sensor SSANGYONG MUSSO 1998 Workshop Owners Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 730 of 1463

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1

Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15Idle Speed Adjustment . . . . . . . . . . . . . . . . 1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of

Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test

(Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut

Fuel Pump Pressure Line

Fuel Injection Nozzle

Fuel Injection Pipe

Nozzle Tensioning Nut

Screw Plug

Left-Hand Thread BoltN·m

28 - 47

13

35 - 40

18

80

30

46

Page 766 of 1463

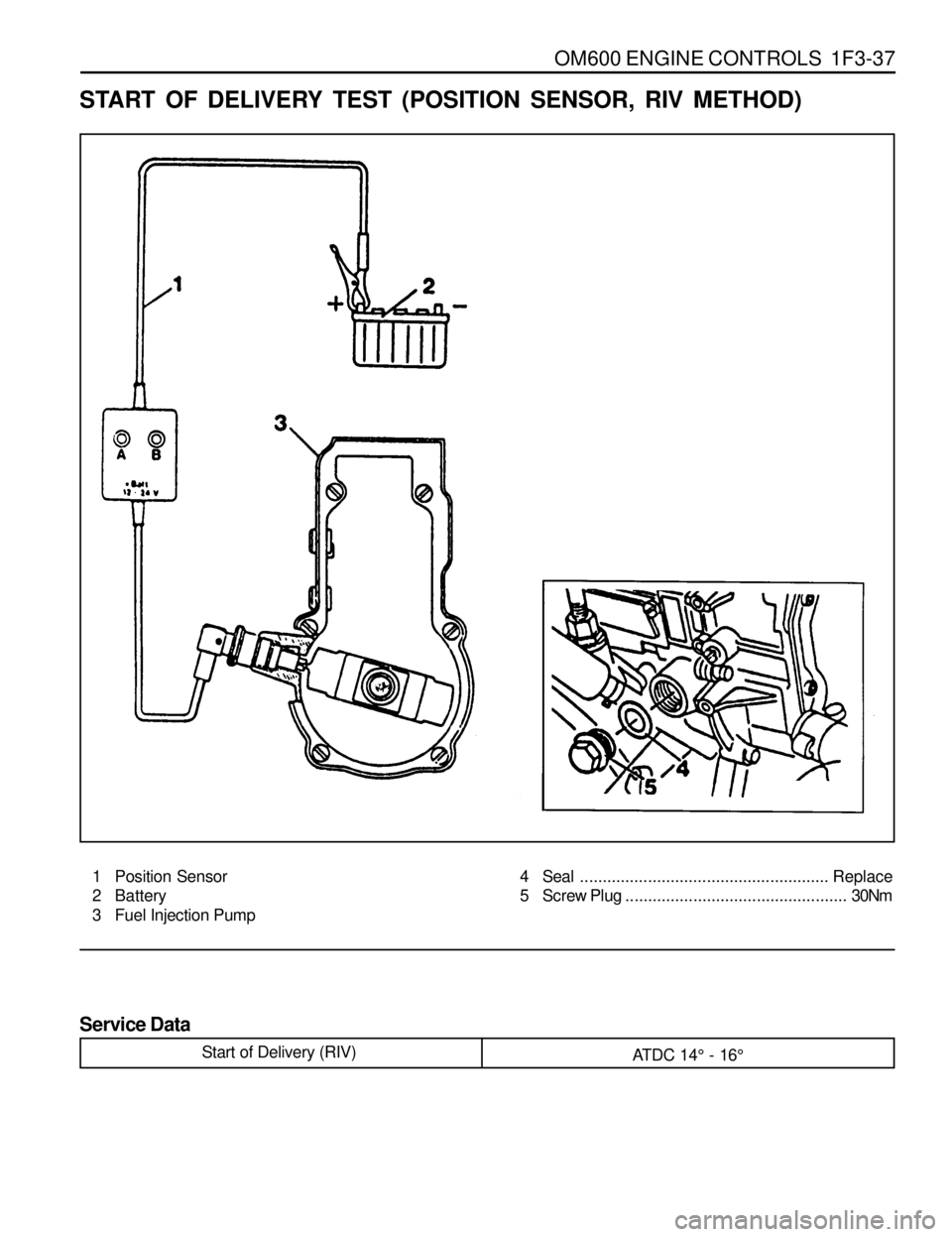

OM600 ENGINE CONTROLS 1F3-37

START OF DELIVERY TEST (POSITION SENSOR, RIV METHOD)

1 Position Sensor

2 Battery

3 Fuel Injection Pump4 Seal....................................................... Replace

5 Screw Plug.................................................30Nm

Service Data

Start of Delivery (RIV)

ATDC 14° - 16°

Page 767 of 1463

1F3-38 OM600 ENGINE CONTROLS

Tools Required

617 589 08 21 00 Position Sensor

Test Procedure

1. Remove the screw plug (5) and seal (4) and collect oil in a

suitable vessel.

