maintenance SSANGYONG MUSSO 1998 Workshop Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 683 of 1463

1F2-34 M161 ENGINE CONTROLS

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ECU

Appearance

1 Cover

2 Plate

3 Connector

4 Flat pin

Vehicle side : number 1 - 12

Engine side : number 61 - 725 Pin

Vehicle side : number 13 - 60

Engine side : number 73 - 120

A Vehicle Connector : Black

B Engine Connector : Gray

Page 704 of 1463

M161 ENGINE CONTROLS 1F2-55

Removal & Installation Procedure

1. Remove the O-ring.

Check for damage and replace it if necessary.

2. Remove the injector bracket from the injector.

Installation Notice

Exactly seat the anti-twist lock into the square groove in

injector.

3. Separate the injector from the fuel distributor.

Inspection & Maintenance

Inspection of the Injector operation and spray pattern

1. Connect the contact box to the ECU.

2. Connect the shop made test plug to the injector and place

it into the tank.

3. Position the ignition switch to ON.

4. Connect the pin 63(+) and 69(-) of the contact box with a

test cable.

5. Check the injector spray pattern.

Notice

Replace the injector if the injector spray pattern is abnormal

or the fuel doesn't inject.

Injector Resistance Inspection

1. Remove the injector connector.

2. Measure the injector coil resistance using a resistance

tester.

Notice

Replace the injector if the measured values is out of the

specified values. Check the connector and wire connection

between the ECU and the injector if the measured values

are normal.

Specified Value

14 - 17 W

Page 730 of 1463

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1

Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15Idle Speed Adjustment . . . . . . . . . . . . . . . . 1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of

Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test

(Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut

Fuel Pump Pressure Line

Fuel Injection Nozzle

Fuel Injection Pipe

Nozzle Tensioning Nut

Screw Plug

Left-Hand Thread BoltN·m

28 - 47

13

35 - 40

18

80

30

46

Page 731 of 1463

1F3-2 OM600 ENGINE CONTROLS

FUEL SYSTEM

1 Fuel Injection Pump

2 Fuel Feed Pump

3 Overflow Valve

4 Injection Nozzle

5 Pre-filter6 Fuel Return Hose

7 Injection Line

8 Fuel Tank

9 Fuel Filter

10 Choke Orifice

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 781 of 1463

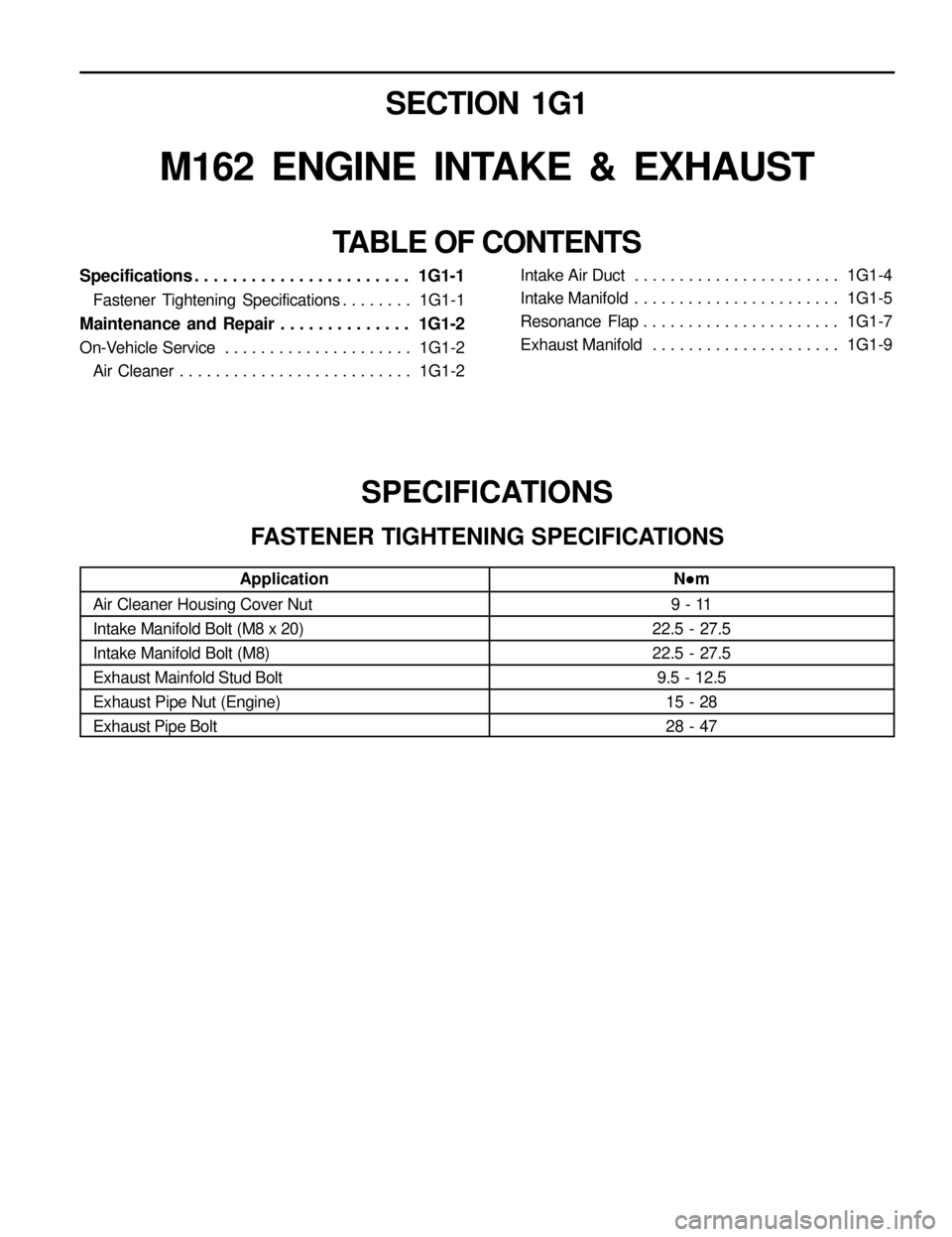

SECTION 1G1

M162 ENGINE INTAKE & EXHAUST

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1G1-1

Fastener Tightening Specifications . . . . . . . . 1G1-1

Maintenance and Repair . . . . . . . . . . . . . . 1G1-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1G1-2

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . 1G1-2

TABLE OF CONTENTS

Intake Air Duct . . . . . . . . . . . . . . . . . . . . . . . 1G1-4

Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . 1G1-5

Resonance Flap . . . . . . . . . . . . . . . . . . . . . . 1G1-7

Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . 1G1-9

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Nlm

9 - 11

22.5 - 27.5

22.5 - 27.5

9.5 - 12.5

15 - 28

28 - 47 Application

Air Cleaner Housing Cover Nut

Intake Manifold Bolt (M8 x 20)

Intake Manifold Bolt (M8)

Exhaust Mainfold Stud Bolt

Exhaust Pipe Nut (Engine)

