ignition SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1058 of 1463

AUTOMATIC TRANSMISSION 5A-81

Throttle Clearing

The leant throttle clearing routine uses the mode switch and gear lever. Carry out the following steps to complete the

automated throttle clearing procedure:

1. Switch ignition ‘ON’ with handbrake applied and engine ‘OFF’.

2. Select ‘M1’ and ‘WINTER’ mode.

3. Move the T-bar to ‘M2’ and then select ‘NORMAL’ or ‘POWER’ mode.

4. Move the T-bar to ‘M3’ and then select ‘WINTER’ mode.

Vehicle Coding

The vehicle coding is integrated as part of the diagnostic software. The coding applies to the following vehicle

models:

1. 4WD Gasoline E32.

2. 4WD Gasoline 523

3. 4WD Gasoline 520.

4. 4WD Diesel D29NA.

5. 4WD Diesel D29LA.

6. 4WD Diesel D23LA.

7. RWD E20.

8. RWD E23.

Page 1154 of 1463

Type

Clutch Pedal

Clutch Disc

Clutch Master Cylinder

Clutch Release Cylinder

Clutch FluidDescription

Hydraulic

Suspended

158 mm

5 - 10 mm

Single Dry Diaphragm

9.85 - 10.2 mm

9.2 mm

19.8 mm

f15.87 mm

14.0 mm

f17.46 mm

SAE J1703 / DOT3

SECTION 5C

CLUTCH

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5C-1

General Specifications . . . . . . . . . . . . . . . . . . 5C-1

Fastener Tightening Specifications . . . . . . . . . 5C-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 5C-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . . 5C-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-4

Clutch Slips . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-4

Poor Disengagement . . . . . . . . . . . . . . . . . . . 5C-4

Hard to Shift or Will not Shift . . . . . . . . . . . . . . 5C-4

Clutch Chatters When Starting . . . . . . . . . . . . 5C-4

Difficult Pedal Operation . . . . . . . . . . . . . . . . . 5C-5

SPECIFICATIONS

GENERAL SPECIFICATIONS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Application

Type

Max. Pedal Stroke

Pedal Free Play

Type

Thickness of Disc

Stroke

Inner Diameter

Stroke

Inner DiameterFree

With Load

Clutch Noisy . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-5

Component Locator . . . . . . . . . . . . . . . . . . . 5C-6

Clutch Assembly . . . . . . . . . . . . . . . . . . . . . . . 5C-6

Pedal and Master Cylinder . . . . . . . . . . . . . . . 5C-7

Maintenance and Repair . . . . . . . . . . . . . . . 5C-8

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 5C-8

Bleeding of Clutch System . . . . . . . . . . . . . . . 5C-8

Clutch Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-9

Master Cylinder . . . . . . . . . . . . . . . . . . . . . . 5C-13

Clutch Pedal . . . . . . . . . . . . . . . . . . . . . . . . . 5C-15

Clutch Oil Chamber . . . . . . . . . . . . . . . . . . . 5C-17

Page 1171 of 1463

Model

Type

Gear Ratio

Oil

Manufacturer

WeightPart-Time 4408 (E)

E.S.O.F. Type

1 : 1

2.48 : 1

ATF S-3, S-4 or DEXRON II, III

1.2 L

Check : Every 15,000 km

Replace : Every 50,000 km

Borg Warner

30 kg

SECTION 5D1

TRANSFER CASE (PART TIME 4408)

TABLE OF CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 5D1-1

General Specifications . . . . . . . . . . . . . . . . . 5D1-1

Schematic and Routing Diagram . . . . . . . . 5D1-2

Part Time Transfer Case - 4408 . . . . . . . . . . 5D1-2

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 5D1-3

Self-Diagnosis . . . . . . . . . . . . . . . . . . . . . . 5D1-4

System Description . . . . . . . . . . . . . . . . . . . . 5D1-4

Self-Diagnosis Test . . . . . . . . . . . . . . . . . . . . 5D1-8Diagnostic Diagram . . . . . . . . . . . . . . . . . . . 5D1-9

