clutch SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 14 of 1463

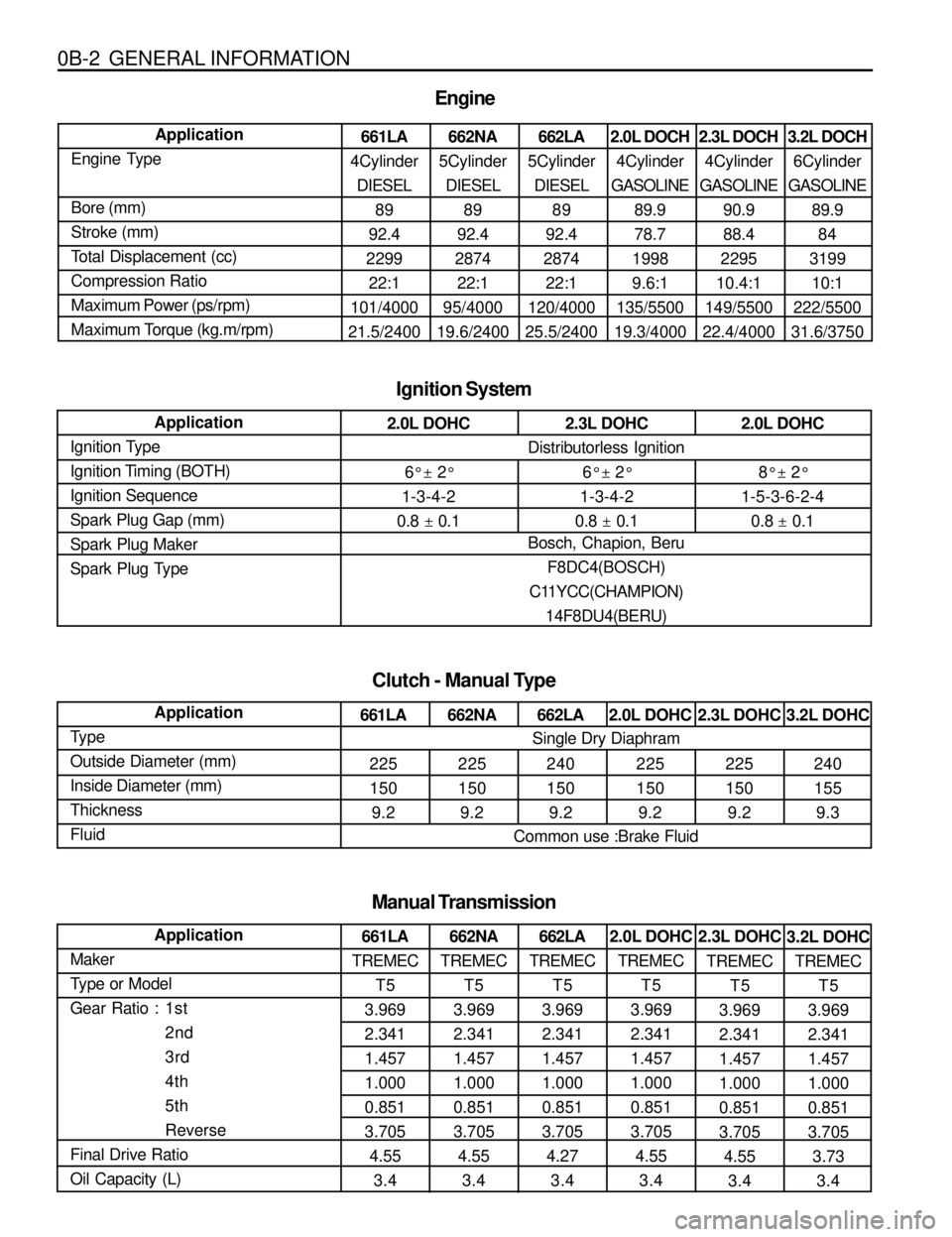

0B-2 GENERAL INFORMATION

661LA

4Cylinder

DIESEL

89

92.4

2299

22:1

101/4000

21.5/2400 Application

Engine Type

Bore (mm)

