service SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 418 of 1463

1B3-116 OM600 ENGINE MECHANICAL

8.000

- 8.030

9.000

- 9.05039.5 Intake

Exhaust0.029

- 0.051

0.029

- 0.051 Red

White

Red

White

Diameter ‘a’

Service Data

ItemBasic Bore

Repair size 1

Repair size 2

Repair size 1

Repair size 2Outer Diameter ‘D’

14.251

14.440 - 14.451

14.240 - 14.251

14.440 - 14.451Color Code

14.200 - 14.211

14.400 - 14.411

14.200 - 14.211

14.400 - 14.411Overlap

‘D’ - ‘a’Valve Guide

Inner Diameter ‘A’

37.7

Length ‘L’

CHECK AND REPLACEMENT OF VALVE GUIDES

Preceding Work : Removal of cylinder head

Removal of valve spring

Removal of valve

1 Cylinder Head

2 Valve Guide3 Valve Seat Ring

a Basic Bore Diameter

Page 424 of 1463

1B3-122 OM600 ENGINE MECHANICAL

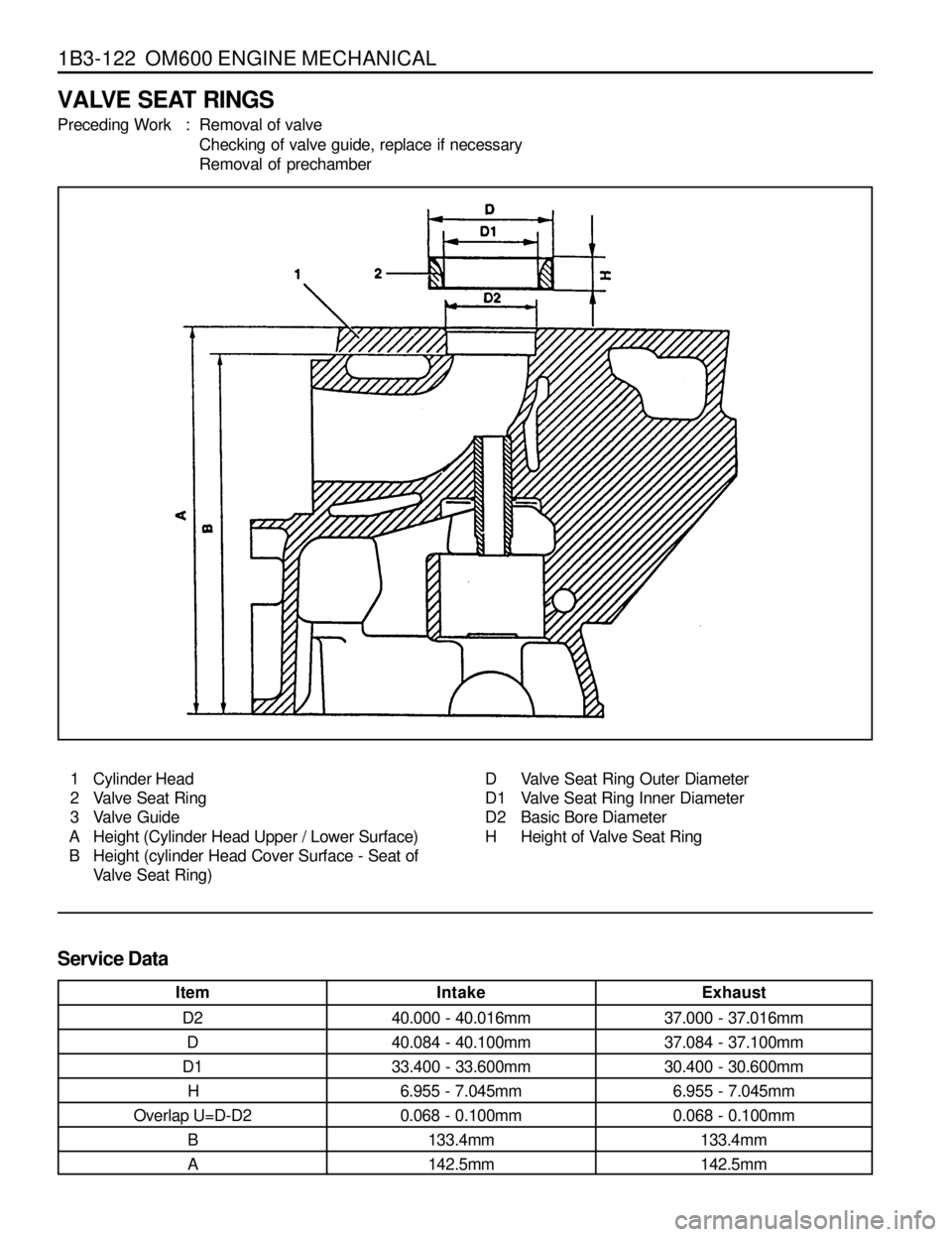

VALVE SEAT RINGS

Preceding Work : Removal of valve

Checking of valve guide, replace if necessary

Removal of prechamber

1 Cylinder Head

2 Valve Seat Ring

3 Valve Guide

A Height (Cylinder Head Upper / Lower Surface)

