service SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 32 of 1463

SECTION 1

ENGINE

SECTION 1A1(M162 ENGINE)

GENERAL ENGINE INFORMATION

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A1-1

Engine Specifications . . . . . . . . . . . . . . . . . . 1A1-1

Component Locator . . . . . . . . . . . . . . . . . . 1A1-3

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-3

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-4

Performance Curve . . . . . . . . . . . . . . . . . . 1A1-5

E32 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-5

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A1-6

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A1-6

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1A1-7

Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . . 1A1-7

Engine Cranking at The

Front of Crankshaft . . . . . . . . . . . . . . . . . . 1A1-8

Compression Pressure Test . . . . . . . . . . . . . 1A1-9

Cylinder Pressure Leakage Test . . . . . . . . . 1A1-11

General Information . . . . . . . . . . . . . . . . . 1A1-13

Cleanliness and Care . . . . . . . . . . . . . . . . . 1A1-13

On-Engine Service . . . . . . . . . . . . . . . . . . . 1A1-13

Application

Engine Model

Displacement (CC)

Cylinder (Bore x Stroke) (mm)

Fuel Injection / Ignition System

Compression Ratio

Number of Cylinders

Camshaft Valve Arrangement

Camshaft Drive Type

Max. Output (ps/rpm)

Max. Torque (kg•m/rpm)

Firing Order

Ignition Type

Ignition Timing

Valve Timing Intake Open/Close

ExhaustOpen/Close

Valve Clearance Adjustment

SPECIFICATIONS

ENGINE SPECIFICATIONS

E32 Engine

M162.990

3199

89.9 x 84.0

MSE 3.62S

10 : 1

6

DOHC

Chain-Driven

222 / 5500

31.6 / 3750

1-5-3-6-2-4

Distributorless Double Ignition

BTDC 8° ± 2°

ATDC 11° / ABDC 34°

BBDC 31° / BTDC 14°

Automatic Control

TABLE OF CONTENTS

Page 40 of 1463

GENERAL ENGINE INFORMATION 1A1-9

COMPRESSION PRESSURE TEST

1 Compression Pressure Tester

2 Diagram Sheet3 Adaptor

4 Sealing Cone

Tools Required

001 589 76 21 00 Compression Pressure Tester

119 589 01 09 00 Spark Plug Wrench

Standard Service Data

Compression Ratio

Normal Engine Temperature

Normal Compression Pressure

Permissible Pressure Difference Between Individual

Cylinders10 : 1

80°C

Min. 10 bar, Max. 14 bar

Min. 6 bar, Max. 10 bar

Max. 1.5 bar General

Fuel Optimization

Page 44 of 1463

GENERAL ENGINE INFORMATION 1A1-13

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

enigne oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on initial

operation. Proper cleaning and protection of machined

surfaces and friction areas is part of the repair

procedure. This is considered standard shop practice

even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable

before removing or installing any electrical unit, or

when a tool or equipment could easily come in

contact with exposed electrical terminals.

Disconnecting this cable will help prevent personal

injury and damage to the vehicle. The ignition must

also be in LOCK unless otherwise noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

Page 45 of 1463

SECTION 1

ENGINE

SECTION 1A2(M161 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A2-1

Engine Specifications . . . . . . . . . . . . . . . . . . 1A2-1

Component Locator . . . . . . . . . . . . . . . . . . 1A2-3

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-3

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-4

Performance Curve . . . . . . . . . . . . . . . . . . 1A2-5

E23 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-5

E20 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-6

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A2-7

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A2-7

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1A2-8

Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . . 1A2-8

Engine Cranking At The

Front of Crankshaft . . . . . . . . . . . . . . . . . . 1A2-9

Compression Pressure Test . . . . . . . . . . . . 1A2-10

Cylinder Pressure Leakage Test . . . . . . . . . 1A2-12

General Information . . . . . . . . . . . . . . . . . 1A2-14

Cleanliness and Care . . . . . . . . . . . . . . . . . 1A2-14

On-Engine Service . . . . . . . . . . . . . . . . . . . 1A2-14

E20 Engine

M161.940

1998

89.9 x 78.7

¬

9.6:1

¬

¬

¬

135 / 5500

19.3 / 4000

¬

¬

¬

ATDC 13.15° / ABDC 13.57°

BBDC 16.58° / BTDC 17.05°

¬ Application

Engine Model

Displacement (CC)

Cylinder (Bore x Stroke) (mm)

Fuel Injection / Ignition System

Compression Ratio

Number of Cylinders

Camshaft Valve Arrangement

Camshaft Drive Type

Max. Output (ps/rpm)

Max. Torque (kg•m/rpm)

