turn signal SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1212 of 1463

TRANSFER CASE (TOD) 5D2-5

Definitions

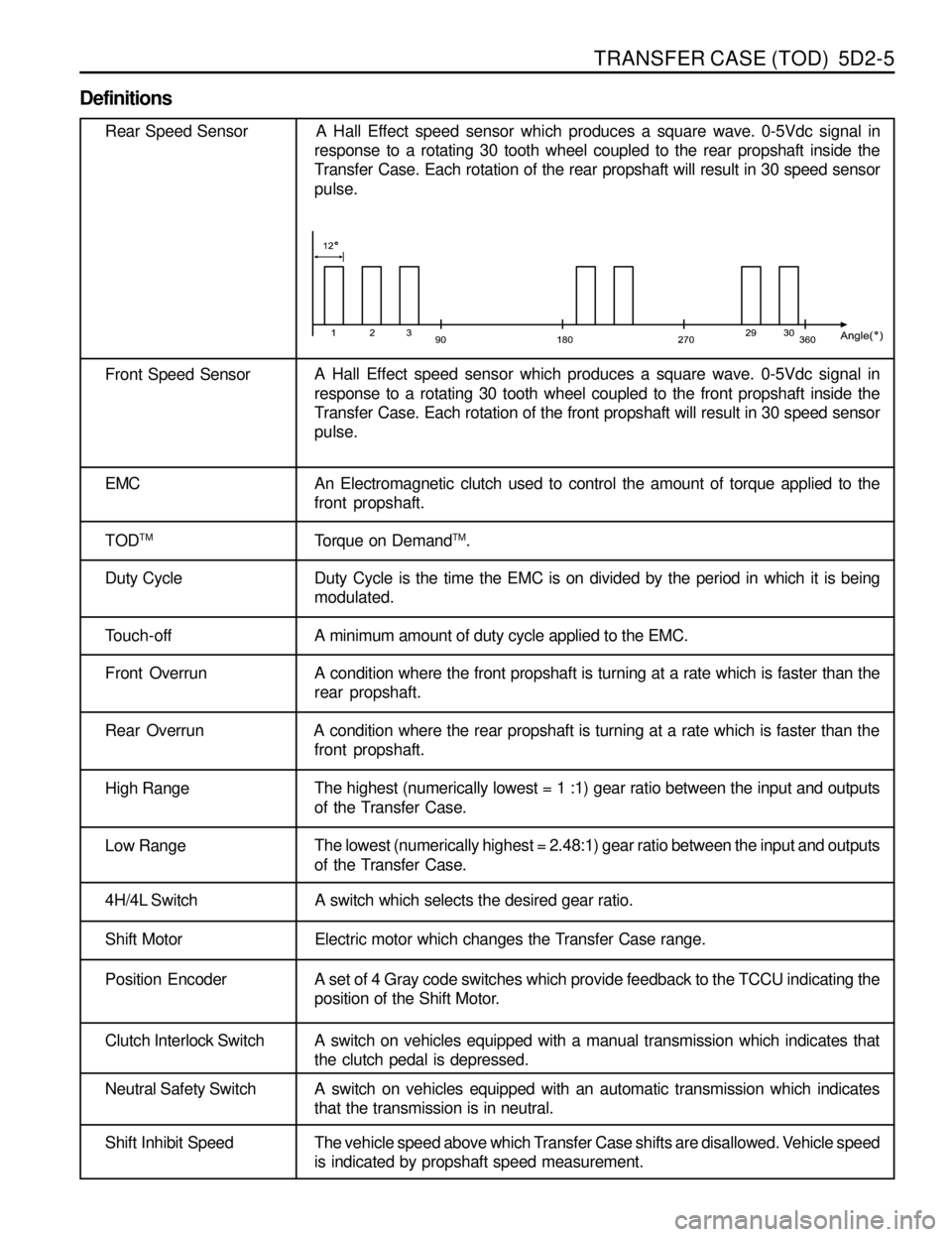

Rear Speed Sensor A Hall Effect speed sensor which produces a square wave. 0-5Vdc signal in

response to a rotating 30 tooth wheel coupled to the rear propshaft inside the

Transfer Case. Each rotation of the rear propshaft will result in 30 speed sensor

pulse.