B Height (cylinder Head Cover Surface - Seat of

Valve Seat Ring)D Valve Seat Ring Outer Diameter

D1 Valve Seat Ring Inner Diameter

D2 Basic Bore Diameter

H Height of Valve Seat Ring

Service Data

Item

D2

D

D1

H

Overlap U=D-D2

B

AIntake

40.000 - 40.016mm

40.084 - 40.100mm

33.400 - 33.600mm

6.955 - 7.045mm

0.068 - 0.100mm

133.4mm

142.5mmExhaust

37.000 - 37.016mm

37.084 - 37.100mm

30.400 - 30.600mm

6.955 - 7.045mm

0.068 - 0.100mm

133.4mm

142.5mm

Page 431 of 1463

OM600 ENGINE MECHANICAL 1B3-129

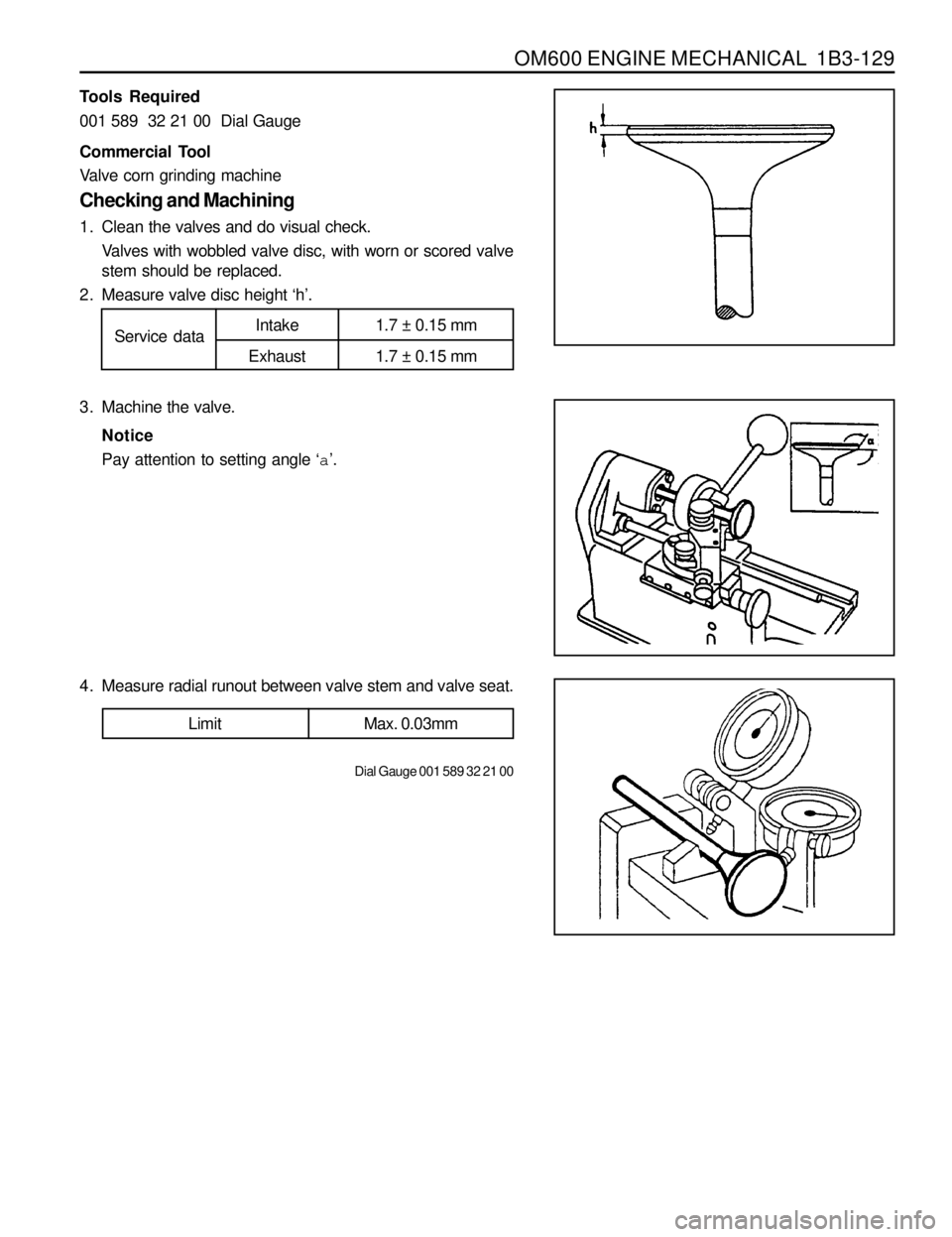

Tools Required

001 589 32 21 00 Dial Gauge

