service SSANGYONG MUSSO 1998 Workshop Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 74 of 1463

SECTION 1B1

M162 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B1-2

Fastener Tightening Specifications . . . . . . . . 1B1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B1-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B1-4

Maintenance and Repair . . . . . . . . . . . . . . 1B1-8

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1B1-8

Engine Assembly . . . . . . . . . . . . . . . . . . . . . 1B1-8

Crankcase Ventilation System . . . . . . . . . . 1B1-16

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-18

Power Steering Pump and A/C Bracket . . . 1B1-19

Hydraulic Engine Mounting Insulator . . . . . . 1B1-22

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-25

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B1-27

Poly V-Belt Inspection . . . . . . . . . . . . . . . . . 1B1-29

Cylinder Head Cover . . . . . . . . . . . . . . . . . 1B1-31

Cylinder Head Front Cover . . . . . . . . . . . . . 1B1-33

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B1-35

Timing Gear Case Cover . . . . . . . . . . . . . . 1B1-38

Crankshaft Sealing Rear Cover . . . . . . . . . 1B1-40

Belt Pulley and Vibration Damper . . . . . . . . 1B1-42

Crankshaft Front Radial Seal . . . . . . . . . . . 1B1-45

Crankshaft Rear Radial Seal . . . . . . . . . . . 1B1-46

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-47

Flywheel / Driven Plate . . . . . . . . . . . . . . . . 1B1-53

Camshaft Adjuster . . . . . . . . . . . . . . . . . . . 1B1-55

Camshaft Sprocket Bolt . . . . . . . . . . . . . . . 1B1-58

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-59

TABLE OF CONTENTS

Camshaft Timing Position . . . . . . . . . . . . . . 1B1-64

Valve Spring . . . . . . . . . . . . . . . . . . . . . . . . 1B1-67

Valve Stem Seal . . . . . . . . . . . . . . . . . . . . . 1B1-71

Chain Tensioner . . . . . . . . . . . . . . . . . . . . . 1B1-72

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . . 1B1-75

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . . 1B1-80

Cylinder Head Guide Rail . . . . . . . . . . . . . . 1B1-81

Crankcase Guide Rail . . . . . . . . . . . . . . . . . 1B1-82

Crankshaft Sprocket . . . . . . . . . . . . . . . . . . 1B1-83

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-85

Connecting Rod . . . . . . . . . . . . . . . . . . . . . 1B1-88

Piston Ring . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-90

Engine Oil Specification . . . . . . . . . . . . . . . 1B1-92

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-93

Engine Oil and Oil Filter Element . . . . . . . . 1B1-95

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-97

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B1-99

Oil Pressure Relief Valve . . . . . . . . . . . . . 1B1-101

Oil Non-Return Valve . . . . . . . . . . . . . . . . 1B1-102

Oil Dipstick Guide Tube . . . . . . . . . . . . . . 1B1-103

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B1-104

Oil Gallery in Crankcase . . . . . . . . . . . . . . 1B1-104

Oil Gallery in Cylinder Head . . . . . . . . . . . 1B1-106

Core Plugs in Crankcase . . . . . . . . . . . . . 1B1-109

Cylinder Bore . . . . . . . . . . . . . . . . . . . . . . 1B1-111

Crankcase Mating Surface . . . . . . . . . . . . 1B1-113

Cylinder Head Mating Surface . . . . . . . . . 1B1-115

Page 81 of 1463

1B1-8 M162 ENGINE MECHANICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ENGINE ASSEMBLY