Front Speed SensorA Hall Effect speed sensor which produces a square wave. 0-5Vdc signal in

response to a rotating 30 tooth wheel coupled to the front propshaft inside the

Transfer Case. Each rotation of the front propshaft will result in 30 speed sensor

pulse.

EMC An Electromagnetic clutch used to control the amount of torque applied to the

front propshaft.

TOD

TMTorque on DemandTM.

Duty Cycle Duty Cycle is the time the EMC is on divided by the period in which it is being

modulated.

Touch-off A minimum amount of duty cycle applied to the EMC.

Front OverrunA condition where the front propshaft is turning at a rate which is faster than the

rear propshaft.

Rear Overrun A condition where the rear propshaft is turning at a rate which is faster than the

front propshaft.

High RangeThe highest (numerically lowest = 1 :1) gear ratio between the input and outputs

of the Transfer Case.

Low RangeThe lowest (numerically highest = 2.48:1) gear ratio between the input and outputs

of the Transfer Case.

4H/4L Switch A switch which selects the desired gear ratio.

Shift Motor Electric motor which changes the Transfer Case range.

Position Encoder A set of 4 Gray code switches which provide feedback to the TCCU indicating the

position of the Shift Motor.

Clutch Interlock Switch A switch on vehicles equipped with a manual transmission which indicates that

the clutch pedal is depressed.

Neutral Safety Switch A switch on vehicles equipped with an automatic transmission which indicates

that the transmission is in neutral.

Shift Inhibit Speed The vehicle speed above which Transfer Case shifts are disallowed. Vehicle speed

is indicated by propshaft speed measurement.

Page 1213 of 1463

5D2-6 TRANSFER CASE (TOD)

Input/Output diagram

TOD control unit and main wiring harness is linked by 30 pin

connector. Each pin joins with switche and actuator whose

details refer to the below diagram.

Battery Power

Ignition ON/OFF

Position Encoder 1

Position Encoder 2

Position Encoder 3

Position Encoder 4

4H / 4L Switch Signal

A/T “N” Position Signal

Speed / TPS Supply

Front Speed Sensor Input

Rear Speed Sensor Input

ABS Operation Signal

Brake Switch Signal

4

5

27

10

28

30

9

24

16

11

29

25

26

19

CAN H

CAN L

Shift Motor output port

(LO-HI)

Shift Motor output port

(HI-LO)

EMC

'4L' Indicator

Position Return

'4WD CHECK' IND

TPS/speed Sensor Ground

(Speed / TPS Return)

2

1

3

21

6

7

13 15

14

K-Line20 22

23

17

18

Page 1214 of 1463

TRANSFER CASE (TOD) 5D2-7

1. K-LINE : Communication line for coding and diagnosis with SCANNER.

Classification of Pin No.

ClassificationPin No. Pin NameDescription

Power Supply17,18Ground

TOD control unit ground

4,19Battery

TOD control unit battery supply : (Fuse No 13,20A)

5IgnitionIgnition ON / OFF

27Position 1

Position encoder 1 : check of shift motor position

10Position 2

Position encoder 2 : check of shift motor position

28Position 3

Position encoder 3 : check of shift motor position

30Position 4

Position encoder 4 : check of shift motor position

94H/4L SwitchTransfer case mode input

24Auto T/M Neutral

Check of neutral gear position in Auto T/M

16Speed5V supply (TPS / speed sensor)

11Front Speed

Front speed sensor signal input Signal Input

29Rear Speed

Rear speed sensor signal input

25ABS Operation

ABS ON / OFF

6Position Return

Position encoder ground

13Speed / TPS ReturnGround for speed sensor / TPS

22CAN-LCAN bus low line

23CAN-HCAN bus high line

2,15Motor LO-HIMotor output port

- LO to HI : join with battery

- HI to LO (or motor brake) : join with ground

1,14Motor HI-LO

Motor output port

- HI to LO : join with battery

- LO to HI (or motor brake) : join with ground

3EMCTOD output

Signal Output

214L IlluminationIlluminates “4L” indicator

7Diagnosis Display

4WD check lamp illuminator

- Upon defect ; Ground circuit

20K-LINE1)Diagnosis

Page 1218 of 1463

TRANSFER CASE (TOD) 5D2-11

4. Electric Shift Default Mode

If the motor fails to reach its destination, the TCCU will attempt the following (in order):

a. The TCCU will wait 3 seconds then attempt the shift again.

b. If the second attempt to reach the destination fails the TCCU will wait 3 seconds then attempt to rotate the

motor back to the original position. If successful, all future shifts will be inhibited until the Ignition is cycled.

c. If the attempt to return to the original position fails, the TCCU will wait 3 seconds then attempt to rotate the

motor to the original position again. If the second attempt to return to the original position is successful, the

“4WD CHECK” lamp will be illuminated, and all future shifts will be inhibited until the Ignition is cycled.

d. If the second attempt to return to the original position fails the motor will be turned off, the “4WD CHECK” lamp

will be illuminated, and all future shifts will be inhibited until the Ignition is cycled.