Firing Order

Ignition Type

Ignition Timing

Valve Timing Intake Open/Close

ExhaustOpen/Close

Valve Clearance Adjustment

SPECIFICATIONS

ENGINE SPECIFICATIONS

E23 Engine

M161.970

2295

90.9 x 88.4

MSE 3.53S

10.4:1

4

DOHC

Chain-Driven

149 / 5500

22.4 / 4000

1-3-4-2

Distributorless

BTDC 6° ± 2°

ATDC 19.25° / ABDC 28.76°

BBDC 20.62° / BTDC 15.08°

Automatic Control

Page 54 of 1463

1A2-10 GENERAL ENGINE INFORMATION

COMPRESSION PRESSURE TEST

1 Compression Pressure Tester

2 Diagram Sheet3 Adaptor

4 Sealing Cone

Tools Required

001 589 76 21 00 Compression Pressure Tester

119 589 01 09 00 Spark Plug Wrench

Standard Service Data

Compression Ratio

Normal Engine Temperature

Normal Compression Pressure

Permissible Pressure Difference Between Individual

Cylinders10.4, 9.6

80°C

Min. 11 bar, Max. 15 bar

Min. 10.5 bar, Max. 14 bar

Max. 1.5 bar E23 Engine(e = 10.4)

E20 Engine(e = 9.6)

Page 58 of 1463

1A2-14 GENERAL ENGINE INFORMATION

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

enigne oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on initial

operation. Proper cleaning and protection of machined

surfaces and friction areas is part of the repair

procedure. This is considered standard shop practice

even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable be-

fore removing or installing any electrical unit, or

when a tool or equipment could easily come in con-

tact with exposed electrical terminals. Disconnect-

ing this cable will help prevent personal injury and

damage to the vehicle. The ignition must also be in

LOCK unless otherwise noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

Page 59 of 1463

Application

Engine Type

Displacement (CC)

Cylinder (Bore x Stroke) (mm)

Fuel Injection / Ignition System

Compression Ratio

Number of Cylinders

Camshaft Valve Arrangement

Camshaft Drive Type

Max. Output (ps/rpm)

Max. Torque (kg•m/rpm)