Exhaust Pipe Bolt

Page 782 of 1463

1G1-2 M162 ENGINE INTAKE & EXHAUST

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

AIR CLEANER

1 Air - Cleaner Assembly

2 Air - Cleaner Shield Upper Cover

3 Blot4 Blot

5 Air Intake Shield

Page 792 of 1463

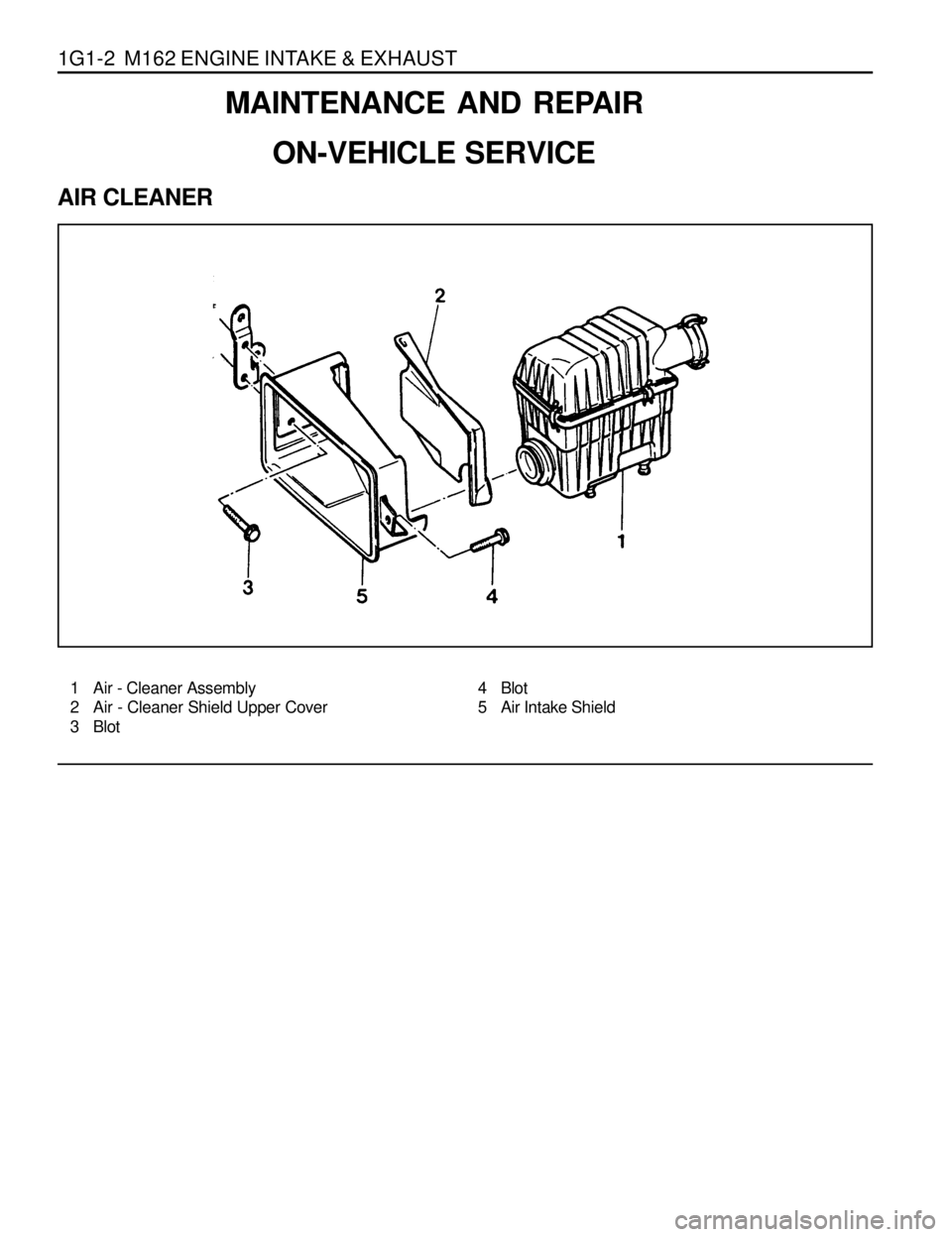

SECTION 1G2

M161 ENGINE INTAKE & EXHAUST

TABLE OF CONTENTS

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Nlm

9 - 11

22.5 - 27.5

22.5 - 27.5

9.5 - 12.5

15 - 28

28 - 47 Application

Air Cleaner Housing Cover Nut

Intake Manifold Bolt (M8 x 20)

Intake Manifold Bolt (M8)

Exhaust Mainfold Stud Bolt

Exhaust Pipe Nut (Engine)

Exhaust Pipe Bolt

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1G2-1

Fastener Tightening Specifications . . . . . . . . 1G2-1

Maintenance and Repair . . . . . . . . . . . . . . 1G2-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1G2-2

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . 1G2-2Air Intake Shield . . . . . . . . . . . . . . . . . . . . . . 1G2-4