2. Install the position sensor (1) into the governor housing of

the injection pump to be the guide pin of the position sensor

facing up.

3. Connect the battery terminal of position sensor (1) to positive

terminal (+) of battery.

Position Sensor 617 589 08 21 00

4. Rotate the crankshaft by hand (in direction of engine rotation)

until the lamp ‘B’ lights up. Rotate the crankshaft carefully

further until both lamps ‘A and B’ come on. In this position,

check the Rl value on the crankshaft vibration damper.

Notice

If only lamp ‘A’ lights up, repeat the test and if out of

specification, adjust start of delivery.

Specification ATDC 14° - 16°

Page 768 of 1463

OM600 ENGINE CONTROLS 1F3-39

Digital Tester, RIV Method

(Connection Diagram for Testers Without Adapter)

1 Fuel Injection Pump

2 Rl Sensor

3 Digital Tester4 TDC Pulse Sender Unit

5 Battery

Page 769 of 1463

1F3-40 OM600 ENGINE CONTROLS

Start of Delivery (RIV)

Idle Speed (Connection Diagram for Testers With Adapter)

1 Fuel Injection Pump

2 Rl Sensor

3 Digital Tester4 TDC Pulse Sender Unit

5 Battery

6 Rl Pulse Generator

Service Data

ATDC 14° - 16°

OM661LA : 720 - 820 rpm, OM662LA : 750 - 850 rpm

Page 770 of 1463

OM600 ENGINE CONTROLS 1F3-41

With Pulse Generator Tools Required

617 589 09 21 00 Rl Sensor

617 589 10 21 00 Timing Tester

667 589 00 21 00 TDC Pulse Generator

Commercial Tools

Item

Digital Tester

Without Pulse GeneratorTools

Bosch, MOT 001.03

Hartmann & Braun, EOMT3

Bosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel - Tester 875

Test Procedure

1. Remove the screw plug (7) and seal (8) collect oil in a suitable

vessel.

2. Install the Rl sensor into the governor housing of injection

pump (1).

Rl Sensor 617 589 10 21 00

3. Connect the digital tester and TDC pulse sender unit

according to connection diagram.

4. Run the engine at idle speed and check the Rl value on the

digital tester

Notice

If out of standard, adjust the start of delivery.

5. Stop the engine.

6. Remove the Rl sensor, digital tester and TDC pulse sender

unit.