Checking and Machining

1. Clean the valves and do visual check.

Valves with wobbled valve disc, with worn or scored valve

stem should be replaced.

2. Measure valve disc height ‘h’.

Service data

Intake

Exhaust1.7 ± 0.15 mm

1.7 ± 0.15 mm

3. Machine the valve.

Notice

Pay attention to setting angle ‘a’.

Commercial Tool

Valve corn grinding machine

4. Measure radial runout between valve stem and valve seat.

Limit Max. 0.03mm

Dial Gauge 001 589 32 21 00

Page 435 of 1463

OM600 ENGINE MECHANICAL 1B3-133

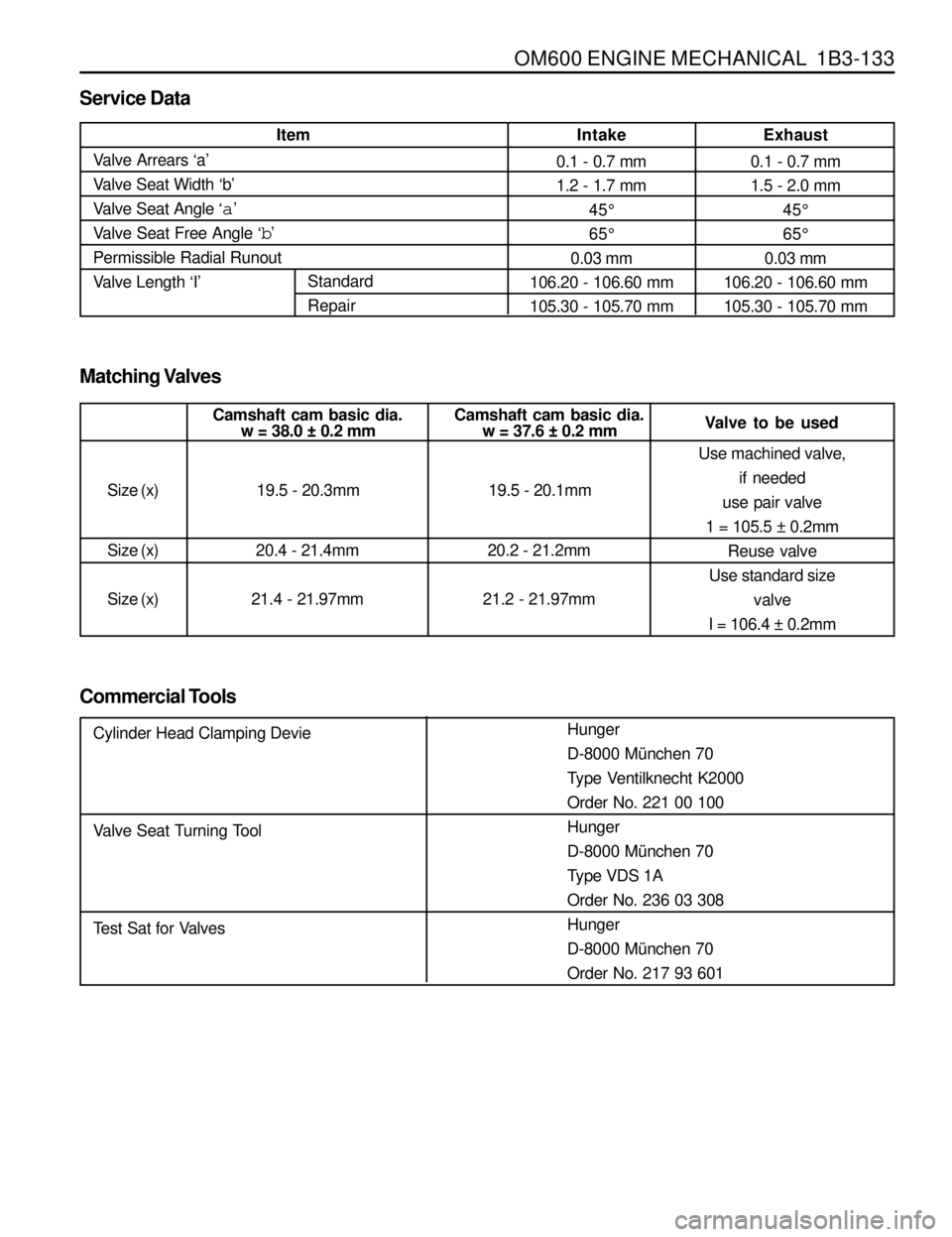

Service Data

Item

Valve Arrears ‘a’