Stroke (mm)

Total Displacement (cc)

Compression Ratio

Maximum Power (ps/rpm)

Maximum Torque (kg.m/rpm)

Engine

662NA

5Cylinder

DIESEL

89

92.4

2874

22:1

95/4000

19.6/2400662LA

5Cylinder

DIESEL

89

92.4

2874

22:1

120/4000

25.5/24002.0L DOCH

4Cylinder

GASOLINE

89.9

78.7

1998

9.6:1

135/5500

19.3/40002.3L DOCH

4Cylinder

GASOLINE

90.9

88.4

2295

10.4:1

149/5500

22.4/40003.2L DOCH

6Cylinder

GASOLINE

89.9

84

3199

10:1

222/5500

31.6/3750

661LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4 Application

Ignition Type

Ignition Timing (BOTH)

Ignition Sequence

Spark Plug Gap (mm)

Spark Plug Maker

Spark Plug Type

Ignition System

Clutch - Manual Type

2.0L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.3L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.0L DOHC

8° ± 2°

1-5-3-6-2-4

0.8 ± 0.1 Distributorless Ignition

Bosch, Chapion, Beru

F8DC4(BOSCH)

C11YCC(CHAMPION)

14F8DU4(BERU)

661LA

225

150

9.2

662NA

225

150

9.2662LA

240

150

9.22.0L DOHC

225

150

9.22.3L DOHC

225

150

9.23.2L DOHC

240

155

9.3 Application

Type

Outside Diameter (mm)

Inside Diameter (mm)

Thickness

Fluid

Single Dry Diaphram

Common use :Brake Fluid

Application

Maker

Type or Model

Gear Ratio : 1st

2nd

3rd

4th

5th

Reverse

Final Drive Ratio

Oil Capacity (L)

Manual Transmission

662NA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4662LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.27

3.42.0L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.42.3L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.43.2L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

