torque SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 14 of 1463

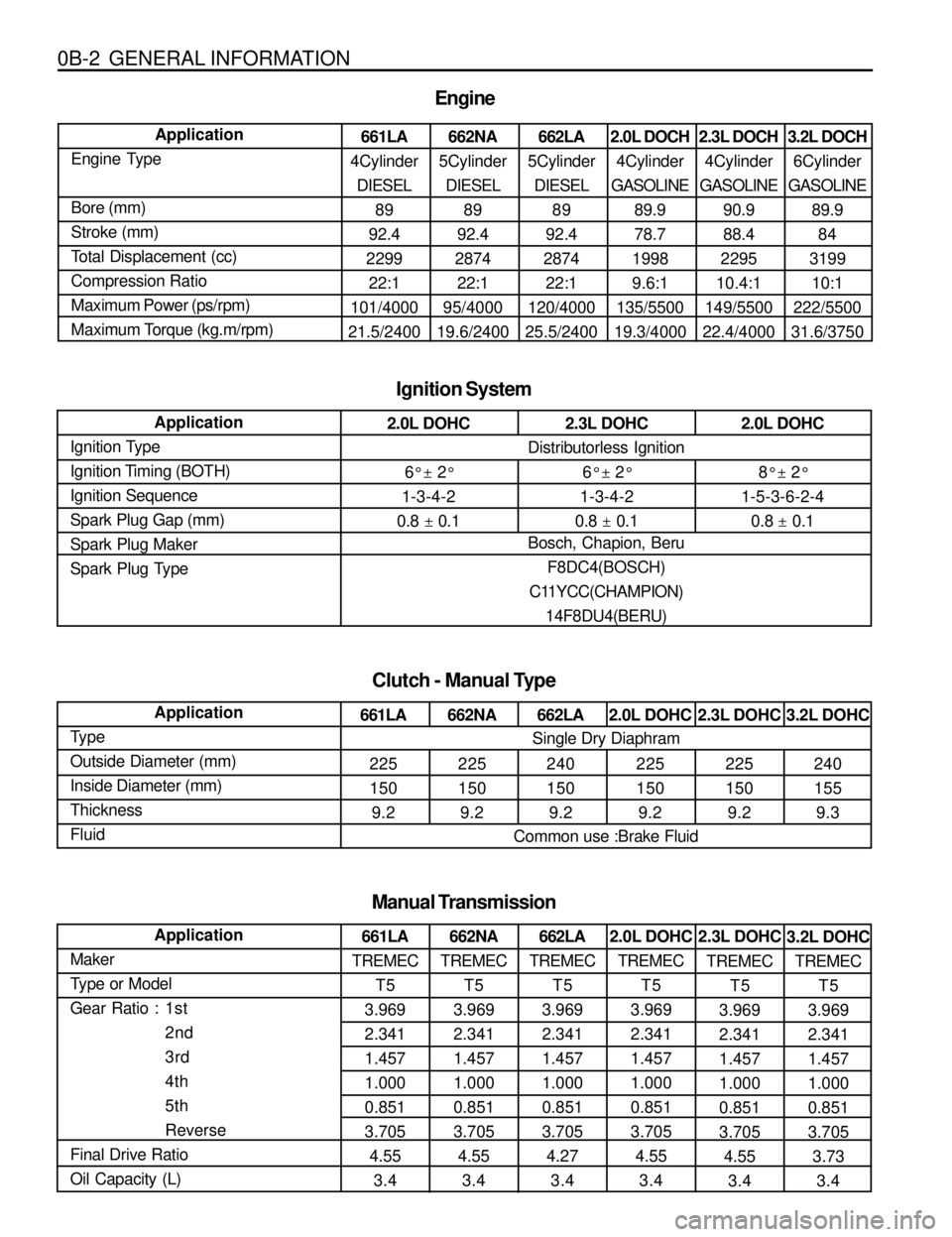

0B-2 GENERAL INFORMATION

661LA

4Cylinder

DIESEL

89

92.4

2299

22:1

101/4000

21.5/2400 Application

Engine Type

Bore (mm)

Stroke (mm)

Total Displacement (cc)

Compression Ratio

Maximum Power (ps/rpm)

Maximum Torque (kg.m/rpm)

