maintenance SSANGYONG MUSSO 1998 Workshop Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 549 of 1463

M162 ENGINE ELECTRICAL 1E1-11

Circuit Diagram

Inspection & Maintenance Procedure (for MSE)

1. While the ignition switch is in 'OFF' position, remove the

wiring connectors (1 and 15) from ignition coil and measure

the primary resistance between terminal No.1 and No.15.

2. During engine cranking, measure primary voltage (T1/1)

between ECU terminal No. 71 and No. 69. Notice

If out of specified value, replace the ignition coil.

Specified Value 0.9 - 1.6 W (20°C)

Specified Value 200 - 350 V

Notice

lMeasure remaining cables.

- T1/2 : No. 72 and 69.

- T1/3 : No. 70 and 69.

lIf out of specified value, check ignition cable and ECU.

3. Using a multi-tester, measure the secondary coil resistance

between 5a and 5b.

Specified Value 6 - 8.5 kW

Page 551 of 1463

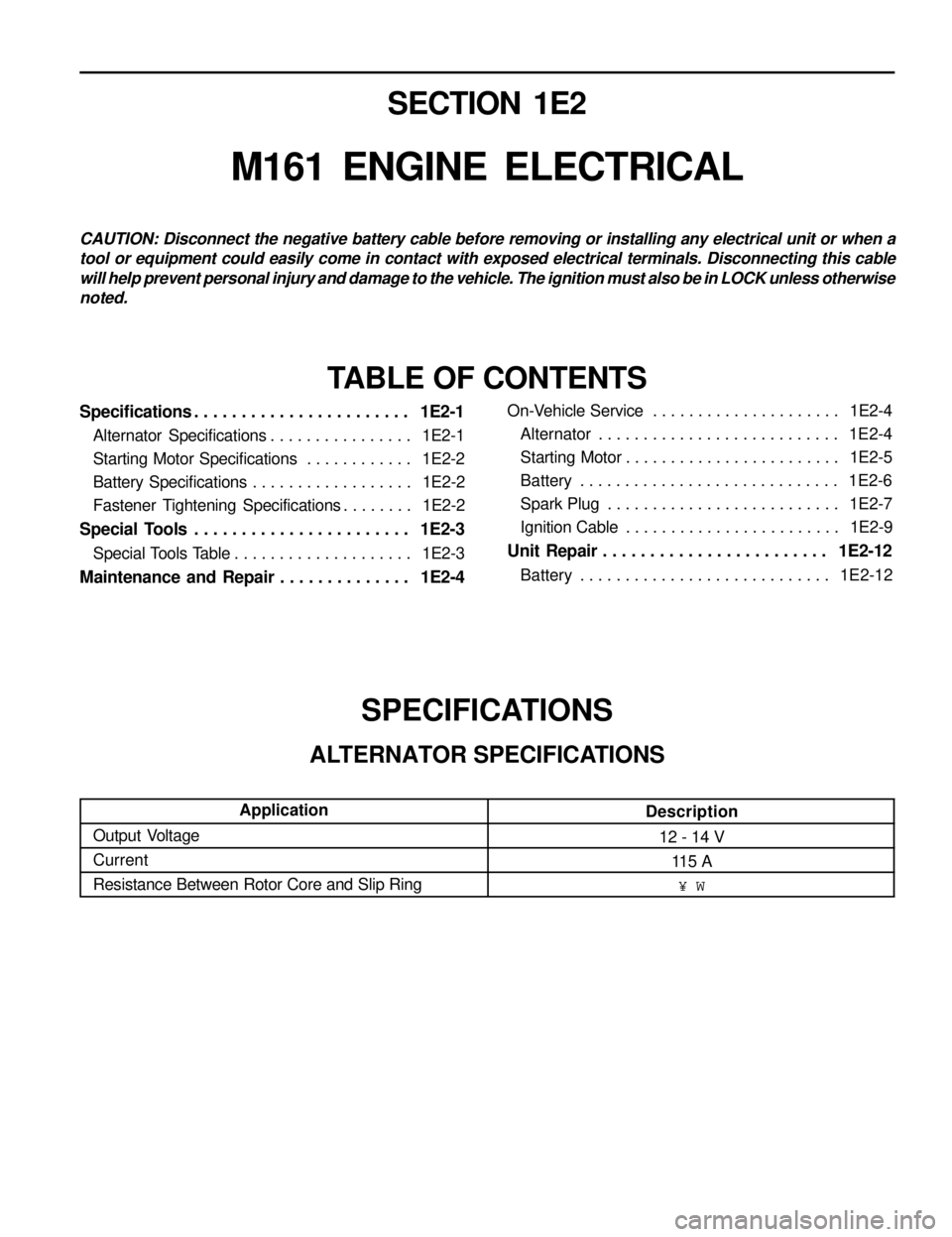

SECTION 1E2

M161 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E2-1

Alternator Specifications . . . . . . . . . . . . . . . . 1E2-1

Starting Motor Specifications . . . . . . . . . . . . 1E2-2

Battery Specifications . . . . . . . . . . . . . . . . . . 1E2-2

Fastener Tightening Specifications . . . . . . . . 1E2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1E2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1E2-3

