wheel bolts SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 941 of 1463

FRONT DISC BRAKES 4D-3

Removal & Installation Procedure

1. MANDO Brake

Tightening Torque 25 - 35 Nm

2. PBR Brake

Remove the eye-hose bolt and disconnect the hose.

Installation Notice

Tightening Torque 15 - 18 Nm

3. Remove the wheel speed sensor (for ABS vehicies).

Installation Notice

Tightening Torque 6 - 8 Nm

4. Remove the mounting bolts and then caliper assembly.

Installation Notice

Tightening Torque 85 - 105 Nm

Remove the hose mounting nut and disconnect the hose.

Installation Notice

Page 946 of 1463

REAR DISC BRAKES 4E-3

Tightening Torque 15 - 18 Nm

Tightening Torque 85 - 105 Nm

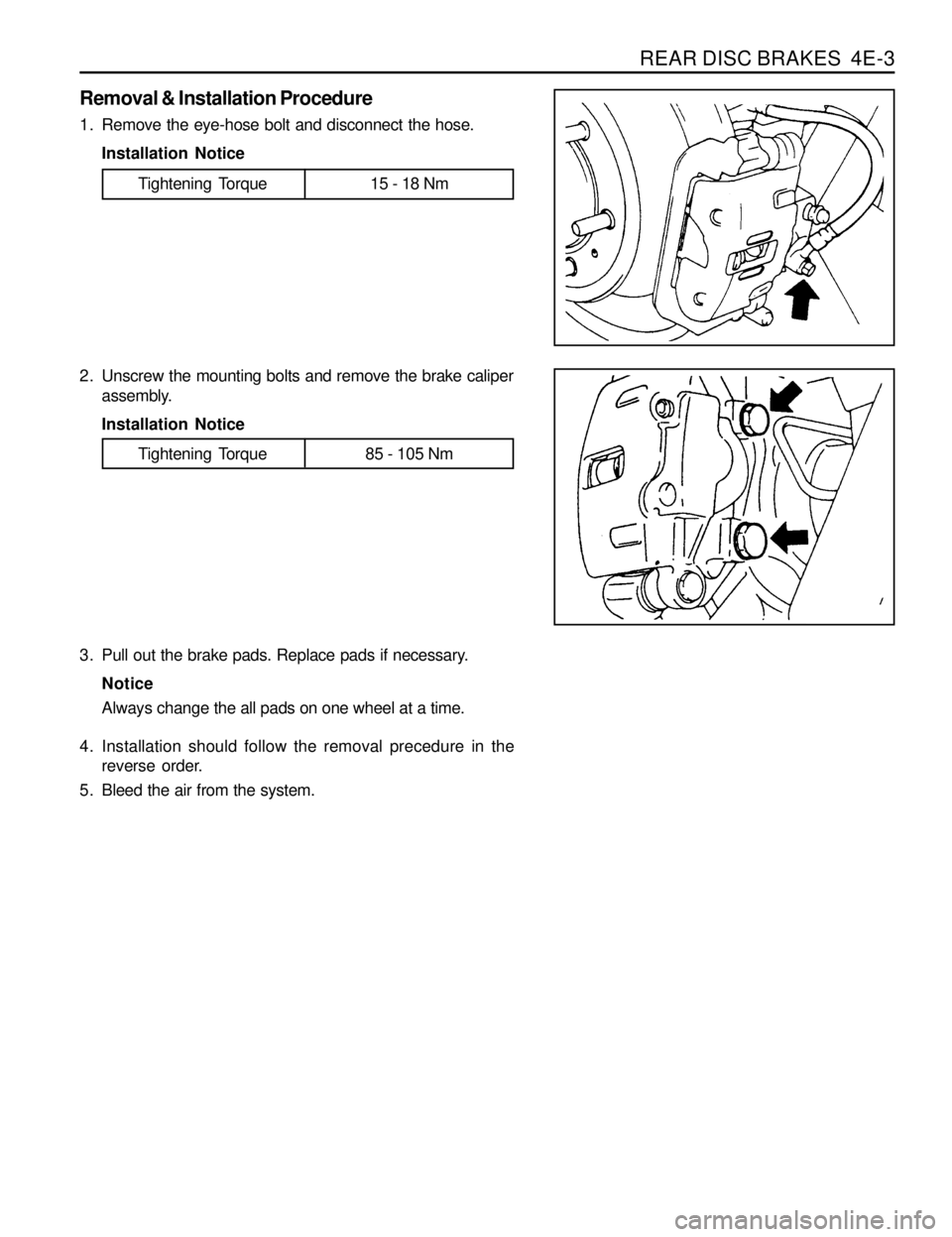

Removal & Installation Procedure

1. Remove the eye-hose bolt and disconnect the hose.

Installation Notice

2. Unscrew the mounting bolts and remove the brake caliper

assembly.

