engine oil SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 670 of 1463

M161 ENGINE CONTROLS 1F2-21

Failure

codeItem

Checking method Test

stepRequirement

Specified

valuePossible cause

Þ 5.1· ·· ·

· Crankshaft

position

sensor:

- Resistance· Ignition:OFF

- Disconnect the

coupling “No.2”

from ECU (engine

side coupling).· Cable

· Crankshaft position

sensor Þ 5.0

· Engine:in cranking

99 100Measure the

signal (refer to

figure 6)· ·· ·

· Crankshaft

position

sensor:

- Signal17,

18,

20,

67,· Increament failure

in driven plate

· Þ 5.1

> 5 V - 99 100

99 100

1050 - 1400W

Þ 6.0

· Engine:in cranking

104 106· Þ 6.1

· Cable

· Camshaft position

sensor Measure the

signal(refer to

figure 8)

· ·· ·

· Camshaft

position

sensor:

(E23 only)

- Signal

Þ 4.0· Ignition:ON

69 7111 -14 V· ·· ·

· Ignition

coil(T1/2)

- No.2,3

Cylinder65,· Cable

· Ignition coil(T1/2)

· Fuse No.17

· Engine:in cranking > 10 V

· Engine:idling

- Voltage

(alternating)

· Engine:in cranking

· Engine:idling> 2.5 V -

19,

58,

106 11The value will

be changed in

1.2 - 1.7 V. - Voltage

(alternating)

· Engine:in cranking

Þ 6.1

· Ignition:ON

- Remove the

connector from the

camshaft position

sensor 1311 -14 V· ·· ·

· Camshaft

position

sensor

(E23 only)

- Power supply· Cable

· OVPR

Camshaft position

sensor

Page 671 of 1463

1F2-22 M161 ENGINE CONTROLS

Failure

codeItem

Checking method Test

stepRequirement

Specified

valuePossible cause

0.9 - 1.6 W 72 11

72 71

· ·· ·

· Ignition

coil(T1/1)

- Primary coil

voltage

(No.1 , 4

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %

(using engine tester)

· Ignition:OFF200 - 350 V

64,Þ 7.0· Þ 7.1

Þ 7.1

· ·· ·

· Connection

ignition coil

between T1/

1 and T1/2· Cable

· Ignition coil T1/1

· Ignition coil T1/2

71 11

· ·· ·

· Ignition

coil(T1/2)

- Primary coil

voltage

(No.2 , 3

cylinder)· Engine:in cranking

(starter operating)

- Measuring range:

400 V

- Time range: 100 %

(using engine tester)200 - 350 V 65,Þ 8.0· Þ 8.1

0.9 - 1.6 W

71 72

· Ignition:OFFÞ 8.1· ·· ·

· Connection

ignition coil

between T1/

1 and T1/2· Cable

· Ignition coil T1/1

· Ignition coil T1/2 The

resistance of

ignition coil at

20°C is

approached

0.6W. The

resistance of

ignition coil at

20°C is

approached

0.6W.

8 - 20 KV

· ·· ·

· Ignition coil

(T1/1, T1/2)

- Secondary

ignition

voltage· Engine:in cranking

- Select the ignition

coil in order of T1/1,

T1/2

- Measuring range :

20KV

- Time range : 100%Þ 9.0 64,

65,Engine tester· Þ 9.1

· Ignition plug

· ECU

· High tension cable

Page 672 of 1463

M161 ENGINE CONTROLS 1F2-23

Failure

codeItem

Checking method Test

stepRequirement

Specified

valuePossible cause

> 10 MW

11 7 11 8· Ignition:OFF

- Disconnect the

coupling "No.2"

from ECU.Þ 10.1· ·· ·

· Knock

sensor

- Resistance· Connecting

condition

· Cable

· ECU 6 - 8.5 KW

· ·· ·

· Ignition coil

(T1/1, T1/2)

- Secondary

coil

resistance· Remove the high

tension cable of

T1/1, T1/2 Þ 9.1Ignition coil

(T1/1, T1/2)· Ignition coil T1/1

· Ignition coil T1/2

TM.4a

TM.4b

56,

Page 687 of 1463

1F2-38 M161 ENGINE CONTROLS

Engine Connector

Pin No.Abbreviation

Description

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80-

-

EV1

EV4

EV2

EV3

M+

M-

TM.31

-

ZSB23

ZSA14

NWS

EGR

-

SLP

-

MT

GND

LT -

-

Injector-cylinder 1

Injector-cylinder 2

Injector-cylinder 3

Injector-cylinder 4

E-GAS motor plus

E-GAS motor minus

Power ground TM.31

-

Ignition coil cylinder 2+3

Ignition coil cylinder 1+4

Camshaft control

EGR (Exhaust Gas Recirculation)

-

Second air pump relay

-

Engine coolant temperature

Intake air temperature ground

Intake air temperature

Page 691 of 1463

1F2-42 M161 ENGINE CONTROLS

Pin No.