Maintenance and Repair . . . . . . . . . . . . . . 1E2-4

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E2-4

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-4

Starting Motor . . . . . . . . . . . . . . . . . . . . . . . . 1E2-5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-6

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-7

Ignition Cable . . . . . . . . . . . . . . . . . . . . . . . . 1E2-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E2-12

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

SPECIFICATIONS

ALTERNATOR SPECIFICATIONS

Application

Output Voltage

Current

Resistance Between Rotor Core and Slip RingDescription

12 - 14 V

115 A

¥ W

Page 554 of 1463

1E2-4 M161 ENGINE ELECTRICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ALTERNATOR

Preceding Work : Removal of the drivebelt

Removal & Installation Procedure

1. Disconnect the negative battery terminal.

2. Unscrew the nut and disconnect the terminal (1).

Installation Notice

1 Terminal (B+)

2 Terminal (D+)

3 Combination Bolt

4 Alternator

3. Unscrew the nut and disconnect the terminal (2).

Installation Notice

Tightening Torque 14 - 18 Nm

4. Unscrew the combination bolt (3).

Installation Notice

Tightening Torque 4 - 5 Nm

5. Remove the alternator.

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 42 - 50 Nm

Page 561 of 1463

M161 ENGINE ELECTRICAL 1E2-11

Inspection & Maintenance (for E2.3 MSE)

1. Measure the primary resistance between the cable terminals

1 and 15 after removing the ignition cable wiring connector

(1 and 15) with ignition switch OFF.

Notice

Replace the ignition coil if out of the specified resistance.

lT1/2 : between No.71 and No.69

Notice

Check the ignition cable and the ECU if out of the

specified value.

3. Measure the secondary cable resistance between the

ignition coil 5a and 5b using a multimeter. 2. Measure the primary voltage(T1/1) between the ECU

terminals No.72 and No.69 during the engine cranking

(starter motor activated).

Specified Value 6 - 8.5 KW

Specified Value 0.9 - 1.6 W

Specified Value 200 - 350 V

Page 563 of 1463

SECTION 1E3

OM600 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E3-1

General Specifications . . . . . . . . . . . . . . . . . 1E3-1

Maintenance and Repair . . . . . . . . . . . . . . 1E3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E3-2

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Application

Alternator

Starter

Glow PlugDescription

12V - 75A

12V - 2.2kW

11.5V

SPECIFICATIONS

GENERAL SPECIFICATIONS

Glow Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-2

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-6

Starter Motor . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-8

Page 564 of 1463

1E3-2 OM600 ENGINE ELECTRICAL

Preheating System

General information

The preheating system consists of control, coolant temperature

sensor and glow plugs.

lControl relay - preheating time.

lCoolant temperature sensor.

lGlow plug.

GLOW PLUG

1 Wiring Harness

2 Nut .............................................................. 4 Nm3 Wire Terminal

4 Glow Plug

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 571 of 1463

SECTION 1F1

M162 ENGINE CONTROLS

TABLE OF CONTENTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F1-2

Fastener Tightening Specifications . . . . . . . . 1F1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1F1-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1F1-3

Schematic and Routing Diagrams . . . . . . . 1F1-4

E32 ECU (HFM) . . . . . . . . . . . . . . . . . . . . . . 1F1-4

E32 ECU (MSE) . . . . . . . . . . . . . . . . . . . . . . 1F1-5

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-6

Self Diagnosis Socket Pin Numbers and

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 1F1-6

Self Diagnosis Failure Code . . . . . . . . . . . . . 1F1-7

Test Box Connection . . . . . . . . . . . . . . . . . . 1F1-10

Fuel Injection System Test (MSE3.62) . . . . . 1F1-11

Ignition System Test . . . . . . . . . . . . . . . . . . 1F1-21

Idling Control and Electronic Pedal

System Test . . . . . . . . . . . . . . . . . . . . . . . 1F1-26

Air Conditioner Control System Test . . . . . . 1F1-28

Fuel Pressure and Internal Leakage Test . . 1F1-29

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F1-31Injector Test . . . . . . . . . . . . . . . . . . . . . . . . 1F1-33