Engine

662NA

5Cylinder

DIESEL

89

92.4

2874

22:1

95/4000

19.6/2400662LA

5Cylinder

DIESEL

89

92.4

2874

22:1

120/4000

25.5/24002.0L DOCH

4Cylinder

GASOLINE

89.9

78.7

1998

9.6:1

135/5500

19.3/40002.3L DOCH

4Cylinder

GASOLINE

90.9

88.4

2295

10.4:1

149/5500

22.4/40003.2L DOCH

6Cylinder

GASOLINE

89.9

84

3199

10:1

222/5500

31.6/3750

661LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4 Application

Ignition Type

Ignition Timing (BOTH)

Ignition Sequence

Spark Plug Gap (mm)

Spark Plug Maker

Spark Plug Type

Ignition System

Clutch - Manual Type

2.0L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.3L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.0L DOHC

8° ± 2°

1-5-3-6-2-4

0.8 ± 0.1 Distributorless Ignition

Bosch, Chapion, Beru

F8DC4(BOSCH)

C11YCC(CHAMPION)

14F8DU4(BERU)

661LA

225

150

9.2

662NA

225

150

9.2662LA

240

150

9.22.0L DOHC

225

150

9.22.3L DOHC

225

150

9.23.2L DOHC

240

155

9.3 Application

Type

Outside Diameter (mm)

Inside Diameter (mm)

Thickness

Fluid

Single Dry Diaphram

Common use :Brake Fluid

Application

Maker

Type or Model

Gear Ratio : 1st

2nd

3rd

4th

5th

Reverse

Final Drive Ratio

Oil Capacity (L)

Manual Transmission

662NA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4662LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.27

3.42.0L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.42.3L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.43.2L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

3.73

3.4

Page 18 of 1463

0B-6 GENERAL INFORMATION

STANDARD BOLTS SPECIFICATIONS

Bolt*Torque (N·m / Ib-in)

Standard

Limit

4T

7T

9T4T 7T

9T

M3 ´ 0.5

M4 ´ 0.7

M5 ´ 0.8

M6 ´ 1.0

M8 ´ 1.25

M10 ´ 1.25

M10 ´ 1.5

M12 ´ 1.25

M12 ´ 1.75

M14 ´ 1.5

M16 ´ 1.5

M18 ´ 1.5

M20 ´ 1.5

M22 ´ 0.5

M24 ´ 1.5

M24 ´ 2.00.5 N

· ·· ·

·m

(4.5 lb-in)

1.2 N

· ·· ·

·m

(11 lb-in)

2.4 N

· ·· ·

·m

(22 lb-in)

4.0 N

· ·· ·

·m

(36 lb-in)

8.6 N

· ·· ·

·m

(77 lb-in)

18.6 N

· ·· ·

·m

(14 lb-in)

18.6 N

· ·· ·

·m

(14 lb-in)

34.3 N

· ·· ·

·m

(25lb-in)

32.3 N

· ·· ·

·m

(24 lb-in)

54.0 N

· ·· ·

·m

(40 lb-in)

81.3 N

· ·· ·

·m

(60 lb-in)

117.6 N

· ·· ·

·m

(87 lb-in)

166.6N

· ·· ·

·m

(123 lb-in)

225.4N

· ·· ·

·m

(167 lb-in)

284.2 N

· ·· ·

·m

(210 lb-in)

274.4 N

· ·· ·

·m

(203 lb-in)0.9 N

· ·· ·

·m

(8 lb-in)

2.0 N

· ·· ·

·m

(18 lb-in)

4.0 N

· ·· ·

·m

(36 lb-in)

6.7 N

· ·· ·

·m

(60 lb-in)

15.7 N

· ·· ·

·m

(12 lb-in)

32.3 N

· ·· ·

·m

(24 lb-in)

30.4 N

· ·· ·

·m

(22 lb-in)

56.8 N

· ·· ·

·m

(42 lb-in)

53.9 N

· ·· ·

·m

(40 lb-in)

89.2 N

· ·· ·

·m

(66 lb-in)

107.8 N

· ·· ·

·m

(80 lb-in)

196.0 N

· ·· ·

·m

(145 lb-in)

274.4 N

· ·· ·

·m

(203 lb-in)

372.4 N

· ·· ·

·m

(276 lb-in)

480.2 N

· ·· ·

·m

(355 lb-in)

460.6 N

· ·· ·

·m

(341 lb-in)1.3 N

· ·· ·

·m

(12 lb-in)

3.0 N

· ·· ·

·m

(27 lb-in)

5.6 N

· ·· ·

·m

(50 lb-in)

9.7 N

· ·· ·

·m

(87 lb-in)