Intake Air Duct . . . . . . . . . . . . . . . . . . . . . . . 1G2-5

Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . 1G2-7

Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . 1G2-9

Page 793 of 1463

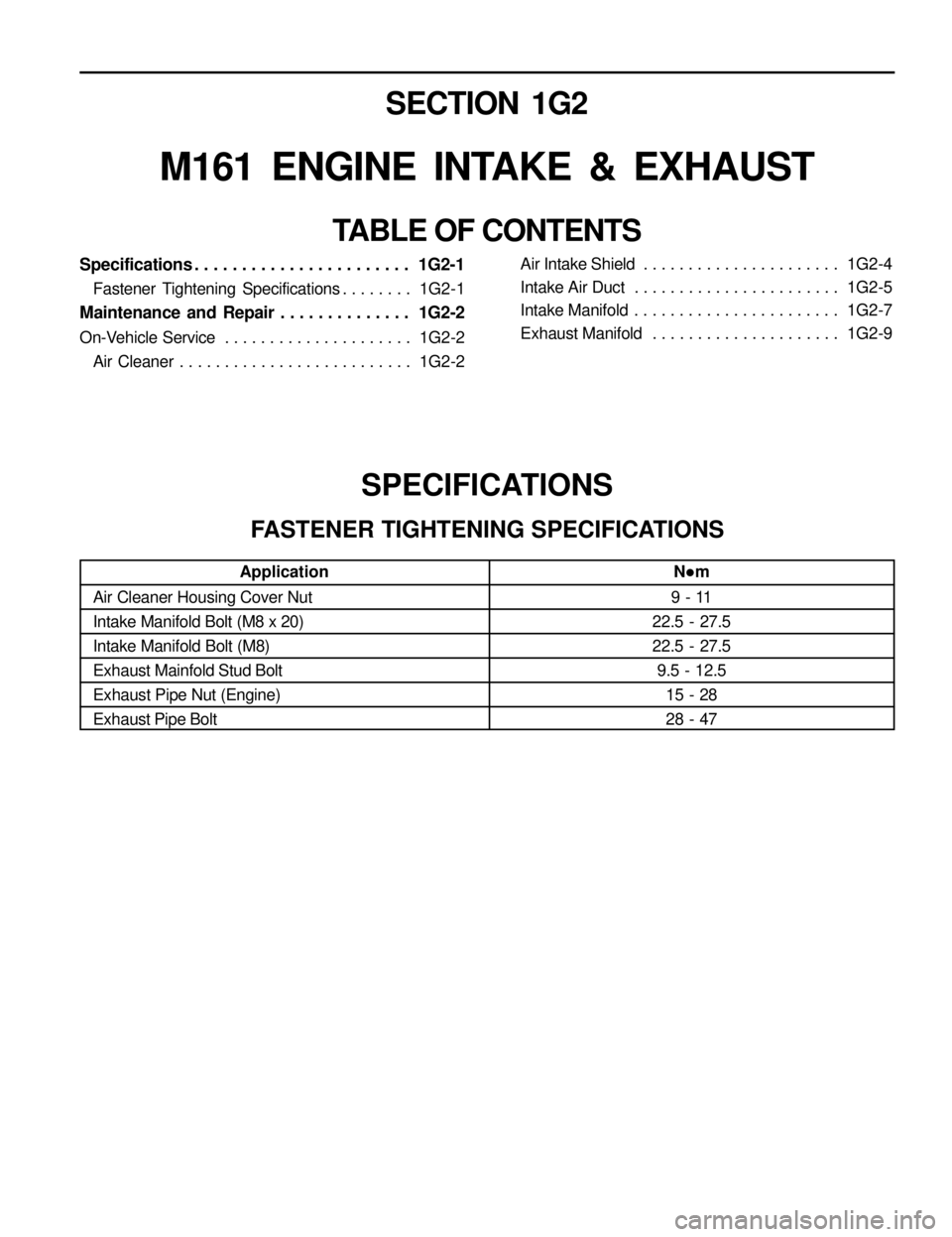

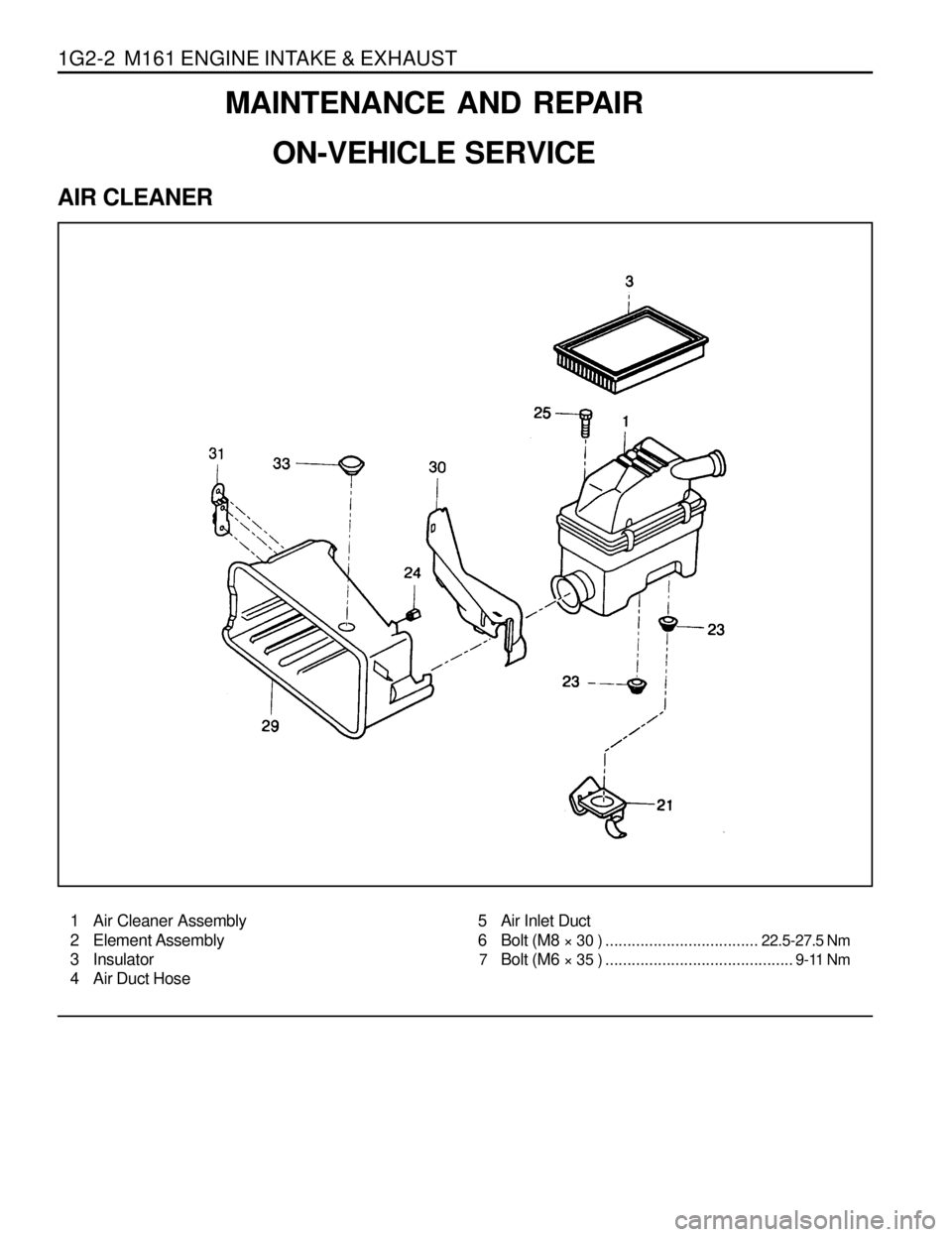

1G2-2 M161 ENGINE INTAKE & EXHAUST

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

AIR CLEANER

1 Air Cleaner Assembly

2 Element Assembly

3 Insulator

4 Air Duct Hose5 Air Inlet Duct

6 Bolt (M8

× 30 ) ...................................22.5-27.5 Nm

7

Bolt (M6 × 35 ) ........................................... 9-11 Nm

Page 803 of 1463

SECTION 1G3

OM600 ENGINE INTAKE & EXHAUST

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1G3-1

Fastener Tightening Specifications . . . . . . . . 1G3-1

Schematic and Routing Diagrams . . . . . . . 1G3-2

EGR Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 1G3-2

Maintenance and Repair . . . . . . . . . . . . . . 1G3-3

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1G3-3

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Air Cleaner Housing Cover Nut

Intake Manifold Bolt (M8 x 20)

Intake Manifold Bolt (M8)

Exhaust Mainfold Stud Bolt

Exhaust Pipe Nut (Engine)