Maintenance and Repair . . . . . . . . . . . . . 1F1-35

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F1-35

ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-35

Fuel Pressure Regulator . . . . . . . . . . . . . . 1F1-46

Fuel Distributor . . . . . . . . . . . . . . . . . . . . . . 1F1-50

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-54

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-57

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F1-58

Purge Switchover Valve . . . . . . . . . . . . . . . 1F1-62

Vacuum System . . . . . . . . . . . . . . . . . . . . . 1F1-64

Crankshaft Position Sensor . . . . . . . . . . . . 1F1-65

Camshaft Position Sensor . . . . . . . . . . . . . 1F1-67

Hot Film Air Mass (HFM) Sensor . . . . . . . . . 1F1-69

Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . 1F1-72

Knock Sensor . . . . . . . . . . . . . . . . . . . . . . . 1F1-74

Coolant Temperature Sensor . . . . . . . . . . . 1F1-75

Accelerator Pedal Module . . . . . . . . . . . . . . 1F1-78

Page 605 of 1463

M162 ENGINE CONTROLS 1F1-35

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ECU

Appearance

1 Cover

2 Plate

3 Connector

4 Flat Pin

Vehicle Side : No. 1 - 12

Engine Side : No. 61 - 725 Pin

Vehicle Side : No. 13 - 60

Engine Side : No. 73 - 120

A Vehicle Side Connector : Black

B Engine Side Connector : Gray

Page 625 of 1463

M162 ENGINE CONTROLS 1F1-55

Removal & Installation Procedure

1. Remove the O-ring.

Check for damage and replace it if necessary.

2. Remove the injector bracket from the injector.

Installation Notice

Exactly seat the anti-twist lock into the square groove in

injector.

3. Separate the injector from the fuel distributor.

Inspection & Maintenance

Inspection of the Injector operation and spray pattern

1. Connect the contact box to the ECU.

2. Connect the shop made test plug to the injector and place

it into the tank.

3. Position the ignition switch to ON.

4. Connect the pin 63(+) and 69(-) of the contact box with a

test cable.

5. Check the injector spray pattern.

Notice

Replace the injector if the injector spray pattern is abnormal

or the fuel doesn't inject.

Injector Resistance Inspection

1. Remove the injector connector.

2. Measure the injector coil resistance using a resistance

tester.

Notice

Replace the injector if the measured values is out of the

specified values. Check the connector and wire connection

between the ECU and the injector if the measured values

are normal.

Specified Value

14 - 17 W

Page 650 of 1463

SECTION 1F2

M161 ENGINE CONTROLS

TABLE OF CONTENTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F2-2

Fastener Tightening Specifications . . . . . . . . 1F2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1F2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1F2-3

Schematic and Routing Diagrams . . . . . . . 1F2-4

E23 ECU (MSE) . . . . . . . . . . . . . . . . . . . . . . 1F2-4

E23 ECU (HFM) . . . . . . . . . . . . . . . . . . . . . . 1F2-5

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-6

Self Diagnosis Socket Pin Numbers and

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 1F2-6

Self Diagnosis Failure Code (for E23 ENG) . 1F2-7

Test Box Connection . . . . . . . . . . . . . . . . . . 1F2-10

Fuel Injection System Test . . . . . . . . . . . . . 1F2-11

Ignition System Test . . . . . . . . . . . . . . . . . . 1F2-20

Idling Control and Electronic Pedal

System Test . . . . . . . . . . . . . . . . . . . . . . . 1F2-25

Air Conditioner Control System Test . . . . . . 1F2-27

Fuel Pressure and Internal Leakage Test . . 1F2-28

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F2-30Injector Test . . . . . . . . . . . . . . . . . . . . . . . . 1F2-32

Maintenance and Repair . . . . . . . . . . . . . 1F2-34

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F2-34

ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-34

Fuel Pressure Regulator . . . . . . . . . . . . . . 1F2-45

Fuel Distributor . . . . . . . . . . . . . . . . . . . . . . 1F2-49

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-54

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-57

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-58

Purge Switchover Valve . . . . . . . . . . . . . . . 1F2-62

Vacuum System . . . . . . . . . . . . . . . . . . . . . 1F2-64

Crankshaft Position Sensor . . . . . . . . . . . . 1F2-66

Camshaft Position Sensor . . . . . . . . . . . . . 1F2-68

Hot Film Air Mass (HFM) Sensor . . . . . . . . . 1F2-70

Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . 1F2-73

Knock Sensor . . . . . . . . . . . . . . . . . . . . . . . 1F2-75

Coolant Temperature Sensor . . . . . . . . . . . 1F2-76

Accelerator Pedal Module . . . . . . . . . . . . . . 1F2-79