3.73

3.4

Page 21 of 1463

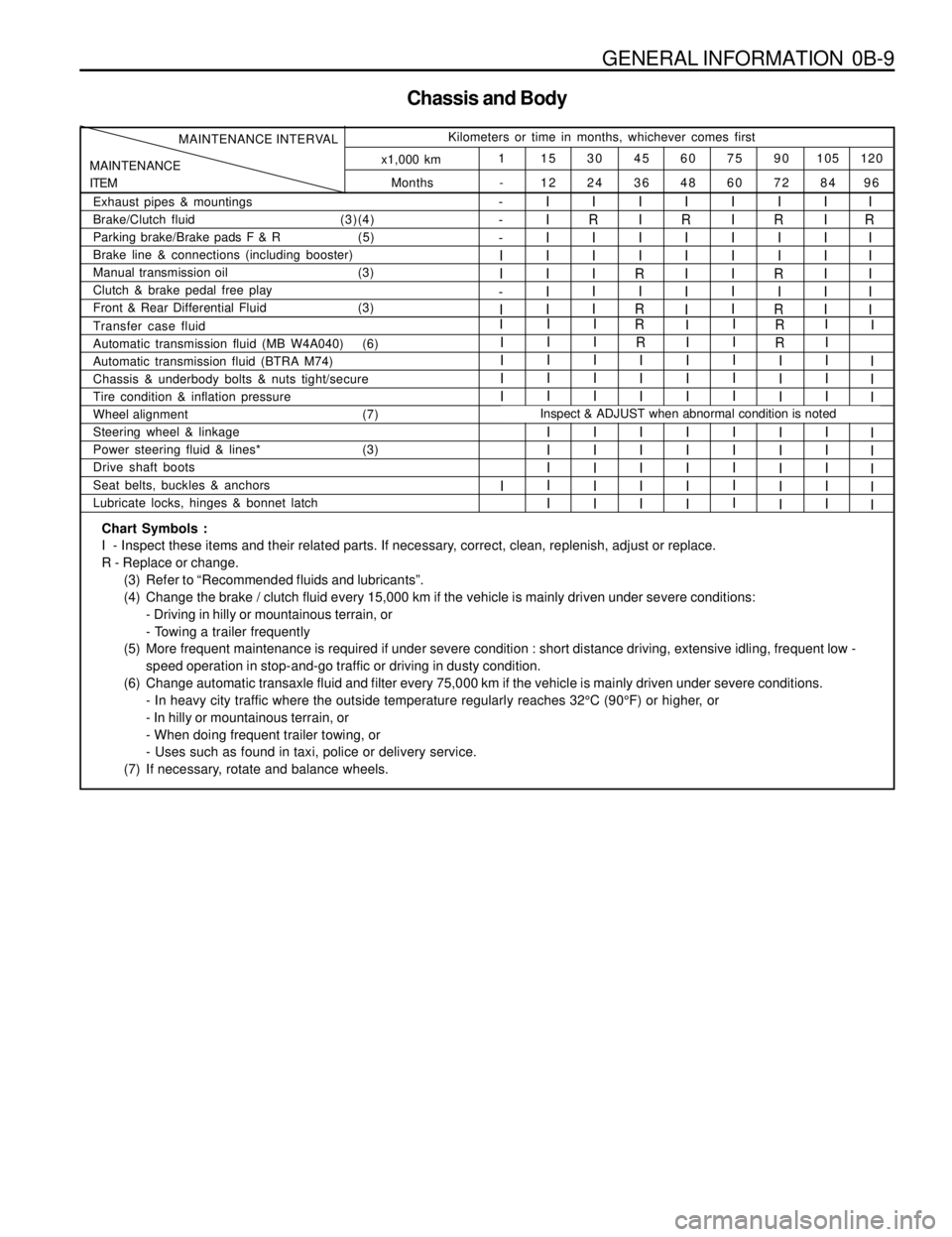

GENERAL INFORMATION 0B-9

Chassis and Body

Months

MAINTENANCE

ITEMMAINTENANCE INTERVALKilometers or time in months, whichever comes first

120 105 90 75 60 45 30 15 1

96 84 72 60 48 36 24 12

- x1,000 km

Exhaust pipes & mountings

Brake/Clutch fluid(3)(4)

Parking brake/Brake pads F & R (5)

Brake line & connections (including booster)

Manual transmission oil (3)

Clutch & brake pedal free play

Front & Rear Differential Fluid (3)I

R

I

I

I

I

I-

-

-

I

I

-

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

R

I

RI

I

I

I

I

I

II

R

I

I

R

I

RI

I

I

I

I

I

II

R

I

I

I

I

I

Automatic transmission fluid (MB W4A040) (6)

Automatic transmission fluid (BTRA M74)

Chassis & underbody bolts & nuts tight/secure

Tire condition & inflation pressure

Wheel alignment (7)

Steering wheel & linkage

Power steering fluid & lines* (3)