22.5 N

· ·· ·

·m

(17 lb-in)

46.0 N

· ·· ·

·m

(34 lb-in)

44.1 N

· ·· ·

·m

(33 lb-in)

82.3 N

· ·· ·

·m

(61 lb-in)

77.4 N

· ·· ·

·m

(57 lb-in)

127.4 N

· ·· ·

·m

(94 lb-in)

196.0 N

· ·· ·

·m

(145 lb-in)

284.2 N

· ·· ·

·m

(210 lb-in)

392.0 N

· ·· ·

·m

(290 lb-in)

529.2 N

· ·· ·

·m

(392 lb-in)

686.0 N

· ·· ·

·m

(508 lb-in)

666.4 N

· ·· ·

·m

(493 lb-in)0.7 N

· ·· ·

·m

(6.3 lb-in)

1.6 N

· ·· ·

·m

(14 lb-in)

3.1 N

· ·· ·

·m

(28 lb-in)

5.4 N

· ·· ·

·m

(49 lb-in)

12.7 N

· ·· ·

·m

(9 lb-in)

25.5 N

· ·· ·

·m

(19 lb-in)

24.5 N

· ·· ·

·m

(18 lb-in)

45.0 N

· ·· ·

·m

(33 lb-in)

43.1 N

· ·· ·

·m

(32 lb-in)

71.6 N

· ·· ·

·m

(53 lb-in)

107.8 N

· ·· ·

·m

(80 lb-in)

156.8 N

· ·· ·

·m

(116 lb-in)

215.6 N

· ·· ·

·m

(160 lb-in)

294.0 N

· ·· ·

·m

(218 lb-in)

382.2 N

· ·· ·

·m

(283 lb-in)

372.4 N

· ·· ·

·m

(276 lb-in)1.2 N

· ·· ·

·m

(11 lb-in)

2.6 N

· ·· ·

·m

(23 lb-in)

5.2 N

· ·· ·

·m

(47 lb-in)

9.0 N

· ·· ·

·m

(81 lb-in)

20.6 N

· ·· ·

·m

(15.2 lb-in)

42.1 N

· ·· ·

·m

(31 lb-in)

41.2 N

· ·· ·

·m

(30 lb-in)

75.5 N

· ·· ·

·m

(56 lb-in)

71.5 N

· ·· ·

·m

(53 lb-in)

117.6 N

· ·· ·

·m

(87 lb-in)

186.2 N

· ·· ·

·m

(138 lb-in)

264.6 N

· ·· ·

·m

(196 lb-in)

362.6 N

· ·· ·

·m

(268 lb-in)

490.0 N

· ·· ·

·m

(362 lb-in)

637.0 N

· ·· ·

·m

(471 lb-in)

617.4 N

· ·· ·

·m

(457 lb-in)17 N

· ·· ·

·m

(15 lb-in)

4.0 N

· ·· ·

·m

(36 lb-in)

7.6 N

· ·· ·

·m

(68 lb-in)

12.7 N

· ·· ·

·m

(114 lb-in)

30.4 N

· ·· ·

·m

(22 lb-in)

60.8 N

· ·· ·

·m

(31 lb-in)

58.8 N

· ·· ·

·m

(44 lb-in)

107.8 N

· ·· ·

·m

(80 lb-in)

98.0 N

· ·· ·

·m

(73 lb-in)

166.6 N

· ·· ·

·m

(123 lb-in)

264.6 N

· ·· ·

·m

(196 lb-in)

372.4 N

· ·· ·

·m

(276 lb-in)

519.4 N

· ·· ·

·m

(384 lb-in)

705.6 N

· ·· ·

·m

(522 lb-in)

921.2 N

· ·· ·

·m

(682 lb-in)

891.8 N

· ·· ·

·m

(660 lb-in)

*Diameter ´ pitch in millimeters

Page 27 of 1463

GENERAL INFORMATION 0B-15

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL REPAIR INSTRUCTIONS

lIf a floor jack is used, the following precautions are

recommended.

lPark the vehicle on level ground, “block” the front or

rear wheels, set the jack against the frame, raise the

vehicle and support it with chassis stands and then

perform the service operation.

lBefore performing the service operation, disconnect

the negative battery cable in order to reduce the

chance of cable damaged and burning due to short-

cir cuiting.

lUse a cover on the body, the seats and the floor to

protect them against damage and contamination.

lHandle brake fluid and antifreeze solution with care

as they can cause paint damage.