7. Replace the seal and tighten the plug.

8. Check engine oil level and adjust if necessary.

Rl value ATDC 14° - 16°

Tightening Torque 30 Nm

Page 771 of 1463

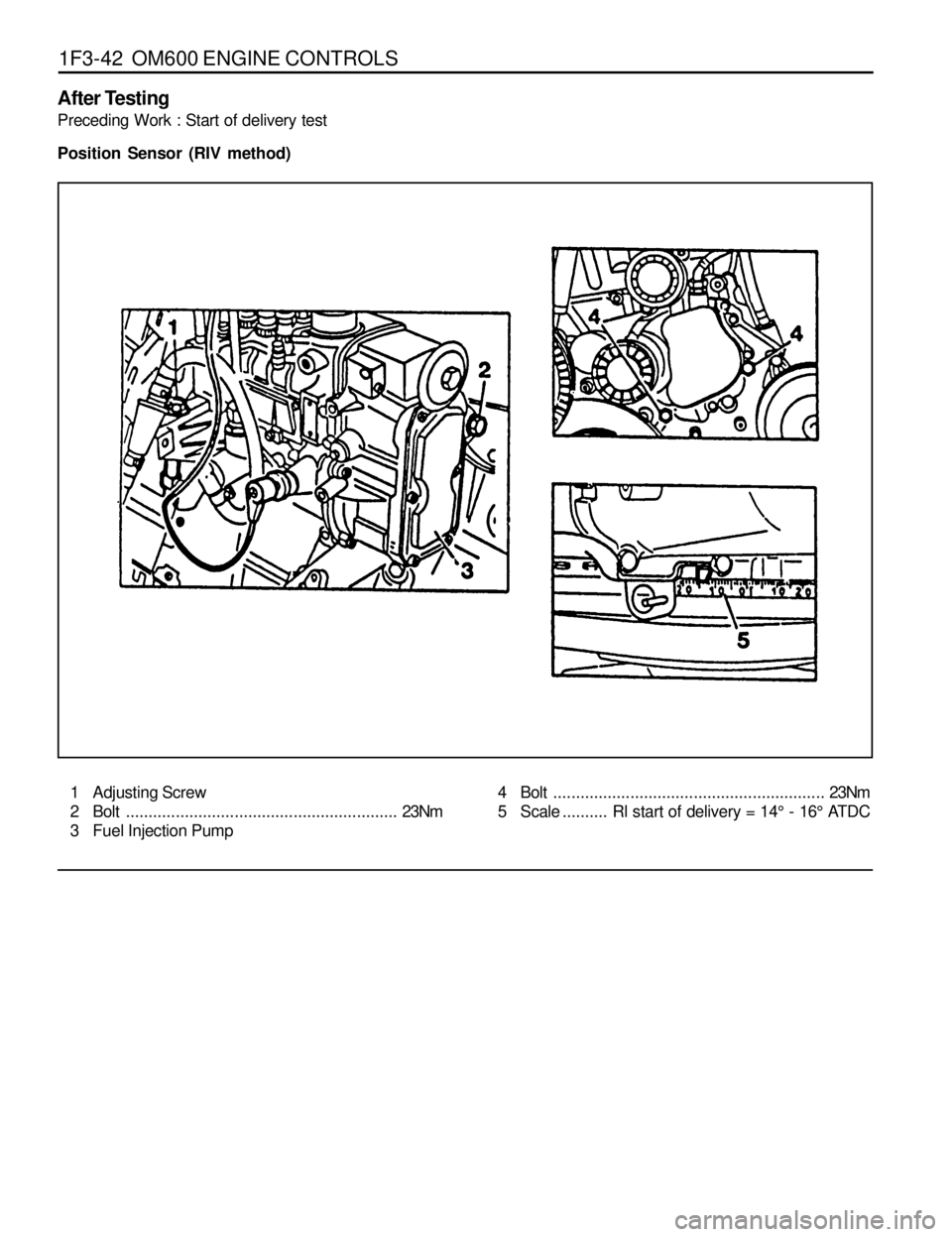

1F3-42 OM600 ENGINE CONTROLS

After Testing

Preceding Work : Start of delivery test

Position Sensor (RIV method)

1 Adjusting Screw

2 Bolt............................................................23Nm

3 Fuel Injection Pump4 Bolt............................................................23Nm

5 Scale.......... Rl start of delivery = 14° - 16° ATDC

Page 772 of 1463

OM600 ENGINE CONTROLS 1F3-43

Tools Required

617 589 08 21 00 Position Sensor

Adjustment Procedure

1. Position the No. 1 cylinder at ATDC 15°

Notice

Do not rotate the engine in opposite direction of engine

rotation.

2. Remove the bolt (2) at the supporting bracket.

3. Remove the bolt (4).

4. Turn the adjusting screw (1) until both lamps ‘A’ + ‘B’ on

the position sensor light up.

Notice

If the adjustment range is not adequate, remove the injection

pump and reinstall.

