wheel SSANGYONG MUSSO 1998 Workshop Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 240 of 1463

M161 ENGINE MECHANICAL 1B2-51

Engine Lock 602 589 00 40 00

2. Remove the start motor and install the engine lock to the

flywheel ring gear.

3. Remove the center bolt.

Installation Notice

4. Remove the vibration damper assembly using the puller.

5. Installation should follow the removal procedure in the

reverse order.

Notice

If possible, don’t separate the vibration damper and the

pulley.Tightening Torque1st step 180 - 220 Nm

2nd step + 90°

Page 242 of 1463

M161 ENGINE MECHANICAL 1B2-53

CRANKSHAFT REAR RADIAL SEAL

Preceding Work : Removal of flywheel or drive plate

1 Special Tool

2 Special Tool3 Crankshaft Rear Seal

Tools Required

601 589 03 43 00 Sleeve

Replacement Proceudre

1. Remove the radial seal with a screw driver.

Notice

Use a clean cloth not to damage the radial seal mounting

hole and the crankshaft.

2. Install the special tool (2) to the crankshaft.

3. Apply the engine oil on the special tool (2).

Notice

Do not use the grease.

4. Install the radial seal on the inner parts assembler.

5. Press in the special tool (1) until the radial seal is stopped.

6. Check for leaks while operating the engine.

Page 249 of 1463

1B2-60 M161 ENGINE MECHANICAL

FLYWHEEL/DRIVEN PLATE

Preceding Work : Removal of manual or automatic transmission

1 Flywheel Mounting Bolt

(M10 x 22, 8 pieces) ................ 1st Step 45 Nm

2nd Step 90°+10°

2 Plate3 Driven Plate (A/T)

4 Dowel Pin

5 Flywheel (M/T)

Service Data Standard (Stretch Bolt)

Nominal Size

Stretch Side Diameter

Bolt Length

Tightening TorqueM x 1.5

8.5 - 0.2 mm

8.0 mm

21.8 - 22.2 mm-

When New

Min. Diameter

When NewD

d

L

1st step 50 Nm, 2nd step 90°

Page 250 of 1463

M161 ENGINE MECHANICAL 1B2-61

Removal & Installation Procedure

1. Unscrew the stretch bolt.

Installation Notice

Sectional View

1 Oil Pan

2 Cover

3 Radial Seal

4 Bolt

5 Crankshaft

6 Dowel Pin

7 Washer (Thickness : 3.5 mm)

8 Washer

9 Bolt

10 Front Drive Plate

11 Rear Drive Plate

12 Rivet

13 Segment

14 Ring Gear

lReplace the bolt when the stretch side diameter (d) of

the flywheel mounting bolt is less than 8.0mm.

lFor the stretch bolt tightening, keep the socket wrench

and Tommy-bar to be 90° and tighten as specified.

2. Remove the flywheel for manual transmission vehicles,

or the driven plate (3), and plate (2) for Auto. transmission

vehicle.

3. Installation should follow the removal procedure in the

reverse order.Tightening Torque1st step 45 Nm

2nd step90°+5°

Page 303 of 1463

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B3-2

Fastener Tightening Specifications . . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection . . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

TABLE OF CONTENTS

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of

Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface . . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Page 304 of 1463

1B3-2 OM600 ENGINE MECHANICAL

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N

· ·· ·

·m

28 - 47

30

3 - 7

8 - 18

20 - 34

30

70 - 80

81 - 84

50 - 75

N

· ·· ·

·m

10

23

200 / 90°

10

55 / 90°

45 / 90°

25 / 90°

25

N

· ·· ·

·m

35 / 90°

N

· ·· ·

·m

45 / 90°Application

Skid Plate Bolt

Drain Plug Bolt

Coolong Fan Shroud Bolt

Control Linkage Nut

Clutch Linkage Cylinder Nut

Exhaust Manifold Bolt

Propeller Shaft Bolt & Nut (Axle)

Propeller Shaft Bolt & Nut(T/C)