Installation Notice

3. Pull out the brake pads. Replace pads if necessary.

Notice

Always change the all pads on one wheel at a time.

4. Installation should follow the removal precedure in the

reverse order.

5. Bleed the air from the system.

Page 1113 of 1463

5B-6 MANUAL TRANSMISSION

Check

Loosened transmission or flywheel housing bolts,

improper alignment.

Synchronizer damaged or excessively worn.

Blocking ring damaged, worn index slots or friction

surfaces worn or damaged.

Excessive countershaft end play.

Worn or damaged fork due to loosened shaft, rail or

shifting fork.

TRANSMISSION JUMPS OUT

Action

Tighten bolts to specified value. Realign if necessary.

Check or replace synchronizer parts.

Check or replace blocking ring.

Check worn or damaged parts. Adjust shim thickness

using roller bearings if necessary.

Check for wear or damaged. Replace worn or

damaged parts.

Check

Fork or offset lever loose on shaft or rail.

Worn or damaged forks, offset lever, shaft or rail.

Worn or damaged synchronizer.

Worn or damaged gears.

TRANSMISSION LOCKED IN ONE GEAR

Action

Replace extension, adapter or case cover. Check or

replace loose parts on shaft or rail. Replace roll pin(s).

Remove extension, adapter or case cover. Check for

wear or damaged. Replace damaged parts.

Check worn or damaged synchronizer parts and

replace if necessary.

Check worn or damaged gears and replace if neces-

sary.

Check

Improper or low transmission oil.

Loose bolts or other attaching parts.

Improper flywheel housing to engine crankshaft

alignment.

Noisy transmission bearing.

Noisy gears.

TRANSMISSION NOISE

Action

Add or drain and replace with proper oil.

Tighten as specified.

Realign correctly.

Check bearings, bearing rollers and parts for wear or

damage.

Replace if necessary.

Check for worn or damaged gears

(including speedometer gear).

Replace if necessary.

Page 1163 of 1463

5C-10 CLUTCH

Removal & Installation Procedure

1. Remove the starter motor. Install the special tool to the

flywheel through the starter motor mounting holes.

Tightening Torque

47 Nm

Engine Lock 602 589 00 40 00

2. Unscren the release cylinder mounting bolts and remove

the release cylinder.

Installation Notice

3. Unscrew the clutch housing bolts and remove the clutch

housing, release fork and release bearing.

Installation Notice

4. Insert the centering pin into the clutch spline.

Loosen the clutch cover bolts 1/2 turn in crisscross sequence

until the spring tension is released.

Notice

Do not remove the bolts at a time, or clutchcover can be

damaged or deformed.

Centering Pin 661 589 00 15 00

Tightening Torque

30 - 40 Nm

Page 1164 of 1463

CLUTCH 5C-11

5. Unscrew the bolts and remove the clutch cover, pressure

plate and clutch disc.

Notice

Be careful not to drop the pressure plate and clutch disc.

Installation Notice

Tightening Torque 21 - 27 Nm

6. Installation should follow the removal procedure in the

reverse order.

Notice

lBefore installation, clean oil and grease on the

flywheel surface.

lDo not clean the clutch disc and release bearing in

solvent.

Page 1173 of 1463

TRANSFER CASE (PART TIME 4408) 5D1-3

Cannot Front Wheel Drive when Shifted 4H,4L

DIAGNOSIS

Electric Shift Problems

Action

Overhaul and check, replace if necessary.

Overhaul and check for wear and damage.

Replace if necessary.

Check sliding parts, replace if necessary. Checks

Faulty or Damaged TCCU, Speed Sensor, Motor, Clutch

or Internal Wirings

Damaged or Worn Shift Cam, Hub, Fork and Rail Shift

Binding Shift Fork, Hub Collar or Gear

Checks

Broken Drive ChainAction

Check sliding parts, replace if necessary.

Noise in 4WD Operation

Checks

Improper or low oil

Loosened bolts or mounted parts

Noisy T/C bearing

Noisy gearsAction

Drain and replace with specified oil.