Valve Seat Width ‘b’

Valve Seat Angle ‘

a’

Valve Seat Free Angle ‘

b’

Permissible Radial Runout

Valve Length ‘I’Intake

0.1 - 0.7 mm

1.2 - 1.7 mm

45°

65°

0.03 mm

106.20 - 106.60 mm

105.30 - 105.70 mmExhaust

0.1 - 0.7 mm

1.5 - 2.0 mm

45°

65°

0.03 mm

106.20 - 106.60 mm

105.30 - 105.70 mm

Standard

Repair

w = 38.0 ± 0.2 mm

Matching Valves

Camshaft cam basic dia.

Size (x)

Size (x)

Size (x)19.5 - 20.3mm

20.4 - 21.4mm

21.4 - 21.97mmw = 37.6 ± 0.2 mm Camshaft cam basic dia.

19.5 - 20.1mm

20.2 - 21.2mm

21.2 - 21.97mmValve to be used

Use machined valve,

if needed

use pair valve

1 = 105.5 ± 0.2mm

Reuse valve

Use standard size

valve

I = 106.4 ± 0.2mm

Commercial Tools

Hunger

D-8000 München 70

Type Ventilknecht K2000

Order No. 221 00 100

Hunger

D-8000 München 70

Type VDS 1A

Order No. 236 03 308

Hunger

D-8000 München 70

Order No. 217 93 601 Cylinder Head Clamping Devie

Valve Seat Turning Tool

Test Sat for Valves

Page 466 of 1463

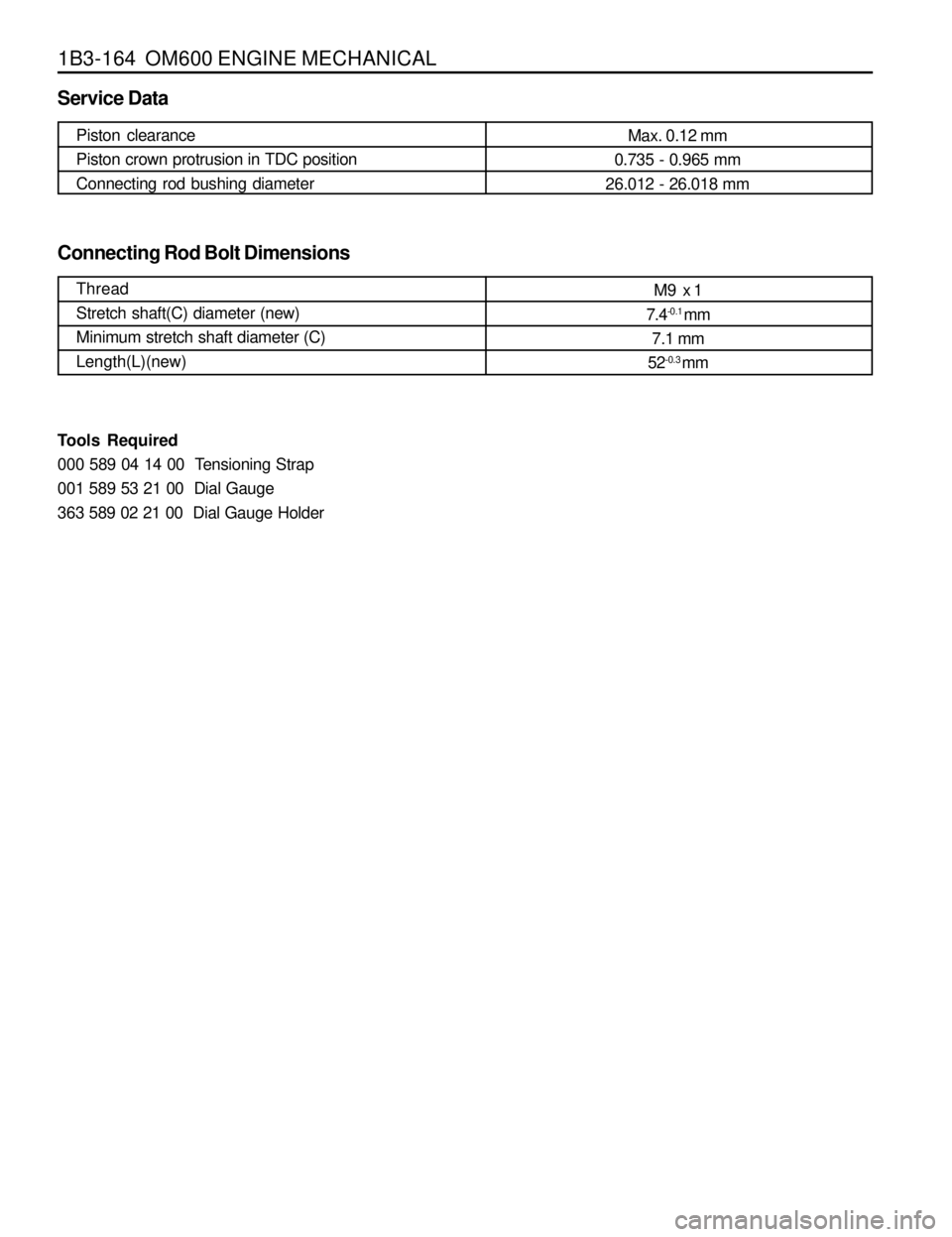

1B3-164 OM600 ENGINE MECHANICAL

Service Data

Piston clearance

Piston crown protrusion in TDC position

Connecting rod bushing diameterMax. 0.12 mm

0.735 - 0.965 mm

26.012 - 26.018 mm

Connecting Rod Bolt Dimensions

Thread

Stretch shaft(C) diameter (new)

Minimum stretch shaft diameter (C)

Length(L)(new)