Exhaust Pipe BoltN

· ·· ·

·m

9 - 11

22.5 - 27.5

22.5 - 27.5

9.5 - 12.5

15 - 28

28 - 47

Air Cleaner and Inlet Duct & Hose . . . . . . . . 1G3-3

Intake and Exhaust Manifold . . . . . . . . . . . . . 1G3-5

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . 1G3-8

Charge Air System Diagram . . . . . . . . . . . . . 1G3-8

Intercooler . . . . . . . . . . . . . . . . . . . . . . . . . . 1G3-9

Turbocharger Assembly . . . . . . . . . . . . . . . 1G3-11

Page 805 of 1463

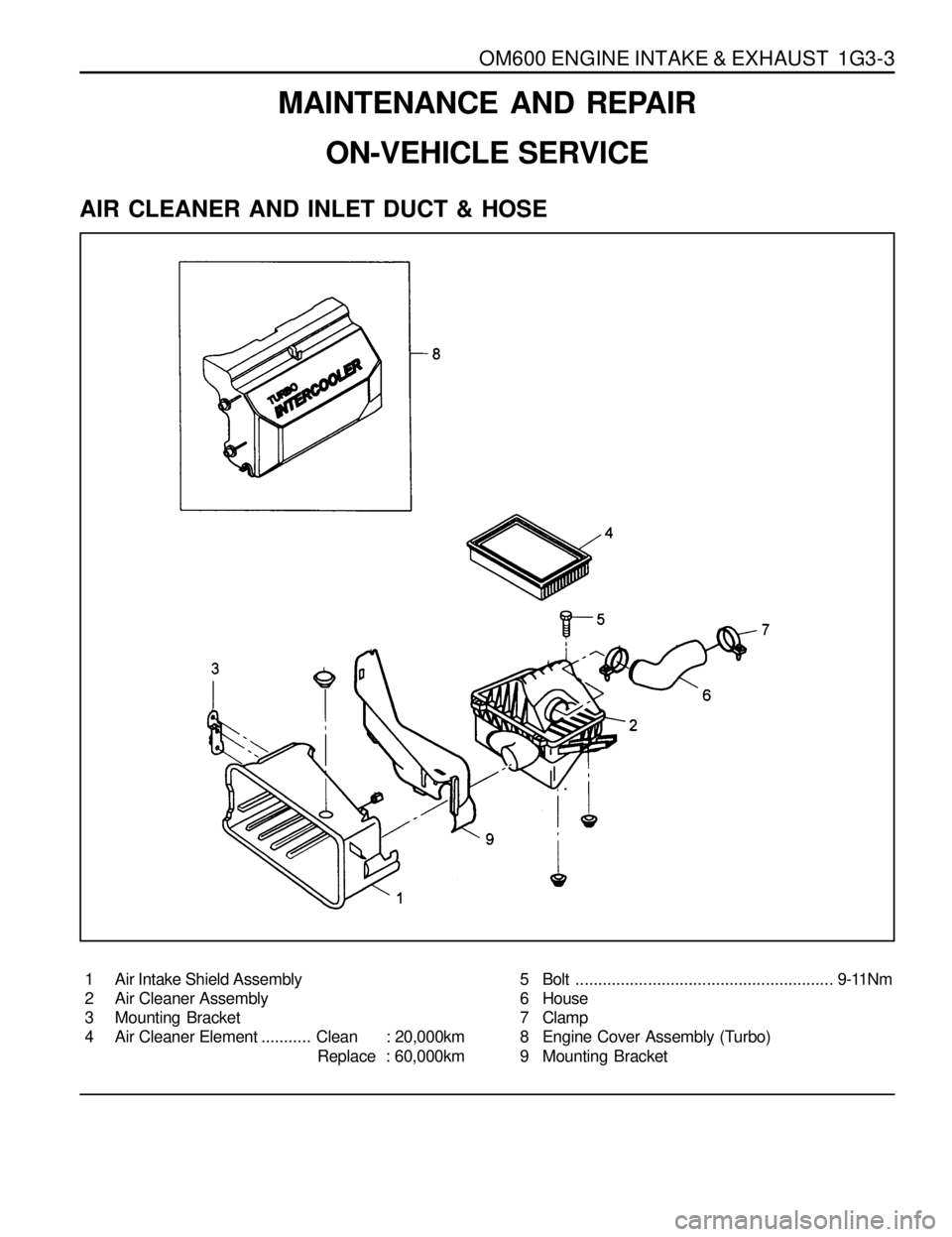

OM600 ENGINE INTAKE & EXHAUST 1G3-3

AIR CLEANER AND INLET DUCT & HOSE

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

1 Air Intake Shield Assembly

2 Air Cleaner Assembly

3 Mounting Bracket

4 Air Cleaner Element...........Clean : 20,000km

Replace : 60,000km5 Bolt......................................................... 9-11Nm

6 House

7 Clamp

8 Engine Cover Assembly (Turbo)

9 Mounting Bracket