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & bonnet latchI

I

I

I

II

I

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

IR

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

IR

R

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

Transfer case fluidRIII

Inspect & ADJUST when abnormal condition is noted

I

I

I

I

I

I

I

I

I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 23 of 1463

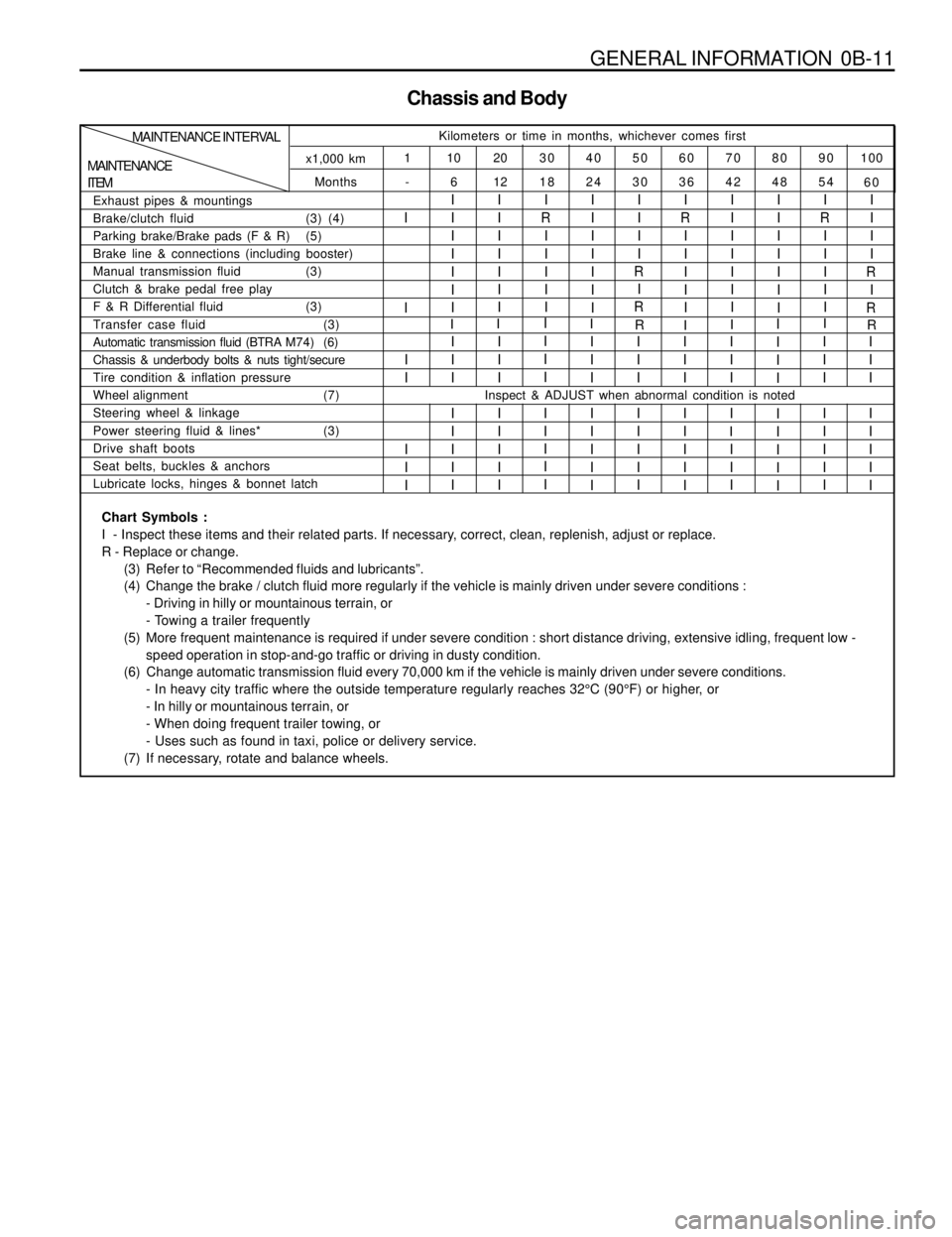

GENERAL INFORMATION 0B-11

Chassis and Body

Months

-

MAINTENANCE

ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100 90 80 70 60 50 40 30 20 10 1

60 54 48 42 36 30 24 18 12 6 x1,000 km

Exhaust pipes & mountings

Brake/clutch fluid(3) (4)

Parking brake/Brake pads (F & R) (5)

Brake line & connections (including booster)

Manual transmission fluid (3)

Clutch & brake pedal free play

F & R Differential fluid (3)

I

II

I

I

I

I

I

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

I

I

II

I

I

I

R

I

RI

R

I

I

I

I

II

I

I

I

I

I

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

R

I

R

Automatic transmission fluid (BTRA M74) (6)

Chassis & underbody bolts & nuts tight/secure

Tire condition & inflation pressure

Wheel alignment (7)

Steering wheel & linkage

Power steering fluid & lines* (3)