lThe use of proper tools, and the recommended

essential and available tools where specified, are

important for efficient and reliable performance of

the service repairs.lUse genuine DAEWOO parts.

lDiscard used cotter pins, gaskets, O-rings, oil seals,

lock washers and self-locking nuts. Prepare new ones

for installation. Normal function of these parts cannot

be maintained if these parts are reused.

lKeep the disassembled parts neatly in groups to

facilitate proper and smooth reassembly.

lKeep attaching bolts and nuts separated, as they

vary in hardness and design depending on the

position of the installation.

lClean the parts before inspection or reassembly.

lAlso clean the oil parts, etc. Use compressed air to

make certain they are free of restrictions.

lLubricate rotating and sliding faces of parts with oil

or grease before installation.

lWhen necessary, use a sealer on gaskets to prevent

leakage.

lCarefully observe all specifications for bolt and nut

torques.

lWhen service operation is completed, make a final

check to be sure service was done properly and the

problem was corrected.

Page 32 of 1463

SECTION 1

ENGINE

SECTION 1A1(M162 ENGINE)

GENERAL ENGINE INFORMATION

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A1-1

Engine Specifications . . . . . . . . . . . . . . . . . . 1A1-1

Component Locator . . . . . . . . . . . . . . . . . . 1A1-3

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-3

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-4

Performance Curve . . . . . . . . . . . . . . . . . . 1A1-5

E32 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-5

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A1-6

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A1-6

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-7

Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . . 1A1-7

Engine Cranking at The

Front of Crankshaft . . . . . . . . . . . . . . . . . . 1A1-8

Compression Pressure Test . . . . . . . . . . . . . 1A1-9

Cylinder Pressure Leakage Test . . . . . . . . . 1A1-11

General Information . . . . . . . . . . . . . . . . . 1A1-13

Cleanliness and Care . . . . . . . . . . . . . . . . . 1A1-13

On-Engine Service . . . . . . . . . . . . . . . . . . . 1A1-13

Application

Engine Model

Displacement (CC)

Cylinder (Bore x Stroke) (mm)

Fuel Injection / Ignition System

Compression Ratio

Number of Cylinders

Camshaft Valve Arrangement

Camshaft Drive Type

Max. Output (ps/rpm)

Max. Torque (kg•m/rpm)

Firing Order

Ignition Type

Ignition Timing

Valve Timing Intake Open/Close

ExhaustOpen/Close

Valve Clearance Adjustment

SPECIFICATIONS

ENGINE SPECIFICATIONS

E32 Engine

M162.990

3199

89.9 x 84.0

MSE 3.62S

10 : 1

6

DOHC

Chain-Driven

222 / 5500

31.6 / 3750

1-5-3-6-2-4

Distributorless Double Ignition

BTDC 8° ± 2°

ATDC 11° / ABDC 34°

BBDC 31° / BTDC 14°

Automatic Control

TABLE OF CONTENTS

Page 37 of 1463

1A1-6 GENERAL ENGINE INFORMATION

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01

Torque Wrench

001 589 76 21 00

Compression Pressure

Tester119 589 01 09 00

Spark Plug Wrench001 589 65 09 00

Socket

Page 39 of 1463

1A1-8 GENERAL ENGINE INFORMATION

ENGINE CRANKING AT THE FRONT OF CRANKSHAFT

Preceding Work : Removal of cooling fan

1 Vibration Damper Assembly

2 Crankshaft Pulley

Notice

lRemove the negative ground cable before proceeding the work.

lRotate the pulley in normal engine rotating direction when cranking.3 Bolt.................................................8.6 ± 0.9 Nm

Tools Required

000 589 10 99 01 Torque wrench

001 589 65 09 00 Socket

Page 45 of 1463

SECTION 1

ENGINE

SECTION 1A2(M161 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A2-1

Engine Specifications . . . . . . . . . . . . . . . . . . 1A2-1

Component Locator . . . . . . . . . . . . . . . . . . 1A2-3

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-3

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-4

Performance Curve . . . . . . . . . . . . . . . . . . 1A2-5

E23 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-5

E20 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-6

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A2-7

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A2-7

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-8

Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . . 1A2-8

Engine Cranking At The

Front of Crankshaft . . . . . . . . . . . . . . . . . . 1A2-9

Compression Pressure Test . . . . . . . . . . . . 1A2-10

Cylinder Pressure Leakage Test . . . . . . . . . 1A2-12

General Information . . . . . . . . . . . . . . . . . 1A2-14

Cleanliness and Care . . . . . . . . . . . . . . . . . 1A2-14

On-Engine Service . . . . . . . . . . . . . . . . . . . 1A2-14

E20 Engine

M161.940

1998

89.9 x 78.7

¬

9.6:1

¬

¬

¬

135 / 5500

19.3 / 4000

¬

¬

¬

ATDC 13.15° / ABDC 13.57°

BBDC 16.58° / BTDC 17.05°

¬ Application

Engine Model

Displacement (CC)