Tools Required

000 589 10 99 01 Torque Wrench

000 589 40 37 00 Hose Clamp

112 589 00 72 00 Oil Extractor

Page 95 of 1463

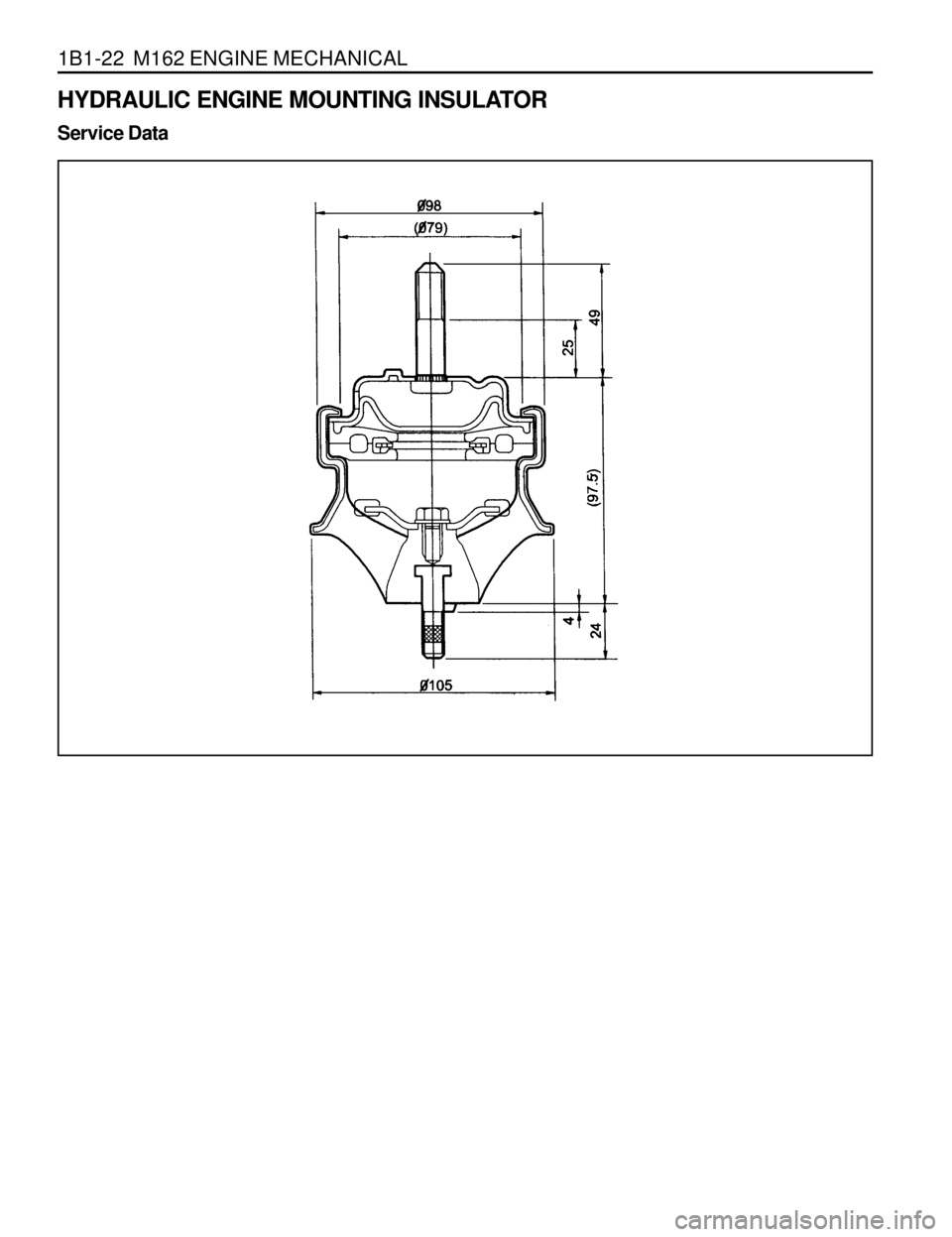

1B1-22 M162 ENGINE MECHANICAL

HYDRAULIC ENGINE MOUNTING INSULATOR

Service Data

Page 116 of 1463

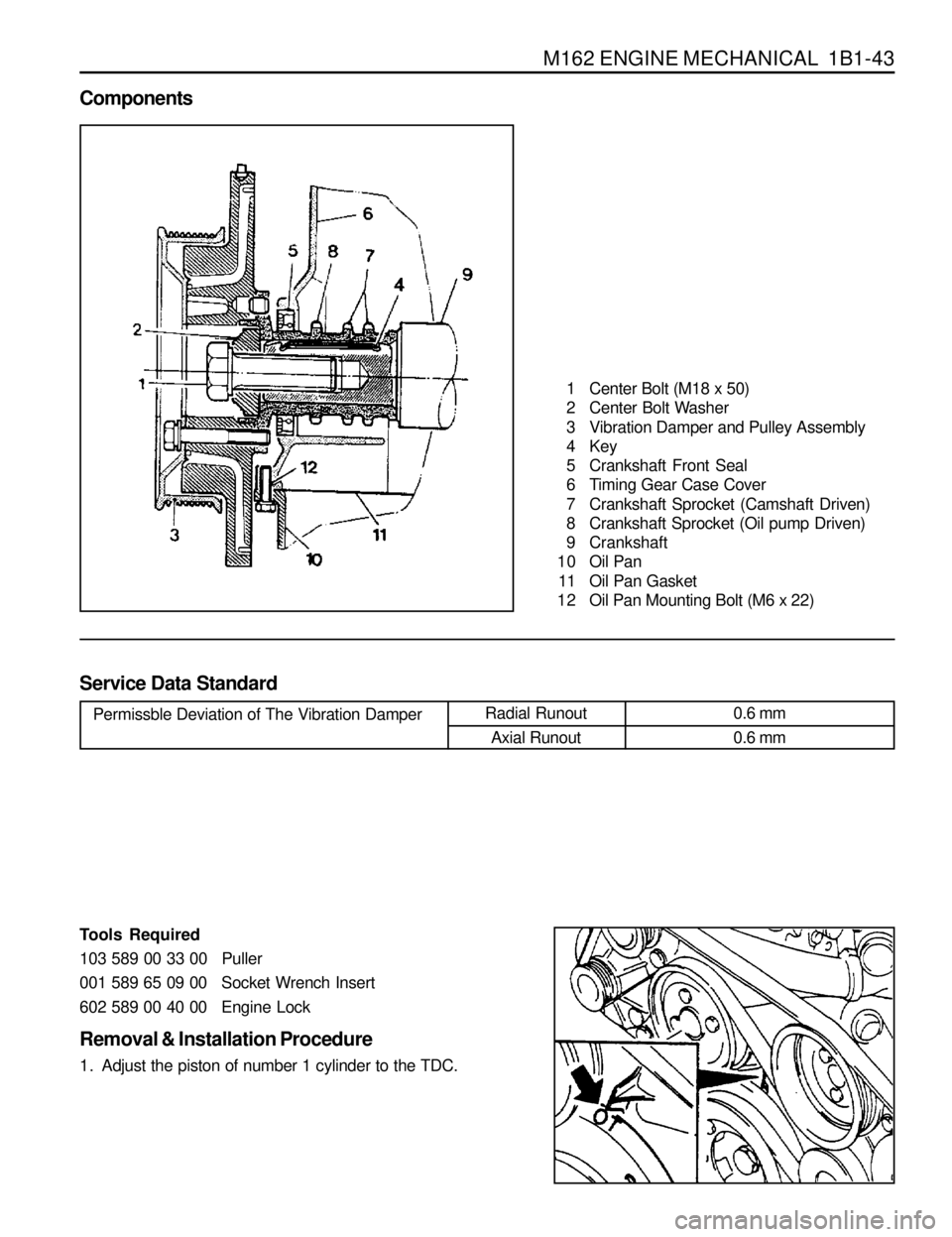

M162 ENGINE MECHANICAL 1B1-43

Components

1 Center Bolt (M18 x 50)

2 Center Bolt Washer

3 Vibration Damper and Pulley Assembly

4 Key

5 Crankshaft Front Seal

6 Timing Gear Case Cover