TODTM System Operation

The TODTM System is responsible for distributing torque between the front and rear axles. The TCCU monitors the

propshaft speeds, operating range (High/Low), and ABS activity and then applies a calculated amount of torque to

the front axle by Pulse Width Modulating the current applied to the EMC.

1. Touch-off Torque

The minimum EMC Duty Cycle is based on the vehicle speed and throttle position

The TCCU receives the TPS signal from the following sources:

On vehicles equipped with CAN, the TCCU receives the TPS signal from the CAN bus.

2. When Slip Detection

The TCCU continuously monitors the front and rear propshaft speeds to detect wheel slip.

3. Wheel Slip Control

When wheel slip is detected the TCCU controls the EMC duty cycle as necessary until the wheel slip is reduced

below the allowable limit. The EMC Duty Cycle will then be reduced to the Touch-Off value.

4. Brake/ABS Strategy

When the ABS System is active, the EMC Duty Cycle is set to a fixed duty cycle (30%) to aid in braking without

counteracting the ABS System.

5. 4L Strategy

When the system is operating in 4L, the TCCU continues TOD

TM (operation provided that the propshaft speed is

below 175 rpm (5220 pulses/minute)). When the speed increases above 175 rpm, the EMC Duty Cycle is set to

the maximum value (88%) which applies the maximum available torque to the front axle.

Page 1312 of 1463

8B-8 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

Energy Reserve System

Energy reserve system is consisted of condensor and energy switch and will check following items continuously

during system operation.

- High voltage

- Low voltage

- Low rating capacity

- Function of the energy reserve switch

If there is fault in the energy reserve system, warning lamp will turn on. And defects are found by continuous

checking of the condenser voltage, the system will enter overall shutdown status for safety reason.

Shutdown Switch

There is 1 energy shutdown switch in the system and it will be checked during start-up. And it also checks that

condenser is discharging properly. If shutdown switch is short, it will be detected during condensor voltage test.

If squib line fault is obvious, the warning lamp will turn on and the module will enter overall shutdown status.

Accelerometer Check

Accelerometer function will be checked during start-up. During operation, accelerometer off-set signal will be checked,

If there is fault, module will enter overall shutdown status.

ASIC Overheat

Module monitors upper side ASIC overheats continuously. If overheated, the module will enter overall shutdown

status.

Microprocessor Fault

Module checks EEPROM, ROM checksum and RAM during start-up. EEPROM tests checksum operation.

If RAM or ROM checksum is defective, module will not allow start-up continuously but will be re-set,

If EEPROM is defective, warning lamp will turn on and the module will enter overall shutdown status.

During operation, RAM will continuously verify the proper operation of temporary memory program data usage. If

there is fault, the module will enter overall shutdown status and the warning lamp will turn on.

Watchdog Test

Watchdog function will be tested in start-up. If there is fault during the test, warning lamp will turn on and the module

will enter overall shutdown status.

Page 1332 of 1463

9A-6 BODY WIRING SYSTEM

Engine Room Fuse (EF) and Relay Box

1 Fuse (15A) : ABS, ABD

2 Fuse (20A) : Sun Roof

3 Fuse (10A) : Air Bag

4 Fuse (15A) : Audio, Clock, Out Side Mirror

5 Fuse (30A) : Cigarette lighter, Power Socket

6 Fuse (30A) : Heater

7 Fuse (15A) : Door Lock

8 Fuse (30A) : Rear Heated

9 Fuse (10A) : Audio, Buzzer, Chime, Clock

10 Fuse (30A) : Power Window

11 Fuse (10A) : Immobilizer

12 Fuse (20A) : T/C

13 Fuse (15A) : Interior Lamp

14 Fuse (15A) : Hazard Lamp

15 Fuse (15A) : Stop Lamp

16 Fuse (15A) : Turn signal Lamp, Head Lamp

17 Fuse (10A) : Back up Lamp

18 Fuse (15A) : Cluster, STICS

19 Fuse (15A) : A/T, Diagnosis

20 Fuse (15A) : Over Voltage Protection Relay

(Gasolin Only)