Position Sensor 617 589 08 21 00

5. After adjusting, retighten all the bolt to the specified torque.

To the right

To the leftStart of delivery retarded

Start of delivery advanced

Page 773 of 1463

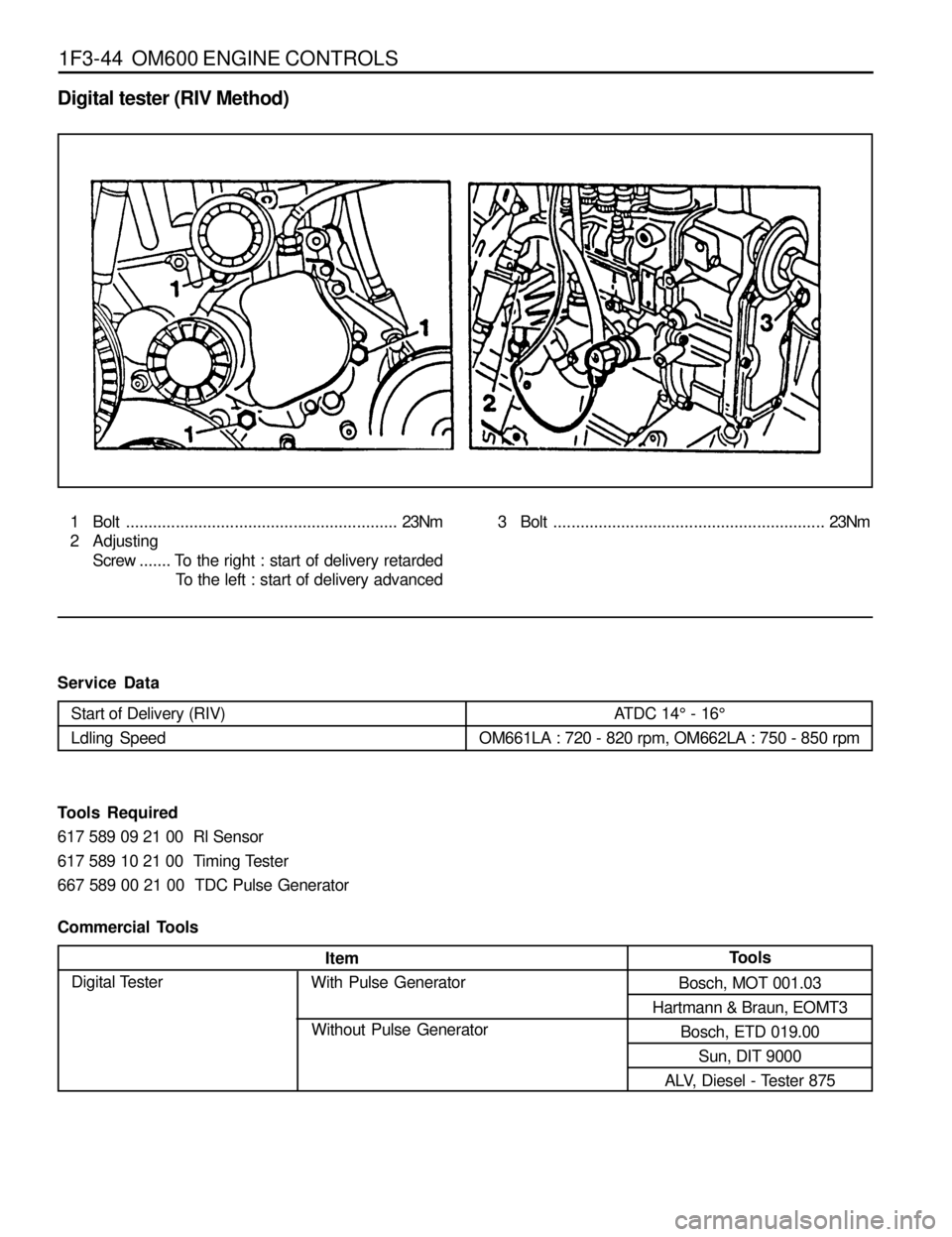

1F3-44 OM600 ENGINE CONTROLS

Tools Required

617 589 09 21 00 Rl Sensor

617 589 10 21 00 Timing Tester

667 589 00 21 00 TDC Pulse Generator

Commercial Tools

Item

Digital Tester

With Pulse Generator

Without Pulse GeneratorTools

Bosch, MOT 001.03

Hartmann & Braun, EOMT3

Bosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel - Tester 875

Digital tester (RIV Method)

1 Bolt............................................................23Nm

2 Adjusting

Screw....... To the right : start of delivery retarded

To the left : start of delivery advanced3 Bolt............................................................23Nm

Service Data

Start of Delivery (RIV)

Ldling Speed

ATDC 14° - 16°

OM661LA : 720 - 820 rpm, OM662LA : 750 - 850 rpm

Page 783 of 1463

M162 ENGINE INTAKE & EXHAUST 1G1-3

Removal & Installation Procedure

1. Release the clamp securing HFM sensor and air cleaner.

2. Disengage the air cleaner assembly and HFM sensor

assembly.

3. Unserew the mounting bolt(6) from the bracket.

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

4. Release the clamp from air cleaner assembly housing and

remove the cover.

5. Remove the air cleaner assembly.

6. Remove the air cleaner housing from insulator.

Notice

Make sure the air cleaner to be seated in insulator.

7. Disengage the air duct hose and air cleaner housing and

remove the housing.

8. Remove the air duct hose.

9. Unscrew the two bolts(7) from air inlet duct.

Installation Notice

10. Remove the air inlet duct.

11. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 8 - 9 Nm