Engine Mounting Nut

Application

Cooling Fan Belt Pulley Bolt

Socket Bolt

Tighten The Bolt

End Cover Bolt

Crankshaft Bearing Cap Bolt

Ball Bearing

Camshaft Sprocket Bolt

Oil Pump Sprocket Bolt

Application

Connecting Rod Bolt

Application

12-Sided Stretch Bolt

Engine Assembly

Crankshaft Assembly

Piston

Flywheel

Cylinder Head

Application

Prechamber Threaded Ring

Cylinder Head Cover Bolt

Fuel Injsction Pipe Nut

Socket Bolt

Fuel Filter Pipe Bolt

Idle Pulley Bolt

Damper BoltN

· ·· ·

·m

130

10

18

25

25

23

21

Page 310 of 1463

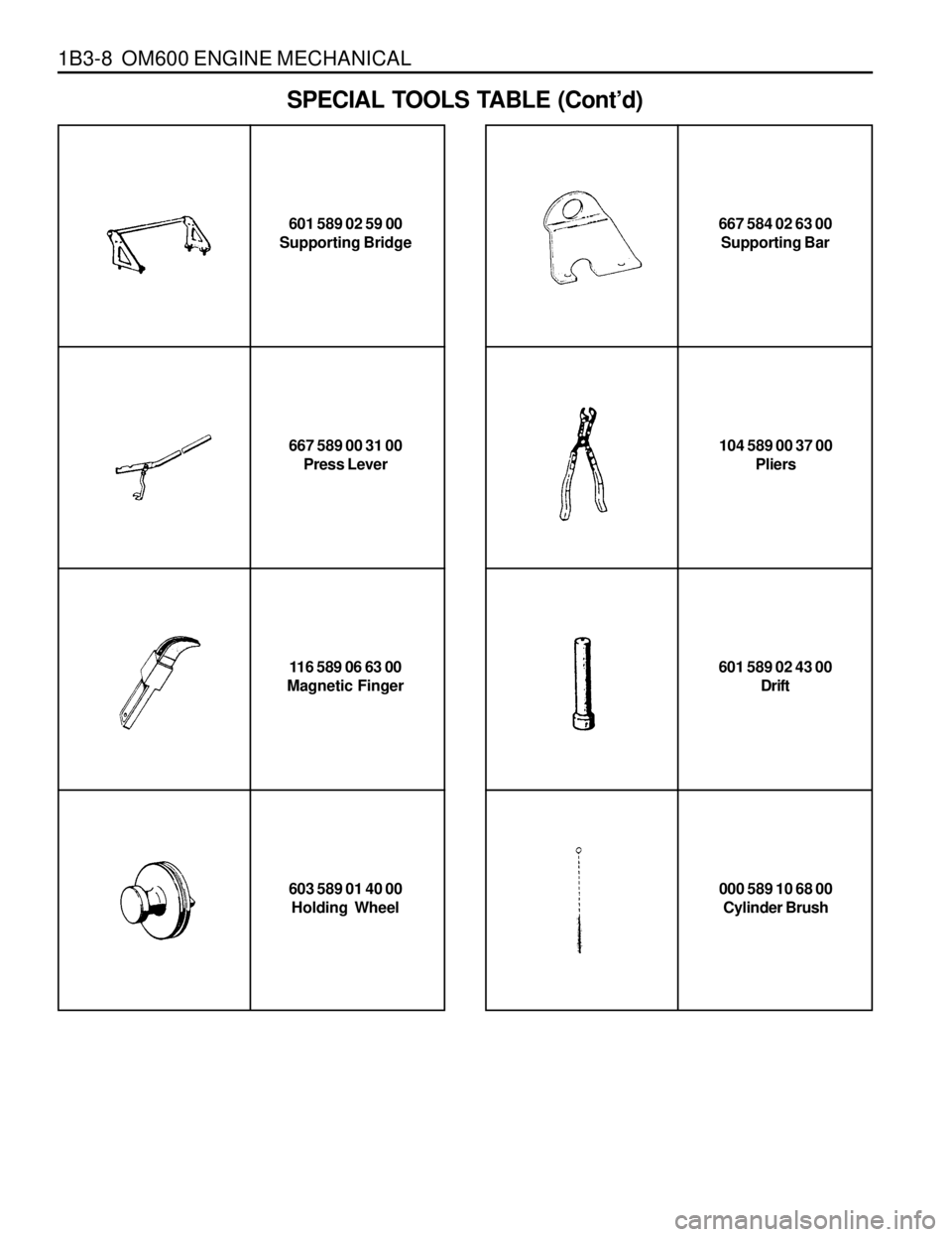

1B3-8 OM600 ENGINE MECHANICAL

601 589 02 59 00

Supporting Bridge

667 589 00 31 00

Press Lever104 589 00 37 00

Pliers

SPECIAL TOOLS TABLE (Cont’d)

667 584 02 63 00

Supporting Bar

116 589 06 63 00

Magnetic Finger

603 589 01 40 00

Holding Wheel000 589 10 68 00

Cylinder Brush 601 589 02 43 00

Drift

Page 348 of 1463

1B3-46 OM600 ENGINE MECHANICAL

30. Rotate the crankshaft and set the no.1 cylinder at TDC.

Notice

Do not rotate the crankshaft to the opposite direction of

engine revolution.

31. Place alignment marks on the camshaft gear and timing

chain.

32. Ensure that the camshaft and the bearing cap marking

are aligned.

33. Remove the starter motor and install the engine lock onto

the flywheel ring gear.