Tools Required

000 589 04 14 00 Tensioning Strap

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge HolderM9 x 1

7.4

-0.1 mm

7.1 mm

52

-0.3 mm

Page 480 of 1463

1B3-178 OM600 ENGINE MECHANICAL

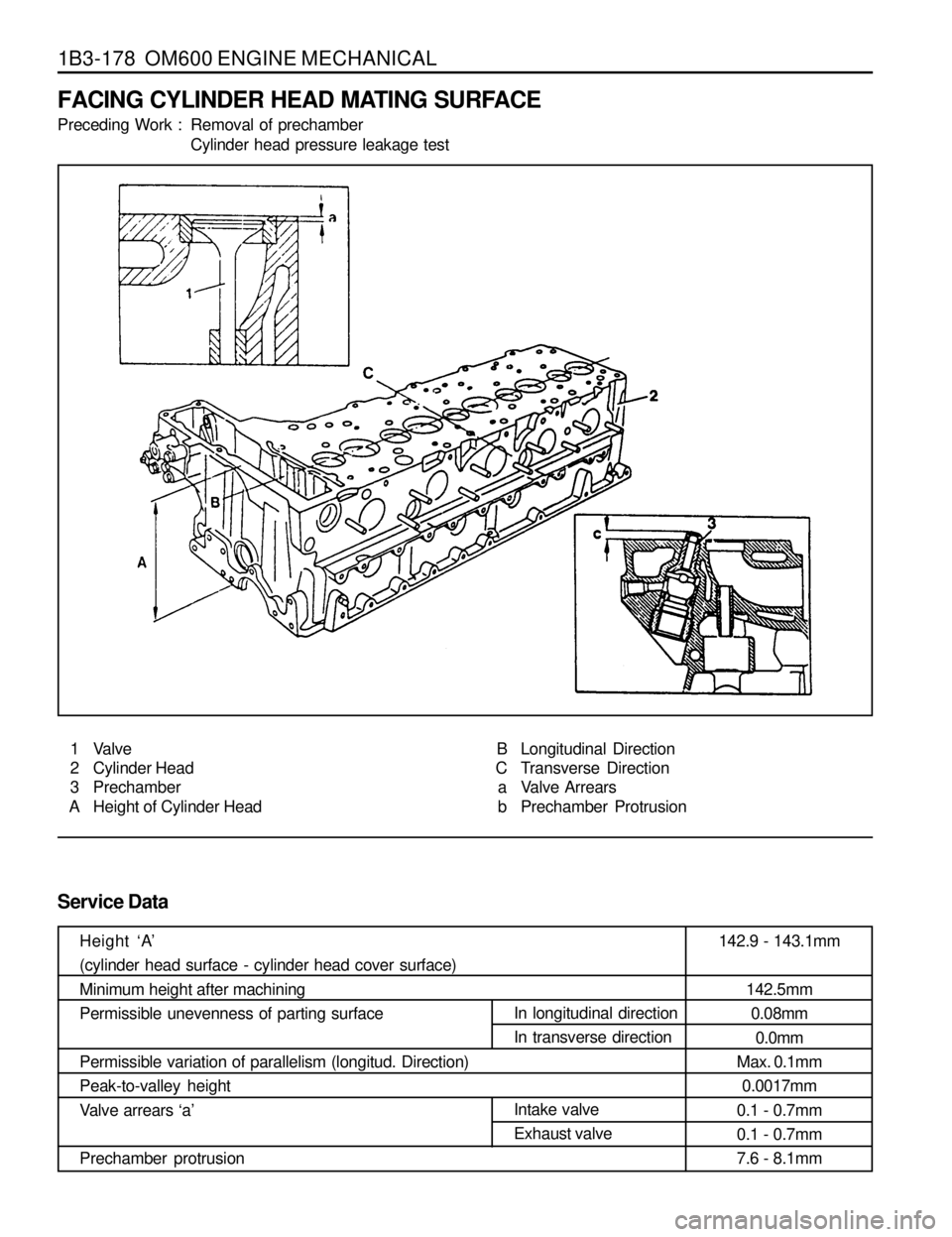

Height ‘A’

(cylinder head surface - cylinder head cover surface)

Minimum height after machining

Permissible unevenness of parting surface

Permissible variation of parallelism (longitud. Direction)

Peak-to-valley height

Valve arrears ‘a’

