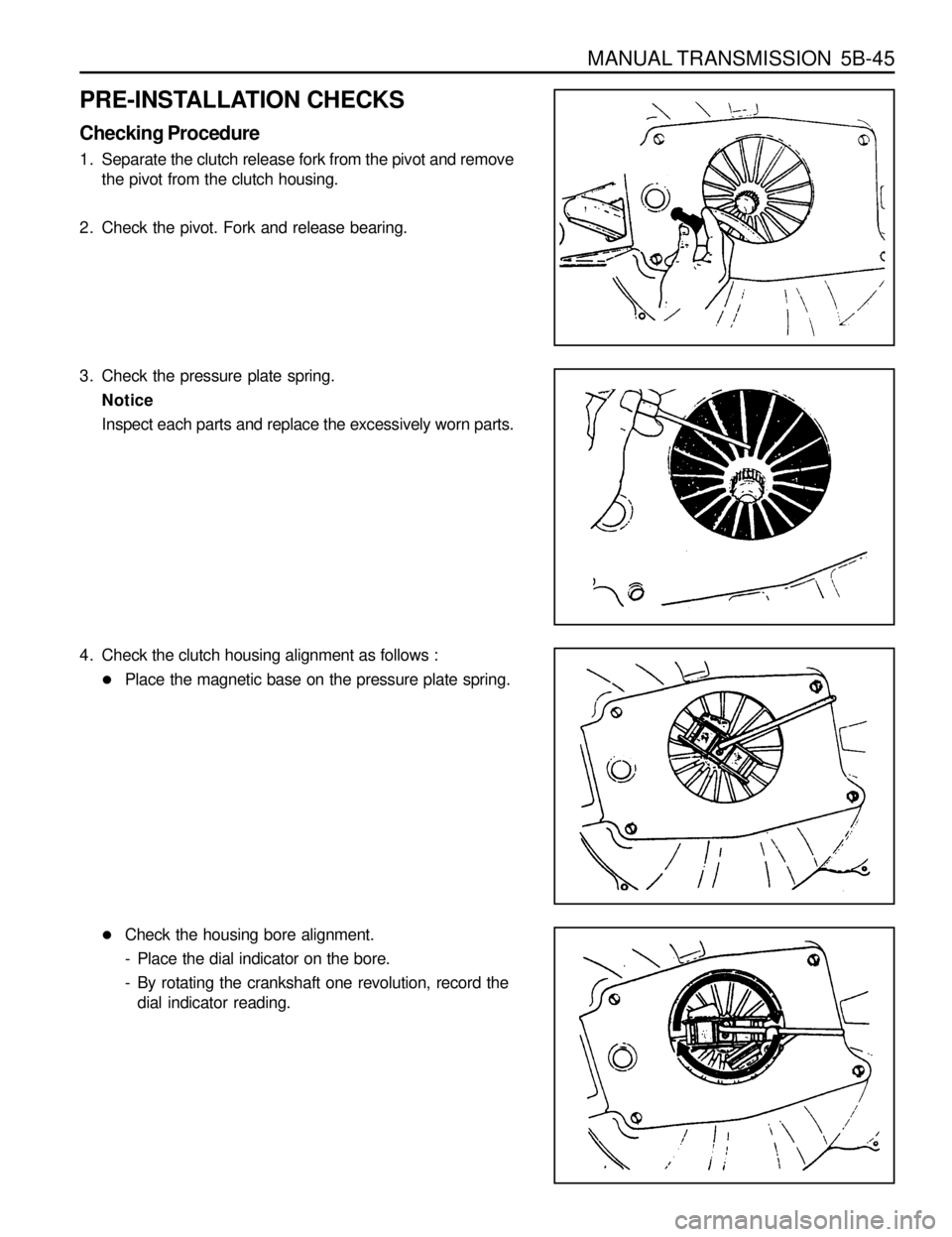

PRE-INSTALLATION CHECKS

Checking Procedure

1. Separate the clutch release fork from the pivot and remove

the pivot from the clutch housing.

2. Check the pivot. Fork and release bearing.

3. Check the pressure plate spring.

Notice

Inspect each parts and replace the excessively worn parts.

4. Check the clutch housing alignment as follows :

lPlace the magnetic base on the pressure plate spring.

lCheck the housing bore alignment.

- Place the dial indicator on the bore.

- By rotating the crankshaft one revolution, record the

dial indicator reading.