Retighten as specified.

Disassemble bearings and parts and check for wear or

damage. Replace if necessary.

Check for wear and damage including speedometer

gear, replace if necessary.

Noise in 4H or 4L

Checks

Worn or Damaged Sprockets or Drive Chain

Incorrect Tire PressureAction

Disassemble and check for wear and damage, replace

if necessary.

Adjust tire pressure.

Transfer Case Oil Leakage

Action

Replace the case.

Clean case and parts and check for leakage.

Remove breather hose and clean, replace if necessary.

Use specified oil and adjust oil level.

Retighten

Use specified sealant and retighten.

Replace Checks

Cracked Transfer Case

Leakage from Other Parts

Breather Clogging

Improper or too much Oil

Loosened Sealing Bolts

Improperly Applied Sealant

Worn or Damaged Oil Seal

Page 1251 of 1463

5D2-44 TRANSFER CASE (TOD)

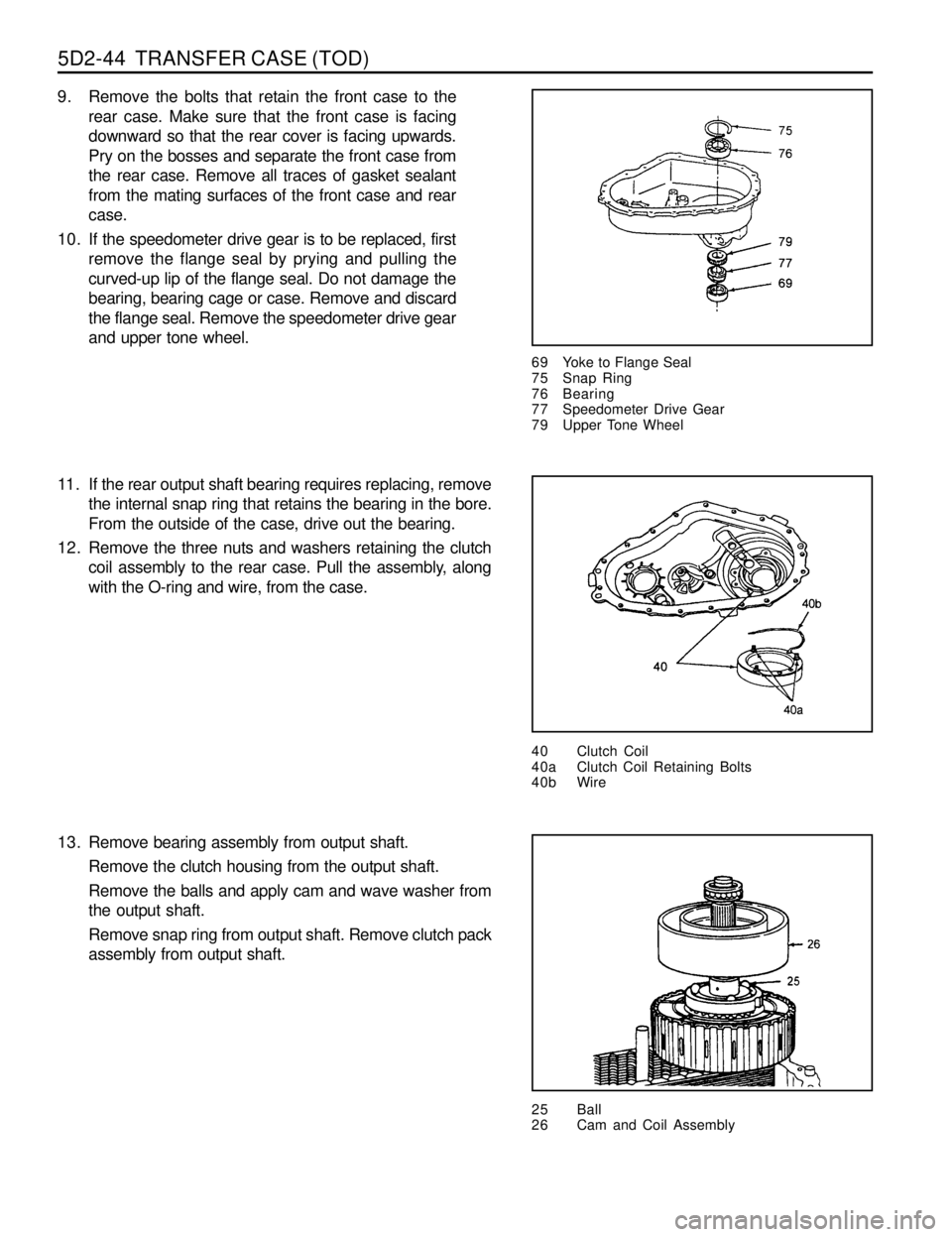

9. Remove the bolts that retain the front case to the

rear case. Make sure that the front case is facing

downward so that the rear cover is facing upwards.