Maintenance and Repair . . . . . . . . . . . . . 5D1-10

On-Vehicle Service . . . . . . . . . . . . . . . . . . . 5D1-10

Maintenance of Transfer Case Lubricant . . 5D1-10

Transfer Case . . . . . . . . . . . . . . . . . . . . . . . 5D1-11

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 5D1-14

Transfer Case . . . . . . . . . . . . . . . . . . . . . . . 5D1-14

Transfer Case Control Unit (TCCU) . . . . . . 5D1-36

High

Low

Specification

Capacity

Lubrication ApplicationDescription

Page 1174 of 1463

5D1-4 TRANSFER CASE (PART TIME 4408)

SELF-DIAGNOSIS

SYSTEM DESCRIPTION

1. TCCU detects transfer case system malfunctions and

indicates malfunctioning part(s) through flashing 4H,4L

indicator lights.

Using a service connector, connect it to the diagnosis box

in the engine room and read the flashing of the ‘4WD

CHECK’ indicator light.

The flashing indicator light will show you defective code(s).

2. Identify 7 defective codes after reading the flashing indicator

light.

lTCCU

lShift motor

lMagnetic synchronizer clutch

lSpeed sensor

lHub solenoid

lSelector switch

lMotor position sensor

3. Transfer case system is malfunctioning when:

l4H ,4L indicator lights are remain on after 0.6 second

when turning the ignition switch ‘ON’

l4H,4L indicator lights are continuously come on during

driving.

4. If only 1 part is malfunctioning, ‘4WD CHECK’ indicator light

will display defective code 3 times continuously.

5. If more then 2 part is malfunctioning, the first malfunctioning

part will be displayed 3 times and following malfunctioning

parts will be displayed .

6. To read defective code, connect the service connector and

turn the ignition switch 'ON'.

7. After repairing, eliminate the defective code stored in the

TCCU.

Notice

Before replacing the malfunction parts with defective code,

check the wires and connectors for proper condition.