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & bonnet latchI

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

I

Transfer case fluid (3)R

IR

I II

I

I

I

I

II

I

I

I

I

I

I

I

I

Inspect & ADJUST when abnormal condition is noted

II

I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 26 of 1463

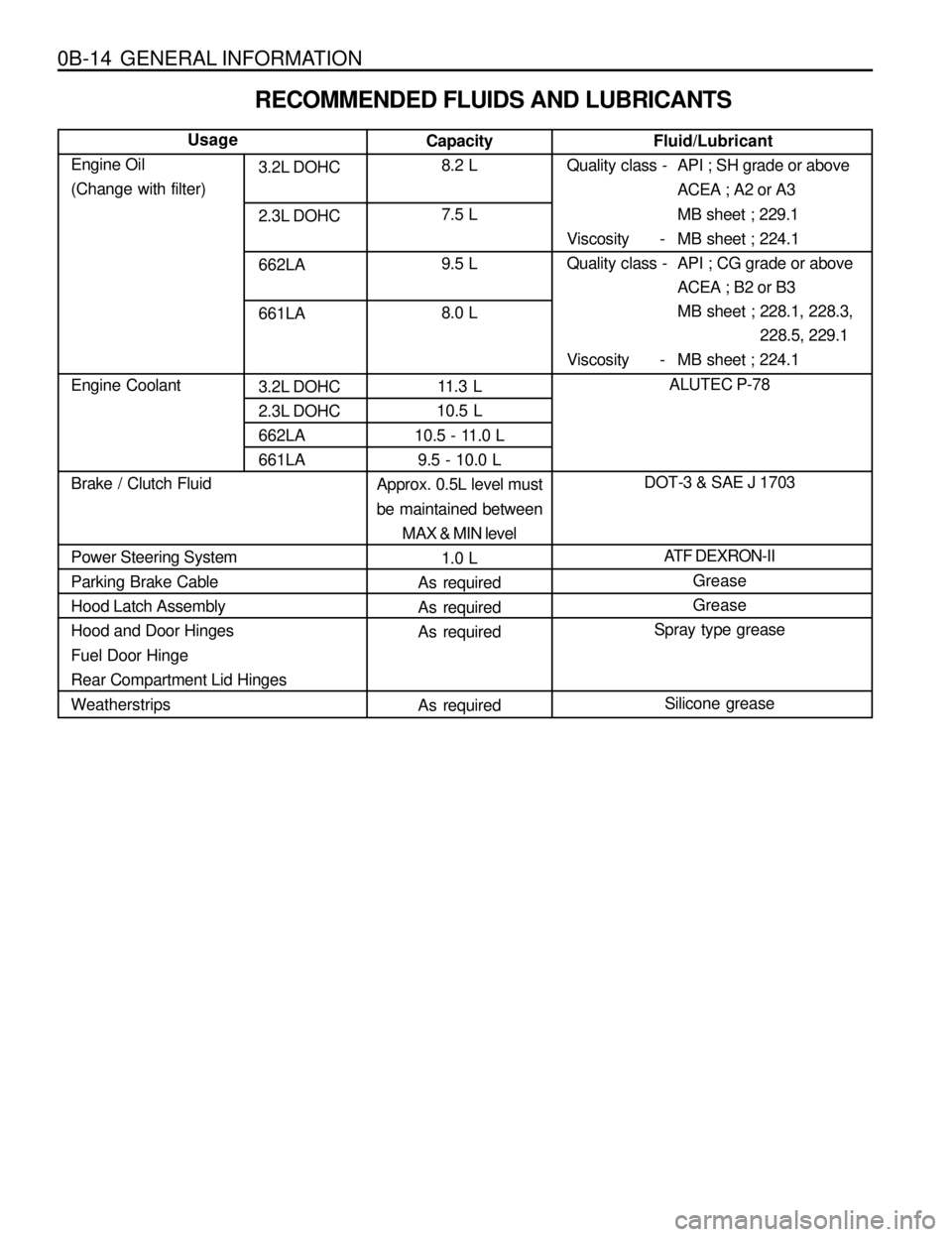

0B-14 GENERAL INFORMATION

Usage

Engine Oil

(Change with filter)