Engine Lock 602 589 00 40 00

Page 373 of 1463

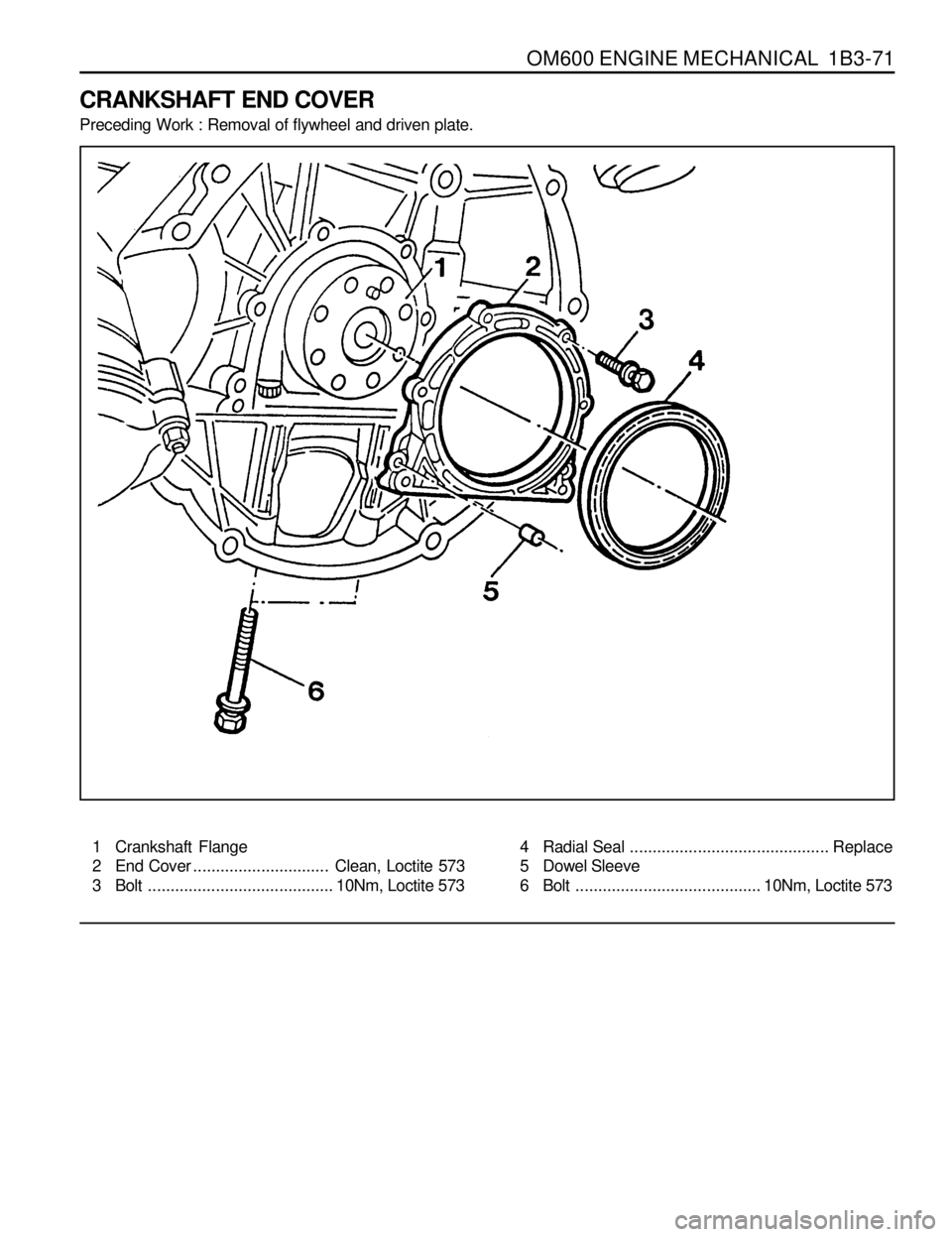

OM600 ENGINE MECHANICAL 1B3-71

CRANKSHAFT END COVER

Preceding Work : Removal of flywheel and driven plate.

1 Crankshaft Flange

2 End Cover..............................Clean, Loctite 573

3 Bolt.........................................10Nm, Loctite 5734 Radial Seal............................................ Replace

5 Dowel Sleeve

6 Bolt.........................................10Nm, Loctite 573

Page 378 of 1463

1B3-76 OM600 ENGINE MECHANICAL

Removal Procedure

1. Remove the starter motor and install the engine lock into

the wheel ring gear.

Engine Lock 602 589 00 40 00

2. Remove the poly V-belt.

3. Remove the cooling fan.

Notice

Keep the fan in vertical position.

4. Remove the cooling fan belt pulley (2).

5. Place alignment marks (arrow) on the vibration damper (5)

and crankshaft belt pulley (4).

6. Remove the timing sensor bracket.

Notice

Remove if necessary.