7 Crankshaft Sprocket (Camshaft Driven)

8 Crankshaft Sprocket (Oil pump Driven)

9 Crankshaft

10 Oil Pan

11 Oil Pan Gasket

12 Oil Pan Mounting Bolt (M6 x 22)

Service Data Standard

Permissble Deviation of The Vibration DamperRadial Runout

Axial Runout0.6 mm

0.6 mm

Tools Required

103 589 00 33 00 Puller

001 589 65 09 00 Socket Wrench Insert

602 589 00 40 00 Engine Lock

Removal & Installation Procedure

1. Adjust the piston of number 1 cylinder to the TDC.

Page 122 of 1463

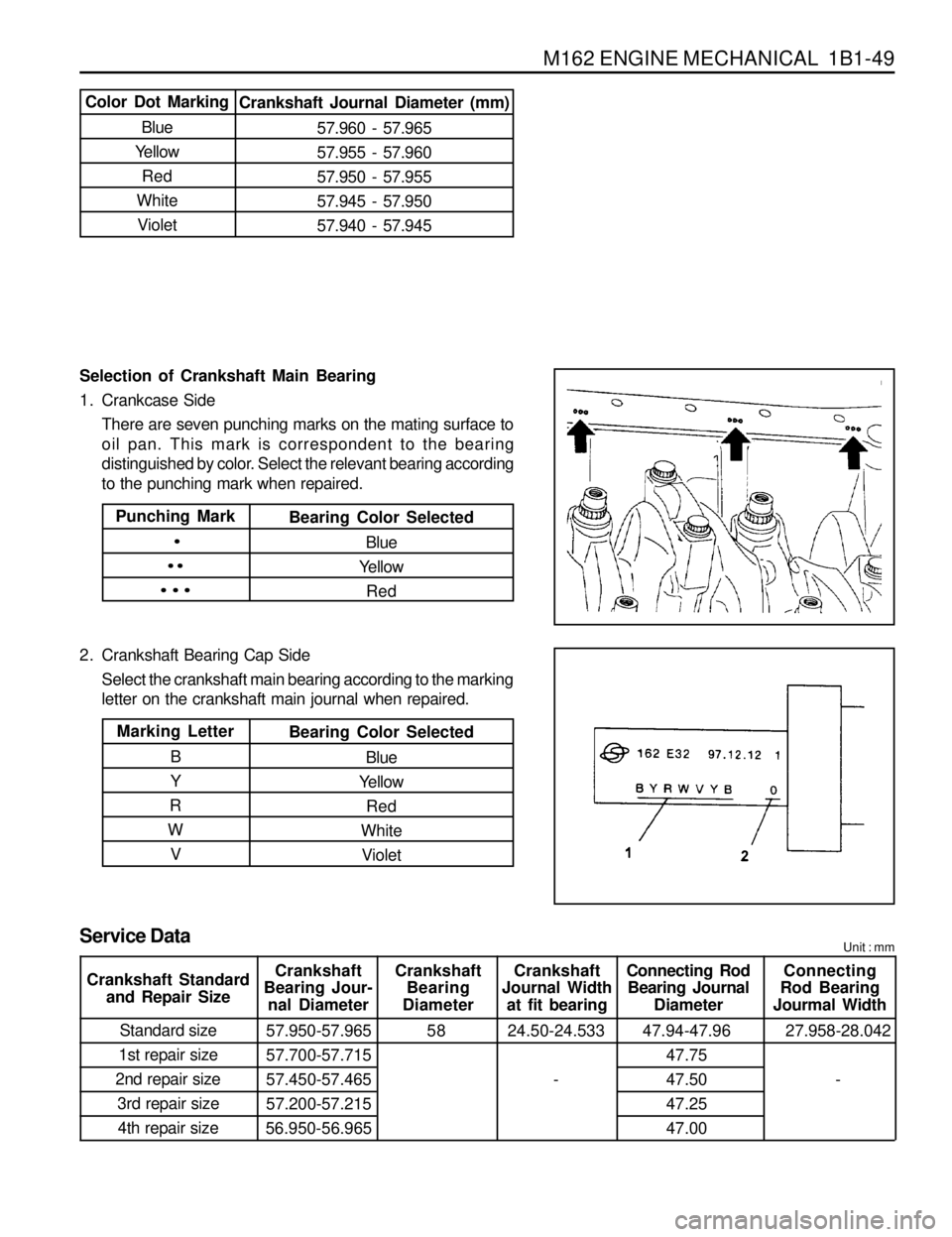

M162 ENGINE MECHANICAL 1B1-49

Selection of Crankshaft Main Bearing

1. Crankcase Side

There are seven punching marks on the mating surface to

oil pan. This mark is correspondent to the bearing

distinguished by color. Select the relevant bearing according

to the punching mark when repaired.

2. Crankshaft Bearing Cap Side

Select the crankshaft main bearing according to the marking

letter on the crankshaft main journal when repaired.