Prechamber protrusion

Service Data

In longitudinal direction

In transverse direction

Intake valve

Exhaust valve142.9 - 143.1mm

142.5mm

0.08mm

0.0mm

Max. 0.1mm

0.0017mm

0.1 - 0.7mm

0.1 - 0.7mm

7.6 - 8.1mm

FACING CYLINDER HEAD MATING SURFACE

Preceding Work : Removal of prechamber

Cylinder head pressure leakage test

1 Valve

2 Cylinder Head

3 Prechamber

A Height of Cylinder HeadB Longitudinal Direction

C Transverse Direction

a Valve Arrears

b Prechamber Protrusion

Page 484 of 1463

1B3-182 OM600 ENGINE MECHANICAL

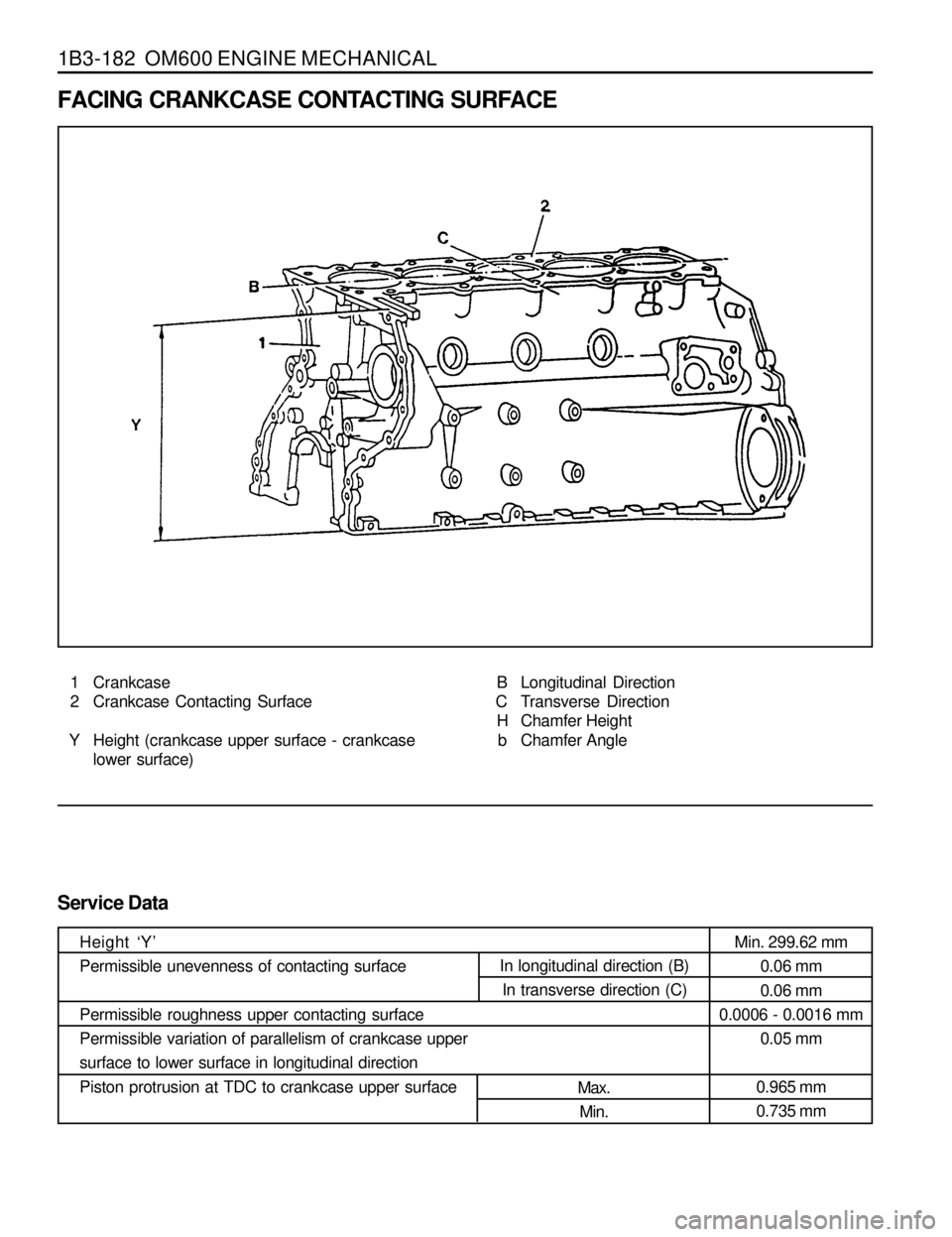

Service Data

Height ‘Y’

Permissible unevenness of contacting surface

Permissible roughness upper contacting surface

Permissible variation of parallelism of crankcase upper

surface to lower surface in longitudinal direction

Piston protrusion at TDC to crankcase upper surface

In longitudinal direction (B)

In transverse direction (C)Min. 299.62 mm

0.06 mm

0.06 mm

0.0006 - 0.0016 mm

0.05 mm

0.965 mm

0.735 mm

Max.

Min.