Pry on the bosses and separate the front case from

the rear case. Remove all traces of gasket sealant

from the mating surfaces of the front case and rear

case.

10. If the speedometer drive gear is to be replaced, first

remove the flange seal by prying and pulling the

curved-up lip of the flange seal. Do not damage the

bearing, bearing cage or case. Remove and discard

the flange seal. Remove the speedometer drive gear

and upper tone wheel.

69 Yoke to Flange Seal

75 Snap Ring

76 Bearing

77 Speedometer Drive Gear

79 Upper Tone Wheel

40 Clutch Coil

40a Clutch Coil Retaining Bolts

40b Wire

11. If the rear output shaft bearing requires replacing, remove

the internal snap ring that retains the bearing in the bore.

From the outside of the case, drive out the bearing.

12. Remove the three nuts and washers retaining the clutch

coil assembly to the rear case. Pull the assembly, along

with the O-ring and wire, from the case.

13. Remove bearing assembly from output shaft.

Remove the clutch housing from the output shaft.

Remove the balls and apply cam and wave washer from

the output shaft.

Remove snap ring from output shaft. Remove clutch pack

assembly from output shaft.

25 Ball

26 Cam and Coil Assembly

Page 1258 of 1463

TRANSFER CASE (TOD) 5D2-51

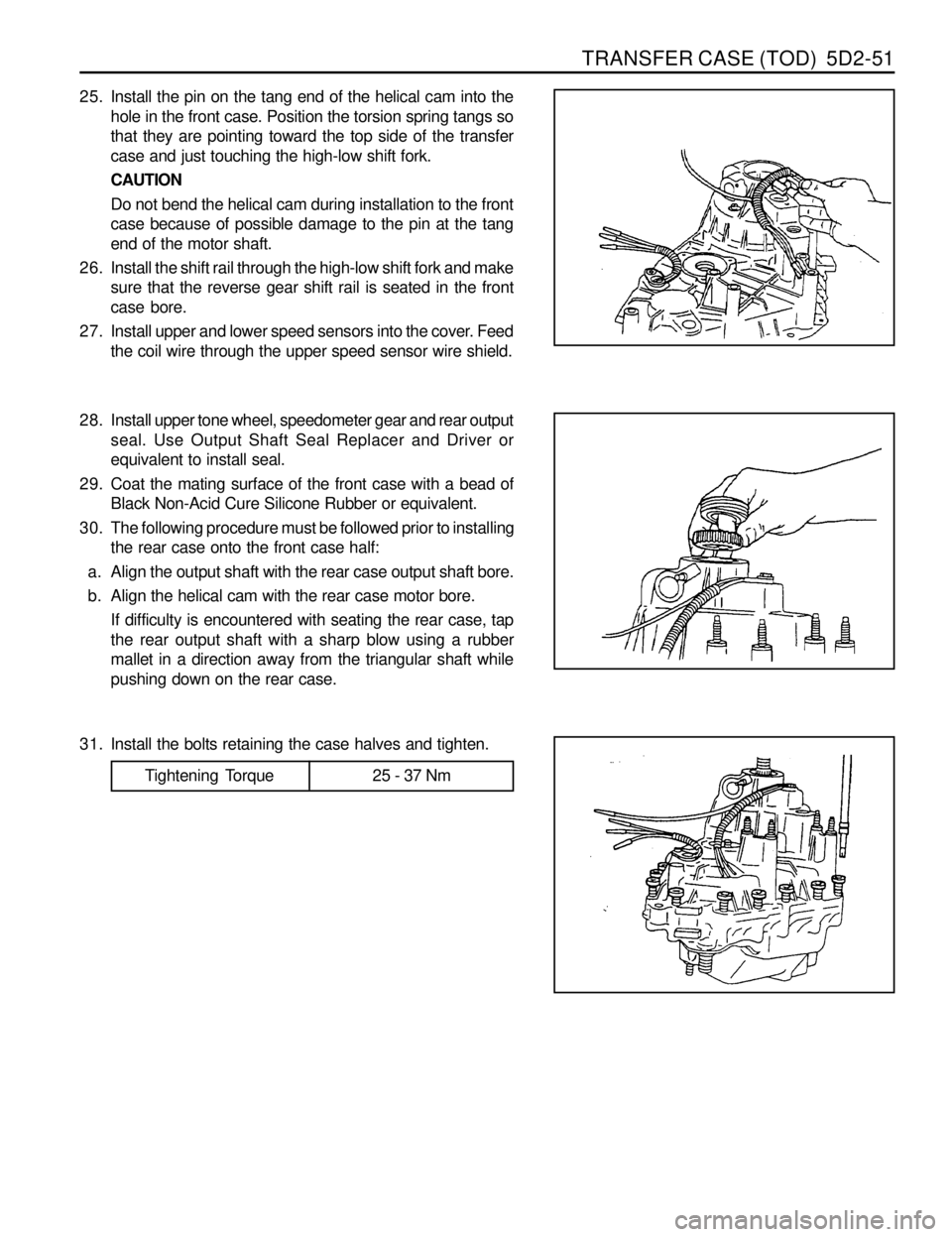

25. Install the pin on the tang end of the helical cam into the

hole in the front case. Position the torsion spring tangs so

that they are pointing toward the top side of the transfer

case and just touching the high-low shift fork.

CAUTION

Do not bend the helical cam during installation to the front

case because of possible damage to the pin at the tang

end of the motor shaft.

26. Install the shift rail through the high-low shift fork and make

sure that the reverse gear shift rail is seated in the front

case bore.

27. Install upper and lower speed sensors into the cover. Feed

the coil wire through the upper speed sensor wire shield.

28. Install upper tone wheel, speedometer gear and rear output

seal. Use Output Shaft Seal Replacer and Driver or

equivalent to install seal.

29. Coat the mating surface of the front case with a bead of