Color Dot Marking

Blue

Yellow

Red

White

VioletCrankshaft Journal Diameter (mm)

57.960 - 57.965

57.955 - 57.960

57.950 - 57.955

57.945 - 57.950

57.940 - 57.945

Punching Mark

·

··

···

Bearing Color Selected

Blue

Yellow

Red

Marking Letter

B

Y

R

W

VBearing Color Selected

Blue

Yellow

Red

White

Violet

Service DataUnit : mm

Crankshaft

Bearing Jour-

nal DiameterCrankshaft

Bearing

DiameterCrankshaft

Journal Width

at fit bearingConnecting Rod

Bearing Journal

DiameterConnecting

Rod Bearing

Jourmal Width

Standard size

1st repair size

2nd repair size

3rd repair size

4th repair size57.950-57.965

57.700-57.715

57.450-57.465

57.200-57.215

56.950-56.96558 24.50-24.533

-47.94-47.96

47.75

47.50

47.25

47.0027.958-28.042

- Crankshaft Standard

and Repair Size

Page 125 of 1463

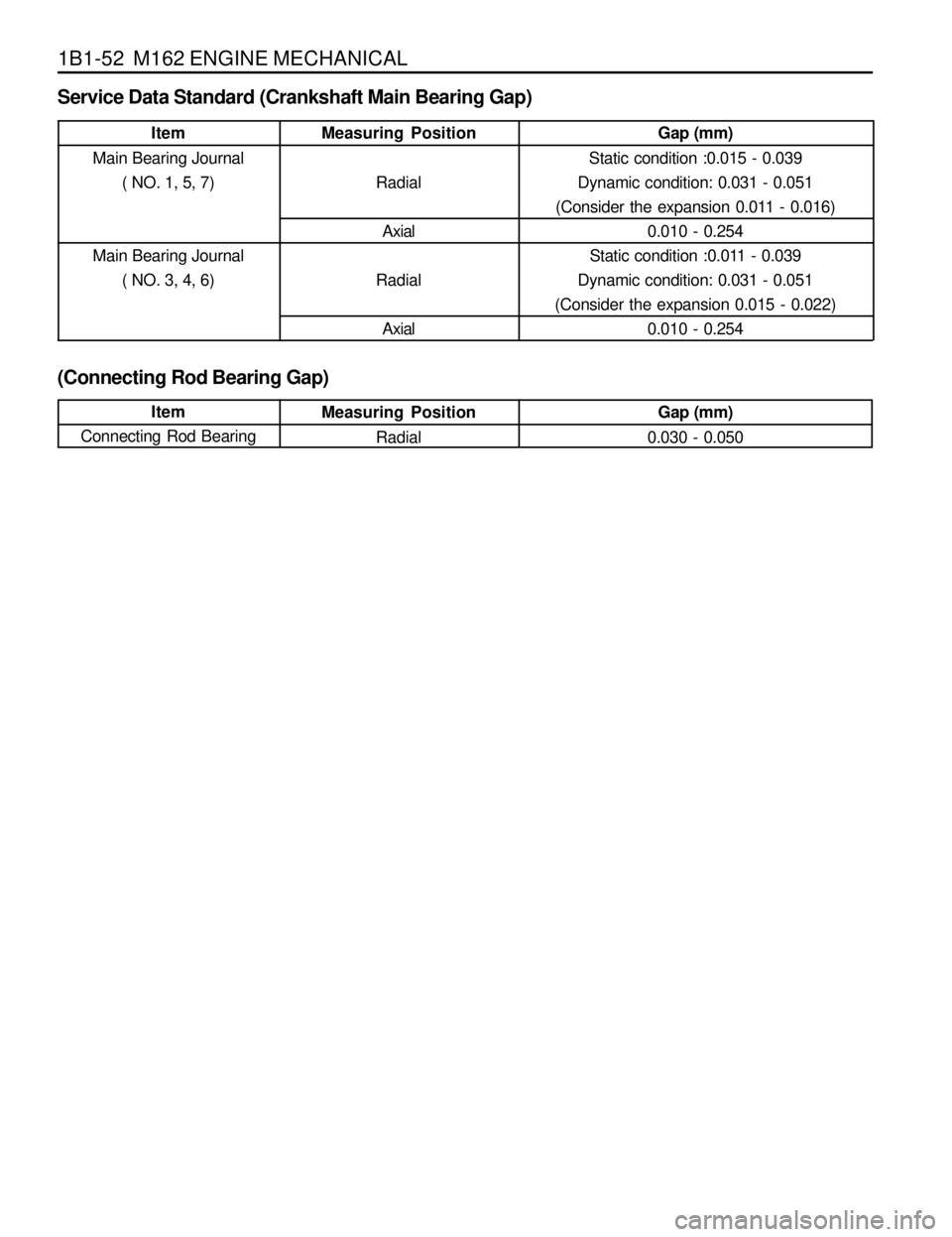

1B1-52 M162 ENGINE MECHANICAL

Service Data Standard (Crankshaft Main Bearing Gap)