Page 1175 of 1463

TRANSFER CASE (PART TIME 4408) 5D1-5

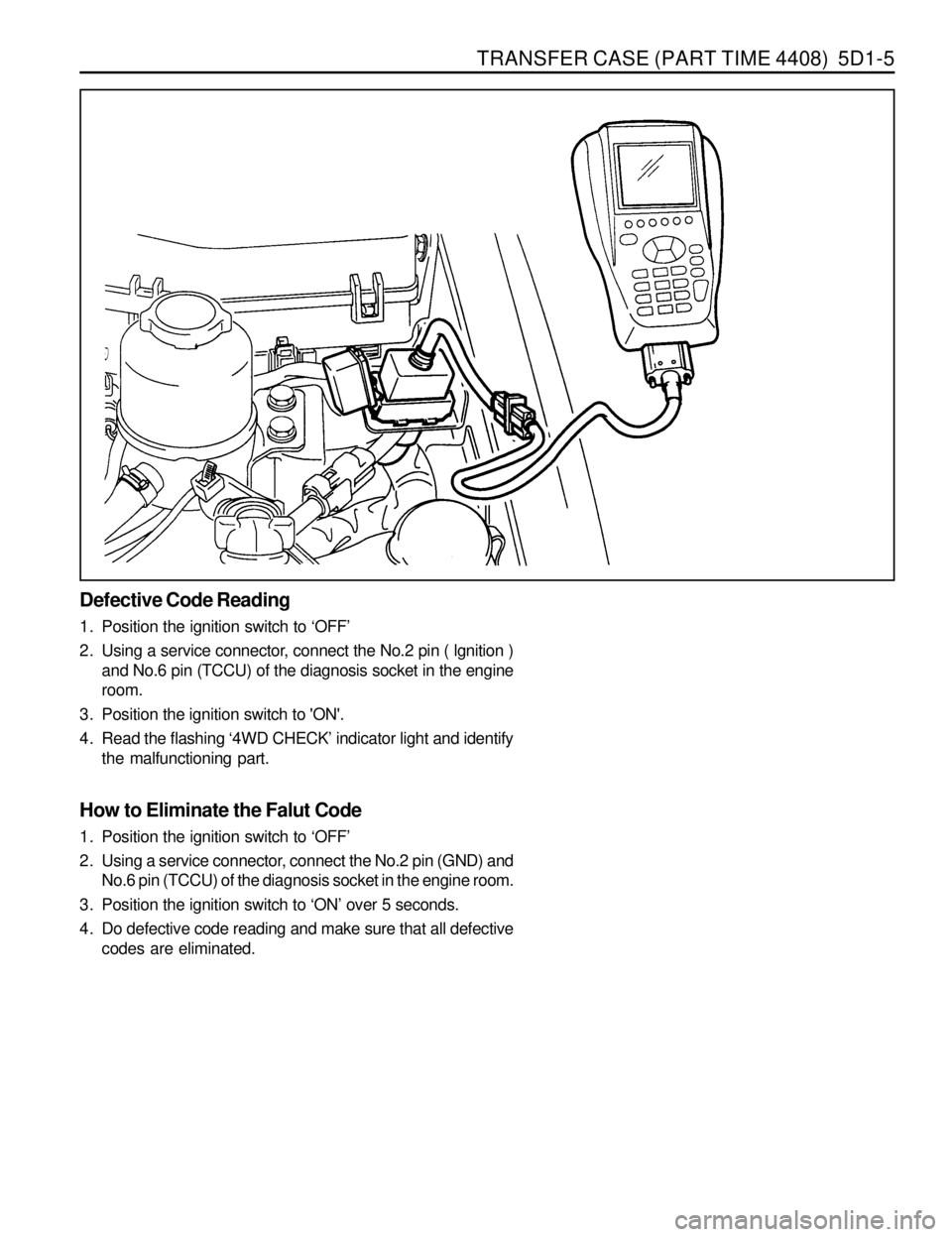

Defective Code Reading

1. Position the ignition switch to ‘OFF’

2. Using a service connector, connect the No.2 pin ( lgnition )

and No.6 pin (TCCU) of the diagnosis socket in the engine

room.

3. Position the ignition switch to 'ON'.

4. Read the flashing ‘4WD CHECK’ indicator light and identify

the malfunctioning part.

How to Eliminate the Falut Code

1. Position the ignition switch to ‘OFF’

2. Using a service connector, connect the No.2 pin (GND) and

No.6 pin (TCCU) of the diagnosis socket in the engine room.

3. Position the ignition switch to ‘ON’ over 5 seconds.

4. Do defective code reading and make sure that all defective

codes are eliminated.

Page 1176 of 1463

5D1-6 TRANSFER CASE (PART TIME 4408)

Diagnostic Table

Connect a service connector. If turn the ignition switch ‘ON’

‘4WD CHECK’ indicator light will come on for 0.6 second and

turn off for 3 seconds and then display a defective code 3

times continuously.

No.Defective Code

Malfunctioning Part

1

2

3

4

5TCCU

Shift Motor

Synchronizer Clutch

Speed Sensor

Hub Solenoid

4WD

CHECK

Light

ON

OFF

Defective Code

4WD

CHECK

Light

ON

OFF

Defective Code

4WD

CHECK

Light

ON

OFF

Defective Code

4WD

CHECK

Light

ON

OFF

Defective Code

4WD

CHECK

Light

ON

OFF

Defective Code

Page 1178 of 1463

5D1-8 TRANSFER CASE (PART TIME 4408)

SELF-DIAGNOSIS TEST

Test Procedure

1. Connect the scanner harness connector to the engine

compartment diagnosis socket.

2. Turn the ignition switch to "ON" position.

3. Select "Electronic control vehicle diagnosis" from the function

selection display and press "Enter".

4. Select "Musso" from vehicle model selection display and

press "Enter".

5. Select "TCCU" from control system selection display and

press "Enter".

6. Select "TCCU Part Time" from TCCU diagnosis selection

display.

Notice

Check sensor valve output display if necessary.

7 . Select "Self-diagnosis" from diagnosis items selection display.

8. Turn the ignition switch to "OFF" position and press

"ENTER". Turn the ignition swtich to "ON" position again

and press "ENTER".