Engine Coolant

Brake / Clutch Fluid

Power Steering System

Parking Brake Cable

Hood Latch Assembly

Hood and Door Hinges

Fuel Door Hinge

Rear Compartment Lid Hinges

Weatherstrips

RECOMMENDED FLUIDS AND LUBRICANTS

Capacity

8.2 L

7.5 L

9.5 L

8.0 L

11.3 L

10.5 L

10.5 - 11.0 L

9.5 - 10.0 L

Approx. 0.5L level must

be maintained between

MAX & MIN level

1.0 L

As required

As required

As required

As requiredFluid/Lubricant

Quality class - API ; SH grade or above

ACEA ; A2 or A3

MB sheet ; 229.1

Viscosity - MB sheet ; 224.1

Quality class - API ; CG grade or above

ACEA ; B2 or B3

MB sheet ; 228.1, 228.3,

228.5, 229.1

Viscosity - MB sheet ; 224.1

ALUTEC P-78

DOT-3 & SAE J 1703

ATF DEXRON-II

Grease

Grease

Spray type grease

Silicone grease 3.2L DOHC

2.3L DOHC

662LA

661LA

3.2L DOHC

2.3L DOHC

662LA

661LA

Page 35 of 1463

1A1-4 GENERAL ENGINE INFORMATION

23 Camshaft Adjuster

24 Cooling Fan and Viscous Clutch

25 Piston

26 Flywheel of Drive Plate27 Oil Pump Drive Chain

28 Oil Return Pipe

29 Timing Chain

30 Oil Pump

SIDE VIEW

Page 48 of 1463

1A2-4 GENERAL ENGINE INFORMATION

23 Camshaft Adjuster

24 Oil Filler Cap

25 Engine Hanger Bracket

26 Cooling Fan and Viscous Clutch

27 Oil Filter

28 Timing Chain29 Oil Pump Drive Chain

30 Oil Strainer

31 Oil Pump

32 Ring Gear and Flywheel of Drive Plate

33 Piston

SIDE VIEW

Page 112 of 1463

M162 ENGINE MECHANICAL 1B1-39

3. Remove the cooling fan and the viscous clutch. Unscrew

the three bolts from the cooling fan bracket and remove the

bracket (arrows).

Installation Notice

4. Remove the timing gear case cover after unscrewing the

bolts (3) and (4) from the timing gear case cover and the

bolt (9) from the oil pan.

Notice

Be careful not to damage the oil pan gasket.

Installation Notice

lApply the sealant after cleaning the timing gear case

cover surface.

lBe careful not to stain the oil chamber of chain tensioner

with the sealant.

5. Installation should follow the removal procedure in the

reverse order.