(Connecting Rod Bearing Gap)

Item

Main Bearing Journal

( NO. 1, 5, 7)

Main Bearing Journal

( NO. 3, 4, 6)Measuring Position

Radial

Axial

Radial

AxialGap (mm)

Static condition :0.015 - 0.039

Dynamic condition: 0.031 - 0.051

(Consider the expansion 0.011 - 0.016)

0.010 - 0.254

Static condition :0.011 - 0.039

Dynamic condition: 0.031 - 0.051

(Consider the expansion 0.015 - 0.022)

0.010 - 0.254

Item

Connecting Rod BearingMeasuring Position

RadialGap (mm)

0.030 - 0.050

Page 126 of 1463

M162 ENGINE MECHANICAL 1B1-53

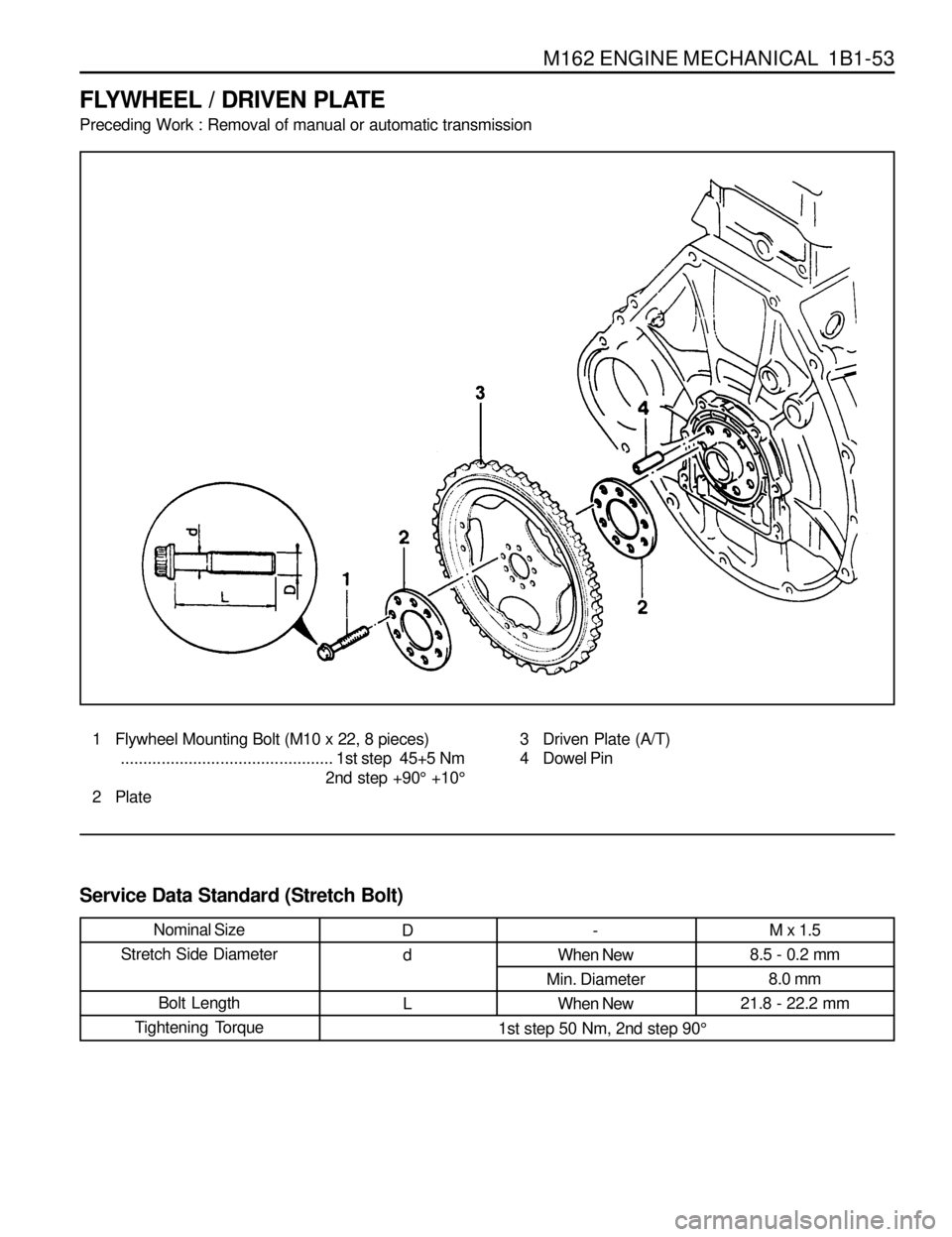

FLYWHEEL / DRIVEN PLATE

Preceding Work : Removal of manual or automatic transmission

1 Flywheel Mounting Bolt (M10 x 22, 8 pieces)

...............................................1st step 45+5 Nm

2nd step +90° +10°

2 Plate3 Driven Plate (A/T)

4 Dowel Pin

Service Data Standard (Stretch Bolt)

Nominal Size

Stretch Side Diameter

Bolt Length

Tightening TorqueM x 1.5

8.5 - 0.2 mm

8.0 mm

21.8 - 22.2 mm-

When New

Min. Diameter

When NewD

d

L

1st step 50 Nm, 2nd step 90°

Page 161 of 1463

1B1-88 M162 ENGINE MECHANICAL

CONNECTING ROD

Preceding Work : Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bolt

(M9 x 52, 12 m pieces) .. 1st step 40+5 Nm

2nd step 90°+10°

5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 BearingShell Lug

9 Marking [Indication(//) or Numbers]

Service Data Standard

Distance (L) from The Connecting Rod Bearing Bore Center to The Bushing Bore Center

Width of The Connecting Rod (B) at Bearing Bore

Width of The Connecting Rod (b) at Bushing Bore

Basic Bore at The Bearing Shell (D1)

Basic Bore at The Bushing (d1)

Bushing Inner Diameter (d)