21 Fuse (15A) : Seat Heater

22 Fuse (15A) : ECS

23 Fuse (15A) : Front Wiper & Washer

24 Fuse (10A) : Rear Wiper & Washer, A/C

25 Relay : Front Wiper26 Relay : ABS Warning Lamp

27 Relay : Flasher Unit

28 Relay : Fuel Pump (Gasoline Only)

29 Relay : Shift Lock (A/T)

30 Relay : Clutch Interlock & Neutral

31 Relay : Sun Roof

32 Relay : A/T ‘B’ Interlock (MB A/T)

33 Relay : Power Window

34 Relay : Rear Fog Lamp

35 Relay : ECS

36 Relay : Compressor (Diesel E/G)

Condenser Fan (Gasoline E/G)

37 Relay : Condenser Fan

38 Relay : Air Conditioner

39 Fuse (10A) : Tail Lamp

40 Fuse (15A) : Head Lamp(LH)

41 Fuse (15A) : Head Lamp(RH)

42 Fuse (15A) : Front Fog Lamp

43 Fuse (10A) : Horn

44 Fuse (10A) : Compressor

45 Relay : Resistor with Diode (Gasoline E/G)

46 Relay : Front fog Lamp

47 Relay : Condenser Fan

48 Relay : Tail Lamp

49 Relay : Horn

Page 1353 of 1463

Low (Philips H4)

Tail Lamp

Brake Lamp

High Mounted Stop Lamp

Reverse Lamp

Fog Lamp*

Turn Signal Lamp

Position Lamp

Front Lamp

Rear Lamp

Luggage Lamp

Door Courtesy Lamp

SECTION 9B

LIGHTING SYSTEM

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

SPECIFICATIONS

BULB USAGE CHART

Head Lamp

Rear

Front

Interior

Application

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 9B-1

Bulb Usage Chart . . . . . . . . . . . . . . . . . . . . . . 9B-1

Schematic and Routing Diagrams . . . . . . . . 9B-2

Tail Lamp & B/O Lamp . . . . . . . . . . . . . . . . . . 9B-2

Head Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 9B-3

Head Lamp Leveling Device . . . . . . . . . . . . . . 9B-4

Turn Signal Lamp and Hazard Lamp . . . . . . . . 9B-5Back-Up Lamp and Stop Lamp . . . . . . . . . . . . 9B-6

Front and Rear Fog Lamp . . . . . . . . . . . . . . . 9B-7

Room Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . 9B-8Maintenance and Repair . . . . . . . . . . . . . . . 9B-9

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 9B-9

Front and Rear Lamps . . . . . . . . . . . . . . . . . . 9B-9

Hi

(Philips H1)

Hi

LowWatt/Quantity

55W / 2

55W / 2

55W / 2

5W / 4

21W / 4

21W / 1

21W / 2

55W / 2

21W / 2

5W / 2

8W / 2

10W / 1

8W / 1

5W / 4

Page 1357 of 1463

LIGHTING SYSTEM 9B-5

TURN SIGNAL LAMP AND HAZARD LAMP

3.0BG

Page 1361 of 1463

LIGHTING SYSTEM 9B-9

FRONT AND REAR LAMPS

1 Low-beam Head Lamp

2 High-beam Head Lamp

3 Turn Signal Lamp

4 Position Lamp5 Back-up Lamp

6 Tail / Stop Lamp

7 Turn Signal Lamp

8 Tail / Stop Lamp

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 1364 of 1463

9B-12 LIGHTING SYSTEM

Tail/stop and turn signal lamp

Tail/stop Lamp and backup lamp

Rear Combination Lamp

Removal & Installation Procedure

1. Open the tailgate and remove the inner cover of the rear

combination lamp.

2. Unscrew 4(8mm) nuts of tail/stop lamp and turn signal lamp

assembly.

3. Unscrew 6(8mm) nuts of tail/stop lamp and back-up

lamp assembly.

4. Disconnect each connectors and remove the rear

combination lamp. Replace with specified bulb, if

necessary.

Notice

Refer to lamp specification.