9. Determine fault code and check the defective component.

Notice

Refer to self-diagnosis list.

Page 1207 of 1463

TRANSFER CASE (PART TIME 4408) 5D1-37

Inspection and Repair

1. 4H and 4L indicator light inspection

lWhen turn the ignition switch to "ON" position, 4H and

4L indicator light will turn on for 0.6 second and will turn

off immediately.

Notice

If indicator light does not turn on, check bulb, wiring harness

and TCCU.

2. TCCU inspection

Pin No.

Operation Condition

4H or 4L

2H

4H indicator light ON

4H indicator light OFF

2H or 4H

4L

Clutch pedal applied

Clutch pedal released

4L indicator light ON

4L indicator light OFF

Motor OFF

Motor ON

Motor OFF

Motor ON

Auto locking hub ON

Auto locking hub OFFVoltage(V)

4.75 - 5.35

0 - 0.50

< 1.00

> 11.00

4.75 - 5.35

0 - 0.50

< 0.50

> 11.00

< 1.00

> 11.00

< 1.00

> 11.00

< 1.00

> 11.00

> 11.00

< 1.00 J1 - 7

J1 - 8

J1 - 13

J1 - 14

J1 - 15

J1 - 16

J1 - 17

J1 - 23

Notice

lDC 12V for the TCCU operation should be maintained.

lIn case of J1-8 and J1-15, indicator light will turn on for 0.6

second when turn the ignition switch ON.

lIf 4H and 4L indicator lights remain turned on when turn the

ignition switch on or during driving, perform the TCCU

diagnosis.

Page 1213 of 1463

5D2-6 TRANSFER CASE (TOD)

Input/Output diagram

TOD control unit and main wiring harness is linked by 30 pin

connector. Each pin joins with switche and actuator whose

details refer to the below diagram.

Battery Power

Ignition ON/OFF

Position Encoder 1

Position Encoder 2

Position Encoder 3

Position Encoder 4

4H / 4L Switch Signal

A/T “N” Position Signal

Speed / TPS Supply

Front Speed Sensor Input

Rear Speed Sensor Input

ABS Operation Signal

Brake Switch Signal

4

5

27

10

28

30

9

24

16

11

29

25

26

19

CAN H

CAN L

Shift Motor output port

(LO-HI)

Shift Motor output port

(HI-LO)

EMC

'4L' Indicator

Position Return

'4WD CHECK' IND

TPS/speed Sensor Ground

(Speed / TPS Return)

2

1

3

21

6

7

13 15

14

K-Line20 22

23

17

18

Page 1214 of 1463

TRANSFER CASE (TOD) 5D2-7

1. K-LINE : Communication line for coding and diagnosis with SCANNER.

Classification of Pin No.

ClassificationPin No. Pin NameDescription

Power Supply17,18Ground

TOD control unit ground

4,19Battery

TOD control unit battery supply : (Fuse No 13,20A)

5IgnitionIgnition ON / OFF

27Position 1

Position encoder 1 : check of shift motor position

10Position 2

Position encoder 2 : check of shift motor position

28Position 3

Position encoder 3 : check of shift motor position

30Position 4

Position encoder 4 : check of shift motor position

94H/4L SwitchTransfer case mode input

24Auto T/M Neutral

Check of neutral gear position in Auto T/M

16Speed5V supply (TPS / speed sensor)

11Front Speed

Front speed sensor signal input Signal Input

29Rear Speed

Rear speed sensor signal input

25ABS Operation

ABS ON / OFF

6Position Return

Position encoder ground

13Speed / TPS ReturnGround for speed sensor / TPS

22CAN-LCAN bus low line

23CAN-HCAN bus high line

2,15Motor LO-HIMotor output port

- LO to HI : join with battery

- HI to LO (or motor brake) : join with ground

1,14Motor HI-LO

Motor output port

- HI to LO : join with battery

- LO to HI (or motor brake) : join with ground

3EMCTOD output

Signal Output

214L IlluminationIlluminates “4L” indicator

7Diagnosis Display

4WD check lamp illuminator

- Upon defect ; Ground circuit

20K-LINE1)Diagnosis