Clearance Between The Piston Pin and The Bushing

Peak-to-valley Height of Connecting Rod Bushing on Inside

Permissible Wwist of Connecting Rod Bearing Bore to Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore to Connecting

Rod Bushing Core

Permissible Deviation of Connecting Rod Bearing Bore from Concentricity

Permissible Difference of Each Connecting Rod in Weight145 ± 0.05 mm

21.940 - 22.000 mm

21.940 - 22.000 mm

51.600 - 51.614 mm

24.500 - 24.571 mm

22.007 - 22.013 mm

0.007 - 0.018 mm

0.005 mm

0.15 mm

0.07 mm

0.01 mm

0.4 g

Page 185 of 1463

1B1-112 M162 ENGINE MECHANICAL

Service Data Standard

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore size in

axial and transverse direction at three points (1,2,3).

1,2,3. Measuring Points

A . Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Wear Limit in Longitudinal and Transverse Direction

Permissible Deviation of Cylinder Out-of-round

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)

Basic Peak-to-valley Height After Final Honing and Brushing

Chamfer Angle

Honing AngleWhen new

Wear limit0.1 mm

0.007 mm

0.05 mm

0.05 mm

0.003 - 0.006 mm

60°

50° ± 10°

Page 186 of 1463

M162 ENGINE MECHANICAL 1B1-113

CRANKCASE MATING SURFACE

Service Data Standard

Height of The Crankcase “H” (When new)

Minimum Height After Milling

Flatness

Permissible Deviation of Parallelism of The

Upper to Lower Mating Surface

Peak-to-valley HeightCrankcase Upper Mating Surface

Crankcase Lower Mating Surface

Axial Direction

Transverse Direction

Crankcase Upper Mating Surface

Crankcase Lower Mating Surface282.25 - 282.35mm

281.95mm

0.03mm

0.04mm

0.1mm

0.05mm

0.005 - 0.020mm

0.025mm