FACING CRANKCASE CONTACTING SURFACE

1 Crankcase

2 Crankcase Contacting Surface

Y Height (crankcase upper surface - crankcase

lower surface)B Longitudinal Direction

C Transverse Direction

H Chamfer Height

b Chamfer Angle

Page 489 of 1463

OM600 ENGINE MECHANICAL 1B3-187

Standard size

Wear limit in direction of travel and in transverse direction

Permissible deviation of cylinder shape

Honing angle

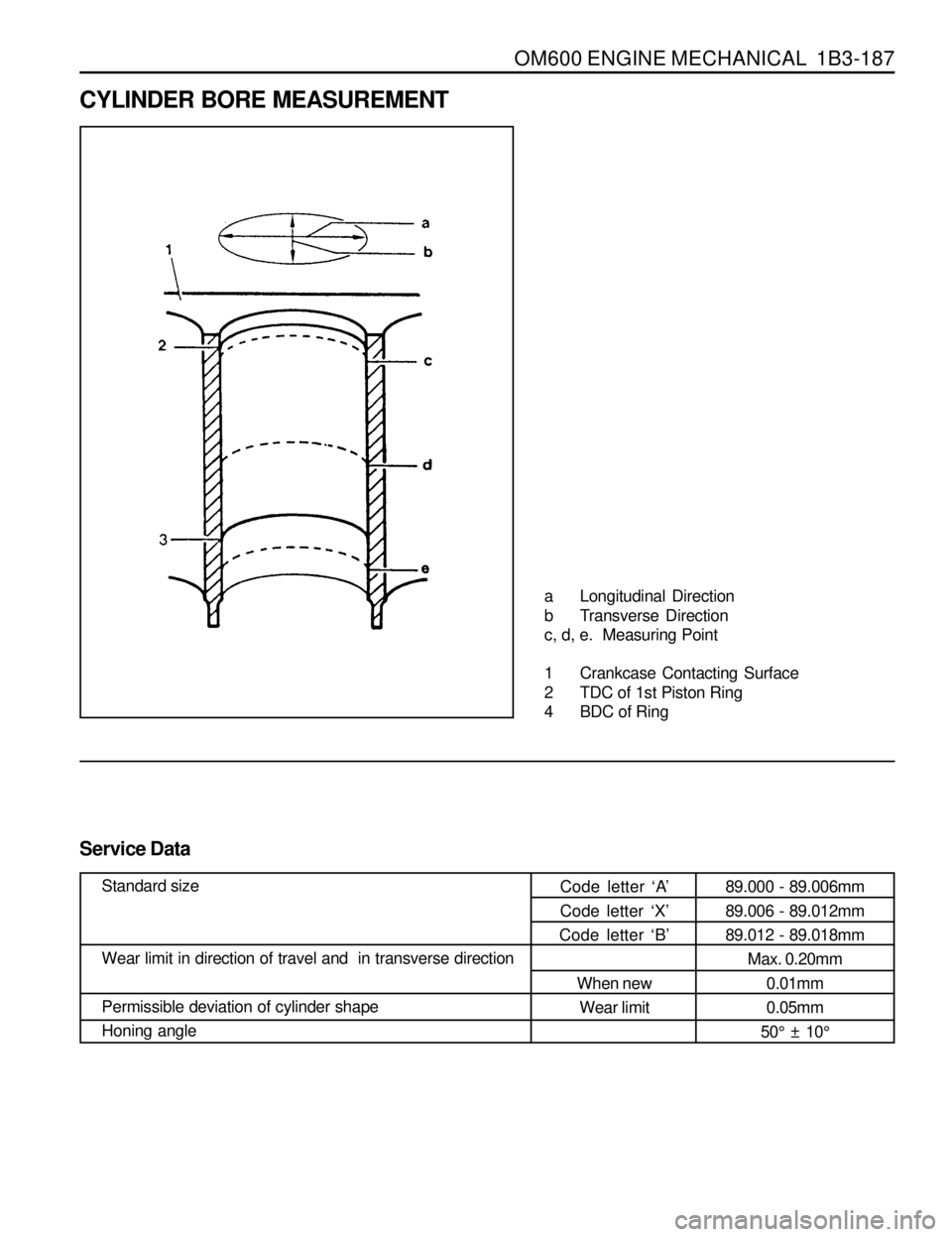

CYLINDER BORE MEASUREMENT

a Longitudinal Direction

b Transverse Direction

c, d, e. Measuring Point

1 Crankcase Contacting Surface

2 TDC of 1st Piston Ring

4 BDC of Ring

Service Data

Code letter ‘A’

Code letter ‘X’

Code letter ‘B’

When new

Wear limit89.000 - 89.006mm

89.006 - 89.012mm

89.012 - 89.018mm

Max. 0.20mm

0.01mm

0.05mm

50° ± 10°

Page 490 of 1463

SECTION 1D1

M162 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D1-1

General Specifications . . . . . . . . . . . . . . . . . 1D1-1

Fastener Tightening Specifications . . . . . . . . 1D1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1D1-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1D1-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-4

System Leakage Test . . . . . . . . . . . . . . . . . . 1D1-4

Maintenance and Repair . . . . . . . . . . . . . . 1D1-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1D1-5Coolant Drain and Fill Up . . . . . . . . . . . . . . . 1D1-5

Coolant Connection Fitting . . . . . . . . . . . . . . 1D1-7

Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-8

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-10

Oil Cooler Pipe Line . . . . . . . . . . . . . . . . . . 1D1-11