Cylinder (Bore x Stroke) (mm)

Fuel Injection / Ignition System

Compression Ratio

Number of Cylinders

Camshaft Valve Arrangement

Camshaft Drive Type

Max. Output (ps/rpm)

Max. Torque (kg•m/rpm)

Firing Order

Ignition Type

Ignition Timing

Valve Timing Intake Open/Close

ExhaustOpen/Close

Valve Clearance Adjustment

SPECIFICATIONS

ENGINE SPECIFICATIONS

E23 Engine

M161.970

2295

90.9 x 88.4

MSE 3.53S

10.4:1

4

DOHC

Chain-Driven

149 / 5500

22.4 / 4000

1-3-4-2

Distributorless

BTDC 6° ± 2°

ATDC 19.25° / ABDC 28.76°

BBDC 20.62° / BTDC 15.08°

Automatic Control

Page 51 of 1463

GENERAL ENGINE INFORMATION 1A2-7

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01

Torque Wrench

001 589 76 21 00

Compression Pressure

Tester119 589 01 09 00

Spark Plug Wrench

001 589 65 09 00

Socket

Page 53 of 1463

GENERAL ENGINE INFORMATION 1A2-9

ENGINE CRANKING AT THE FRONT OF CRANKSHAFT

Preceding Work : Removal of cooling fan

1 Torque Wrench

2 Socket

3 Vibration Damper Ass'y

Notice

lRemove the negative ground cable before proceeding the work.

lRotate the pulley in normal engine rotating direction when cranking.

Tools Required

000 589 10 99 01 Torque Wrench

001 589 65 09 00 Socket4 Center Bolt (M18 ´ 55, 1piece)

.....................................1st Step 200Nm + 20Nm

2nd Step 90° + 10°

Page 59 of 1463

Application

Engine Type

Displacement (CC)

Cylinder (Bore x Stroke) (mm)

Fuel Injection / Ignition System

Compression Ratio

Number of Cylinders

Camshaft Valve Arrangement

Camshaft Drive Type

Max. Output (ps/rpm)

Max. Torque (kg•m/rpm)

Firing Order

Injection Timing

Valve Timing Intake Open/Close

(at 2mm lift) ExhaustOpen/Close

Valve Clearance Adjustment

SECTION 1

ENGINE

SECTION 1A3(OM600 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A3-1

Engine Specifications . . . . . . . . . . . . . . . . . . 1A3-1

Sectional View . . . . . . . . . . . . . . . . . . . . . . 1A3-3

OM662LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-3

OM661LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-5

Performance Curve . . . . . . . . . . . . . . . . . . 1A3-7

OM662LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-7

OM661LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-8

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A3-9

SPECIFICATIONS

ENGINE SPECIFICATIONS

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A3-9

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 1A3-10

Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . 1A3-10

Compression Pressure Test . . . . . . . . . . . . 1A3-11

Cylinder Pressure Leakage Test . . . . . . . . . 1A3-13

General Information . . . . . . . . . . . . . . . . . 1A3-15

Cleanliness and Care . . . . . . . . . . . . . . . . . 1A3-15

On-Engine Service . . . . . . . . . . . . . . . . . . . 1A3-15

OM662LA

Four-Stroke Diesel

2874

89 x 92.4

PES 5 M55 C320 RS 168

22:1

5

SOHC

Chain-Drive

120 / 4000

25.5 / 4000

1-2-4-5-3

BTDC 18°± 10°

ATDC 11.33° / ABDC 17°

BBDC 28° / BTDC 15.25°

Automatic ControlOM661LA

Four-Stroke Diesel

2299

89 x 92.4

PES 5 M55 C320 RS 167

22:1

4

SOHC

Chain-Drive

101 / 4000

21.5 / 2400

1-3-4-2

BTDC 18°± 10°

ATDC 11.33° / ABDC 17°

BBDC 28° / BTDC 15.25°

Automatic Control