Firing Order

Injection Timing

Valve Timing Intake Open/Close

(at 2mm lift) ExhaustOpen/Close

Valve Clearance Adjustment

SECTION 1

ENGINE

SECTION 1A3(OM600 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1A3-1

Engine Specifications . . . . . . . . . . . . . . . . . . 1A3-1

Sectional View . . . . . . . . . . . . . . . . . . . . . . 1A3-3

OM662LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-3

OM661LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-5

Performance Curve . . . . . . . . . . . . . . . . . . 1A3-7

OM662LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-7

OM661LA Engine . . . . . . . . . . . . . . . . . . . . . 1A3-8

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1A3-9

SPECIFICATIONS

ENGINE SPECIFICATIONS

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1A3-9

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 1A3-10

Oil Leak Diagnosis . . . . . . . . . . . . . . . . . . . 1A3-10

Compression Pressure Test . . . . . . . . . . . . 1A3-11

Cylinder Pressure Leakage Test . . . . . . . . . 1A3-13

General Information . . . . . . . . . . . . . . . . . 1A3-15

Cleanliness and Care . . . . . . . . . . . . . . . . . 1A3-15

On-Engine Service . . . . . . . . . . . . . . . . . . . 1A3-15

OM662LA

Four-Stroke Diesel

2874

89 x 92.4

PES 5 M55 C320 RS 168

22:1

5

SOHC

Chain-Drive

120 / 4000

25.5 / 4000

1-2-4-5-3

BTDC 18°± 10°

ATDC 11.33° / ABDC 17°

BBDC 28° / BTDC 15.25°

Automatic ControlOM661LA

Four-Stroke Diesel

2299

89 x 92.4

PES 5 M55 C320 RS 167

22:1

4

SOHC

Chain-Drive

101 / 4000

21.5 / 2400

1-3-4-2

BTDC 18°± 10°

ATDC 11.33° / ABDC 17°

BBDC 28° / BTDC 15.25°

Automatic Control

Page 69 of 1463

GENERAL ENGINE INFORMATION 1A3-11

28bar

Approx.18bar

Max. 3bar

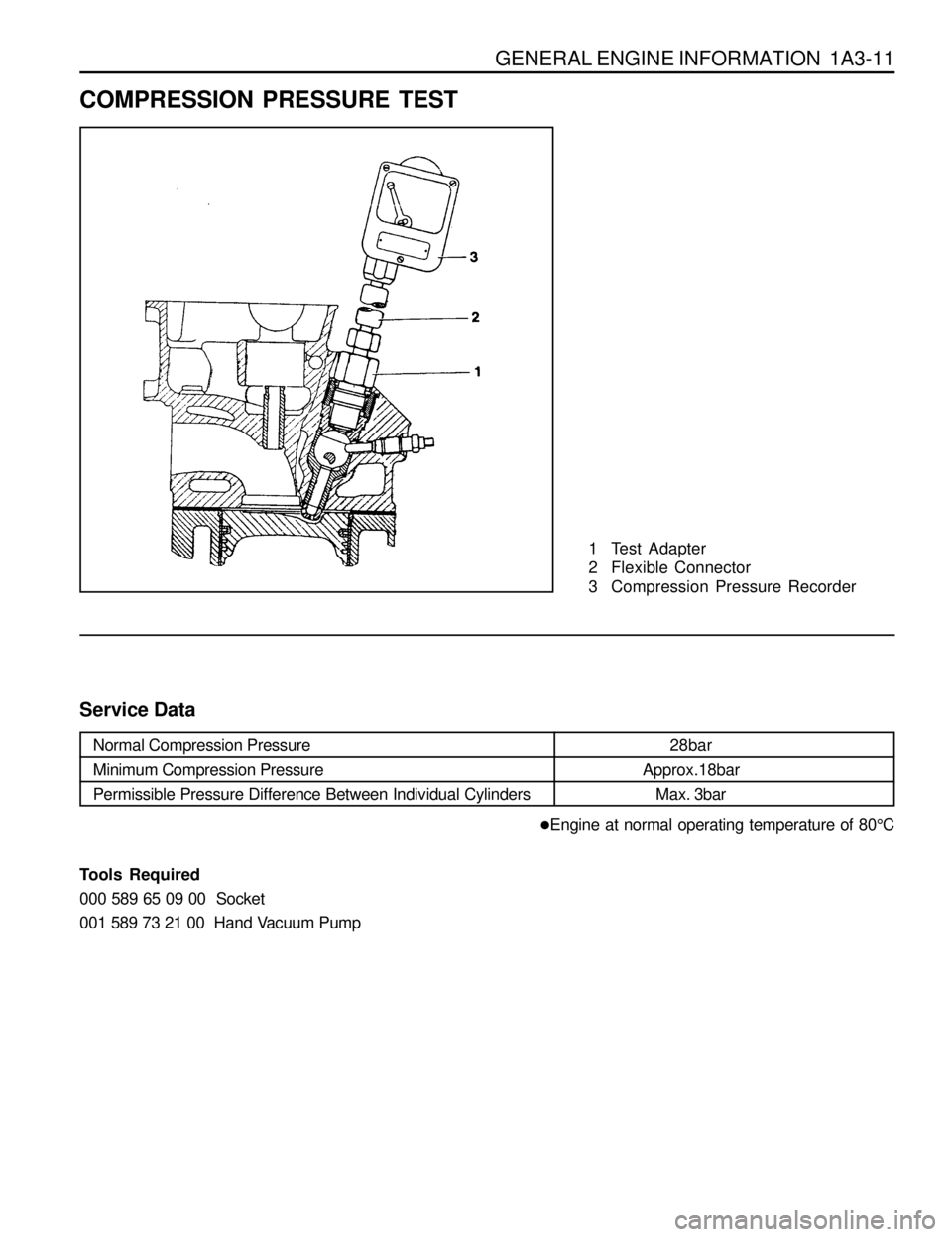

COMPRESSION PRESSURE TEST

1 Test Adapter

2 Flexible Connector

3 Compression Pressure Recorder

Tools Required

000 589 65 09 00 Socket

001 589 73 21 00 Hand Vacuum Pump

Service Data

Normal Compression Pressure

Minimum Compression Pressure

Permissible Pressure Difference Between Individual Cylinders