Cooling Fan and Viscous Clutch . . . . . . . . . 1D1-12

Cooling Fan Shroud . . . . . . . . . . . . . . . . . . 1D1-14

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-15

SPECIFICATIONS

GENERAL SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Description

Water Cooling Forced Circulation

Double Cross Flow

70,000 kcal/h

580 x 482 x 45 mm

f 460, Six Blades

ALUTEC - P78

50 : 50

11.3 L

3.4 L

1.4 bar Application

Cooling Type

Radiator

Dimension(Width´Height´Thickeness)

Cooling Fan

Anti-Freeze Agent

Mixing Ratio of Anti-Freeze Agen with Water (Anti-Freeze Agent : Water)

Coolant Capacity

Reservoir Capacity

Cap Operating Pressure (Reservoir Tank Pressure Cap)

Circulation Type

Radiation Capability

Page 494 of 1463

M162 ENGINE COOLING 1D1-5

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

COOLANT DRAIN AND FILL UP

Draning & Filling up Procedure

1. Loosen the cap a little and release pressure and remove

the cap.

Notice

For the risk of scalding, the cap must not be opened unless

the coolant temperature is below 90

oC.

2. Loosen the radiator lower drain cock and drain the coolant.

Notice

Collect coolant by using a proper container.

3. Drain the coolant from the crankcase by inserting a hose

(dia. 14mm) onto the drain bolt on the side of crankcase

(exhaust manifold) and by loosening the plug.

Notice

lJust loosen the drain plug to drain the coolant and do

not remove the plug completely.

lCollect coolant by using proper container.

4. After complete draining of the coolant, remove the hose

connector to drain plug and reinstall the drain plug.

Installation Notice

5. Tighten the radiator lower drain cock.

Tightening Torque 30 Nm