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Abbreviation Description

-

-

Injector-cylinder 1

Injector-cylinder 2

Injector-cylinder 3

Injector-cylinder 4

E-GAS motor plus

E-GAS motor minus

Power ground TM.31

-

Ignition coil cylinder 2+3

Ignition coil cylinder 1+4

Camshaft control

-

Second air pump relay

-

Engine coolant temperature

Temperature ground

Intake air temperature

Hot film air mass signal

-

-

E-GAS potentiometer ground

E-GAS potentiometer 2 signal

-

E-GAS potentiometer 1 signal

-

-

-

-

-

EV1

EV4

EV2

EV3

M+

M-

TM.31

-

ZSB23

ZSA14

NWS

-

-

SLP

-

MT

GND

LT

HFM

-

-

-

IP2S

-

IP1S

-

-

--

-

l

l

l

l

l

l

l

-

l

l

l

-

-

¡

-

l

l

l

l

-

-

l

l

-

l

-

-

-

-

-

l

l

l

l

l

l

l

-

l

l

l

-

-

¡

-

l

l

l

l

-

-

l

l

-

l

-

-

-

E23 ENG,

4speed A/T E23 ENG,

5speed A/T

Page 695 of 1463

1F2-46 M161 ENGINE CONTROLS

3. Disconnect the vacuum hose.

4. Disconnect the circlip and remove the fuel pressure

regulator.

5. Apply the oil to O-ring lightly and then replace it.

6. Installation should follow the removal procedure in the

reverse order.

7. Check for fuel pressure and internal leaks by operating the

engine. 2. Discharge the pressure in fuel supply system by pressing

the service valve.

Removal & Installation Procedure

1. Remove the fuel pressure test connector.

Page 699 of 1463

1F2-50 M161 ENGINE CONTROLS

Tightening Torque

22.5 - 27.5 Nm

Tightening Torque22.5 - 27.5 Nm

Removal & Installation Procedure

1. Discharge the fuel pressure from the fuel pressure test

connector by pushing service valve (arrow).

2. Disconnect the battery ground cable.

3. Disconnect the vacuum hose from the fuel pressure

regulator.

4. Disconnect the cable from ignition coil.

5. Remove the fuel return and supply line.

Installation Notice

Notice

lFor removal, cover around parts with cloths not to

bestained by fuel.

lIn case of checking the injector only, do not remove the

fuel return and supply line.

6. Remove the four injector connectors (arrows).

7. Unscrew the two combination bolts (8).

Installation Notice

Page 700 of 1463

M161 ENGINE CONTROLS 1F2-51

9. Installation should follow the removal procedure in the

reverse order.

10. Check for fuel pressure and internal leakage by operating

the engine. 8. Pull out the injector from intake manifold and remove the

fuel distributor.

Notice

Replace the injector O-ring with new one.

Ignition Coil & Cable

lIgnition coil T1/1 No.1 cylinder + No.4 cylinder

lInition coil T1/2 No.1 cylinder + No.4 cylinder

Page 704 of 1463

M161 ENGINE CONTROLS 1F2-55

Removal & Installation Procedure

1. Remove the O-ring.

Check for damage and replace it if necessary.

2. Remove the injector bracket from the injector.

Installation Notice

Exactly seat the anti-twist lock into the square groove in

injector.

3. Separate the injector from the fuel distributor.

Inspection & Maintenance

Inspection of the Injector operation and spray pattern

1. Connect the contact box to the ECU.

2. Connect the shop made test plug to the injector and place

it into the tank.

3. Position the ignition switch to ON.

4. Connect the pin 63(+) and 69(-) of the contact box with a

test cable.

5. Check the injector spray pattern.

Notice

Replace the injector if the injector spray pattern is abnormal

or the fuel doesn't inject.

Injector Resistance Inspection

1. Remove the injector connector.

2. Measure the injector coil resistance using a resistance

tester.

Notice

Replace the injector if the measured values is out of the

specified values. Check the connector and wire connection

between the ECU and the injector if the measured values

are normal.