Black Non-Acid Cure Silicone Rubber or equivalent.

30. The following procedure must be followed prior to installing

the rear case onto the front case half:

a. Align the output shaft with the rear case output shaft bore.

b. Align the helical cam with the rear case motor bore.

If difficulty is encountered with seating the rear case, tap

the rear output shaft with a sharp blow using a rubber

mallet in a direction away from the triangular shaft while

pushing down on the rear case.

Tightening Torque 25 - 37 Nm 31. Install the bolts retaining the case halves and tighten.

Page 1262 of 1463

6A-2 POWER STEERING SYSTEM

Checks

Damaged or Binding Steering Ball Joint

Improper Preload of Steering Pinion

Damaged Wheel or Tire

Faulty Suspension SystemChecks

Worn Steering Gear

Worn or Damaged Steering Ball Joint

Loosened Steering Gearbox BoltsChecks

Damaged Steering Linkage

Damaged Wheel and Tire

Faulty Brake System

Faulty Suspension SystemChecks

Lack of Lubrication

Abnormal Wear or Binding of Steering Ball Joint

Damaged or Faulty Steering Gear

Improper Preload of Steering Pinion

Faulty Steering Shaft Joint

Steering Fluid Leaks

Lack of Fluid or Air-in System

Faulty Steering Oil Pump

Damaged or Loosened Pump Drive Belt

Clogging Oil Line

Damaged Wheel or Tire

Faulty Suspension System

DIAGNOSIS

HARD STEERING

Action

Lubricate

Replace

Replace gear assembly

Adjust

Replace

Repair or replace

Replenish or bleed

Replace

Adjust or replace

Repair or replace

Repair or replace

Repair or replace

STEERING PULLS TO ONE SIDE

Action

Repair

Repair or replace

Repair or replace

Repair or replace

EXCESSIVE WHEEL PLAY

Action

Replace gear assembly

Replace

Retighten

POOR RETURN OF STEERING WHEEL

Action

Replace

Replace gear assembly

Repair or replace

Repair or replace

Page 1273 of 1463

6E-4 STEERING WHEEL AND COLUMN

6. Disconnect each connectors.

7. Remove the vacuum hose from the ignition switch(Diesel

only) .

9. Remove the lower shaft by removing the bolt of the steering

column shaft.

Installation Notice

Tightening Torque 9 - 14 Nm

8. Remove the combination switch assembly.

10. Remove the dash panel mounting bolts.

Installation Notice

Tightening Torque 30 - 40 Nm