lEngine at normal operating temperature of 80°C

Page 70 of 1463

1A3-12 GENERAL ENGINE INFORMATION

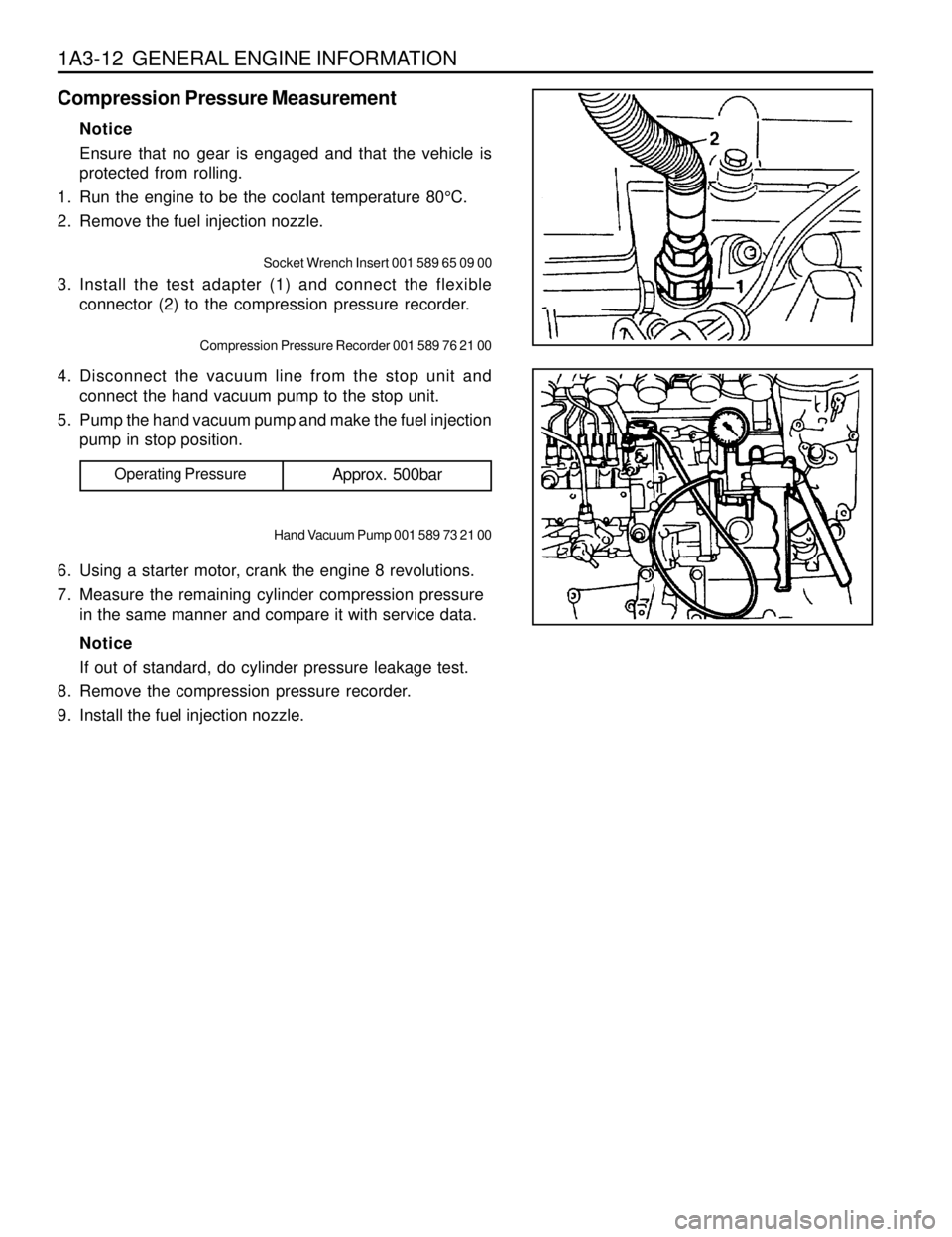

Compression Pressure Measurement

Notice

Ensure that no gear is engaged and that the vehicle is

protected from rolling.

1. Run the engine to be the coolant temperature 80°C.

2. Remove the fuel injection nozzle.

Socket Wrench Insert 001 589 65 09 00

3. Install the test adapter (1) and connect the flexible

connector (2) to the compression pressure recorder.

Compression Pressure Recorder 001 589 76 21 00

4. Disconnect the vacuum line from the stop unit and

connect the hand vacuum pump to the stop unit.

5. Pump the hand vacuum pump and make the fuel injection

pump in stop position.

Operating PressureApprox. 500bar

Hand Vacuum Pump 001 589 73 21 00

6. Using a starter motor, crank the engine 8 revolutions.

7. Measure the remaining cylinder compression pressure

in the same manner and compare it with service data.

Notice

If out of standard, do cylinder pressure leakage test.

8. Remove the compression pressure recorder.

9. Install the fuel injection nozzle.

Page 73 of 1463

GENERAL ENGINE INFORMATION 1A3-15

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths

of an inch. When any internal engine parts are

serviced, care and cleanliness are important. A liberal

coating of enigne oil should be applied to friction areas

during assembly, to protect and lubricate the surfaces

on initial operation. Proper cleaning and protection

of machined surfaces and friction areas is part fo the

repair procedure. This is considered standard shop

practice even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same

mating surfaces, as when they were removed.Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable

before removing or installing any electrical unit,

or when a tool or equipment could easily come in

contact with exposed electrical terminals.

Disconnecting this cable will help prevent

personal injury and damage to the vehicle. The

ignition must also be in LOCK unless otherwise

noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.