Specified Value

14 - 17 W

Page 722 of 1463

M161 ENGINE CONTROLS 1F2-73

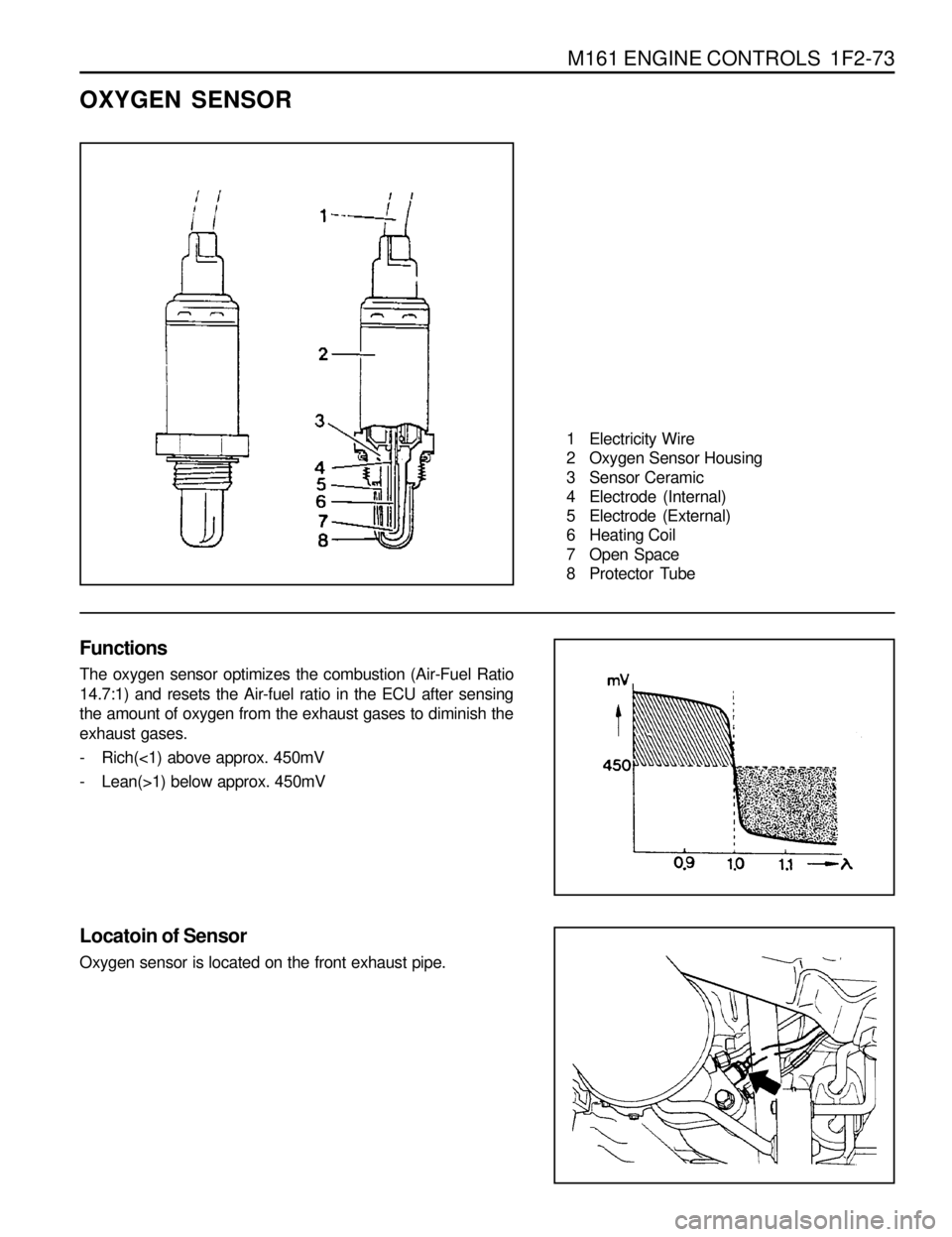

OXYGEN SENSOR

1 Electricity Wire

2 Oxygen Sensor Housing

3 Sensor Ceramic

4 Electrode (Internal)

5 Electrode (External)

6 Heating Coil

7 Open Space

8 Protector Tube

Functions

The oxygen sensor optimizes the combustion (Air-Fuel Ratio

14.7:1) and resets the Air-fuel ratio in the ECU after sensing

the amount of oxygen from the exhaust gases to diminish the

exhaust gases.

- Rich(<1) above approx. 450mV

- Lean(>1) below approx. 450mV

Locatoin of Sensor

Oxygen sensor is located on the front exhaust pipe.