6. Warm up the engine and check for oil leaks.

Tightening Torque 22.5 - 27.5 Nm

Tightening TorqueBolt (3,4) 22.5 - 27.5 Nm

Bolt (9) 9 - 11 Nm

Page 115 of 1463

1B1-42 M162 ENGINE MECHANICAL

1 Center Bolt (M18 x 50)......1st step 200- 220 Nm

2nd step 90°+10°

2 Vibration Damper Disk

3 Bolt (M6 x 20, 6 pieces).....................7.7-9.5 Nm

BELT PULLEY AND VIBRATION DAMPER

Preceding Work : Removal of cooling fan and viscous clutch

Removal of fan shroud

Removal of drive belt

4 Vibration Damper Assembly

5 Woodruff Key

6 Bolt (M6 x 12, 4 pieces)......................... 9-11 Nm

7 Cooling Fan Pulley

Page 233 of 1463

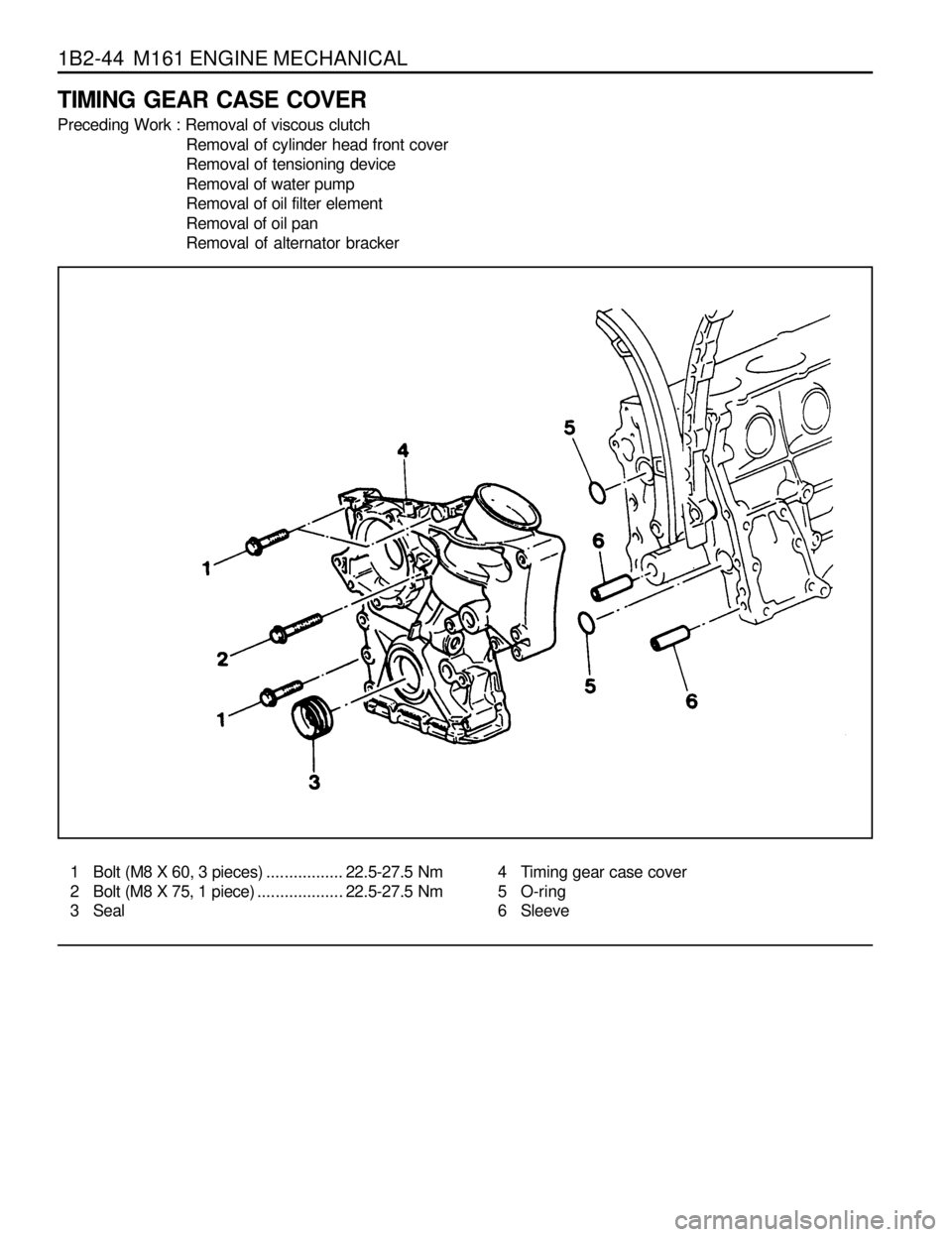

1B2-44 M161 ENGINE MECHANICAL

TIMING GEAR CASE COVER

Preceding Work : Removal of viscous clutch

Removal of cylinder head front cover

Removal of tensioning device

Removal of water pump

Removal of oil filter element

Removal of oil pan

Removal of alternator bracker

1 Bolt (M8 X 60, 3 pieces).................22.5-27.5 Nm

2 Bolt (M8 X 75, 1 piece)...................22.5-27.5 Nm

3 Seal4 Timing gear case cover

5 O-ring

6 Sleeve

Page 238 of 1463

M161 ENGINE MECHANICAL 1B2-49

BELT PULLEY AND VIBRATION DAMPER

Preceding Work : Removal of cooling fan and viscous clutch

Removal of fan shroud

Removal of drive belt

1 Center Bolt

(M18 X 55) ....................... 1st step 200-220 Nm

2nd step 90° + 10° rotation added

2 Vibration Damper Disk5 Vibration Damper Assembly

6 Key